The shield machine is widely used in the construction of subway, river crossing and other long and large tunnel projects.Widely used, the research on fault diagnosis and efficient operation and maintenance of equipment is of great significance for the development of shield tunneling technology.The significance of stable operation and reliable construction of the machine is significantMain reducerIt is a key component of the main drive of the shield machine, usually used in low-speed heavy-load, torqueWorking in harsh conditions with great shocks, leading to gear failure andTherefore, timely and accurate extraction of the fault characteristics of the main reducer gear is very important.It is of great engineering significance to perform fault diagnosis on the main reducer.The main reducer of the shield machine works in a non-steady working condition environment,The vibration signal generated by the reducer is a non-stationary, nonlinear signal that is heavily affected by noise signals generated by the main bearing and main motor.Therefore, the vibration signal generated by the reducer is multi-dimensional.Complex signals that are synthesized by signals. Decomposing such complex signals into multiple signalsNo. component, followed by noise reduction, feature extraction analysis, and other processing, will make the processing more effective.The problem of gear failure diagnosis of reducer becomes simple and efficientIn recent yearsCome on, many experts and scholars have improved the denoising process for vibration signals.Signal decomposition method.Variational modal decomposition (VMD)Method by variationComplete modal decomposition of the problem, which can suppress noise interference during the decomposition process.problems such as modal aliasing and endpoint effectsTherefore, once proposed, this methodBut the decomposition effect of the VMD algorithm is affected by the modality componentsThe number K and the penalty factor α have a large influence, and the optimal values are explored through experimentsThe parameter combination is relatively cumbersome.Through the analysis of bearing experimental data,The selection of K and α in VMD is analyzed, but K and α are not consideredofInteraction effect.Use empirical mode decomposition (EMD)It is necessary to set the characteristics of the modal decomposition and evaluate the effective modes of the EMD decompositionnumber, which is used as the K value for VMD decomposition, but this method relies on humanExperience analysis.Using the kurtosis criterion to analyze the VMD scoreThe reconstructed signal was denoised and the early fault of the bearing under strong noise was extracted.information, but did not perform adaptive optimization on the decomposition parameters K and α.Based on the above research and analysis, in order to adaptively optimize the parameters of the VMD algorithm,It is necessary to optimize and reduce the interference of noise signals to improve the accuracy of fault identification and classification.For diagnostic effectiveness, the minimum average envelope entropy is used as the fitness functionOptimization of the particle swarm algorithm for VMD, based on the kurtosis criterion toThe obtained IMF components are screened and reconstructed to remove noise.and extracts the fault characteristics of the gear from the perspective of time domain and entropy theory, and finallyEnter the PSO-SVM and LightGBM for fault diagnosis.

1 Variational modal decomposition algorithm and parameter optimization

The core idea of the VMD algorithm is to construct the signal as a variational problemmodel, and then iteratively update it to search for the optimal solution of the model.The signal x can be decomposed into K center frequencies ωk and finite bandwidth IMFsThe component.

1.2 Parameter optimization of variational modal decomposition

In the decomposition of VMD, the number of decompositions K and the quadratic penalty factor αBoth require presets, and VMD performance is directly affected by [K, α].The value of KToo small, resulting in mode aliasing;too large K value, resulting in false components; the larger α is,The smaller the value of α, the larger the bandwidth of the decomposed IMF component;the larger the value of α, the smaller the bandwidth of the decomposed IMF component.The smaller the bandwidth, the more accurate the estimation.Therefore, before using VMD, choose the appropriate [K, α] to achieve the best estimation accuracy.This is a problem that needs to be solved urgently.Particle swarm optimization algorithm is a kind of swarm intelligence optimization algorithm, whichThe cooperation and competition between different individuals in the population complete the optimization, with goodglobal optimization ability.Suppose that the position of the ith particle in the N-dimensional spaceSet as Xi = (xi1, xi2, …, xin), with speed Vi = (vi1, vi2, …,v1N), the optimal position the particle passes through is Pi = (pi1, pi2, …, piN),The optimal position for M particles in the population is Pg = (Pg1, Pg2, …,p g N).The particle will update itself based on the individual local extremum and the population extremumposition and speed.

