Introduction

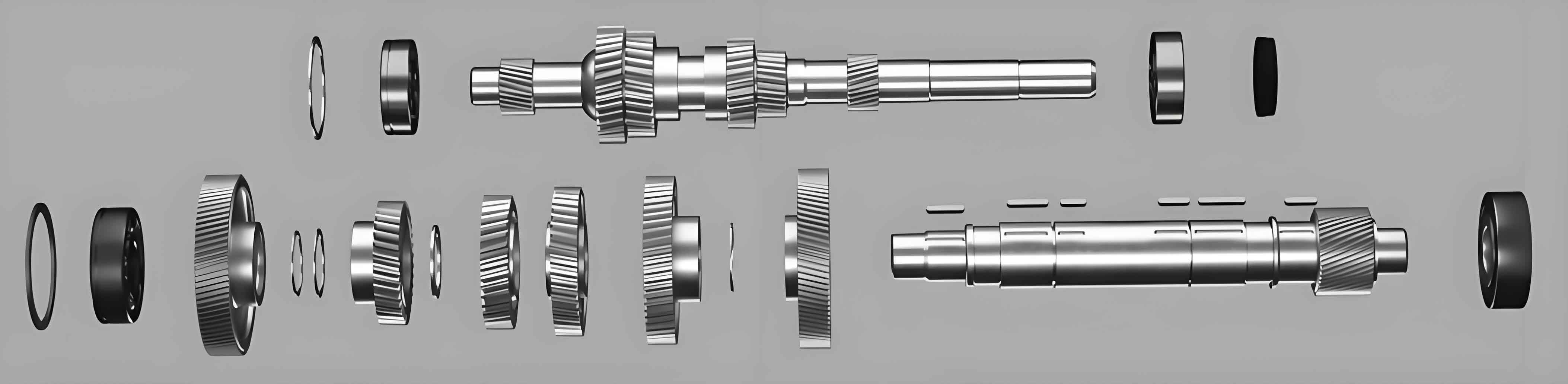

In the realm of mechanical engineering, the Gear Shaft is a crucial component that ensures the smooth operation of various machines. The performance and reliability of a Gear Shaft are heavily influenced by the presence of Gear Defects. These Gear Defects can lead to failures, reduced efficiency, and increased maintenance costs. This article delves into the common types of Gear Defects found in Gear Shaft components, their causes, and effective strategies for reducing these defects to enhance the overall performance and longevity of the Gear Shaft.

Common Gear Defects in Gear Shaft

Gear Defects in Gear Shaft components can arise from various factors including manufacturing processes, material properties, and operational conditions. Understanding these defects is the first step in devising methods to reduce their occurrence.

1. Pitting

Pitting is a surface fatigue failure that manifests as small pits or craters on the Gear Shaft teeth.

Causes:

- Excessive load or stress.

- Insufficient lubrication.

- Material fatigue.

Prevention:

- Ensure proper load distribution.

- Use high-quality lubricants.

- Select appropriate materials with high fatigue strength.

2. Wear

Wear is the gradual removal of material from the Gear Shaft surface due to friction and contact with other components.

Causes:

- Inadequate lubrication.

- Contaminants in the lubricant.

- Poor material hardness.

Prevention:

- Maintain adequate lubrication levels.

- Use clean and high-quality lubricants.

- Select materials with high wear resistance.

3. Scoring

Scoring is a severe form of wear that occurs when there is direct metal-to-metal contact, leading to deep scratches on the Gear Shaft surface.

Causes:

- Inadequate lubrication.

- Excessive load.

- High operational speeds.

Prevention:

- Ensure proper lubrication.

- Avoid overloading.

- Control operational speeds within recommended limits.

4. Microcracking

Microcracking involves the formation of tiny cracks on the Gear Shaft surface, which can propagate and lead to larger fractures.

Causes:

- High cyclic stresses.

- Poor material quality.

- Thermal stresses.

Prevention:

- Use materials with high toughness.

- Optimize heat treatment processes.

- Control operational conditions to minimize thermal stresses.

Strategies to Reduce Gear Defects in Gear Shaft

To reduce the occurrence of Gear Defects in Gear Shaft components, it is essential to adopt a combination of good design practices, quality manufacturing processes, and proper maintenance procedures.

