introduction

The lubricated condition of the arc bevel gear is critical to the reliability and efficiency of the aircraft’s transmission system. Manned aerial vehicles tend to have bulky cooling systems, while some types of drones do not. In recent years, oil-powered heavy-duty quadcopter UAVs For an important equipment that is valued by various countries, in order to reduce weight, the gearbox cooling system is removed, and the flight control problem is considered to be used The grease lubricates the arc bevel gear, so designers must know exactly what the tooth surface is lubricating with. This is a new pick With the rise of oil-powered heavy-duty rotorcraft, the lubrication research of high-speed heavy-duty grease-lubricated gears has become more and more important. Many scholars have carried out deep cultivation in the field of oil-immersion lubrication of helical bevel gears, which has provided rich research methods and ideas for future researchers. Some of the founders of the field, such as Dowson and Cheng, proposed the theory of thermal elastic flow correlation and gave relevant explanations for the effects of heat, which is far-reaching and still widely used today. Pu and Zhu proposed a method for predicting the friction coefficient and flash temperature of the tooth flank of arc bevel gears and hypoid gears. They also studied the influence of different winding speed directions on the tooth surface friction coefficient and flash temperature distribution. Wang established a transient thermal spring flow model for arc-toothed bevel gears, pointing out that the core oil film thickness is more affected by roughness than the average oil film thickness. Using a similar approach, Lars Bobach proposed the establishment of three-dimensional contact geometry and numerical methods to solve generalized Reynolds equations that also consider shear thinning, non-Newtonian fluids, mixed lubrication, and microfluidic dynamics. M Mohammadpour and S Theodossiades studied the transmission efficiency of hypoid gear pairs to improve vehicle fuel efficiency and reduce harmful emissions; They placed hypoid gears under mixed non-Newtonian thermal elastic flow conditions and noted that thermal effects significantly affected the performance of the lubricant. Wang Daofei and Wang Yanzhong emphasized that temperature increases can significantly affect the lubrication state of arc bevel gears, and developed a hybrid thermal elastic flow model to predict parameters such as film thickness, pressure, and temperature rise. The above work is the research of oil-lubricated arc bevel gears, but it can provide some methods and evaluation criteria for the research of grease-lubricated arc bevel gears.

The thermal elastic flow lubrication state of oil-lubricated arc bevel gears has been extensively studied, but the thermal elastic flow of grease-lubricated transmission systems has been wet

There are few slippery studies. In recent years, the research on grease lubrication is mainly based on experimental research, and a few scholars have carried out numerical research on parts with simple surface shapes and relatively single working conditions. Li was found in experiments on grease-lubricated spur gears, in a different way Under stress conditions, the viscosity of the grease has a great influence on the lubrication effect and wear of the gear surface. Zhang proposed A numerical model of grease-lubricated finite line contact is proposed, and a simple method for predicting oil film thickness and load ratio is proposed. Zheng studied the elliptical contact plastic EHL model of grease and found that when grease has a high rheological coefficient and shear modulus, the maximum residual stress and residual deformation of the working surface will be effectively reduced under heavy load conditions. Fryza and Sperka’s study of grease-lubricated plastic parts found that the ratio between the grease and its base oil film thickness was affected by the load and the fluid’s non-Newtonian response. In his experiments, Zhang found that the contact state of the contacts during grease lubrication is very critical, especially It is the change in load, which is quite different from oil lubrication. Mastrone [15] proposed a finite element simulation method based on computational fluid dynamics to study the efficiency of grease-lubricated spur gears, but this method is computationally intensive and requires high requirements for complex surface modeling. Based on the tripod sliding cardan coupling, Y.Zhou [16] studied the thermal elastic flow characteristics of grease; The results show that the thermal effect significantly affects the formation of grease film. Due to the complex nature of grease itself and the particularity of grease-lubricated arc bevel gear applications, there are no relevant reports on the mixed thermal elastic flow of grease-lubricated arc bevel gears. In view of this, a mixed frictional thermal elastic flow model of grease is proposed under the assumption that the roughness of the tooth surface conforms to the normal distribution. The thickness of the grease oil film, the coefficient of friction and the meshing efficiency of the grease under the meshing contact path of the tooth surface of the arc bevel gear were studied. The lubrication status of arc bevel gears in the gearbox of oil-powered heavy-duty UAV was analyzed, which provided a reference for the estimation of the lubrication status of arc-toothed bevel gears lubricated by high-speed heavy-duty grease.

