The constant tooth height arc bevel gear has the advantages of stable and reliable transmission, good impact resistance, and low transmission noise, and is widely used in the automotive industry.It is widely used in various precision systems.As a special tool for machining it, the constant tooth pitch arc bevel gear milling cutter headIt belongs to the precision and complex cutting tools, and its processing methods mainly include two types: integral type and welding type.The welding type isIn order to reduce the deformation of the milling cutter after welding and meet the requirements for use, three types of filled grooves were compared.Analyze and study the influence of groove bottom clearance on the welding deformation of milling cutter disk under multi-layer welding.Specific researchThe research methods and contents are as follows.Firstly, according to the existing technical conditions, the laser multi-layer wire-filling welding method is selected for the welding of the milling cutter head.Follow the simulation.Determine the welding temperature field based on the welding method and welding heat transfer theory, and use the temperature field theoryThe relationship between thermal stress and welding stress is derived to formulate a functional expression for thermal elastoplastic deformation, and a model is constructed to predict the stress and deformation of the milling cutter disk.Mathematical model of strain.Secondly, based on the data of existing milling cutter heads, for different welding groove gaps, the milling cutter heads areModeling.Based on the analysis of the temperature field and stress field described above, select an appropriate welding heat source to perform multi-layer weldingAnalyze and study the thermal cycle, derive the thermal cycle expression, and apply the simufact.welding software toWelding simulation is conducted between the main body of the milling cutter head and the outer ring, taking into account the physical properties of the welding material as it changes over time.The characteristics of the line change can be used to obtain the stress and deformation nephograms of the milling cutter head welding process at different times, as well asBy setting characteristic points, the stress and strain variation curves andThermal cycle curve diagram, and then analyze and process these data results.Finally, welding experiments were conducted on the milling cutter head, and the quality of the weld surface was judged by the milling cutter head weldingWhether it is qualified or not, use a plug gauge to detect the deformation of the milling cutter groove, and compare and analyze different welding slopes.The deformation of the mouth is verified to be consistent with the simulation results. Experiments have shown that the welding simulation is in agreement with the actualThe symbol.

At present, the research on the welding of milling cutter heads mainly focuses on the use of laser deep penetration welding, which is relatively simple.It is convenient for various numerical simulation work, but in the actual welding process, it has too high a requirement for welding power.And welding depth is severely limited, so most factories adopt laser multi-point welding technology in the welding stage of milling cutter head.Layered multi-pass welding.This welding method has the advantages of deeper welding depth and improved weld metal quality.Advantages, but multi-layer and multi-pass welding is time-consuming and laborious, with long welding time and low production efficiency.This article adoptsCompromise means using laser multi-layer wire-filling welding to perform the welding work of milling cutter heads, which has higher production efficiency than multi-layer multi-pass welding, and is superior to laser deep penetration welding in terms of welding depth and improving the quality of weld metal.During the welding process of the milling cutter head, the movement of the moving heat source causes the temperature of the milling cutter head to rise rapidly, and the temperature of the cutting tool is also affected.Due to the limitations of the heat transfer properties of the material, the temperature in different areas of the disk is not the same, and the milling cutter diskThe stress field of the organization structure has changed, resulting in welding deformation of the sipes.Welding simulation of the milling cutterThe technical difficulties and solutions at that time are as follows:(1) Due to the different thermal physical properties exhibited by materials at different temperatures,They are mostly non-linear distributions. At high temperatures, many parameters such as specific heat capacity, Poisson’s ratio, and linear expansion coefficientThe results of welding simulation are not consistent with the actual results due to the estimation of parameters such as welding speed and pressure, so it is necessary tophysical properties, thermal properties, and phase composition, etc., to achieve a deeper understanding of the process, and toDynamic adjustment of material properties at different stages(2) In welding simulation, it is necessary to divide the weldment and the filled weld seam into grids. Generally,said that the finer the finite element grid division, the higher the accuracy of the simulation, but in actual simulation, the number of gridsToo large a grid will lead to a series of problems such as longer computation time and excessive computer load. Therefore, in dividing the gridThe number should be chosen appropriately. If the accuracy is met, the division can be finer near the weld, and slightly divided in other places.It can be divided.(3) The premise of using the same welding process during the experiment due to the different gaps at the bottom of the welding grooveThere may be welding defects such as lack of penetration and fusion, which requires us to ensure the same welding parametersunder the condition of a certain number of times, repeated welding simulation experiments were conducted to find a method that can simultaneously achieve good welding quality between several different grooves.The welding parameters that can be used.

