Vibration test

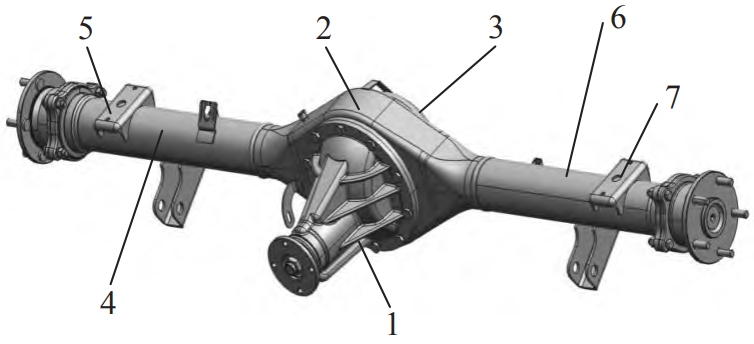

Based on the vibration test of the drive axle transmission system, three-direction acceleration transmissionThe sensor acquires acceleration vibration signals and uses multi-channel signal acquisitionThe vibration signal collected is recorded by the signal processing system and data analysis softwareand subsequent data processing.The main experimental equipment: LMS SCADAS 40Channel-type high-precision signal acquisition and processing system, PCB_356A26 three-directionAcceleration sensor, LMS Test.lab data acquisition and signal processing softwareThe arrangement points of the three-axis acceleration sensor in the experiment are shown in the figure.

Analyze the vertical vibration of the main reducer housing at the bottom of the drive axle,and compare the relevant test values before and after optimizing the design scheme.The vibration test bench for the drive axle assembly is shown in Figure 20.The drive axle isLine vibration test: debug the test system, and conduct the test according to low speed, medium speed, and high speedRun forward and reverse for a period of time, drain the waste oil after running-in, and thenRefill the gear oil and rotate it forward to adjust to the specified power parameters;Start to collect data after the operation is stable, and test 4 groups of specified conditions separatelyVertical vibration at the bottom of the main reducer housing of the lower drive axle.

