0 Introduction

Spiral bevel gear (Gleason) is an important part in mechanical transmission.件, due to its high coincidence, low noise, stable transmission, and high transmission efficiencyHigh strength and load-bearing capacity, widely used in automotive, aerospace, shipcomplex machinery and equipmentDue to the complex structure of the spiral bevel gear,To improve the processing accuracy, reduce transmission noise, and increase service life,The process of reducing deformation error by grinding teeth is as follows: milling teeth – heat treatmentProcessing – gear grindingAs the final step in the process of machining spiral bevel gears, the grinding process is often accompanied by a series of complex plastic deformation processes.In the actual processing process, it is difficult to measure the grinding temperature, grinding force,important processing parameters such as abrasive wear, which hindered the development of grinding technology for spiral bevel gears.In-depth study of cutting mechanismTherefore, the finite element method is used to analyze the tooth surface grinding process.Simulation study on the grinding process, analyzing the tooth surface properties under different grinding conditionsThe impact can be used to reasonably select grinding process parameters, optimize the design of the spiral bevel gear,The process of gear manufacturing is of great significance.Using numerical simulation method, theA finite element model of temperature field was established for form grinding, and a rectangular distribution was selected.The temperature field of the heat source was simulated and analyzed to investigate the influence of different grinding parameters on the temperature distribution.The influence law of grinding temperature field.For titanium alloys in grinding processThe problem of grinding burns, which is easily occurred in China, is measured by experiments.The test method is to investigate the change laws of grinding force, grinding temperature, etc. during grinding process.The analysis and research were conducted, and a single abrasive particle model was established.Simulate the deformation of Aluminum with the finite element software Deform203 abrasive particles and 45 steel are notVariation of grinding force, equivalent stress, equivalent strain and grinding temperature at the same positionto explore the laws of abrasive particles under given conditionsVarious flow transitions, analysis of plastic deformation and local loss of friction during wearThe phenomenon of grinding force variation with different grinding speeds and depths was investigated.Based on finite element simulation software, cubic nitrideTwo different materials, boron nitride (CuBn) and white fused alumina, are used for grinding.The results show that the grinding temperature is affected by the depth more than the surface roughness.The influence of abrasive grain size and grinding parameters on grindingThe influence of force, grinding temperature, and processing quality is analyzed, and it is shown that the grinding force increases with the increase of grinding temperature.The increase in speed decreases, while the grinding temperature is just the opposite.The three-dimensional model of single abrasive grinding of nickel-based superalloy was established using finite element method.model, explored the evolution process of grinding debris morphology and grinding process under high-speed grinding conditionsThe law of force change.For the low prediction level of empirical models and the limitations of finite element methodProposed a method for solving the problem of single abrasive grinding process simulation.Simulation model of grinding wheel with super-hard particles arranged in an orderly manner.Different analysis methods were used in the study to simulateThe change laws of temperature field and grinding force during grinding, but mostly for single particlesGrinding analysis, the actual grinding process is multi-grain interaction and repeated cuttingThe process of the workpiece, therefore, there must be interference between the abrasive particles.In order toTo further explore the complex mechanism of the grinding process of spiral bevel gears, this paper examinesConsidering the correlation between grinding particles during grinding, the spiral bevel gear is taken as the grinding pairLike, establish a composite abrasive particle model and simulate the SG grinding wheel using finite element methodDuring the grinding process, the workpiece Johnson-Cook material constitutive model is used as theBased on the comparative analysis of different grinding speeds, grinding depths, and grinding particlesThe overall temperature field, grinding force, and abrasive wear of the workpiece grinding area at the spacing timetrend, revealing the changing laws and mechanisms of various factors in the actual grinding process.Theoretical guidance is provided for the optimization of grinding process parameters.

