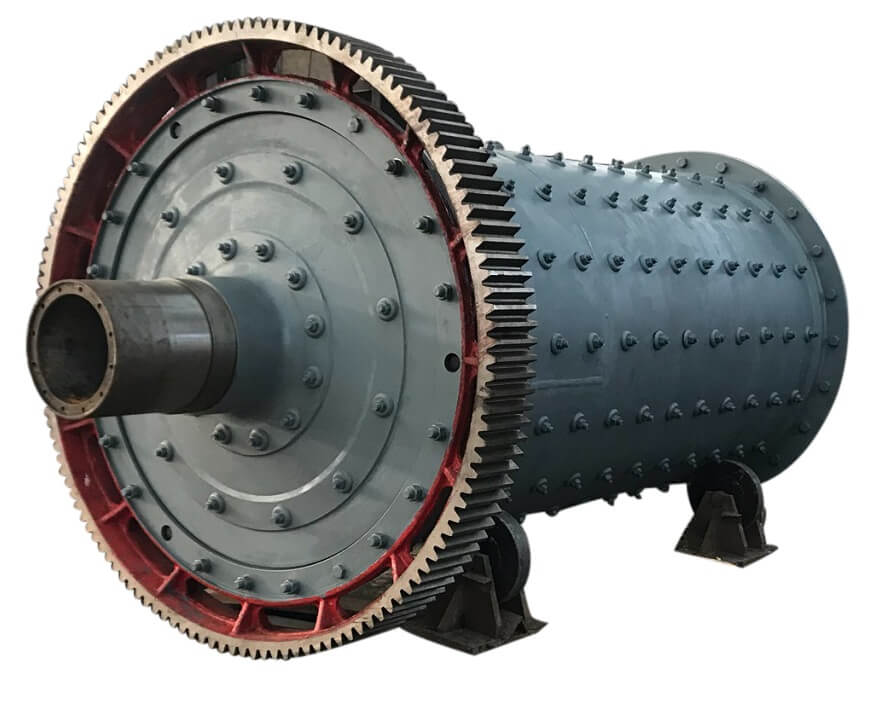

Maximizing efficiency in ball mill gear design involves several innovative strategies that target both operational and energy efficiency. The ball mill, a crucial piece of equipment for grinding materials into fine powder in various industries, including mining, cement, and more, has seen significant advancements in its gear design to improve its performance and sustainability. Here are key innovations that have been influential:

- Improved Material Selection: The adoption of high-quality materials for gears and pinions, such as advanced steel alloys and composite materials, has significantly increased wear resistance and durability. These materials can better withstand the high stresses and temperatures of milling operations, leading to longer gear lifetimes and reduced maintenance needs.

- Gear Geometry Optimization: Through advanced computer simulations and modeling, engineers have optimized the tooth geometry of ball mill gears. This optimization reduces stress concentration and evenly distributes load across the gear teeth, improving efficiency and extending the lifespan of the gear set.

- Use of Gearless Drive Technology: Gearless mill drives (GMDs) eliminate the mechanical components between the motor and the mill itself, such as gearboxes, pinions, and couplings. This direct connection increases efficiency by reducing energy losses associated with gear and bearing friction. GMDs also provide improved control over the grinding process, leading to higher productivity.

- Integrated Lubrication Systems: Modern ball mills incorporate advanced lubrication systems that ensure constant, optimal lubrication of the gears and bearings. These systems not only reduce wear and tear but also significantly decrease energy consumption by minimizing friction losses.

- Variable Speed Drives (VSDs): VSDs allow the mill’s operation speed to be adjusted according to the material being processed. This adaptability can significantly enhance energy efficiency and operational flexibility, reducing energy consumption when full speed is not required.

- Environmental and Noise Reduction: Innovations in gear design also consider environmental impacts, including noise pollution. Enclosed gear designs and the use of noise-dampening materials have helped to reduce the acoustic footprint of ball mills.

- Digital Monitoring and AI Optimization: The integration of sensors and AI-driven analytics into gear systems enables real-time monitoring of gear health and operational efficiency. This technology can predict maintenance needs and adjust operational parameters in real-time to optimize performance and reduce downtime.

Each of these innovations contributes to the overall efficiency of ball mill operations by reducing energy consumption, minimizing maintenance requirements, and extending the lifespan of the equipment. The focus on sustainability and operational efficiency in gear design reflects broader trends in industrial manufacturing towards more environmentally friendly and cost-effective production processes.