1. Material Selection

Selecting the right material is fundamental in minimizing Gear Defects.

Recommendations:

- Use high-quality alloy steels with good fatigue strength and wear resistance.

- Ensure the material has consistent and uniform properties.

2. Precision Manufacturing

High precision in manufacturing processes is critical to reduce Gear Defects.

Recommendations:

- Implement advanced machining techniques such as grinding and honing to achieve high surface finish and accuracy.

- Utilize computer numerical control (CNC) machines for consistent quality.

3. Heat Treatment

Proper heat treatment processes enhance the mechanical properties of the Gear Shaft.

Recommendations:

- Use processes like carburizing and nitriding to improve surface hardness and fatigue strength.

- Ensure uniform heat treatment to avoid thermal stresses and distortion.

4. Lubrication

Adequate lubrication is vital to prevent wear and scoring.

Recommendations:

- Use high-quality lubricants suited to the operating conditions.

- Implement automatic lubrication systems to ensure consistent lubricant supply.

5. Quality Control

Rigorous quality control measures help detect and rectify Gear Defects early.

Recommendations:

- Conduct regular inspections using non-destructive testing methods such as ultrasonic testing and magnetic particle inspection.

- Perform dimensional checks to ensure compliance with design specifications.

Comparative Analysis of Gear Defect Prevention Methods

| Method | Description | Benefits | Challenges |

|---|---|---|---|

| Material Selection | Choosing materials with optimal properties | Enhanced fatigue strength, wear resistance | Higher material costs, availability |

| Precision Manufacturing | Advanced machining techniques for accuracy | High surface finish, reduced defects | Requires investment in advanced machinery |

| Heat Treatment | Processes to improve mechanical properties | Increased hardness, fatigue strength | Control of process parameters, risk of distortion |

| Lubrication | Using suitable lubricants and systems | Reduced friction, wear, and scoring | Maintaining proper lubrication levels |

| Quality Control | Rigorous inspections and testing | Early defect detection, ensuring quality | Requires skilled personnel, can be time-consuming |

Best Practices for Gear Shaft Maintenance

Regular maintenance is essential to keep Gear Shaft components in optimal condition and minimize Gear Defects.

1. Regular Inspections

Conduct routine inspections to identify early signs of Gear Defects.

Tips:

- Use visual inspection and advanced diagnostic tools.

- Monitor for unusual noises, vibrations, and temperature changes.

2. Lubrication Management

Maintain proper lubrication levels to ensure smooth operation of the Gear Shaft.

Tips:

- Schedule regular lubrication intervals.

- Use the recommended type and grade of lubricant.

3. Alignment Checks

Ensure that the Gear Shaft is correctly aligned with other components.

Tips:

- Use alignment tools to check and correct misalignment.

- Regularly monitor alignment during maintenance checks.

4. Load Management

Avoid overloading the Gear Shaft to prevent stress-related Gear Defects.

Tips:

- Monitor load conditions and adjust operational parameters.

- Use overload protection devices where necessary.

Common Gear Shaft Defects and Their Impact

| Gear Defect | Cause | Impact |

|---|---|---|

| Pitting | Excessive load, insufficient lubrication, fatigue | Reduced efficiency, increased noise, potential failure |

| Wear | Inadequate lubrication, contaminants, poor hardness | Gradual loss of material, reduced performance |

| Scoring | Metal-to-metal contact, high speeds, heavy loads | Deep surface scratches, potential for severe damage |

| Microcracking | High cyclic stresses, poor material quality, thermal stress | Propagation of cracks, eventual component failure |

Conclusion

Reducing Gear Defects in Gear Shaft components is crucial for maintaining the reliability and efficiency of mechanical systems. By understanding the common types of Gear Defects, their causes, and implementing effective strategies such as proper material selection, precision manufacturing, adequate lubrication, and rigorous quality control, manufacturers and operators can significantly enhance the performance and longevity of Gear Shaft components. Regular maintenance practices, including inspections, lubrication management, alignment checks, and load management, further contribute to minimizing Gear Defects and ensuring the smooth operation of Gear Shaft components in various applications.