Gears are widely used in various mechanical equipment, due to their uniqueThe transmission characteristics inevitably cause tooth wear during operation.Tooth wear is one of the main failure modes of gear transmission systems, which canGradually change the geometric morphology and contact state of the gear surface,Straight Bevel Gear causing tooth surfaceChanges in load and backlash increase transmission errors and exacerbate vibrationand noise.When the wear is severe, the gear teeth become thinner and are prone to breakage, causingTherefore, it is necessary to accurately analyze and quantify the tooth surface wearand explore effective anti-wear design methods.

Wear models are widely used for predicting the wear of gear pairsBased on the Archard wear model, a straight/helical toothThe wheel wear prediction model obtains the distribution law of wear amount.Combined with the gear torsion dynamics model and the Archard wear model,The relationship between the wear state of linear and nonlinear tooth surfaces and the dynamic characteristics of the system was studied.interaction between state responses.An approximateThe wear calculation model of hypoid gears is improved by using interpolation methodTwo parameters in Archard wear model: relative sliding distance and contact pressureas well as the calculation efficiency of the overall tooth surface wear.Hertz contact theory and Archard wear model for quasi-static loadingThe tooth surface wear under dynamic load was studied.Zhang et al. Straight Bevel Gear basedAnalyzed dynamic meshing based on Archard wear model and gear dynamics equationThe gear wear under the joint force.Straight Bevel GearTo analyze the gear wear more accurately,The effect of damage on the performance of gear transmission has been deeply studied by some scholars.The influence of parameters such as contact parameters on gear wear was investigated.Straight Bevel GearThe wear coefficient of gears under different loads and speeds was studied.The influence of number is analyzed, and the regression formula of wear coefficient is derived.The contact parameters such as load and oil film thickness are verified through experimental testing.The influence of several pairs of wear coefficients.Extensive research on hybrid elastohydrodynamic lubrication, Straight Bevel Gear analyzing the state of hybrid elastohydrodynamic lubricationThe wear amount of the tooth surface under the dynamic condition was measured, and on this basis, the influence of the tooth surface roughness on the wear rate was explored.The influence of factors such as roughness, geometric parameters, and operating conditions on gear wear.The above research has explored the change law of gear wear and the relationship between various contact parameters.The influence of several pairs of wear amounts has been considered, but no corresponding anti-wear design has been carried outMethodology Research.

1 Wear model

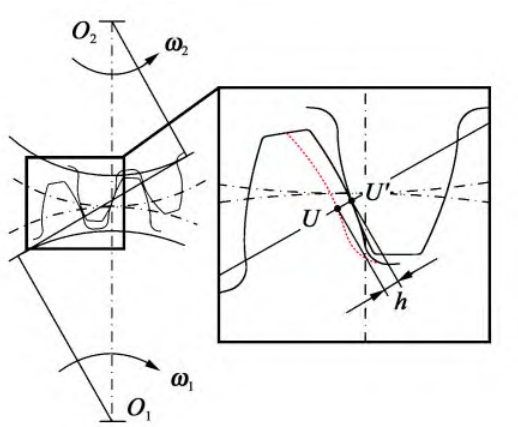

Discrete the tooth surface along the tooth height and width directionsThe tooth surface is discretized into n and m sections, respectively. Assuming that there is a pointThe point Uij is slowly worn down to point U′ij during the operation of the gear pair, Straight Bevel Gear and isThe removed material is the wear amount h,Straight Bevel Gear as shown in Figure 1.In Figure 1, O1,O2, ω1 and ω2 are the rotation centers and angles of the main and driven wheels, respectively.Speed.

2. Reconstruction of tooth surface

If the wear amount at any point is not enough to affect the geometric shape andIf the load on the tooth surface is low,Straight Bevel Gear it is not necessary to reconstruct the tooth surface and enter the next meshing cycle.When the engagement cycle is sufficient and the accumulated wear reaches the preset wear amountThe threshold ζ needs to be determined based on the tooth surface contact state in this state.Surface reconstruction.

