Introduction

The rapid development of national defense, robotics industry, and aerospace technology has propelled precision machine tools towards high speed, efficiency, and precision. The cycloidal gear forming grinding machine is one of the core equipment for the localization of industrial robot cycloidal pinwheel precision reducers in China. The column, as a key basic component and guiding element of the machine tool, directly affects the grinding accuracy. How to optimize the stiffness, seismic resistance, and stability of precision machine tools Realizing lightweighting of components and optimal layout of structures is a technical challenge currently faced by precision machine tools. Many scholars at home and abroad have used methods such as finite element analysis and topology optimization to study the structures of machine tool columns, bed bodies, etc. The lightweight design of key structural components of the machine tool has been achieved through topology optimization, while improving the dynamic characteristics of the machine tool. Selecting beams with different internal structures for finite element comparative analysis, the optimal beam thickness was obtained through dimensional analysis. Taking the spherical worm wheel gear grinding machine body as the research object, sensitivity analysis and multi-objective optimization methods were used to solve the optimal structural parameters of the bed body. The static and dynamic performance of the bed body before and after optimization was compared using finite element method, and the effectiveness of the bed body optimization results was verified. establish A finite element model and mathematical model of the entire machine tool were developed, and topology optimization and modal analysis were conducted on the key components of the machine tool structure. The finite element method was used to optimize the structural dimensions of key components of the machine tool. Through finite element analysis of the static stiffness of the entire machine tool, weak links in the structural design of the machine tool were identified. At present, scholars at home and abroad generally adopt a single optimization design method to optimize the structure of machine tools, and have not used multiple optimization design methods for comprehensive optimization. Multi level and multi-objective optimization design of the column of the cycloidal gear forming grinder is carried out using topology optimization, size optimization, and structural biomimetic optimization.

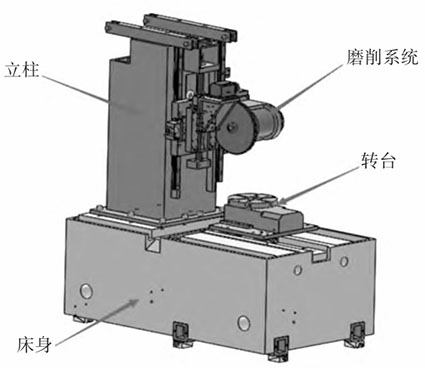

The cycloidal gear grinding machine is an early cycloidal gear grinding machine developed by Qinchuan Machine Tool Factory, and it is also the most representative cycloidal gear grinding machine in China. Compared with the forming grinders produced abroad at the same time, the machining accuracy of the cycloidal gear grinding machine is lower. The fundamental reason is the insufficient static and dynamic performance of the machine tool structure. The column is the key basic component and guiding element of the cycloidal gear forming grinder. The overall static and dynamic performance of the column will affect the machining accuracy of the parts by the cycloidal gear forming grinder. Therefore, the column of the cycloidal gear forming grinder is selected as the research object to deeply study how to reduce the quality of the column and improve its static and dynamic characteristics. View the machine column as a vibration system. The modal analysis of machine tool columns is one of the important components of machine tool structural analysis. The material properties and constraint conditions of machine tool columns are consistent with the above static analysis results, and the first six vibration mode diagrams of machine tool columns are obtained.

Taking the column of the cycloidal gear forming grinder as the research object, a multi-level multi-objective optimization method combining first level topology optimization, second level structural biomimetics, and third level size optimization was adopted to achieve a series of optimization design processes for the machine tool column from preliminary design to detailed design and finally to the final solution. The following conclusions were drawn:

(1) Compared to traditional designs at present, adopting a completely new topology optimization design breaks the constraints of existing design experience and provides the best main layout for the structural design of columns.

(2) Compared to the commonly used reinforcement structure at present, an innovative biomimetic design structure is adopted, and the biomimetic prototype is determined through similarity theory, providing the best design ideas for the reinforcement plate structure of the column main body.

(3) Through response surface methodology size optimization, the optimal size of the internal structure of the column was determined. With the overall size ratio and volume being basically the same as the prototype column, the overall weight of the new column was reduced by 18.4%. Under the same boundary conditions, the maximum stress was reduced by 23.6%, the deformation displacement was reduced by 0.6%, and the natural frequency was improved, achieving lightweight and improved static and dynamic performance of the column. The results indicate that, under the premise of lightweighting, the static and dynamic performance of the machine tool column has been improved to varying degrees, verifying the feasibility of the proposed multi-level multi-objective optimization method.