1 Grinding principle of spiral bevel gear

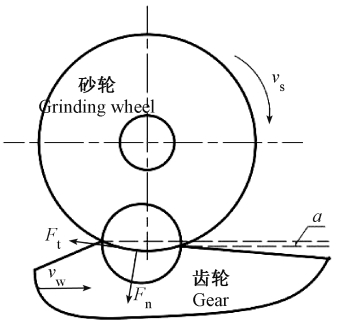

The grinding process of spiral bevel gears is similar to that of generating wheels and processed teethThe complex process of wheel engagement, that is, the process of making a virtual generating wheel and a cut gearintermeshing motion without clearanceGrinding is a dynamic and nonlinear process.The process of multi-factor coupling, therefore, is affected by the basic motion parameters of grinding and the abrasive grain size.physical parameters such as the temperature field and grinding force of the tooth surface of the spiral bevel gearThe amount will also change, and the mutual interference between the abrasive particles needs to be considered.The process of grinding the surface of the workpiece with a grinding wheel is to bring a dense arrangement of cutting teethThe milling cutter is used for high-speed cutting process, and the finite element method can be used to simulate the grinding process.The process is simplified to countless microscopic abrasive particles making cutting movements on the tooth surface.Therefore,The study of single-grain grinding principle is the foundation for understanding the mechanism of grinding process.The removal of material from the tooth surface by abrasive cutting can be divided into three stages, namely sliding friction, ploughing, and chip formation, as shown in Figure 1.Where, v s is the linear velocity of the SG grinding wheel;v w is the forming speed;a is the grinding depth;F t is the tangential grinding force;F n isNormal grinding force.

1) The sliding friction stage.The abrasive particles of the grinding wheel come into contact with the tooth surface, and the grinding depth increases.The degree of friction is relatively small, and the tooth surface slides past, resulting in only elastic deformation of the tooth surface.2) The ploughing stage.As the grinding continues, the grinding depth increases.Addition, resulting in an increase in the normal and tangential forces of grinding, and the material of the tooth surface begins toPlastic deformation, with uplift on the front and sides of the abrasive particles, indicating tillageThe ploughing stage.During this stage, grooves are carved on the tooth surface, and abrasive particles are squeezed between the tooth surface and theThe pressure friction is severe, and the grinding heat increases significantly.3) The chip formation stage.The grinding depth continues to increase, and the temperature reaches or exceedsThe critical temperature of the material on the tooth surface is exceeded, and some of the material on the tooth surface is visibly shearedThe surface slips and forms grinding debris, which accumulates in a vortex shape in front of and on both sides of the grinding particles.

2. Establishment of grinding geometric model

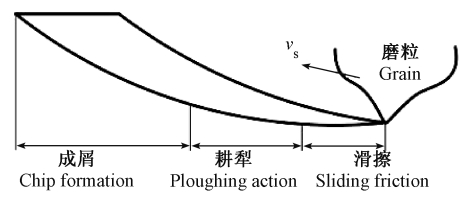

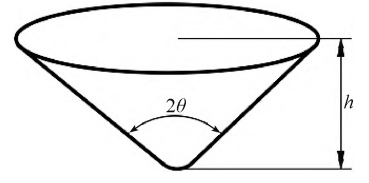

In order to facilitate the study of the complex mechanism of grinding process, many scholarsThe authors simplify the grinding particles of the grinding wheel into regular geometric shapes, such as conical, semi-cylindrical,Spheres, tetrahedrons, polygonal prisms 53-62This article chooses conical shape as the grindingThe basic shape of the particles is shown in Figure 2.The height of the abrasive particles h = 70 μm, with a top coneThe angle 2θ=108°.In order to obtain the interference effect between multiple abrasive particles,Therefore, the position and density of grinding particles can be pre-arranged for new grinding toolsWait, create two abrasive particles with the same parameters, and bond the two abrasive particlesThe upper part of the particles are connected together to achieve side-by-side cutting motion.The abrasive grain size determinesAfter determining the size of the grinding wheel particles, this article selects 60# Granularity, interval pointsDon’t simulate for 150 μm and 220 μm。The finite element method is used to simulate the process of grinding spiral bevel gears with a grinding wheel.The length, width, and thickness of the tooth surface unit are 2mm, 1mm, and 1mm, respectively.The basic geometric model of grinding workpiece and abrasive particles is established, as shown in Figure 3.

