Design of experimental scheme for vibration reduction by misalignment phase tuning

To verify the vibration reduction effect of the misaligned phase tuned gear transmission, letCalculate the vibration response of parallel shaft spur gear pairs with variable misalignmentExperimental research.

1.1 Design of wrong tooth phase tuning scheme

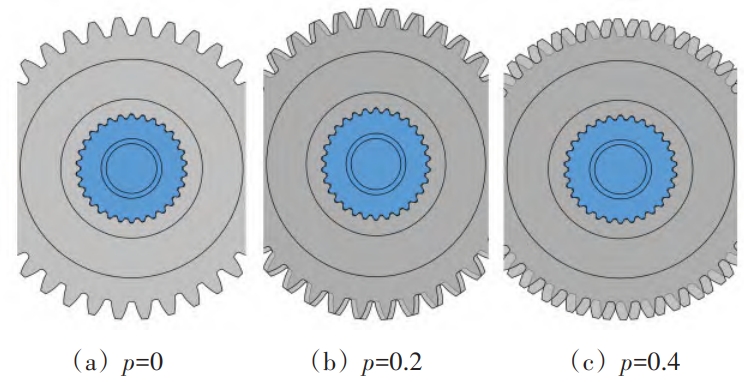

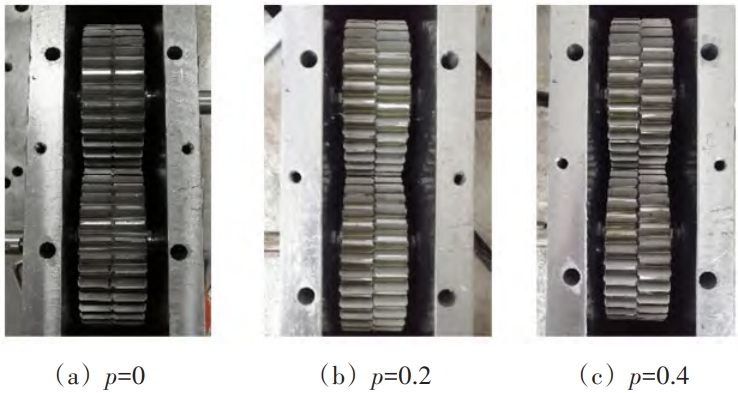

To verify the effect of misalignment phase damping and reduce the machining error of the experimental partsThe error introduced by assembly is addressed in this experiment using a spline connection.Three sets of misalignment phase angles were selected as the experimental research content, and the misalignment phase anglesp=0, 0.2, 0.4.To obtain three different tuned gear sets,The number of teeth of a pair of gear pairs in the design gear is 36, and the pitch angle is360°/36=10°, to match the misaligned phase angle, the spline teeth are designedThe number is 30, and different misalignment phases are obtained by adjusting the misalignment position of the splineTuning gear.When the spline teeth are staggered by 0 tooth, the 0 staggered phase tuning teeth are obtainedWheel, as shown in Figure 7(a);when the spline teeth are staggered by 1 tooth, it is equivalent toOn the same shaft, the first gear remains stationary, while the second gearTurning 360°/30 × 1 = 12°,Straight Bevel Gear the gear tooth misalignment angle is 2°, which isThe tooth phase is 2°/10° = 0.2, as shown in Figure 7(b); when the spline teeth are misalignedWhen 2 teeth are opened, it is equivalent to the first gear remaining on the same shaftIf it does not move, the second gear will rotate 360°/30 × 2 = 24°, at which point the gear toothThe misalignment angle is 4°, and the misalignment phase is 4°/10° = 0.4, as shown in Figure 7(c).When the number of spline teeth is shifted by 3 teeth, the angle of tooth misalignment is6°, the misalignment phase is 6°/10° = 0.6, which is the same as the misalignment phase p=0.4When the number of spline teeth is shifted by 4 teeth, the angle of tooth misalignment is 8°, and the misalignment phase is 8°/10°=0.8.At this time, the misalignment phase isThe structure with p=0.2 is consistent;when the number of spline teeth is shifted by 5 teeth, the wheelThe angle of tooth misalignment is 10°, Straight Bevel Gear which is 1 times the tooth pitch angle. At this time, the misalignment angle isThe structure of bit p=0 is consistent;when the number of spline teeth is staggered by 6 teeth, the gear teethThe misalignment angle is 12°, which is the same as the structure with misalignment phase p=0.2.According to the meshing principle of misaligned tooth phase tuning, Straight Bevel Gear straight gear pairs with different misaligned tooth phases are installed, as shown in Figure 8.