1 Tooth surface contact analysis

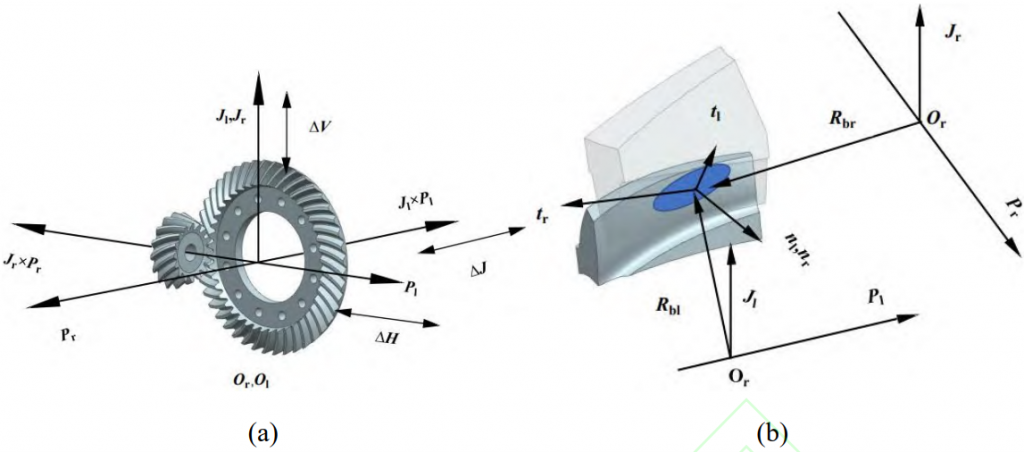

To analyze the thermal elastic flow characteristics and efficiency of grease-lubricated arc bevel gears, the geometry at the gear meshing point is first required Important parameters such as parameters, speed parameters and load parameters. There are many ways to generate gear tooth surface models, the most mature of which are the most established The method is to obtain a tooth flank model by simulating the gear machining process, which V. Simon describes in detail. Required parameters The number can be obtained by loading contact analysis methods, a complex technique for checking the meshing quality of the tooth surface. Due to arc teeth The establishment of bevel gear tooth surface model is more cumbersome, and the calculation method and related references of the required parameters are directly given below. In order to describe the geometric parameters of the tooth surface contact of the arc bevel gear, two coordinate systems with fixed connections to the large gear and pinion need to be established

∑ {r Or,jr × pr,jr, pr}和∑ {OL, j l l × pl,jl, pl}, as shown in Figure 1(a).

Figure 1 Schematic of the gear coordinate system and contact area: (a) gear coordinate system; (b) Vector illustrations of relative motion; (c) Vector illustration of the contact zone;

(d) Winding velocity and sliding velocity vectors in the contact zone

2 Grease-lubricated hybrid thermal elastic flow model considering the direction and roughness of the suction speed

The grease consists of a thickener and a base oil, and its viscosity is sensitive to temperature. Since the drone gear is cruising at high speed When running, the shear force of the tooth on the grease is greater than the ultimate shear stress of the grease, so it is often used under such working conditions Presents as a non-Newtonian fluid.

2.1 Derivation of the Reynolds equation

There are three commonly used constitutive equations to describe greases

𝜏 = 𝜂 ∗ 𝛾𝑛̇ (Ostwald)

𝜏 = 𝜏s + 𝜂 ∗ 𝛾̇(Bingham)

𝜏 = 𝜏s + 𝜂 ∗ 𝛾𝑛̇ (Herschel Bulkley)

where τ, τs and η represent shear stress, yield stress and grease viscosity, respectively; n is the rheological coefficient. γ̇ is the shear rate, which can be expressed as the velocity gradient γ̇ = dudz in the direction of the thickness of the oil film. The Herschel-Bulkley model is sheared at low speed in grease

With high accuracy, once the shear force exceeds the shear limit τs of the grease, then the Herschel-Bulkley die There is no difference between the type and Ostwald. Since the tooth surface is not smooth, the derivation process takes into account the pressure flow coefficient proposed by Patir and Chang .