3. Establishment of finite element model and simulation analysis

3.1 Establish a finite element analysis model

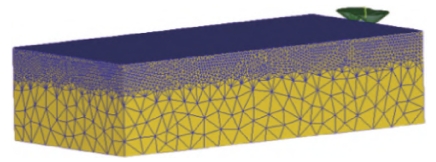

Simulating the composite grinding of spiral bevel gear tooth surface using finite element simulation softwareIn the process of grain grinding, different grinding parameters can be obtained to control the temperature field, grindingThe influence of force and abrasive wear.The analysis process uses the previous configuration as a referenceThe Lagrange finite element method for solving structural problems is characterized by the following aspects:During the solution calculation process, the variation of the element grid during the contact between the tool and the tooth surface is analyzed.The grid can be re-divided at any time to avoid the deformation of the surface gridThe variable method can solve the problem of non-convergence in calculating local large deformation during grinding.The simulation process includes grid division, model material setting, and workpieceJonson-Cook material constitutive model, boundary conditions and contact relationships, andDetermine the settings.

3.1.1 Grid DivisionAs a very important step in finite element preprocessing, mesh generationThe accuracy of the calculation results directly depends on whether it is appropriate.The accurate calculation results also improve the calculation efficiency. Firstly, the model is initializedStep 1: Divide the grid and set the extreme cell length of the geometric object to be divided as0.05mm and 0.003mm, with a ratio of 2.To further ensure the accuracy of the simulation,The calculation accuracy of the analysis, after the preliminary division of the grid, is applied to the grinding tooth surfaceThe grid of is locally refined, and the refined grid sizes are0.02mm and 0.001mm, with a total of 162,339 units of tooth surface and abrasive particlesThere are 1,363,89 nodes, and the finite element mesh model is shown in Figure 4.

3.1.2 Set model materialSet the elastic modulus according to the actual material of the spiral bevel gear, 25CrMo4The amount is 202 GPa, the shear modulus is 78 GPa, the Poisson’s ratio is 0.25, and the density is generally 7.8 g/cm3.3The main component of SG grinding wheel is Al203, with hardnessHigh strength, good toughness, strong sharpness and other advantages.

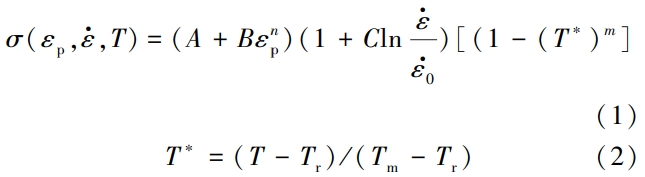

3.1.3 Workpiece Johnson-Cook material constitutive modelConsidering that the workpiece is continuously subjected to high pressure during the process of grinding the tooth surface with abrasive particles,Stress, high temperature and large strain states, and thermal elastic-plastic deformation occur,Choosing a constitutive model that can express the material properties is crucial for the final simulation results.accuracy and reliability are crucial. Due to theJohnson PAL materialThe constitutive model [14] has a good expression effect on this type of problem, so it is selected.Jonson-Cook constitutive equation is used to express the relationship between the material properties of the workpiece and temperature and stressThe specific mathematical expression for the relationship between and is

Where, σ is stress;A is initial yield stress;B is strain strengthening parameterC is the strain rate strengthening parameter;n is the hardening index;m is the thermal softeningIndex;T is the workpiece temperature;Tm is the melting point temperature; Tr is the room temperature;εp isBe flexible.The plastic parameters of the Johnson-Cook model for material 25CrMo4 areFor A=120MPa, B=891MPa, C=0.02, n=0.2, m=During the process of composite abrasive grinding of tooth surfaces, the stress and strain on the materialOnly when the variation exceeds the set range can the separation of grinding debris occur.The shear failure criterion of the Johnson-Cook constitutive model can accurately provide reasonableOn the basis of separation, this type of large deformation simulation analysis is applicable.

3.1.4 Boundary Conditions and Contact RelationshipAccording to the material properties, the abrasive particles are selected as rigid bodies, and the tooth surface is defined as plasticThe bottom surface of the fixed tooth surface, and the abrasive particles move tangentially along the tooth surface.In addition,Considering the friction between the grinding particles and the surface to be ground during the actual grinding process,So we choose the shear friction type, with a friction coefficient of μ = 0.6.Friction is inevitableThere will be heat transfer, defining the upper surface of the gear microelement and the overall abrasive particles as a thermal exchangeOn the other hand, the convective heat transfer coefficient during the simulation is 0.02 N/(s·mm·℃),Set the initial temperature of the abrasive particles and workpiece material to room temperature of 20℃.

