Gear transmission, as one of the most widely used transmission methods in the mechanical industry, has the characteristics of high transmission efficiency, compact structure, and stable transmission ratio. In order to ensure that the gear does not experience pitting failure during its predetermined life, it is necessary to calculate the contact fatigue strength of the tooth surface and ensure that the contact stress on the tooth surface is less than or equal to the allowable contact stress. Scholars at home and abroad have conducted extensive research on the maximum contact stress of the tooth surface. For the first time, the contact problem of an elastic body under normal load was studied, and the load distribution on the contact area was calculated and verified through experiments. The contact stress of a spur gear was studied using finite element method, and a comparative analysis was conducted with the Hertz contact theory calculation method. The meshing equation of a linear contact curved cylindrical gear under different assembly conditions was derived, and the contact stress and bending stress of the gear were analyzed. The problem of severe contact stress caused by edge contact was discussed. Based on the Hertz contact theory, a comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis (LTCA) model was proposed and established, and the contact stress, meshing stiffness, and transmission error of the gear were analyzed. The stress cloud map and contact imprint of a bevel gear were analyzed using finite element method, and the load transmission error curve under different conditions was calculated through simulation analysis. A comprehensive numerical load gear contact analysis 。

A method for dynamically adjusting the tooth width was proposed to optimize the uneven load distribution of helical gears. Through the study of dynamic tooth width modification, the optimal modification parameters were obtained, which made the dynamic load distribution of the tooth surface uniform, with the load distribution center close to the center of the tooth surface, reducing the oscillating phenomenon. Considering the influence of roughness on the normal contact stiffness of gears, a fractal contact model suitable for gear pair contact was established. The distribution laws of bending stress and contact stress of worm gears with different starting times and friction factors were obtained through finite element analysis. The contact stress of spur gears machined from carbon fiber/epoxy resin composite materials was analyzed. A multi-piece stitched NURBS surface parametric model of IGA was constructed, and relevant calculation formulas for planar contact IGA were derived to achieve complete geometric contact analysis of single tooth contact. The contact trajectory and transmission error of variable tooth thickness helical gears were analyzed based on the gear meshing principle and tooth surface equation. The influence of different heat treatment processes on gear contact fatigue was analyzed using experimental methods. In the theoretical contact stress calculation process of cylindrical spur gears and variable tooth thickness gears, the traditional Hertz formula method was still used. This method has high accuracy for general spur gears. However, in the calculation process of variable tooth thickness gears, it can only be used for gears with different tooth numbers and module numbers under the same pitch cone angle and tooth flank angle, and cannot calculate the contact stress of gears with different pitch cone angles and tooth flank angles. Therefore, based on the Hertz formula, a calculation method for contact stress suitable for variable tooth thickness gears was derived considering the tooth flank angle and pitch cone angle of variable tooth thickness gears, based on the structural characteristics of variable tooth thickness gears.

Maximum contact stress of variable tooth thickness gear

When the gear is working, due to the cyclic stress and friction on the tooth surface, tiny cracks will appear on the tooth surface until fine pits or pockmarks appear. Improper design can cause pitting on the tooth surface. Therefore, it is necessary to conduct a strength check on the gear.

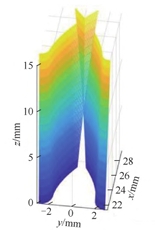

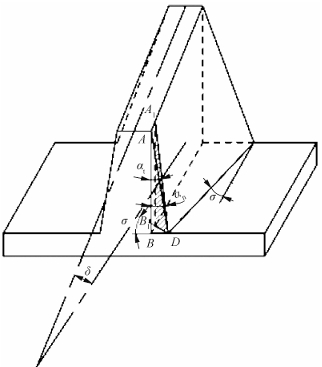

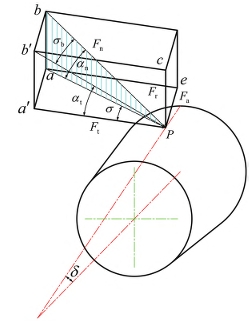

During the transmission process of variable tooth thickness spur gears, due to the presence of the pitch cone angle and the tooth flank angle, the actual meshing area of variable tooth thickness gears has more axial and radial meshing areas than that of spur gears. Therefore, when calculating the contact ratio of variable tooth thickness gears, it should be divided into three parts. Among them, due to the presence of the pitch cone angle δ.

Conclusion

(1) The maximum contact stress calculation formula for parallel shaft variable tooth thickness spur gears is derived based on the Hertz formula, and the contact ratio, contact stress, and contact area of the variable tooth thickness spur gear are calculated

The fitness coefficient, radius of curvature, normal force, and length of contact line were derived and calculated.

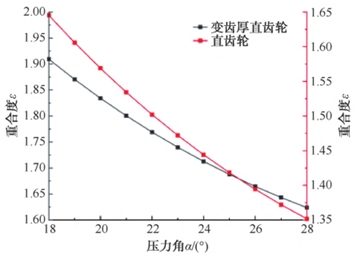

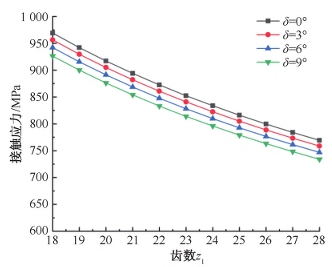

(2) The influence of tooth width, pressure angle, torque, and pitch cone angle on the contact stress of variable tooth thickness spur gears was studied. The results showed that the maximum contact stress of the gear was affected by the tooth width, pressure angle, torque, and pitch cone angle

Stress decreases with the increase of tooth width and pressure angle, and increases with the increase of torque. Therefore, selecting appropriate parameters can reduce the stress of variable tooth thickness gears

Maximum contact stress, reduce stress concentration, improve gear strength.

(3) The influence of the pitch cone angle on the contact ratio and tooth surface contact stress of variable tooth thickness spur gears was studied. Through analysis, it was found that the pitch cone angle had a significant impact on the contact ratio and tooth surface contact stress of variable tooth thickness spur gears

Therefore, when designing a variable tooth thickness gear, increasing the pitch cone angle of the gear as much as possible can improve the performance of the variable tooth thickness spur gear

The performance of the meshing.

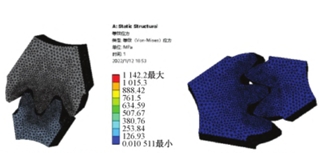

(4) The correctness of the theoretical calculation formula for the contact stress of variable tooth thickness spur gears was verified by finite element method, and the stress values obtained from finite element analysis were basically consistent with the theoretical calculation values. The results showed that the derived formula for calculating the contact fatigue strength of variable tooth thickness spur gears had high accuracy and could accurately reflect the true contact stress values on the tooth surface. The derived formula for calculating the contact stress of variable tooth thickness spur gears provided a theoretical basis for the design and strength verification of the gear.