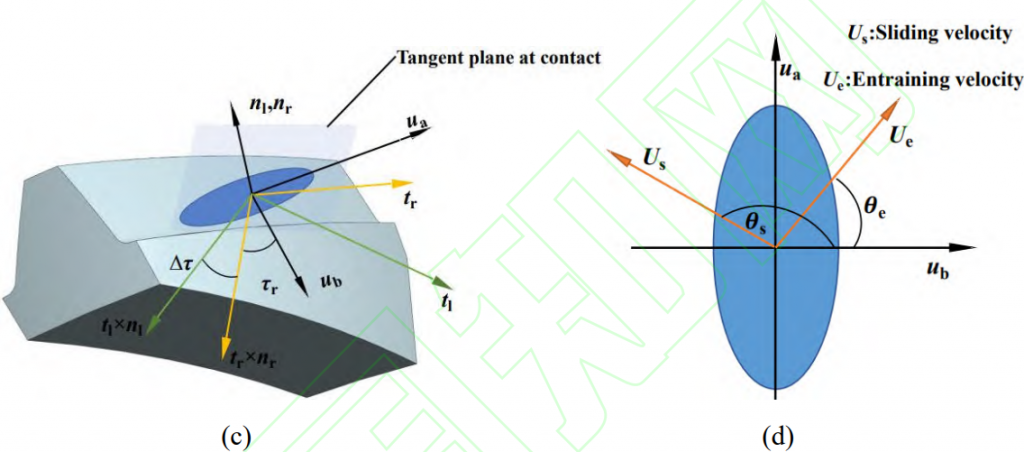

2.2 Consider the viscous compression equation and the dense compression equation considering the influence of temperature

The viscosity and density of grease vary much more by temperature than lubricants, so they cannot be used for lubrication analysis Ignore the effect of temperature. The viscous pressure equation and the dense compression equation considering the influence of temperature are given below

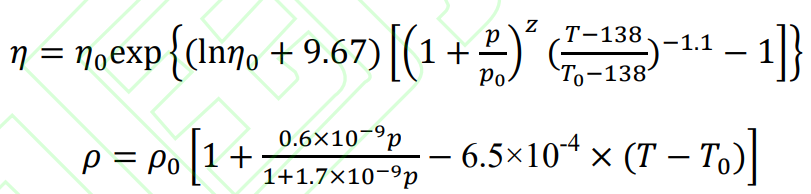

2.3 Consider the energy equation of mixed friction

3 Estimation of coefficient of friction

Grease has the property of shear thinning, that is, the higher the shear rate, the greater the shear force, the lower the viscosity of the grease. However, the shear force that can be transmitted between each layer of the oil film is limited, and according to the description in the literature, the Ostwald constitutive is used

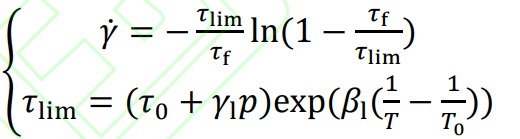

The estimated grease shear friction result is greater than the actual shear friction. In order to bring the results closer to reality,Non-Newtonian fluid constitutive equations are used to approximate the shear force of grease under high-speed shear conditions. Using the B-W model,The form is as follows:

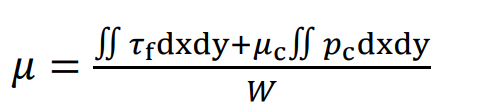

where τlim represents the ultimate shear force, τf represents the actual shear force, γl represents the pressure coefficient, βl is the temperature coefficient, τ0 generally takes the value of 1-8MPa, γl takes the value between 0.03-0.15, then, considering the friction coefficient of the tooth surface of mixed friction can be expressed as:

4 Transmission efficiency under mixed friction

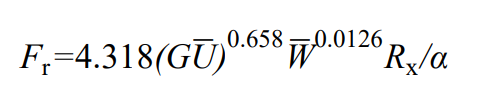

Excluding other factors such as vibration, the maximum efficiency loss of the gear is caused by the relative sliding friction at the meshing position. Due to the complex tooth flank of the arc bevel gear, the rolling friction is expressed as:

5 Numerical methods and results analysis

Numerical methods

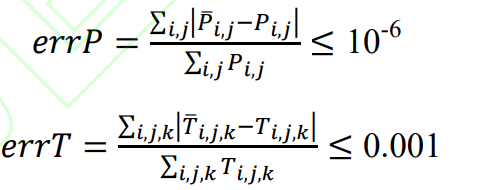

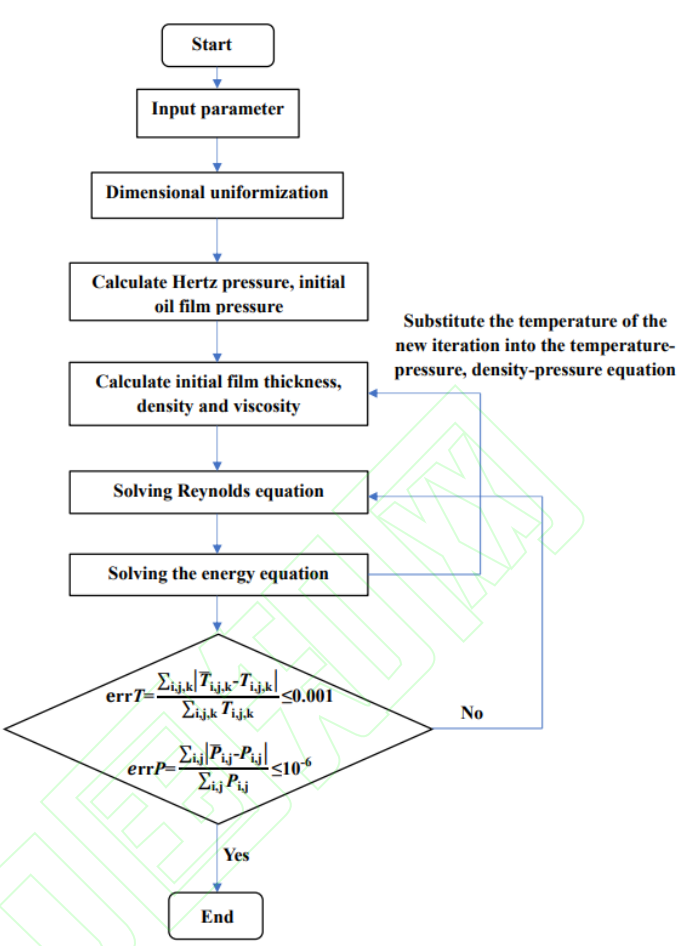

The Reynolds equation is solved by the finite difference method, and the initial fluid pressure of the iteration is assumed to be the Hertzian contact stress. Solve area The domains are 2.5<X<2, -2<Y<2. The discrete mesh covering the entire contact ellipse consists of 275×275 equal-spaced nodes to ensure computational accuracy. Because the solved equation oil film pressure varies greatly in different regions, in order to facilitate convergence, use The Gauss-Seidel iterative method is used to solve the low-pressure area, and the Jacobian iterative method is used to solve the high-pressure area. The oil film temperature distribution is adopted Yang’s proposed column-by-column scanning technique calculation. The pressure and temperature convergence criteria of the oil film in the iteration are:

P̅i,j and T̅i,j,k are the oil film pressure and temperature at the end of the interval, and Pi, j and Ti, j, k are the initial oil film pressure and temperature between the cells. The solution flow is shown in Figure 2.

Figure 2 Flow chart of solving the Reynolds equation

5.2 Results and Analysis

Taking the arc bevel gear of quadrotor oil-driven heavy-duty UAV as the research object, the lubrication state and efficiency were studied. Both gears are made of the same material and have an elastic modulus of 211.11GPa and a Poisson’s ratio of 0.3. Gear surface roughness adopts The Gaussian distribution function is simulated [33], the roughness radius is set to 0.2μm, and the composite rms roughness is based on the gear manufacturing accuracy Set to 0.3μm.

