Based on the formula, the predicted bending fatigue life of cylindrical gears can be obtained, and the results are shown in the table.

| Stress level | Predicting fatigue life 10 ^ 4 |

| 510.00 | 537.67 |

| 541.25 | 140.04 |

| 572.50 | 50.30 |

| 603.75 | 18.96 |

| 635.00 | 7.30 |

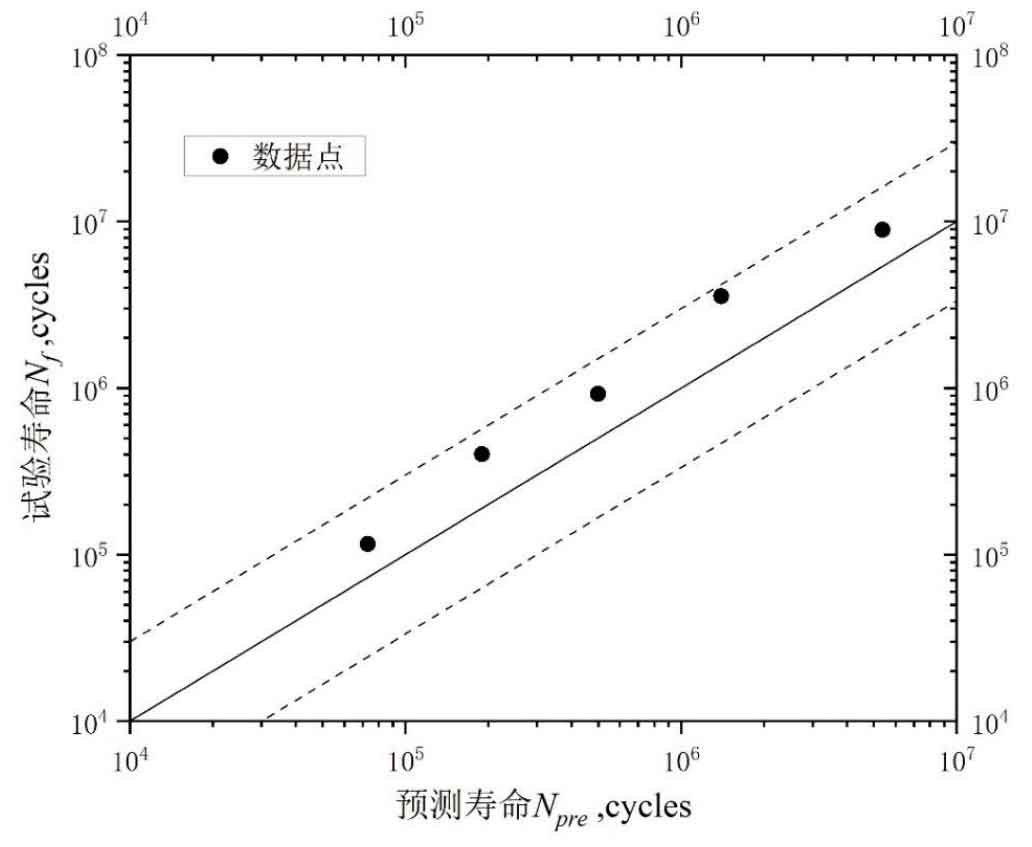

To verify the effectiveness and applicability of the proposed model, a comparison will be made between the bending fatigue test life of cylindrical gears and the predicted bending fatigue life of cylindrical gears, as shown in. As shown in the figure, the predicted fatigue life of cylindrical gears based on energy is relatively low compared to the experimental life value, and the prediction accuracy is low. Overall, the energy based prediction of the bending fatigue life of cylindrical gears is within the range of three times the experimental life, and can be used for predicting the bending fatigue life of cylindrical gears. As the stress applied on the cylindrical gear increases, the predicted bending fatigue life of the cylindrical gear will also decrease, which is consistent with the actual working conditions.

A cylindrical gear bending fatigue life prediction model based on Palmgren Miner linear cumulative damage theory and energy accumulation curve is proposed for the problem of predicting the bending fatigue life of carburized Cr Ni cylindrical gears. The effectiveness and applicability of the model were verified by comparing the bending fatigue test data and predicted data of cylindrical gears under different stress amplitudes.

The main conclusions of the study are as follows:

(1) The bending fatigue test results of cylindrical gears under single stage load show that the large tensile stress near the tooth surface leads to the generation of open type cracks at the tooth root. The fatigue life corresponding to the large crack propagation stage is often less than 10%. Therefore, only the initiation life of cylindrical gears can be predicted, and it can be used as the fatigue life of cylindrical gears.

(2) The bending fatigue test data and predicted data of cylindrical gears under different stress amplitudes were verified, and the test results were within three times the predicted range, verifying that the model can be used for predicting the bending fatigue life of carburized Cr Ni cylindrical gears.

(3) When applying the proposed model, the relationship between stress, cumulative fatigue fracture energy, and bending fatigue life of cylindrical gears was determined through experiments.