For the welding of milling cutter head, welding simulation technology is an important solution to the problem of high experimental costs.Technical means, the application of finite element method can help us find suitable welding methods, which is also the research of welding technology.An important method for understanding deformation.To study welding deformation, it is essential to understand the heat input during the welding process.Research has shown that the heat input from the welding heat source causes changes in the temperature field around the weldment, which in turn causes the deformation of the object.The relative motion between the molecules inside causes welding deformation.

The basic theory of heat transfer is that where there is a temperature difference, there will be heat transfer. In milling cutters,During the welding process of the disk, the heat concentration near the welding joint is high, and there is a huge difference between the surrounding area and other parts of the welding seam.Due to the large temperature difference, there is heat transfer between the weld seam and its surrounding area during the welding of the milling cutter head.

For the study of welding deformation of milling cutter head, it is necessary to not only analyze the welding temperature field, but alsoAnalyze and calculate the changes in stress and strain during and after the welding process of the milling cutter head, and analyze the mechanical properties of solid materialsThe welding process is subject to external interference such as temperature changes, changes in clamping force, and changes in external load,causing changes in stress, strain, and displacement within the material.Among them, elastic mechanics and plastic mechanicsIt is the main discipline for studying this change.

Summary of this chapter

(1) A brief summary of the heat transfer fundamentals used in the welding process, mainly focusing on heat transferThe heat conduction, heat convection and heat radiation problems in are described in detail.(2) A brief summary of the theory of welding temperature field was conducted, establishing the temperature field model that will be used in this article.Theory of degree field.(3) Briefly introduced the theory of thermoelastic-plastic deformation, focusing on the application of hexahedral finite element analysisThe elastic-plastic changes of the unit were analyzed, and the relationship equation between stress strain and deformation was constructed.The relationship between the elastic-plastic increment and deformation of materials under changing temperature conditions.This study focuses on the welding thermalTheoretical analysis and simulation of deformation provide a solid theoretical and practical foundation.

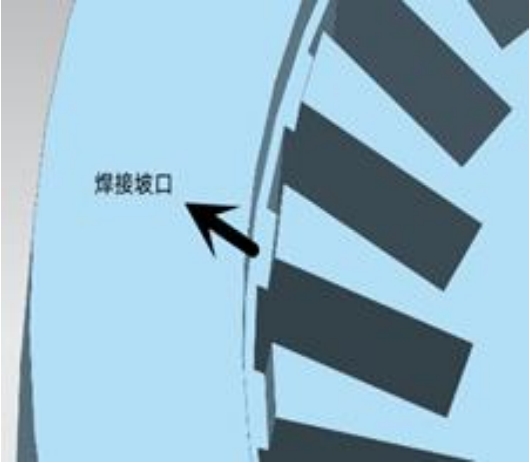

Based on the theory of welding thermal deformation, a milling cutter welding model is established.In order to ensure the smooth progress of subsequent numerical simulation, it is necessary to confirm the position of the welding groove and the number of welds.recognize, and establish the form of welding groove, combined with the specific situation, select the appropriate welding heat source model, andBased on the welding temperature field theory proposed in the previous chapter, the mathematical model of the three-layer temperature field of the milling cutter head is derived and collated.Theoretical model.