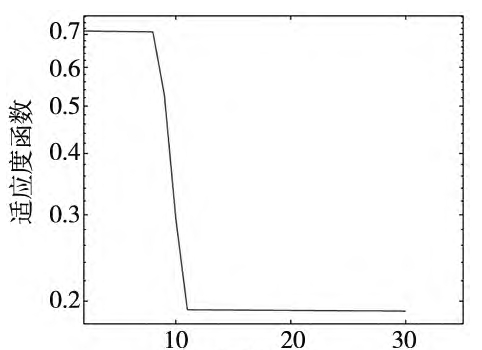

When using PSO to optimize VMD, it is necessary to select fitnessThe function evaluates the optimized parameters.As a measure of informationThe value of the index, which is used to judge the sparsity degree of the signal, reflects the degree ofDegree of uncertainty.The average of the envelope entropy of the IMF components after decomposition by VMDValue, which is the average envelope entropy of the signal. This article chooses the minimum average envelopeEntropy is used as a fitness function to search for the least noisy decomposition component of VMDof [K, α].

2. Crestiness Criterion

Crest factor is a dimensionless parameter describing the peak of waveform, which is related to gearThe parameters such as load and size are irrelevant, and it is sensitive to the impact signal。

When the kurtosis value is close to 3, the gear vibration signal is approximately normal distributed.Indicating that the gear is operating without fault.When the gear fails, the vibration signalshock components will be generated, and the kurtosis value of the signal will increase accordingly.Therefore, inIn gear fault diagnosis, the kurtosis criterion is used to screen the data obtained after VMD.The best and second best components of the IMF can be reconstructed to form a richReconstruct the signal with the characteristics of the noise, and achieve noise reduction of the signal.Vibration signalFor normal signals, select the two groups of components closest to 3 for reconstruction,When the signal is a fault signal, select the two groups with the largest and second largest kurtosis valuesreconstruct the components.

3. Gear fault diagnosis process

Based on the theoretical foundation and research ideas mentioned above, a parameter-basedOptimizing the gear fault diagnosis method based on VMD and kurtosis criteria, with specific proceduresAs shown in Figure 1.The specific steps of the algorithm are:Step 1: Through the comprehensive experimental platform for diagnosis of power transmission faults(DDS) acquires vibration signals under different health conditions of the gear, andTreat according to the required length and requirements;Step 2: use the particle swarm optimization variational mode decomposition algorithm toThe dynamic signal is decomposed, and the resulting IMF components are analyzed using the kurtosis criterion.screening and reconstruction;Step 3: Extracting time-domain features and entropy theory characteristics of the reconstructed signalAccording to the different health conditions of the gear and the required sample size, a fault is constructedFeature dataset;Step 4: Apply the t-SNE algorithm to the fault feature dataset for visualization.visualization, and uses the PSO-SVM and LightGBM algorithms to detect faultsIdentify and classify, complete fault diagnosis.