1.2 Principle and Structure of the Test Bench

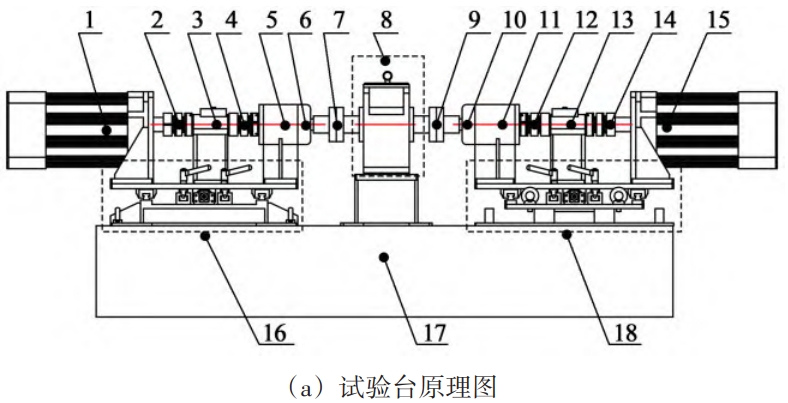

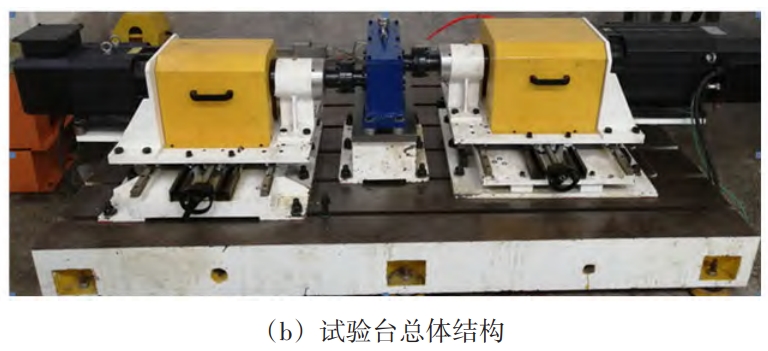

The working principle of the test bench is shown in Figure 9(a), and the overall structure of the test bench isThe structure is shown in Figure 9(b).It mainly includes: 1. Servo drive motor;2, 4, 7, 9, 12, 14, coupling;3, 13, torque speed transmissionSensor;5, 11, bearing seat;6, 10, grating sensor;8, testTooth wheel box;15, load motor;16, 17, 18, testA platform.Straight Bevel Gear

1.3 Sensor layout

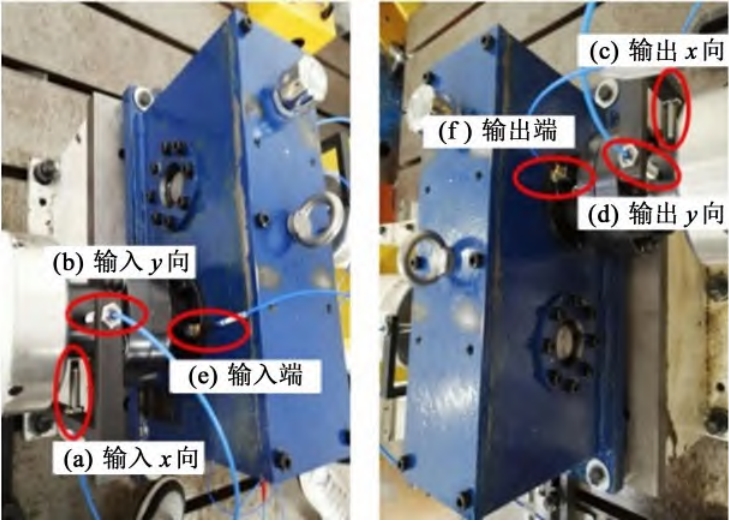

To accurately obtain the vibration parameters of the transmission shaft in the radial direction, it is necessary toIt is fixed on the test bench in two perpendicular directions through Z-shaped brackets, and the measurement points for vibration displacement are arranged as shown in (a), (b), and (c) in Figure 10.Points (c) and (d).Straight Bevel Gear The vibration acceleration sensor can test 3 directionsVibration response, so only one sensor is required at the input and output endsThe layout of vibration acceleration measuring points is shown in Figure 10 (e),(f) Point.