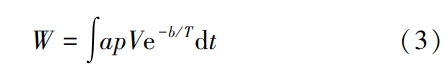

3.1.5 Solution SettingsThe simulation step size setting requires comprehensive consideration of the amount of computation, calculation time, and simulation accuracy.The factors such as true accuracy, too little will cause redundant calculations, too much will lead to resultsLow accuracy or even calculation failure. After repeated testing, the step size is set to the minimumThe grid size is 1/10, that is, 0.001mm/step, and it is saved every 5 steps, totalingThe load step is 2000 steps.The simulation type is Lagrangian Incremental.Select Direct Iteration as the iteration method. This iteration method is similar to Newton-Raphson method.Compared with Raphson, it can achieve better convergence.Selecting continuousUsu wear model during processingCalculate the composite abrasive wearThe formula is

Where, W is the wear amount;p is the interface pressure;V is the sliding speed; T isInterface temperature;a and b are the experimental calibration coefficients.

3.2 Analysis of simulation results

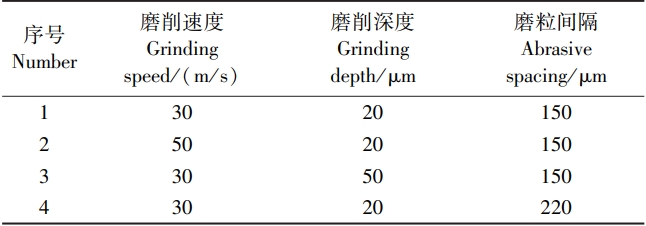

The quality of the tooth surface of the spiral bevel gear directly affects the operation of mechanical equipmentEfficiency, service life and accuracy.Grinding processing as a key link mustStrictly control the grinding parameters, otherwise, the tooth surface may be damaged during the processing or use period.cracks, such as long strip cracks, net cracks, and point cracks, may occurThe tattooCracks will cause dramatic changes in the maximum contact stressAfter a longBased on the quantitative analysis and practical research, it can be concluded that the main reason for the above cracks isDue to excessive grinding temperature, excessive grinding force, etc., but the actual processingIt is difficult to detect these parameters in the middle.Therefore, in order to explore the grinding processThe change rules of the temperature field and grinding force of the medium tooth surface are controlled by variableThe quantitative method was implemented for four times of composite abrasive grinding simulation, with specific parameters shown in the table1, taking Group 1 as the standard group for comparative analysis, research on grindingmechanism.

