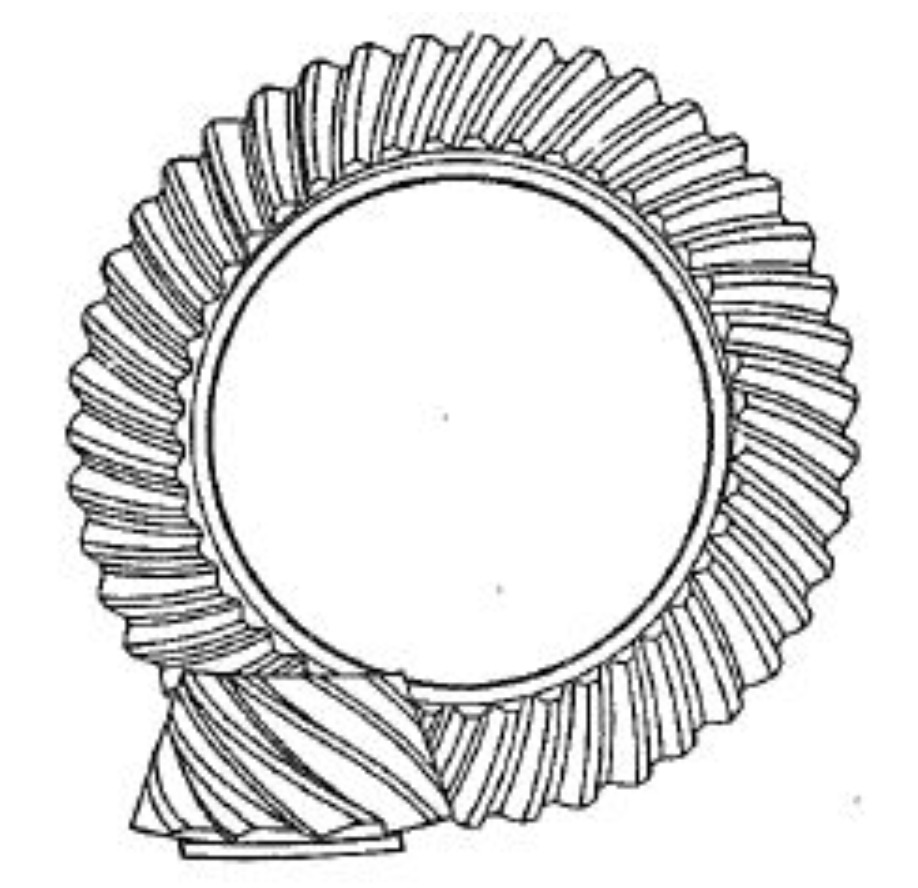

Hypoid gear represent a significant advancement in gear technology, especially for applications demanding high performance. They are a type of bevel gear, similar to spiral bevel gear, but with a key difference: the axes of the hypoid gear and pinion do not intersect. This offset allows for unique advantages, particularly in automotive applications.

Key Features of Hypoid Gear:

- Offset Axes: The most defining feature of hypoid gear is that the axis of the gear does not intersect with the axis of the pinion. This allows for a larger diameter gear, which can transmit more torque.

- Increased Contact Area: The helical shape and the offset of hypoid gear increase the contact area between the gear and the pinion, leading to a smoother and quieter operation.

- High Load Capacity: Due to their increased contact area, hypoid gear can bear higher loads compared to standard bevel gear, making them suitable for heavy-duty applications.

- Improved Efficiency: While they are generally less efficient than straight-cut gear due to sliding contact, modern design and lubrication techniques have significantly improved their efficiency.

- Compact Design: The offset design allows for more compact gear arrangements, which is particularly beneficial in automotive applications where space is limited.

Applications:

- Automotive Industry: Hypoid gear is widely used in the automotive industry, particularly in the differential of rear-wheel and all-wheel drive vehicles. They provide the necessary gear reduction and torque distribution between the vehicle’s wheels.

- Heavy Machinery: Their high load capacity makes them suitable for heavy machinery and industrial applications.

- Aerospace: In some aerospace applications, the compact and efficient design of hypoid gear is advantageous.

Challenges and Considerations:

- Manufacturing Complexity: Producing hypoid gear is more complex and expensive compared to straight bevel gear, requiring specialized equipment and expertise.

- Lubrication: Proper lubrication is crucial due to the sliding motion between the teeth, which can generate significant heat and wear.

- Noise Reduction: While they are generally quieter than straight bevel gear, at high speeds, noise can be a concern, requiring precise design and manufacturing.

In summary, hypoid gear bridge a crucial gap in high-performance gear technology by offering enhanced load capacity, compact design, and smoother operation, albeit with considerations around manufacturing complexity and the need for precise lubrication and noise management. Their widespread use in automotive and heavy-duty applications underscores their importance in modern mechanical design.