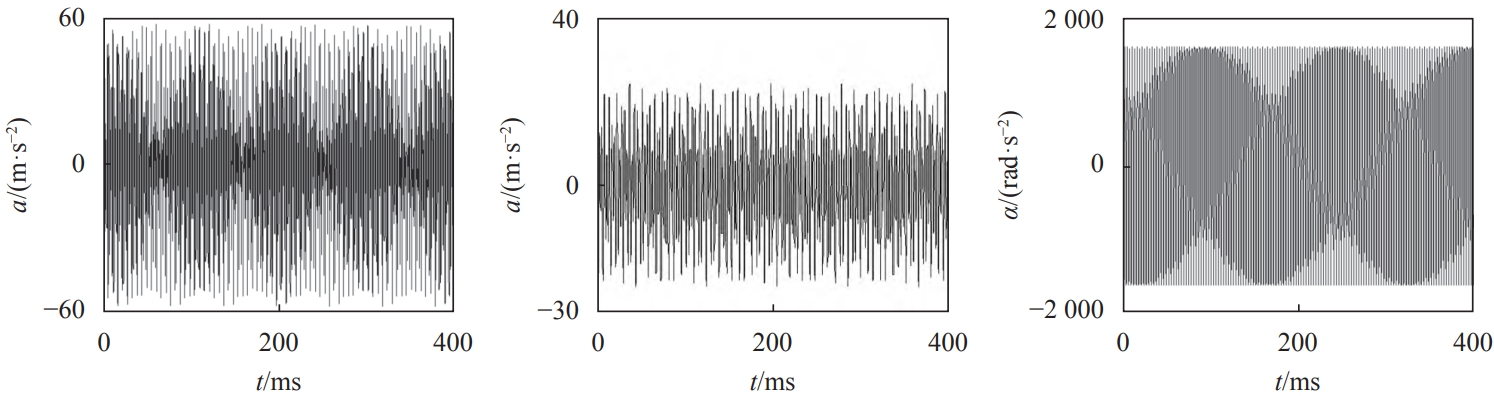

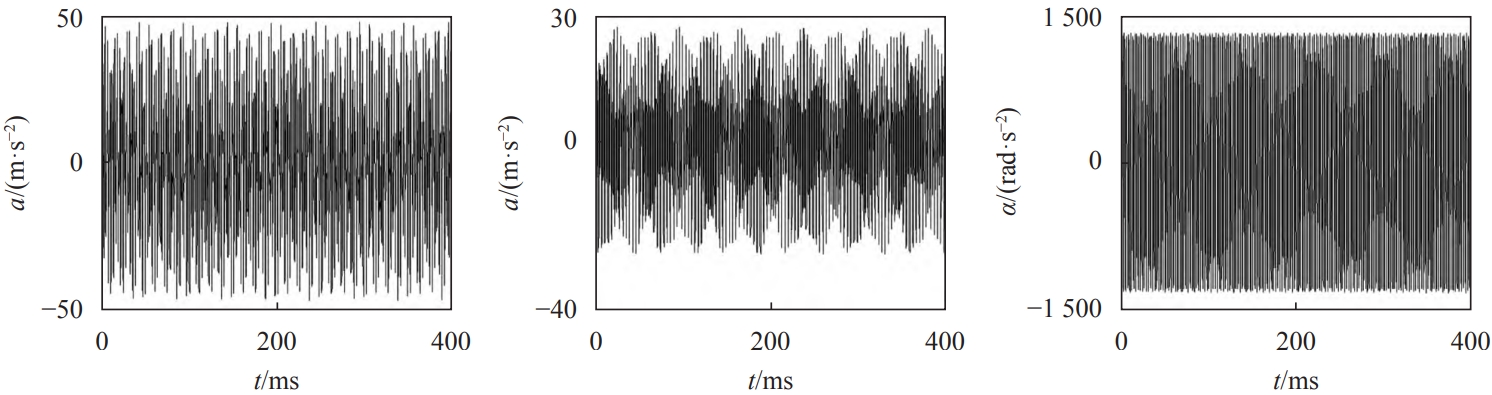

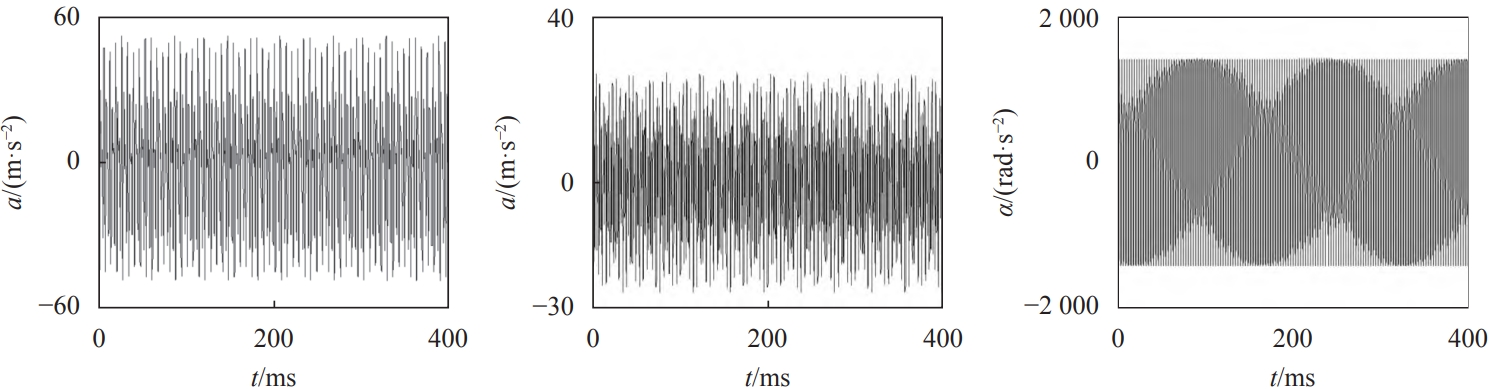

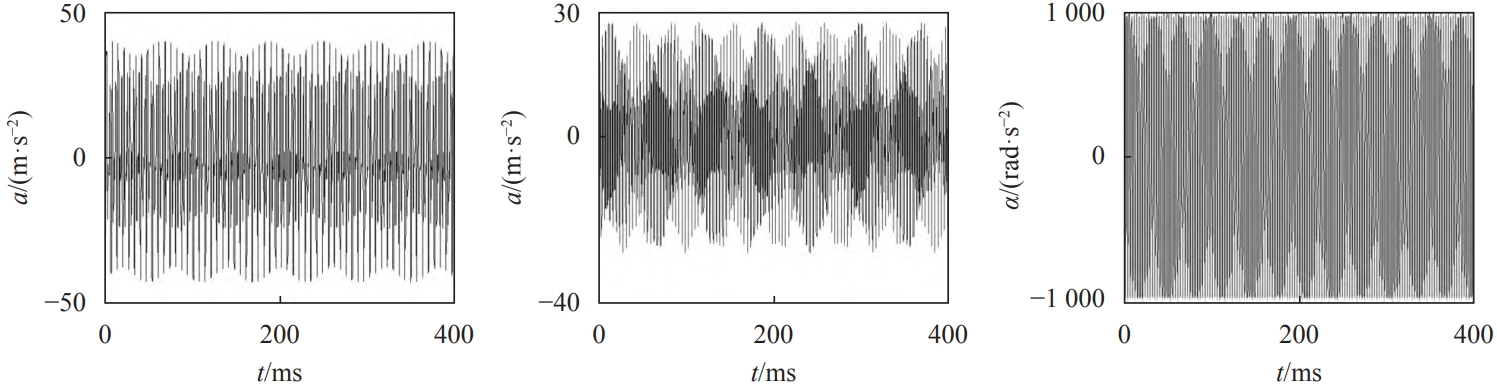

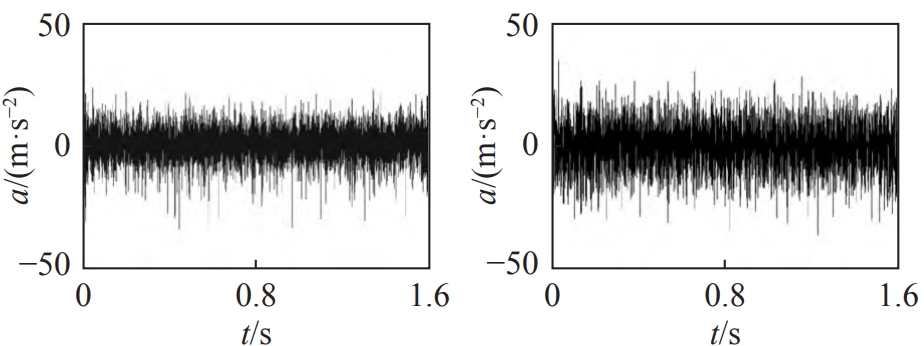

Test parameters: working condition 1, input torque 200 N·m, test speed800 r/min;condition 2, input torque 200 N·m, test speed 1500r/min;working condition 3, input torque 400 N·m, test speed 800 r/min;working condition 4, input torque 400 N·m, test speed 1 500 r/min.The vibration acceleration of the main reducer housing bottom under four test conditions is shown inAs shown in Figure 21, it can be seen that the vibration of the drive axle accelerates in the new state.The amplitude value is less than the original state, and the number of peaks is alsoLess;the main reducer housing bottom in the new state vibrates vertically and acceleratesThe degree change trend is similar to the theoretical vibration trend of the main gear. Due toFriction and lubricant damping are also neglected in the research, which is inconsistent with the actual work.There are some gaps, and the measured vibration acceleration amplitude is smaller than the theoretical value.