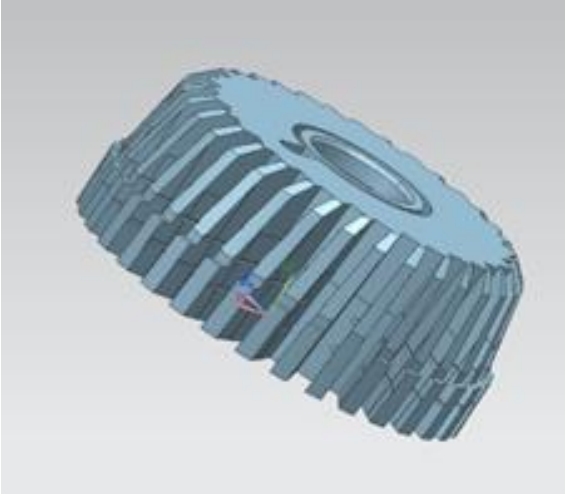

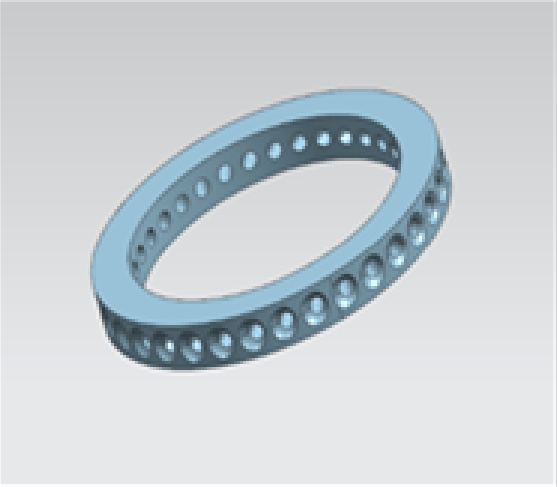

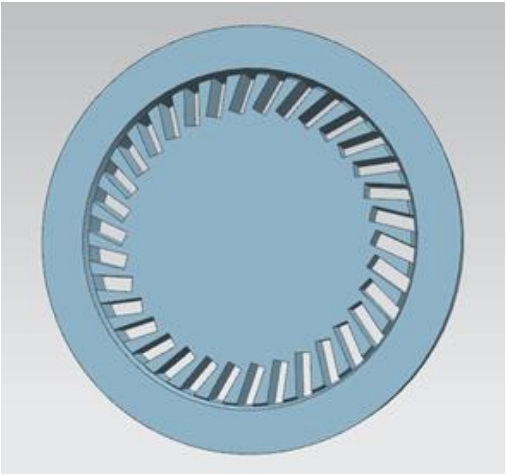

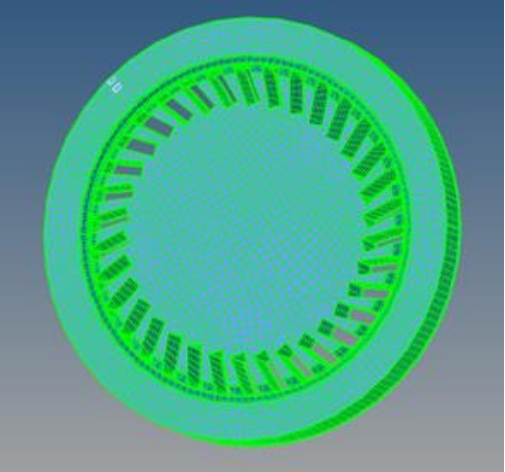

In finite element welding simulation, the establishment of a welding model is crucial.In this article, the milling cutter welding modelThe establishment of the multi-layer welding simulation is mainly based on the influence of welding groove on welding deformation. Through simulating the milling cutterDuring the welding process of the disk, the change of stress and strain caused by the welding temperature field and the filler wire, and thenThe impact on the final welding deformation.Through finite element analysis, the optimal welding groove and the optimalFinally, the experimental method was used to verify that the change of welding groove could achieve the goal of reducing welding deformation.The manufacturing process of the constant tooth pitch spiral bevel gear milling cutter head is relatively complex, and the cutting tool is usually used in the manufacturing process.The main body of the disc and the outer ring are manufactured separately, and finally assembled and welded.Therefore, when machining a milling cutter disc,When modeling, we also adopt the approach of modeling the main body and outer ring separately.

The milling cutter disk needs to be locally heated during the welding process. As the temperature increases, the welding areawill gradually melt, and in this process, the welding heat source plays a continuous heating role.The main body of the milling cutter head and the outer ring are fused together with the addition of filler wire, which plays a welding role.In thisDuring the process, the drastic change in temperature caused the internal stress and strain of the milling cutter to lose balance, resulting in residual stress.This in turn leads to welding deformation.One of the main reasons for this change is theTherefore, studying the welding heat source and selecting an appropriate welding heat source model are important for the research of milling cutter welding.Deformation plays a crucial role.Commonly used welding heat sources include the Gaussian heat source model, the double ellipsoid heat source model,Uniform body heat source model and combined heat source model.