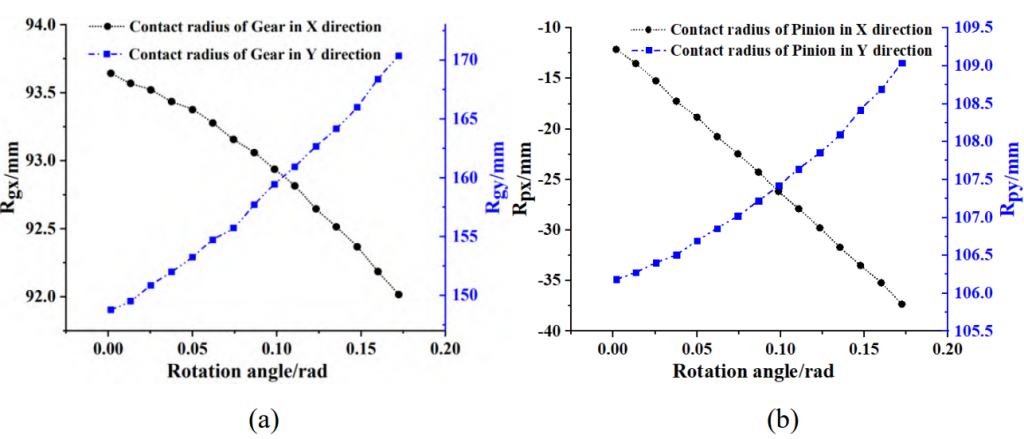

Fig. 3 Tooth surface contact radius: (a) large gear; (b) Pinions

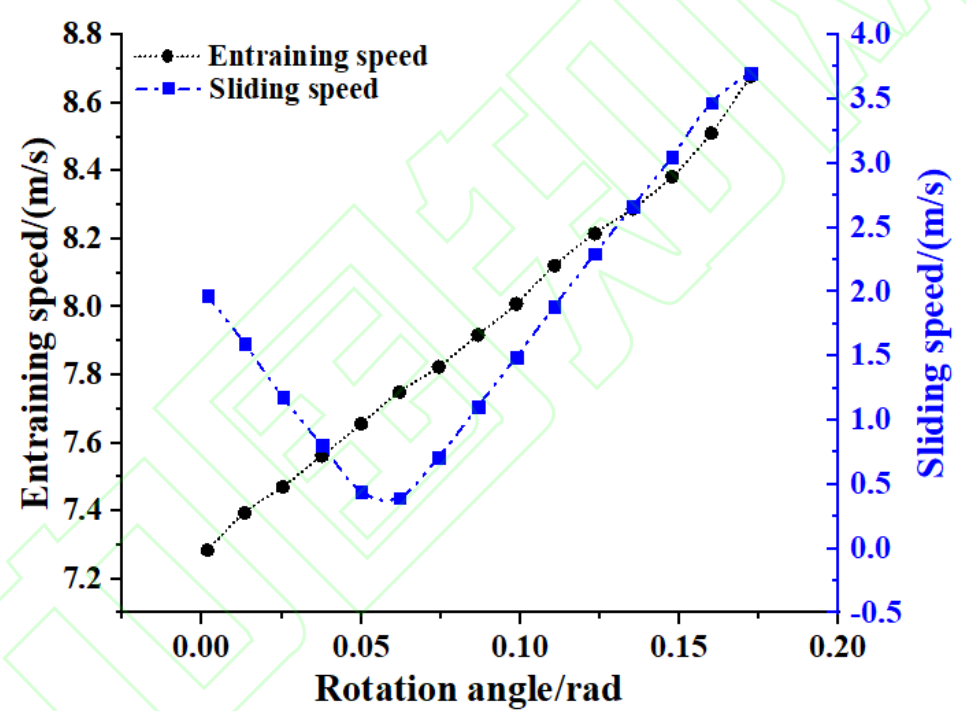

According to the tooth surface contact model of arc bevel gear, the tooth surface suction of the gear at 3000r/min was calculated using formulas (1)-(6).speed and relative sliding speed, the result of which is shown in Figure 4.