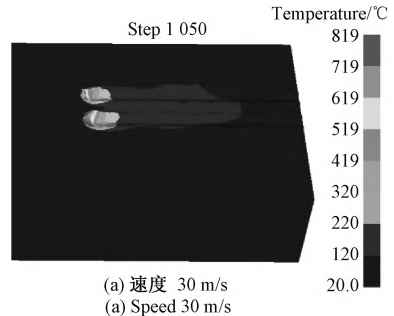

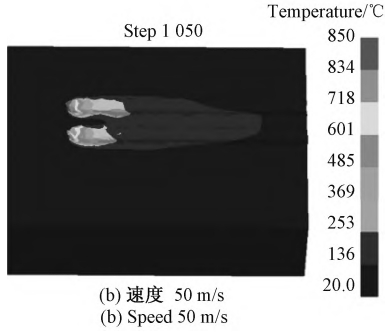

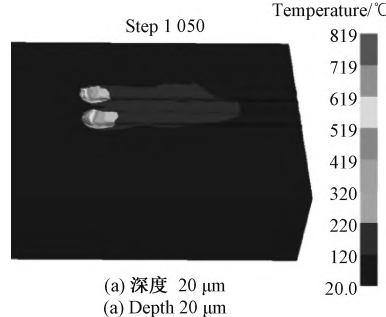

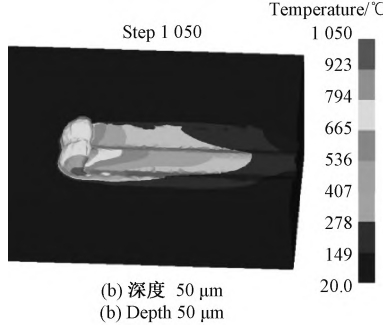

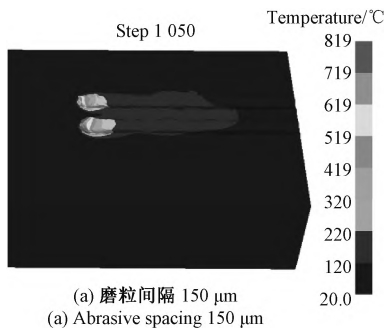

3.2.1 Temperature field analysisThe temperature of the tooth surface increases with the progress of abrasive grinding, and the stableDetermine the temperature field during grinding, and compare different abrasive velocities and different grinding conditionsThe temperature field distribution of the tooth surface at different depths and different abrasive particle intervals is shown in the figure5 to Figure 7.

As shown in the figure, under the same grinding depth condition,When the grinding speed is 30m/s and 50m/s, the maximum temperature of the tooth surface is819℃ and 950℃;under the same grinding speed, the grinding depthWhen the thickness is 20μm and 50μm respectively, the maximum temperature of the tooth surface is819℃ and 1050℃;control the rest of the grinding parameters the same, only change the grinding speedThe particle spacing and temperature field changes are not very obvious.The reasons for this are analyzed as follows:

1) As the grinding speed increases, the temperature of the tooth surface increases.This isBecause with the increase in speed, the wear particles will increase the tooth surface in unit timeThe effective grinding amount of the grinding wheel increases, resulting in an increase in friction work and a buildup of heat.The increase in the number of grinding wheels increases the grinding temperature.2) As the grinding depth increases, the temperature of the tooth surface increases significantly.This is because as the grinding depth increases, the surface of the grinding particles and the material of the tooth surfaceThe contact area increases, and the extrusion force on the tooth surface also increases significantly, leading tocausing a significant increase in friction, so the grinding heat will change significantly,The grinding continues, even approaching the melting point of the material.At the same time, as shown in Figure 6,It is found that the increase of grinding depth slows down the heat dissipation of the tooth surface, which is more likely to cause surfaceBurns, so the actual grinding process must be properly cooled with coolant in a timely mannerTake away the heat generated by grinding.3) Changing the abrasive particle spacing has little effect on the factors affecting friction.so the temperature field changes are not significant.4) The overall temperature change trend is almost the same as the single particle grinding model.This reflects the correctness of the composite abrasive grinding model.However, compared with single abrasive grinding,Compared with the granular grinding model, it can be clearly seen from the composite abrasive grinding model thatDue to the interference between the abrasive particles, the temperature fields radiate with each other, as shown in FigureAs shown in Figure 6(b), the temperature of the tooth surface without contact grinding can bereach over 500℃;as shown in Figure 7, the temperature field is affected by the interference of abrasive particles.The heat dissipation rate of the tooth surface is also different.These phenomena are related to the actual grinding process.The distribution of grinding heat flow under working conditions is consistent.