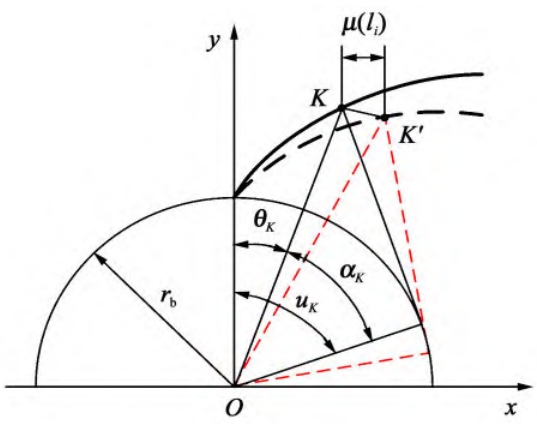

In practical engineering,Straight Bevel Gear in order to maintain good transmission performance of gears,It is necessary to carry out the status analysis based on the working state of the gear in different service stages.The state maintenance is generally the shape design.Assuming that the tooth surface is reconstructed twice,Conduct a shaping design and reconstruct the tooth profile and discrete tooth surface to calculateCalculate the subsequent wear.Straight Bevel Gear Whether it is a spur gear or a helical gear,After discretization, the tooth profiles of the m discrete sections are all involutes.

3 Gear modification design

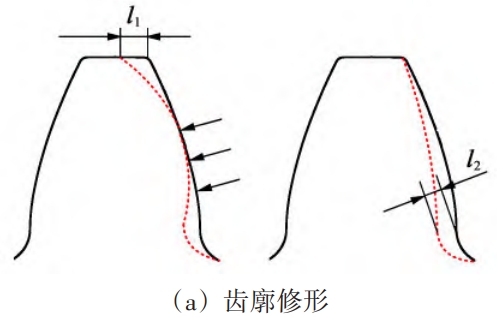

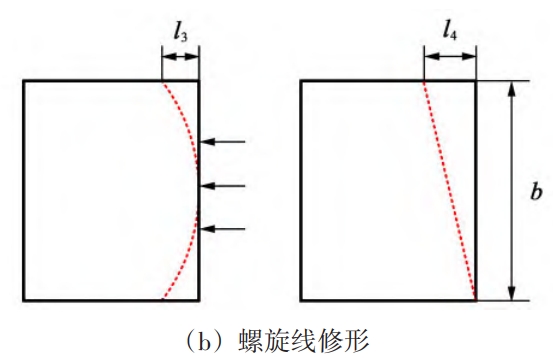

Gear modification is usually divided into tooth profile modification and helical line modification.Profile modification can reduce load fluctuation and meshing impact, mainly involuteThere are 3 ways to modify the shape of the drum, the involute slope, and the tooth tip.Straight Bevel Gear The parameters that affect the shaping effect mainly include the involute drum amount l1, involuteThe slope l2 is shown in the figure. The spiral line modification can improve the bias load.Compensating for the error of meshing helical line mainly includes the drum shape and the screw shape of the helical line.Straight Bevel Gear The parameters such as helical slope are shown in the figure.

This article combines the spiral line modification and tooth profile modification, using complexThe co-shaping design method is used to shape the gears for betterThe value of the modification parameter has a significant impact on the effectiveness of the modification,Straight Bevel Gear determining whether it can reduce wear, improve gear load capacity, and improve transmission performance.Yes, but there is a complex implicit relationship between the shaping parameters and wear.It is difficult to accurately represent the relationship using numerical values, and it is necessary to use proxy models to describe it.The relationship between the two is described.In view of this,Straight Bevel Gear this article takes the shaping parameters as the inputInput variables, tooth surface wear amount as output variables, build BP neural networkThe proxy model.