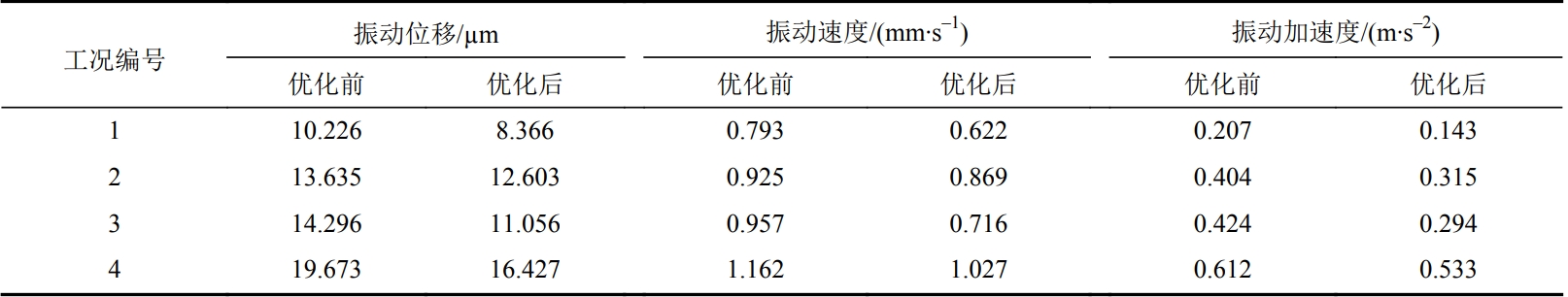

Bottom of main reducer housingThe vibration displacement, vibration velocity and vibration acceleration of the vertical equilibrium position point of the partThe average value of the three test values was taken as the test value for the dynamic acceleration.From Table 2It can be seen that under the same load torque, as the speed increases, the vertical vibrationThe displacement, velocity, and acceleration values increase;at the same speed, as the load increases,As the load torque increases, the vertical vibration displacement, velocity, and acceleration values all increase.It indicates that both load torque and speed have an excitation effect on the vibration response of the drive axle.Under the same load torque or speed, the optimized rear driveVertical vibration displacement, vibration velocity,The test values of vibration acceleration are all lower than the corresponding values of the bottom of the main reducer housing of the drive axle in the original state.The test proves that the optimized drive axle has betterGood vibration characteristics are consistent with the results of theoretical research, and the operation processThe noise in the is lower.

1) With the goal of achieving active control of the dynamic characteristics of the drive axle,The vibration characteristics of the drive axle hypoid gear transmission system were analyzed.Through the analysis of the drive axle gear LTCA, the causes of the gear transmission systemThe key internal excitation factors such as vibration meshing stiffness, transmission error, and meshing impactIncentive factors.2) Constructing a drive axle gear transmission system based on the lumped mass methodVariable parameter coupled vibration model, and derived based on Newton’s second lawThe vibration differential equations are solved using the RK algorithm.CompareThe vertical, torsional and axial directions of the master and slave gears before and after the optimization of the tooth surface modificationThe numerical solution of vibration, and the simulation data are for the dynamic design and vibration of the drive axleNoise suppression provides theoretical basis.3) Study the changes in input speed and load torque on the drive axle transmissionThe influence law of dynamic system vibration characteristics.The results show that the speed and loadThe torque has the greatest impact on the vibration of the main and slave pinions, followed by the vertical direction.The minimum torsional direction provides data support for the prediction of the vibration response of the drive axle.4) Complete the vibration test under the loading condition of the drive axle, and update the statusThe dynamic performance of the prototype is better, and the trend of test data is consistent with theoretical analysis.The analysis results are in good agreement.We will continue to analyze the impact of internal incentive factors on the system in the future.The sounding law is followed, and friction factors, thermal deformation, mass eccentricity, etc. are considered in the calculation.In order to predict the response trend, a more accurate coupled vibration model is established.