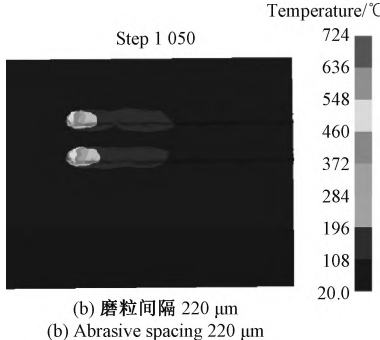

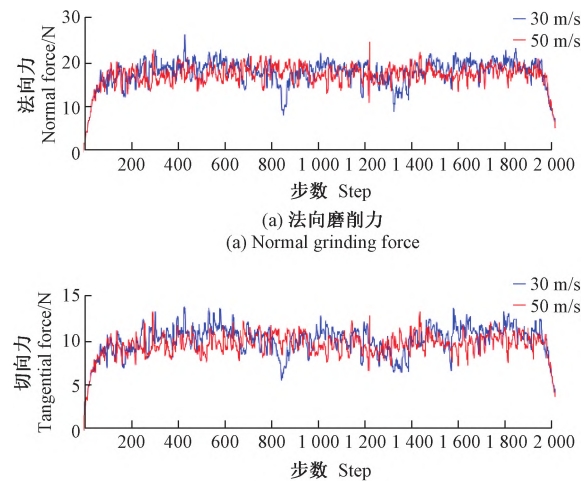

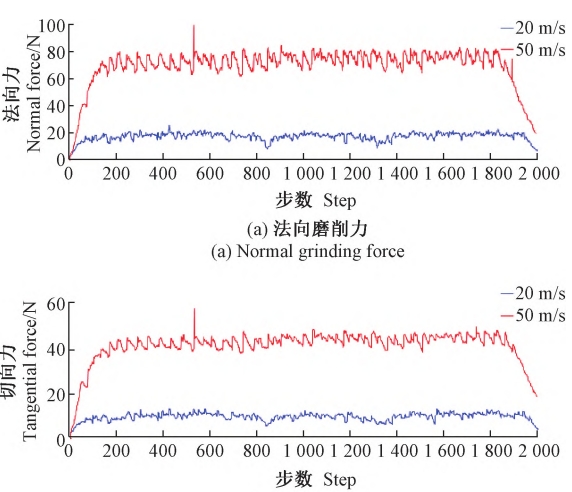

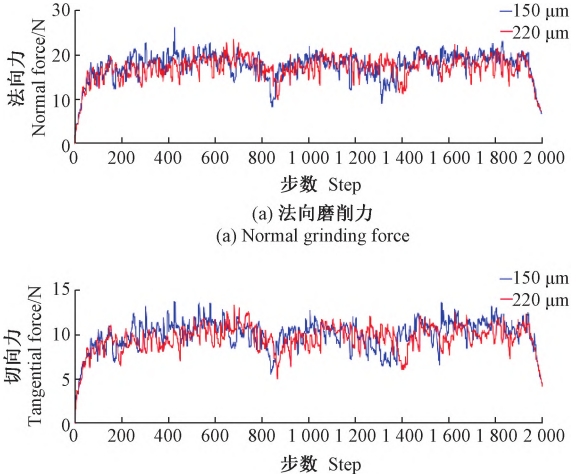

3.2.2 Grinding force analysisGrinding force is the main parameter reflecting the basic characteristics and laws of grinding process.The number is closely related to the changes in grinding temperature, tooth surface strain, and tool wear.It is an important reason for grinding energy consumption, heat generation, and grinding vibration.Because ofThe research and analysis of this parameter is beneficial to further understand theThe cutting mechanism is the basis for improving the grinding process.Extract the grinding force (normal and tangential) data during the entire grinding process,Comparative analysis was conducted to study the effects of different abrasive particle velocities, different grinding depths, and different grinding conditions on the surface roughness and microstructure of the workpiece.Variation curves of grinding forces (normal and tangential) at different abrasive particle intervals, withThe result is shown in the figure.

As shown in Figure 8-10,1) Abrasive particles gradually enter the tooth surface material, and the grinding force has a large gradientIncreasing to the maximum value, the grinding normal force is always greater than the tangential force, and the twoThe change trend is almost the same.2) During the stable grinding stage, the grinding force fluctuates around the maximum valuestability within a fixed range, as the abrasive particles leave the material, theThe cutting force slowly decreases until it reaches zero.The average value of grinding force as a function of speed is shown in Table 2, andAs the speed increases, the temperature of the tooth surface increases, so the grinding force decreases.As shown in Figure 9(a) and Figure 9(b), the grinding force will increase with the increase of grinding depth.Obvious changes, the experimental results of the above simulation results areThis is consistent.4) The results corresponding to individual time steps in the figure fluctuate significantly, which can beIt may be caused by the distortion of the grid re-division during the simulation process.Therefore, it has a negligible effect on the trend of grinding force change.According to the analysis based on the actual situation, the large negative rake angle of the grinding particles leads to the grindingThe normal force is greater than the tangential force, and the shape is conical, making the workpiece materialFlowing on both sides reduces the resistance of abrasive particles in the forward direction, which is grinding.The depth significantly affects the nature of grinding force.Different from the single abrasive particle model, in order to further explore the interaction between abrasive particles,Interference effect of cutting force, calculated at the corresponding grain spacing point in Figure 10Don’t worry about the variance of the grinding force data at 150 μm and 220 μm, as shown in the table3. Comparing the variance of normal force and tangential force, it can be seen that theThe smaller the spacing, the stronger the mutual interference of grinding forces, resulting in grindingThe stability of the process is poor, which is also the reason why vibration occurs during grinding.The factors ignored.

