The vast majority of plastic gears have smaller diameters, so the mold for such gearsThe number of teeth will also be small, so it is more common to use modified gears.The calculation of gears is complicated in itself.Especially the modified gears for cloning need toWhen consistent with the sample gear, the calculation of this cloned modified gear is more accurate.Difficulties.As we all know, for the meshing transmission of cylindrical helical gears, in order toEliminate the phenomenon of undercutting, improve the strength, life and contact strength of the teeth;to reduce the possibility of gear wear and scuffing;to increase the resistance of the teethFor bending strength and matching center distance, variable-position cylindrical helical gear transmission is often used.In order to avoid undercutting of the worm gear, improve the load capacity of the worm and worm gear, andVariable gear ratio is also often used to adjust the center distance or improve the meshing performance and change the speed reduction helical gearrratio.Transmission of the worm and modified worm gear.

Through the mapping of samples, the product can be cloned and redesignedand calculation.Since the number of teeth on the left and right helical gears is only 8, it is possible toFirst qualitatively determine that the left and right helical gears and the large helical gears of the product are variableThe gear, worm, and worm wheel should also be of the modified nature.Then, throughThe calculation of their geometric dimensions can quantitatively determine theThe worm and worm wheel are driven by the radial-shifted worm and worm wheel.helical gear The left and rightHelical gears and helical gears are positive angular modified helical cylindrical gear transmissions.And through the modification coefficients of left and right helical gears and large helical gears, as well as the modification coefficients of wormThe selection of the worm gear modification coefficient can completely clone the same as the sampleThese transmission parts.In this process,helical gearr it is first observed through the sampleand detection, to analyze and judge the displacement properties of the transmission parts preliminarily.Then, through accurate calculation of their geometric dimensions,The nature and geometric dimensions of these transmission parts.

Design of modified helical gear

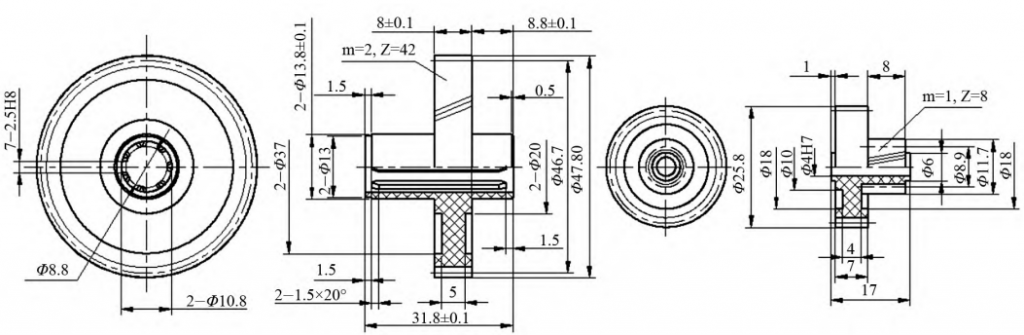

The design of the profile of the modified helical gear is based on the measurement of the sample.The drawing data, while the parameters of the teeth are dependent on the gearbox and the large gear of the gear coverThe data of the center distance between the left and right tooth worm double mounting holes, as well as the modulus, tooth number, helical gear and large diameter of the sample gear and the left and right gears are calculated.The design of the large modified gear and the left and right modified gears is shown in Figure 3.

Based on the above, it can be seen that in any gear transmission mechanism with gear teeth:Z < 17 teeth gear, and the module m ≤ 1, the tooth number Z < 14 smallFor the design and manufacture of analog gears, it is necessary to use the modification method for calculation and design.otherwise, the phenomenon of undercutting will occur.For the cloned products of such products,It is necessary to conduct actual measurements and determine the nature and type of deformation after comparative calculations.helical gear Only after quantitative calculations of various geometric dimensions can product drawing design and mold design and manufacturing work be carried out.Otherwise, it will result in unnecessary economic losses due to rework.