validation analysis

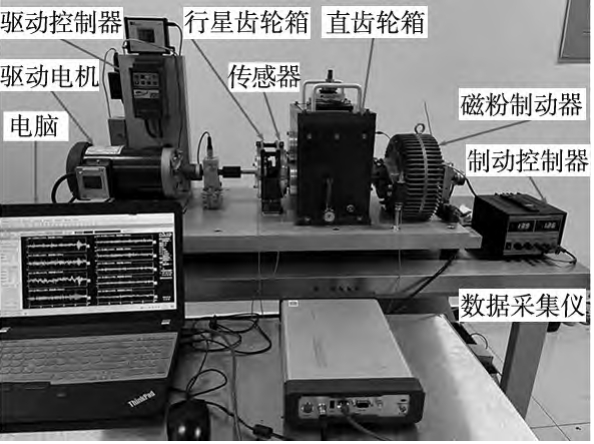

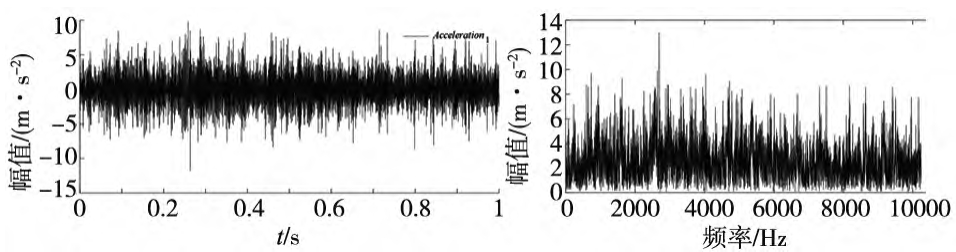

To verify the effectiveness of the proposed method, the author used a dynamic transmission faultThe second-level planetary gear train solar energy conversion system was tested on the comprehensive experimental platform for barrier diagnosis (DDS).Experiments on 4 different health states of the sun wheel to simulate the occurrence of problemsObstacles: root cracks, wear, and broken teeth were processed on 3 different gearsThe fault and fault gear are shown in Figure 2.The parameters of the second-stage planetary gear train areThe relevant frequencies obtained through calculation are shown in Tables 1 and 2.During the test, the input frequency of the drive motor is set to 30Hz, and the current of the magnetic powder brake is set toSet to 1.3A is equivalent to applying a load of 6N·m, the acquisition instrument is the Dongfang Institute’s DASP signal acquisition instrument, and the sensor is a three-channel piezoelectric IEEP vibration sensor.Acceleration sensor, sampling frequency of 10240Hz, sampling for each stateThe time is 1 s.

In the experiment, the drive controller adjusts the drive motor frequency, usingThe magnetic powder brake is loaded.The experiment is completed in 4 times, each timeUse sun gears with different health states.Install sensors on planetary gearsAt the top of the box, vibration signals are collected through a data acquisition instrument.

Fault feature extraction and analysis

Analyze the measured signal using the proposed algorithm and set the particle swarmThe number of parameter iterations is 30, the population size is 20, and the range of K value is 2 ~The α value ranges from 100 to 3000.

Optimize the VMD parameters through PSO to obtain the best parametersThe combination is to use the obtained parameters to perform VMD analysis on the signal.The result is shown in the figure. After decomposition of each component,Under-decomposition or over-decomposition occurs.

The kurtosis values of each IMF component are obtained after the signal passes through the PSO-VMD, as shown inAs shown in Table 3, the largest kurtosis value in Table 3 was selected by the kurtosis criterion.The first component of the IMF, IMF7, and the second largest component, IMF8, are reconstructed and plotted as shown in FigureThe signal fault feature composition before and after fault feature index extraction and reconstruction is shownFeature dataset.

Combine the fault features extracted from the reconstructed signal into feature vectors, generating 50 sets of feature vectors for each state.The quantity, which is constructed as RCharacteristic number of 11 × 200According to space.Through nonlinear T・SNEThe manifold learning algorithm will learn the feature dataReduce the dimension to 2D for visualizationTo changeThe result is shown in the figure.0 to 3 indicate the normal state of the sun gear,Crack, wear and tooth breakage status.It can be found that the dimensionality of feature data can be reduced to 2 dimensions for visualizationAfter normalization, the data samples show a regular distribution, and different fault states are clearly distinguished.The division conforms to the principle of “small intra-class spacing and large inter-class spacing”.This proves thatThe effectiveness of the proposed fault feature extraction method, which can effectivelyIn addition to the redundant information of the original fault signal, the classification of fault characteristics is improved.