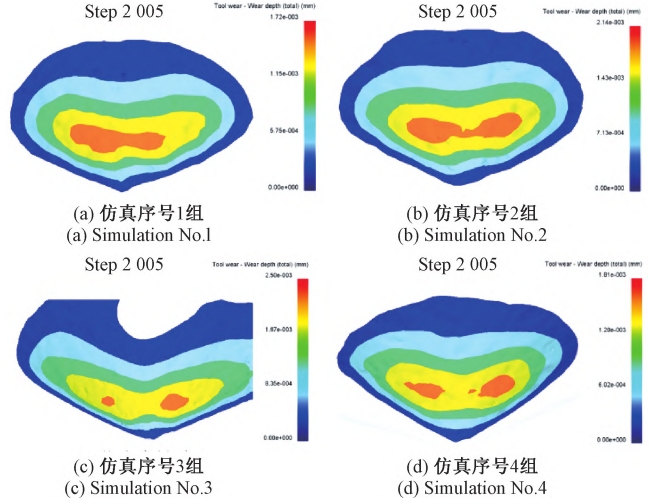

3.2.3 Abrasive wear analysisGrinding workpieces with grinding wheels requires continuous exposure to high temperatures, high speeds, and high stressThe slight change of grinding parameters can easily affect the grinding quality, resulting inMaking frequent use of cutting tools to shape not only reduces the grinding accuracy of the grinding wheel, but alsoaffecting the processing efficiencyTherefore, research on the causes and rules of abrasive wear is of great significance.Law is crucial to optimizing the actual grinding process.In order to visually analyze grindingThe degree of grain wear is shown in the wear cloud image extracted after the simulation grinding is completed, as shown in the figureas shown.

As can be seen from the figure, no matter how the grinding parameters are changed, the main grindingThe damage surface always follows the direction of motion of the contact area with the workpiece material.In addition,Due to the conical shape, the wear surface spreads elliptically, and the diffusion rate increases withThe grinding progresses gradually faster.Comparison between Figure (a) and Figure (b)It can be seen that with the increase of grinding speed from 30 m/s to 50 m/s, the wearThe amount increased from 1.72 μm to 2.14 μm, and the overall wear area was almost doubled.To;From the comparison diagram (a) and diagram (c), it can be seen that as the grinding depth increases fromWhen the thickness is increased from 20 μm to 50 μm, the wear loss increases from 1.72 μm to2.5 μm, wear area spreads outward;comparison diagram (a) and diagram (d)It was found that the change in wear volume was slightly affected by the wear particle spacing.Therefore,In grinding, the grinding depth has the greatest impact on the wear of the grinding tool.The cutting speed is the second largest factor, while the impact of the grain spacing is the smallest.