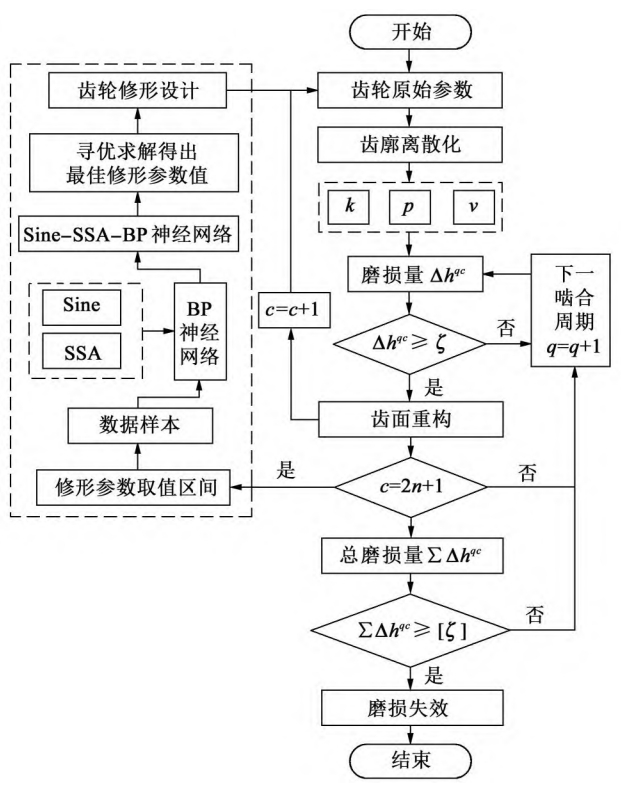

Sine-SSA-BP model-based modification design method and gearThe wear analysis process is shown in Figure 4, and the specific steps are as follows:1) Conduct discretization processing based on the original geometric parameters of the gear, andDetermine the wear threshold and allowable wear amount.2) Optimizing the SSA algorithm using the Sine chaotic mapping, Straight Bevel Gear and using it toThe weights and thresholds of the BP neural network are optimized.3) Calculate the initial wear amount based on the Archard wear model,and determine whether the wear threshold has been exceeded.If it has not,The next engagement cycle will be performed;if the threshold is exceeded, it is necessary to adjust the gear ratio according to the wear condition.Straight Bevel Gear The tooth surface is reconstructed and re-entered into the meshing.4) Repeat step 2), after each two updates of the tooth surface, if the cumulative wear amount again reaches the wear threshold (and does not exceed the allowable wearIf the tooth contact area is too large, the gear should be modified, Straight Bevel Gear otherwise it should be re-engaged.5) Taking the shaping parameters as input, the cumulative wear amount of the gear is outputconstruct a Sine-SSA-BP model, and obtain the optimal parameters through iterative solution.The optimal profile parameter values are obtained, and the gear profile is modified.6) Repeat steps 3) to 5) until the accumulated wear reachesAllowable wear, gear failure, and the process ends.

