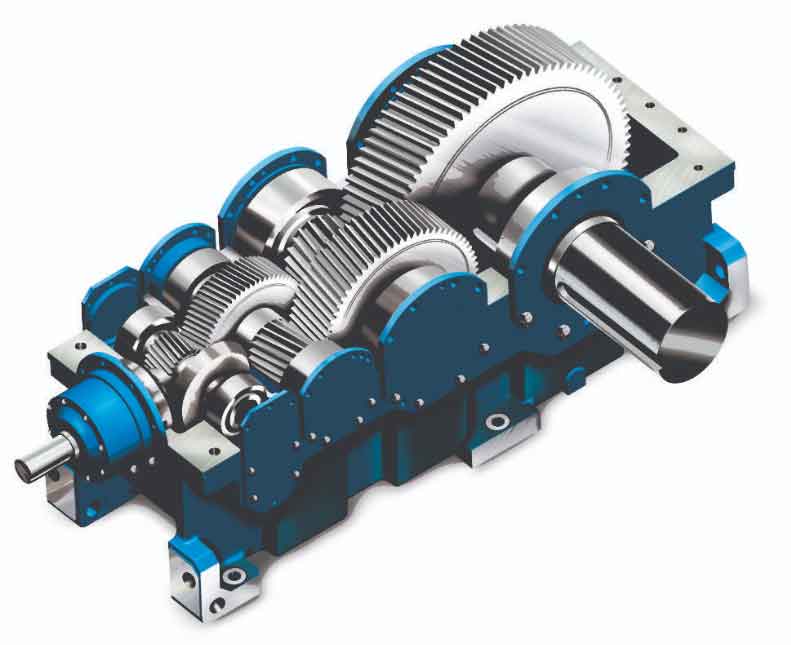

Helical gearboxes are essential components in industrial machinery, providing speed reduction, torque multiplication, and directional changes in power transmission systems. They play a crucial role in various industries, contributing to the efficient operation of heavy machinery and equipment. Let’s explore the key components of helical gearboxes and their functions:

1. Input Shaft:

The input shaft is where mechanical power is applied to the gearbox. It receives rotational power from an external source, such as an electric motor or an engine, and transfers it to the gearbox.

2. Helical Gears:

Helical gears are the primary components responsible for speed reduction and torque multiplication in the gearbox. They have helically shaped teeth that gradually engage with the mating gear, providing smooth and quiet gear meshing.

3. Output Shaft:

The output shaft is connected to the helical gears and transfers the power from the gearbox to the driven machinery or load.

4. Gearbox Housing:

The gearbox housing encloses all the internal components and provides protection and support for the gears and other components.

5. Bearings:

Bearings support the rotating shafts and gears, reducing friction and allowing smooth movement of the gearbox components.

6. Seals and Gaskets:

Seals and gaskets prevent lubricant leakage and protect the gearbox from contaminants, ensuring proper lubrication and extending the gearbox’s life.

7. Lubrication System:

A lubrication system is essential for maintaining proper gear operation. It ensures that the gears and bearings are adequately lubricated to reduce friction and wear.

8. Cooling System:

In high-power applications or applications with continuous operation, a cooling system may be incorporated to dissipate heat generated during gear operation.

9. Housing Covers and Access Panels:

These components provide easy access to the gearbox for maintenance and inspection purposes.

10. Mounting Flanges:

Mounting flanges allow the gearbox to be securely attached to the driven machinery or the mounting structure.

11. Breather and Drain Plugs:

The breather allows the gearbox to breathe and equalize internal pressure, while drain plugs facilitate the removal of old lubricants during maintenance.

12. Input and Output Couplings:

Couplings connect the input and output shafts of the gearbox to the driving and driven machinery, respectively.

Helical gearboxes are used in a wide range of industrial applications, including conveyor systems, pumps, mixers, crushers, and more. They provide efficient power transmission and help optimize the performance of industrial machinery, contributing to increased productivity and reliability. Proper maintenance and regular inspection of these key components are essential to ensure the smooth and reliable operation of helical gearboxes in industrial applications.