Figure 4 Winding velocity vs. relative sliding speed

As can be seen from Figure 4, the suction speed is monotonically increasing from the meshing point to the meshing point during a meshing cycle, while relative The sliding speed is first decreased and then increased, and the point with the lowest relative sliding speed is the node. The cruising working state accounts for the total number of drones More than 90% of the working conditions, in the cruising working state, the actions of the drone are completed by changing the angle of the propeller blades

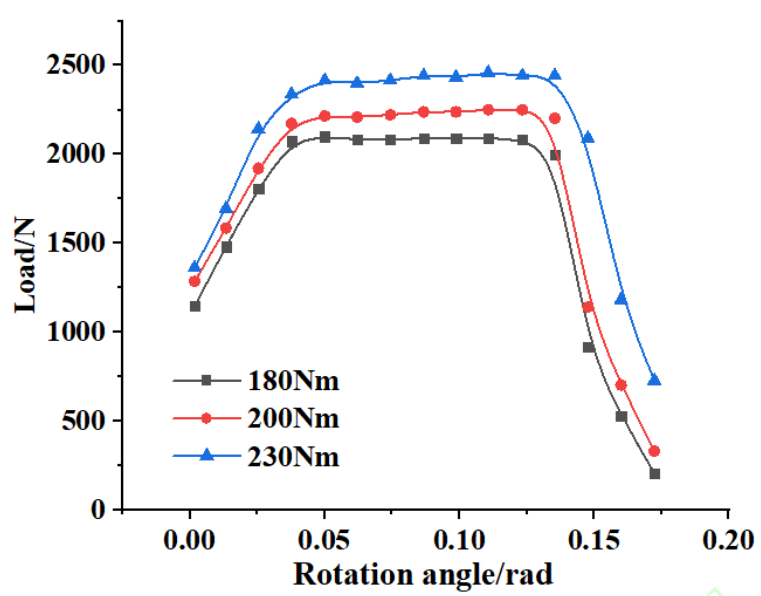

Target. Here are given three types of torque of 180Nm (stable cruise), 200Nm (slow climb), and 230Nm (cruise avoidance).Circumstance. When the arc bevel gear works, multiple gear teeth participate in the meshing at the same time, which is calculated according to the method proposed in the literature [34].

Single tooth loading over a meshing cycle, as shown in Figure 5.

Figure 5 Load distribution

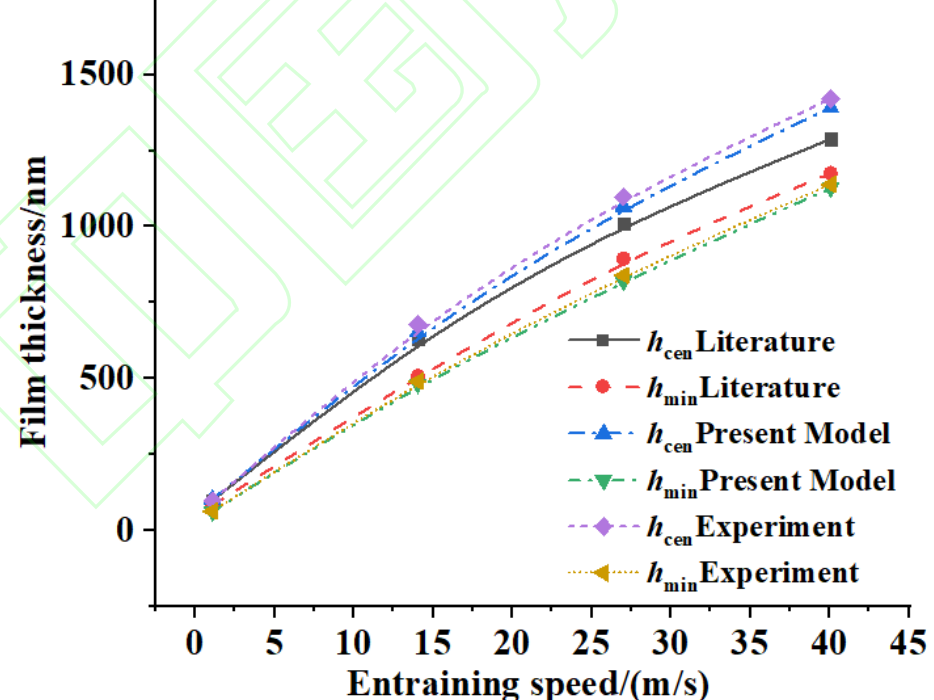

From equation (10) to equation (20), the grease Reynolds equation considering roughness is derived, and in order to prove the validity of the model, it is adopted Literature comparison method proof. Zheng established the plastic dynamic lubrication model of grease, and compared the oil film center thickness and minimum oil film thickness as measurements and experiments in his paper. The model in this paper was used to substitute the relevant parameters in the literature, the central oil film thickness and the minimum oil film thickness were calculated, and the experimental results were compared with the experimental results in the literature, and the results were shown in Figure 6.