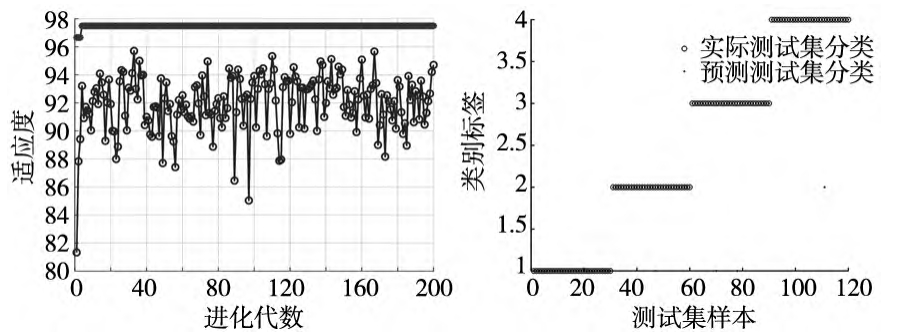

In addition, the fault feature data sets before and after reconstruction are separatelySelect 140 groups of data as the training data set, and 60 groups of data as the test data setDataset, put it into Lig htGBM[14] The classifier performs recognition diagnosis, diagnosisThe results are shown in the figure.

Not reconstructed by PSO-VMD and kurtosis criteriaThe feature vectors of the time domain and entropy theory are extracted from the previous signal, and passed through the LightG-The accuracy of the BMA algorithm for diagnosis is 88%, as shown in the figure.The diagnostic accuracy rate of the signal after processing by the method reached 98%, with only one testThe sample is misclassified.At the same time, collect the top 20 samples of each state in the fault feature dataAs training samples, the last 30 samples are used as test samples.The first 20 samples are input into the PSO-SVM for training, and then the statusThe last 30 samples in the state are input into the trained classifier for identification.The fitness curve and diagnostic results of the PSO algorithm are shown in Figure andas shown in Figure .

The initial parameters of SVM are c1=1.5 and c2=1.7, and the number of iterations is 200.The population size is 20.From the graph, it can be seen that the particle reachesThe best fitness is 97.6%. From the figure, it can be seen that the measured signal on the experimental benchOnly 4 samples in the test set of were misclassified, with a diagnostic accuracy of96.67% can prove that the fault characteristics extracted by the algorithm proposed in this article areThis can achieve better fault diagnosis results.

Conclusion

The problem of difficulty in extracting the fault characteristics of the main reducer gear of the shield machineproblem, proposed a method based on parameter optimization variational mode decomposition and kurtosis criterionThe diagnosis method is to decompose the signal through the PSO-VMD algorithm, and then useThe kurtosis criterion filters and reconstructs the obtained IMF components, and thenThe signal extraction combines multi-feature vectors in time domain and entropy theory, and finally usesPSOSVM and LightGBM algorithms for fault diagnosis.Method: Analyze the measured data of the DDS experimental bench, and the conclusion is:(1) Optimizing the VMD parameters [K, α] through PSO effectively avoidsThe influence of human factors on the selection of [K, α] on the VMD algorithm is avoided.Under-decomposition or mode mixing phenomenon occurs during signal decomposition by VMD algorithmThe generation of high-frequency noise can achieve better decomposition results.(2) Proposed the use of the kurtosis criterion to evaluate the components obtained from the PSO-VMDBy screening and reconstructing, this method can retain effective fault feature informationIt can also eliminate noise interference.

method, an optimal structure with certain local redundancy can be obtained, whileIt has ideal manufacturability and application value.The results show that:(1) Compared with the traditional method, this method has the advantages ofThe optimized structure obtained by the unified topology optimization method has higher redundancy and force transmission pathThe diameter is larger, which can prevent partial local failure in actual working conditions.(2) This method breaks the current popular seamless repair mode for local damage.Tiling or overlapping tiling to estimate the distribution of local damaged areasThe most dangerous local failure is determined by maximizing the strain energy as the goal.Topological optimization is performed on damaged areas to avoid abnormal optimization, and the optimization results areWith higher manufacturability, the application value is improved.However, the current application scope of this method is limited, and it cannot beConduct a more comprehensive risk assessment based on actual usage scenarios, and then determineIt is an accurate dangerous area.Further research is needed to explore its three-dimensionalThe expansion and application of the structure.