Conclusion

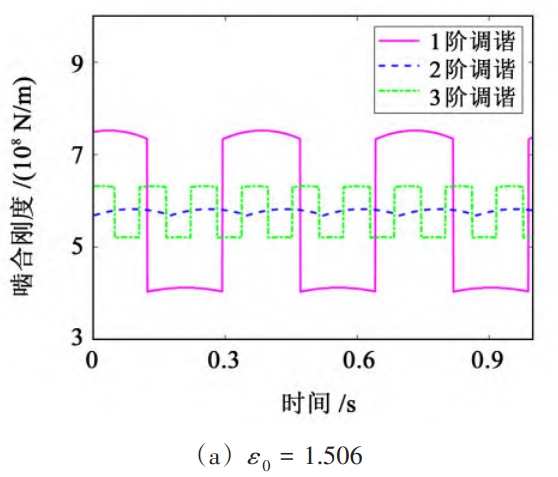

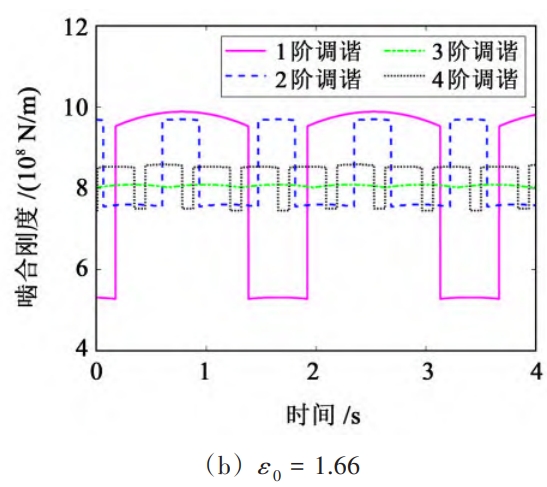

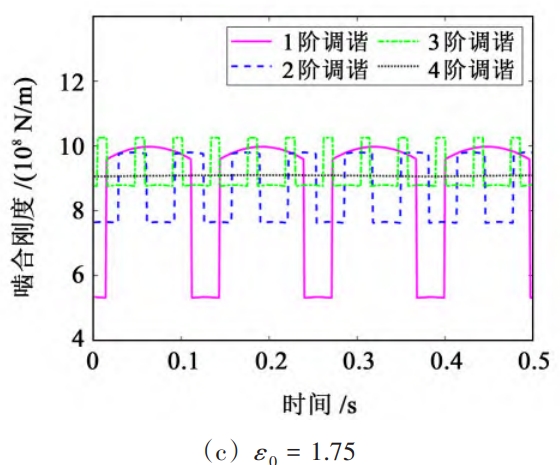

The meshing of the misaligned phase-tuned spur gear pair/helical gear pair was studiedThe relationship between stiffness and misalignment phase, and the method of misalignment phase for parallel stagesThe vibration reduction effect of the spur gear/helical gear transmission system;designed to achieveThe parallel shaft spur gear pair and helical gear pair with different misalignment phases are developedThe parallel axis spur gear pair and helical gear under different misalignment conditionsExperimental research on the secondary vibration response was conducted and compared with the simulation results.The main conclusions are as follows:1) Established a calculation model for the meshing stiffness of misaligned phase gear pairs,The results show that the time-varying meshing stiffness of the misaligned phase-tuned gear is not onlyIt is also related to the degree of coincidence and the phase of the misalignment p.2) Studied the vibration of parallel shaft gear pairs with different misalignment phasesResponse, based on the vibration response andTime-varying meshing stiffness, and the optimal misalignment phase of the gear pair are obtained.3) Designed different misalignment experiment schemes for parallel shaft gear pairs and conducted experiments.Straight Bevel Gear The experimental research is conducted, Straight Bevel Gear and the simulation model and experimental results are compared, indicating that the mismatch between the gearsThe theoretical model and experimental results of phase damping have a very good agreement in terms of damping trend.Good consistency.