Figure 6 Model validation

In order to study the efficiency loss law of gears at different speeds, Figure 8 shows the load rate and friction coefficient of microconvexity

Calculation results. Figure 8(a) shows the change in load rate at the node with the winding speed; Figure 8(b) shows the change in friction coefficient at the node with the winding speed; Figure 8(c) shows the change of the coefficient of tooth surface friction in a meshing cycle at a speed of 3000r/min. According to the evaluation criteria given by the literature [38], if the load rate of the microconvex body is above 85%, it can be defined as boundary friction, and when the load rate is 0%, it enters the full-film lubrication state, and the state in between is mixed lubrication. The coefficient of friction is the same

The sample is related to the load rate of the microconvex body, and when the tooth surface is not in the state of full film lubrication, the value of the friction coefficient has the contribution of dry friction.

Observing Figure 8(a), it can be seen that under the same suction speed, the higher the viscosity of the grease, the lower the load rate of the microconvexity, and the greater the torque The higher the load ratio. The viscosity of the grease has a great influence on the value of the coefficient of friction, and the high viscosity can be seen in Figure 8(b). Although the grease can increase the thickness of the oil film and reduce the load rate, the shear force of the grease itself is larger, and the low viscosity grease is more capable Effectively reduce the coefficient of friction. Figure 8(c) shows that the coefficient of friction within a meshing cycle is time-varying because in one During the meshing cycle, the contact radius, winding speed, relative sliding speed, etc. of the tooth surface are all changed, and these changes can cause large changes in the properties of the grease. Therefore, the previous practice of using the benedic empirical formula to estimate gear efficiency should be used cautiously on grease-lubricated arc bevel gears.

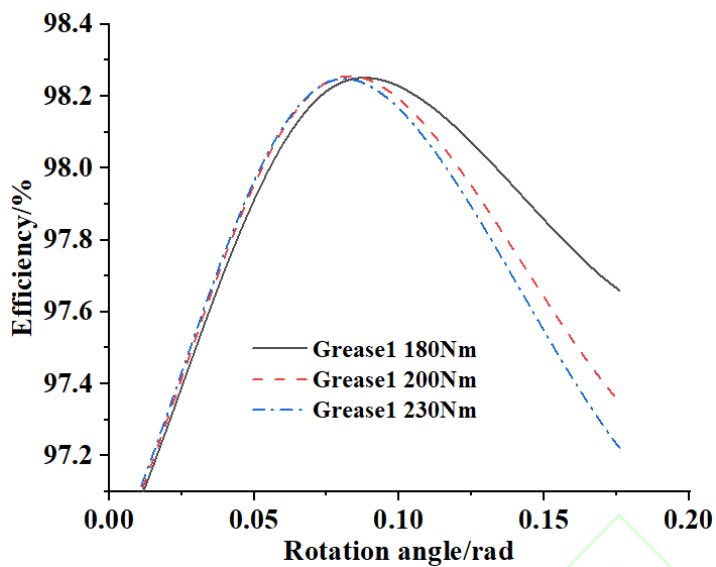

The efficiency change of the gear teeth over a meshing cycle is shown in Figure 9. It can be seen that under the same lubricant but different loads, the efficiency in one meshing cycle is different. At the point of engagement, the efficiency is minimal, where the friction is determined by