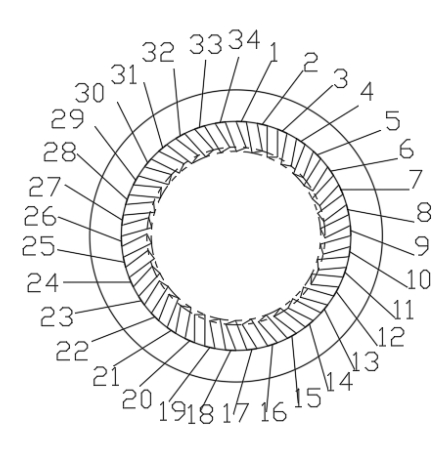

There are 34 arc welding seams on the high tooth spiral bevel gear milling cutter head, and each welding seamThe seams are not continuous and are welded in multiple layers. During the welding process, their thermal cycle curves are also different from ordinary multi-layer welds.There are differences between the two.When studying the thermal cycle around the weld seam of the milling cutter head, we make the following assumptions:(1) During the welding process, the thermal physical properties of materials such as thermal conductivity, specific heat capacity, and Poisson’s ratio, as well as the temperature distribution, are closely related to the welding process.The degree of change is not significant;(2) The effect of latent heat of phase change is neglected during welding;During welding, the relative position of each layer of weld remains unchanged;The temperature field formula of the conical heat source model is assumed to be the temperature field formula under the action of a moving heat source;(5) After each weld is completed, it can only affect the initial temperature of the next weld, but not the temperature of the previous weld.The influence of other welds is neglected.(6) Since the welding temperature field is generally expressed using a moving coordinate system, the welding temperature field in this section is represented using a moving coordinate system.As the temperature field changes between the welds with the welding heat source, the center of the coordinate system is also constantly changing.(7) Due to the short welding time of each weld, the problems of welding thermal saturation and temperature homogenization are not considered.The question.

The main analysis of the mathematical model of the welding of the milling cutter head is as follows:(1) The welding model of the milling cutter head was established, and the milling cutter head was modeled using UG software.(2) Introduced and selected a suitable welding heat source model, using a combined heat source model, which will be used for the followingThe foundation of finite element analysis is laid.(3) A thermal cycle physical model for multi-layer welding was established using the theory of welding temperature field.(4) The design and analysis of the welding groove of the milling cutter head were carried out.

The milling cutter model is relatively complex, and the performance requirements for the computer during simulation calculation are relatively high.High, but the main research area during welding simulation is located in the weld and its surrounding areas, and there is no need for milling cuttersThe entire disk is subject to welding simulation calculations.Therefore, without affecting the accuracy of welding simulation, the milling cutterThe milling cutter model is finally obtained after a certain degree of simplification.

As one of the important measures to reduce welding deformation, preheating the milling cutter before welding can effectivelyreduce the formation of martensite during the welding process of the cutter head, reduce the generation of pores in the weld, and also effectivelyProlong the cooling time after welding, reduce the speed of welding deformation, improve the quality of welding, and reduce the occurrence of welding cold cracks.In simufact.welding, you can preheat the weldment by setting the ambient temperature, and also setHeat transfer coefficient.Generally, the size of the preheating temperature is greatly related to the physical properties of the material itself, mainly depending onIt is influenced by the following factors:(1) The carbon equivalent of the material. Generally speaking, the higher the carbon equivalent, the higher the preheating temperature.The cooling rate of welding is related to the ambient temperature and heat transfer coefficient. The faster the cooling rate, the higher theThe higher the preheating temperature required.The more constraints and fixing of the weldment, the higher the required preheating temperature.(4) The higher the hydrogen content in the weldment, its flux, and the surrounding environment, the greater the risk of hydrogen embrittlement during weld cooling.The probability of hydrogen induced cracking in the weld and its heat affected zone increases. Increasing the preheat temperature of welding can effectively reduce the risk of hydrogen induced cracking.The hydrogen content in the metal.If post-welding heat treatment processes such as tempering, normalizing, annealing, etc. are not performed, the preheating temperature should be appropriately increased.High.