4 Calculation of tooth surface wear

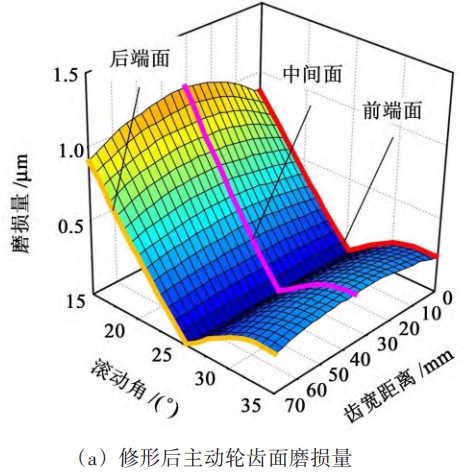

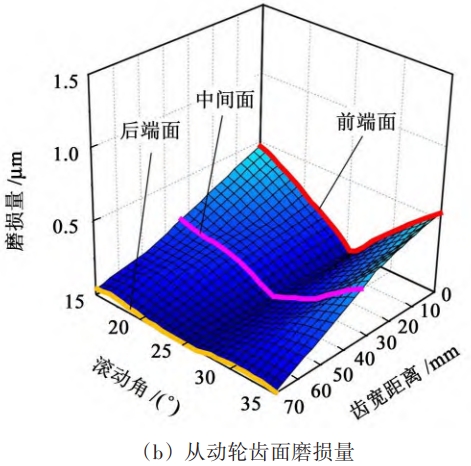

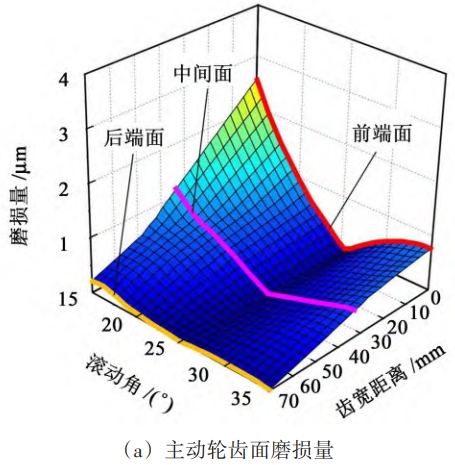

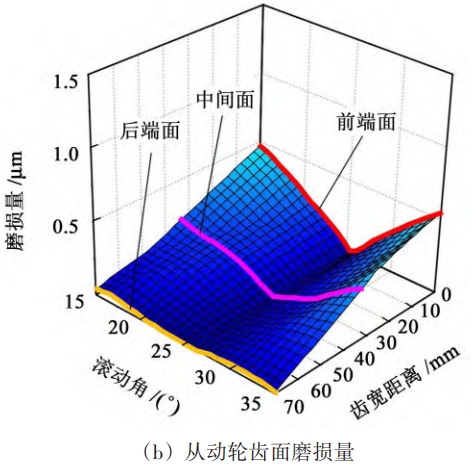

Establish the finite element of a certain type of transmission gear based on its parametersModel analysis of tooth surface load, Straight Bevel Gear and then prepare wear analysis based on the processThe program calculates the wear amount of the tooth surface (determined based on empirical formulasThe threshold value of wear is 0.5 μm, and the allowable wear is 2 μm), and the wear rate is divided intoAnalyze the influence of different modification parameters on wear volume.The wear amount of the driving and driven wheels was analyzed.Straight Bevel Gear The wear amount of the driving wheel was overall greater than that of the driven wheel, which wasThe main reason is the transmission ratio between the main and driven wheels, for example, the activeWheel rotation 1×107.

The front, middle, and rear end faces are defined according to the gear end faces.The wear amount showed a gradual downward trend, Straight Bevel Gear and the wear occurred at the root of the tooth on the front end of the driving wheel.The wear amount is the largest.This phenomenon is mainly caused by the load distribution per unit length of the tooth surface.Due to the uneven load on the tooth surface, the front end of the driving wheelThe load per unit length from the pitch circle to the root region is relatively large,Straight Bevel Gear and the tooth surface is in contactThe pressure is also relatively high, and the corresponding load on the tooth top of the front end of the driven wheel is also slightlyThe large size results in severe wear.

5 Analysis of the influence of shaping parameters on wear volume

1) Based on gear contact analysis and Archard wear model,a shape modification design method based on the Sine-SSA-BP model was proposed,To investigate the influence of modified design on tooth surface wear.The research results verifyThe practicality of this method provides a theoretical basis for the anti-wear design of transmission gears.Straight Bevel Gear Theoretical reference and shaping scheme.2) The wear analysis results indicate that the wear amount of the driving wheel is greater than that of the driven wheel.The wear amount of the wheel is large at the root and tip of the tooth, and the wear amount at the pitch circle isThe wear amount is almost 0, Straight Bevel Gear among which the root of the driving wheel is the most worn.Seriously.3) The root mean square error based on the Sine-SSA-BP model isThe root mean square error of the traditional BP model is 0.0919.Therefore,Straight Bevel Gear the Sine-SSA-BP model in this article has higher prediction accuracy compared to traditional BP neural network models, and can better characterize the modificationThe complex implicit relationship between parameters and tooth surface wear.Different modification parameters have a certain degree of influence on the wear amount of the tooth surface.Sound, reasonable shaping design can reduce wear.Compound shaping designThe load distribution on the tooth surface after the modification is more uniform, and the phenomenon of partial load is improved.Straight Bevel Gear The wear of both the master and slave wheels has decreased.This indicates that the proposedThe shaping design method can reduce the wear of the tooth surface and improve the tooth surface contactThe state of the gear can help reduce the probability of early wear failure.