The grease consists of shear and microconvex body friction and is minimally affected by torque. As the gear angle increases, it slides relatively The speed is greatly reduced at the node, the friction loss of the microconvex body is reduced, and the meshing efficiency is improved. As can be seen at the point of the mesh, twist The smaller the torque, the higher the efficiency, and it can be said that the smaller the torque, the smaller the efficiency loss. This is due to the fact that at the point of engagement, the tooth surface is almost full In the film lubrication state, the loss of efficiency is almost entirely due to the shearing and extrusion of the grease. Shear rate vs. relative sliding speed Relatedly, extrusion is load dependent, and the coupling of the two causes this phenomenon. Note that although the point of engagement is almost full The film is lubricated, but its relative sliding velocity is the largest, and the shear loss to the grease is large. Due to coincident, The load bearing at the rodent point is minimal, so the efficiency loss varies greatly. It can be seen that the relative sliding speed and load at the rod point should be minimized to reduce the efficiency loss in gear design.

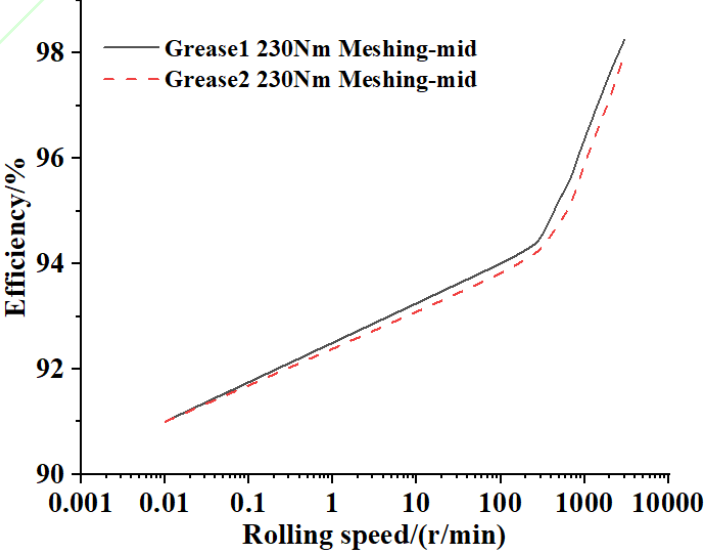

Figure 10 Meshing efficiency as a function of rotational speed

Fig. 10 shows the change in efficiency at the tooth surface node with speed under different viscosities of the grease. It is not difficult to see that low-viscosity greases can effectively reduce efficiency losses. This is because greases with high viscosity require high shear stress, which wastes the power of the power source. In the low speed area, the difference between the meshing efficiency of the two is small, and as the speed increases, the gear meshing efficiency using two different greases will increase; As the speed increases, the difference gradually increases, approaching 3000r/min The difference gradually decreases. This is due to the low shear rate of the grease in the very low speed region and its strong nature of the plastic fluid, The loss of efficiency during meshing is large, resulting in low meshing efficiency; At the same time, the relative sliding speed of the tooth surface is low, so that the two are both

The difference is not significant. As the speed increases, the grease with lower viscosity begins to shear thinning first, at which time the two The meshing efficiency gap becomes more obvious, and as the speed increases, the grease with high viscosity also begins to have a shear-thinning reaction, and the gap between the two begins to narrow.

6 Conclusion

a. The oil film thickness results obtained by the elastic fluid hypothesis are closer to the results obtained by the elastic fluid hypothesis at low shear rates assuming that the grease is plastic fluid, and the oil film thickness calculated by the elastic fluid hypothesis at high shear rates is closer to the experimental results.

b. The tooth surface of the arc bevel gear is complex, and the estimation method of oil film thickness of the oil lubrication center is used to estimate the lubrication state of the grease lubricated arc bevel gear tooth surface at high shear rate. When using low-viscosity greases, only the center film thickness at the point of engagement is approximately the thickness of the base oil film.

c. The friction coefficient of the tooth surface will be affected by the speed and meshing position, that is, the friction coefficient at different meshing points in a meshing cycle is different. Under certain operating conditions, different lubrication states may occur simultaneously in a single meshing cycle, and designers need to be careful about the setting of drone cruise conditions.

d. The meshing efficiency increases with the increase of speed, and the use of lower viscosity grease can improve the meshing efficiency to a certain extent. During a meshing cycle, most of the efficiency loss occurs at the entry point and the exit point, where at the engagement point

The greater the torque at the station, the greater the efficiency loss.