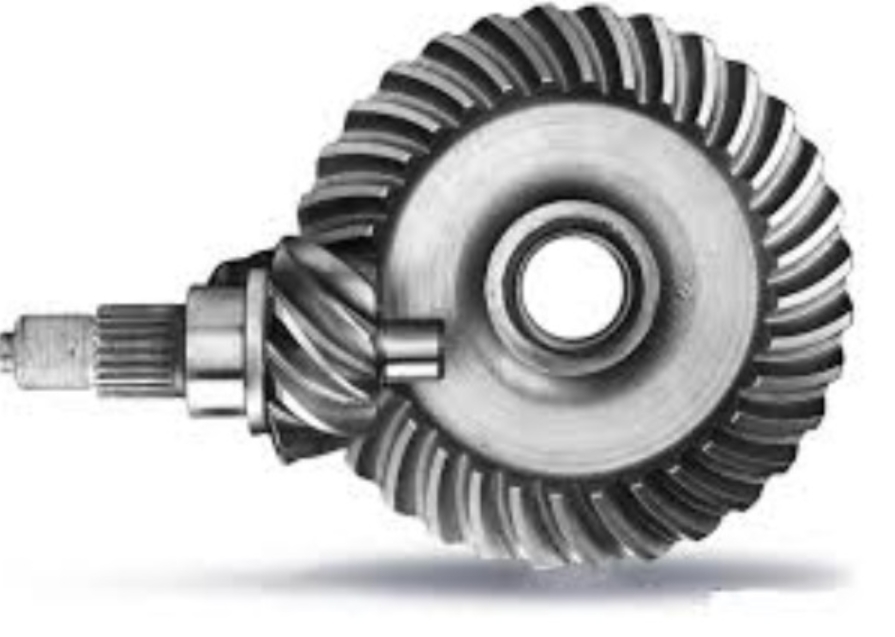

Understanding hypoid gear involves delving into their unique design and how this translates into specific applications and advantages. Here’s a deeper look:

Design Characteristics

- Offset Axes: Unlike standard bevel gear, hypoid gear have axes that do not intersect. This offset allows for unique engagements and power transmissions.

- Spiral Teeth: The teeth on hypoid gear is helical, providing a larger surface area and a more gradual engagement between teeth, which reduces shock loads.

- Large Pinion Diameter: This design feature allows hypoid gear to handle larger loads.

Advantages

- Improved Load Distribution: The extended tooth contact area allows for more even distribution of load, enhancing durability and lifespan.

- High Torque Transmission: Due to their robust design, hypoid gear can transmit higher levels of torque compared to traditional gears.

- Reduced Noise and Vibration: The gradual engagement of teeth and the overall design result in quieter operation and less vibration, ideal for applications where noise is a concern.

- Increased Efficiency: They offer superior efficiency in power transmission, especially at high speeds.

- Compactness: The non-intersecting shaft arrangement allows for a more compact gearbox design, saving space.

Applications

- Automotive Differential Gears: The most common use of hypoid gear is in the differentials of rear-wheel-drive vehicles. Here, they provide smooth transmission of power from the drive shaft to the wheels at different speeds, especially during turns.

- Heavy Machinery: Their ability to handle heavy loads makes them suitable for construction equipment, mining machinery, and agricultural machines.

- Aerospace and Marine: In these industries, the compact design and efficient power transmission of hypoid gear is beneficial for various applications.

- Robotics and Automation: Their compact size and efficiency make them suitable for precision machinery in robotics and automated systems.

- Wind Turbines: Hypoid gear can be used in wind turbines for efficient power transmission from the rotor to the generator.

Conclusion

Hypoid gear is an advanced type of gear system offering numerous benefits over traditional gears. Their unique design allows for efficient power transmission, reduced noise, and a compact footprint, making them invaluable in various applications from automotive to heavy industry and aerospace. As technology evolves, their adoption is likely to increase, further revolutionizing these sectors.

Pages: 1 2