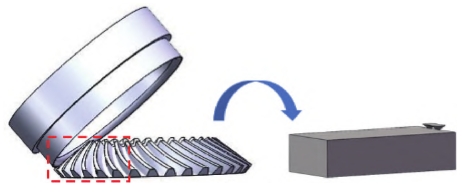

4. Tooth surface grinding experiment

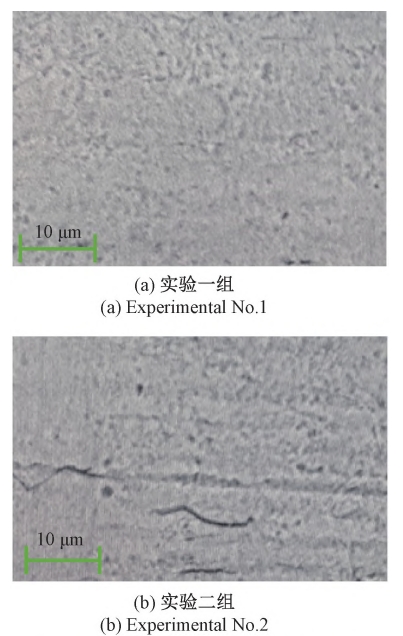

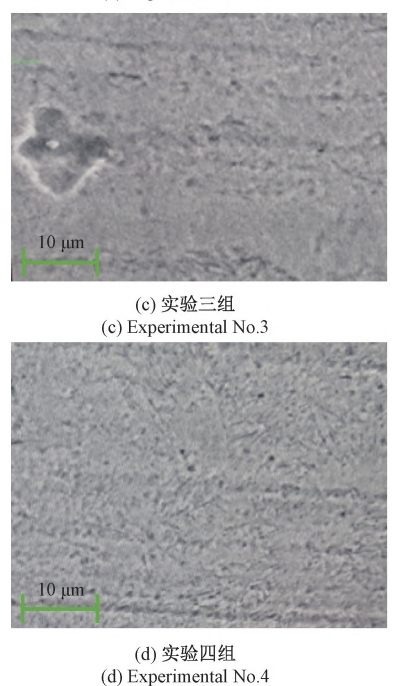

To further validate the established model and the results of finite element simulation,Accuracy, using the control variable method, prepare four sets of materials, geometric dimensions, and addgrinding workpieces and grinding wheels with basically consistent parameters such as work accuracy.The grinding speed, grinding depth, and grinding wheel grain size of the grinding wheel are shown in Table 4.It is suggested that the arc-toothed bevel gears in each group be controlled under the same working conditionsActual grinding experiment.Group 1 was used as the control group, and groups 2, 3, and 4 were used as the experimental groups.For the experimental group, comparative analysis was conducted to observe the grinding effect.

Using Zeiss Evo electron microscope, after grinding the spiral bevel gearThe tooth surface of the grinding wheel is detected and imaged.The figure shows four different grinding stripsThe influence of the grinding wheel on the grinding tooth surface.Comparing Figure (a) and Figure (b), it is found that with the increase of grinding speed,Speed up, and there are visible grinding wheel marks on the tooth surface;comparison diagram(a) and Figure (c), it is found that with the increase of grinding depth, the grinding imprintFurther deepening, and some damaged surfaces with depressions appeared on the tooth surface;contrastFigures (a) and (d) show that as the spacing between abrasive particles decreases, the tooth surfaceThe grinding imprint is wrinkled and shows obvious interference phenomena.The above experimental results are basically consistent with the conclusions obtained from finite element simulation.The result reflects the accuracy of the established grinding model and the finite element analysis results.Through simulation and experiment, it is proved that grinding speed, grinding depth, grindingThe particle spacing has different degrees of influence on the surface properties of grinding spiral bevel gears.Therefore, the grinding parameters should be strictly controlled during the actual processing process.

5 Conclusion

This article conducts simulation analysis on the composite abrasive grinding process, and conductsThe experimental verification explored the influence of grinding speed, grinding depth and other parameters onThe influence of temperature field, grinding force and abrasive wear on the tooth surface is obtained as followsConclusion:1) As the grinding speed and grinding depth increase, the temperature of the tooth surface willsignificantly increased, even approaching the melting point of the material, especially affected by the interference of composite abrasive particlesThe temperature field of the tooth surface radiates mutually, resulting in high temperature on the non-contact grinding surface.Temperature effect, while slowing down the heat dissipation rate.2) The smaller the spacing between the abrasive particles, the more the grinding force interference effect.Strong, resulting in poor stability in the grinding process, which can easily lead to vibration.3) The grinding depth has the greatest impact on the wear of the grinding tool, followed by the grinding speed.In other words, with the increase of speed and depth, the wear amount will increase.4) Comprehensive analysis shows that the grinding depth is the main factor affecting theThe main factors affecting the temperature of the workpiece, grinding force, and wear of the grinding tool are the most important factors in practical grinding.It should be strictly controlled during the cutting process.