1. Introduction

Gear transmission is a fundamental mechanism widely used in various mechanical systems. Understanding the kinematic and dynamic properties of gear transmission is crucial for the design and analysis of mechanical devices. In this article, we will focus on an important property of the nodes in gear transmission, which has been overlooked in many traditional studies. This property has significant implications for the accurate analysis of gear motion and can help engineers and researchers better understand and predict the behavior of gear systems.

1.1 Background

Gear transmission involves the meshing of gears or gear racks, which transmits motion and power from one component to another. The traditional analysis of gear transmission mainly focuses on parameters such as gear ratios, velocities, and torques. However, the acceleration properties of the nodes in gear transmission have not been thoroughly investigated in some cases, leading to potential errors in understanding the dynamic behavior of the system.

1.2 Objectives

The main objective of this study is to explore and understand the acceleration property of nodes in gear transmission. We aim to prove this property through theoretical analysis and provide practical examples to illustrate its application. Additionally, we will discuss the implications of this property for gear design and analysis.

2. Gear Transmission Basics

Before delving into the specific property of the nodes, it is essential to understand the basic concepts of gear transmission.

2.1 Gear Types and Their Characteristics

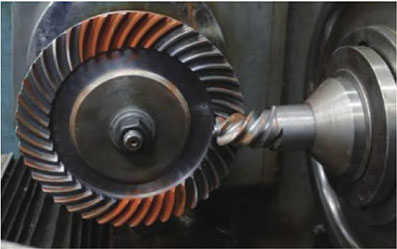

There are various types of gears, such as spur gears, helical gears, bevel gears, and worm gears. Each type has its own unique characteristics in terms of tooth shape, meshing method, and application scenarios. For example, spur gears have straight teeth and are suitable for transmitting power between parallel shafts. Helical gears have angled teeth, which provide smoother meshing and higher load-carrying capacity compared to spur gears. Bevel gears are used for transmitting power between intersecting shafts, and worm gears are typically used for high reduction ratios.

| Gear Type | Tooth Shape | Meshing Method | Application Scenarios |

|---|---|---|---|

| Spur Gear | Straight | Parallel shafts | General power transmission between parallel shafts |

| Helical Gear | Angled | Parallel shafts | High-speed and high-load applications between parallel shafts |

| Bevel Gear | Conical | Intersecting shafts | Power transmission between intersecting shafts |

| Worm Gear | Helical (on worm) and straight (on worm wheel) | Perpendicular shafts (usually) | High reduction ratio applications |

2.2 Gear Meshing Principles

The meshing of gears is based on the principle of conjugate action. When two gears mesh, the teeth of one gear must precisely fit into the spaces between the teeth of the other gear. This requires that the profiles of the gear teeth be designed in such a way that the relative motion between the gears is smooth and continuous. The common normal at the meshing point of the two gears always passes through a fixed point on the line connecting the centers of the two gears, which is called the pitch point. The pitch circles of the two gears are tangent at the pitch point, and the velocities of the points on the pitch circles are equal. This allows the gears to be considered as pure rolling at the pitch point.

3. The Node in Gear Transmission

The node is a crucial concept in gear transmission, and its understanding is essential for analyzing the acceleration property.

3.1 Definition and Location of the Node

The node in gear transmission is defined as the intersection point of the common normal of the meshing teeth and the line connecting the centers of the two gears. It is located on the pitch circle of the gears. For a gear rack, it can be considered as a gear with an infinite radius, and the node becomes a point on the pitch line.

3.2 Velocity Relationship at the Node

As mentioned earlier, the velocities of the nodes on the two meshing gears are equal. This is a fundamental property that is based on the pure rolling condition at the pitch point. When a gear rotates, the node on its pitch circle moves with a certain velocity, and this velocity is the same as the velocity of the corresponding node on the meshing gear or gear rack.

4. The Acceleration Property of Nodes

The acceleration property of nodes in gear transmission is a key aspect of this study.

4.1 Statement of the Property

It has been found that regardless of whether the gear or the rack is in a fixed-axis rotation or a general planar motion, the projections of the nodes’ accelerations on the direction of the common tangent of the nodes are equal. This property holds true for various types of gear transmissions, including those involving gear racks.

4.2 Geometric Proof

We can prove this property geometrically. Consider two meshing gears, and let one of the gears be the reference gear and the other be the moving gear. Let the node on the reference gear be and the node on the moving gear be . When the moving gear rotates relative to the reference gear, we can analyze the motion of the nodes using the concept of relative motion.

The acceleration of relative to a fixed frame can be decomposed into components along and perpendicular to the line connecting the centers of the gears. The acceleration of can also be decomposed in a similar way. Since the velocities of and are equal at the node, the relative velocity between and is zero. According to the principles of kinematics, the projections of the accelerations of and on the direction of the common tangent of the nodes (which is perpendicular to the line connecting the centers of the gears) are equal.

4.3 Analytical Proof

We can also prove this property analytically. Let’s establish a coordinate system and consider the equations of motion of the gears. By using the kinematic equations and the conditions of gear meshing, we can derive the accelerations of the nodes and show that their projections on the common tangent direction are equal.

For example, assume the equations of motion of the gears are given in terms of angles and angular velocities. We can differentiate these equations with respect to time to obtain the angular accelerations. Then, by considering the relationships between the nodes and the gears, we can calculate the accelerations of the nodes and verify the property.

5. Examples and Applications

To better understand the acceleration property of nodes, let’s consider some practical examples and its applications.

5.1 Example of a Simple Gear System

Consider a simple spur gear system with two gears of different radii meshing with each other. One gear is driven by a motor with a constant angular velocity, and we want to analyze the accelerations of the nodes.

Using the principles of gear meshing and the acceleration property of nodes, we can calculate the accelerations of the nodes on both gears. We find that the projections of the accelerations on the common tangent direction are indeed equal, as predicted by the property.

5.2 Application in Gear Design

The acceleration property of nodes can be applied in gear design. For example, when designing a gear transmission system, engineers can use this property to ensure the smooth operation of the gears. By considering the accelerations of the nodes, they can optimize the gear profiles and the meshing conditions to reduce vibrations and noise.

| Application Area | How the Property is Used | Benefits |

|---|---|---|

| Gear Design | Optimize gear profiles and meshing conditions based on node accelerations | Reduced vibrations and noise, improved gear performance |

| Gear Analysis | Analyze the dynamic behavior of gears using the node acceleration property | More accurate understanding of gear motion, better prediction of system behavior |

6. Comparison with Traditional Analysis

The acceleration property of nodes provides a new perspective compared to traditional analysis methods of gear transmission.

6.1 Traditional Approaches and Their Limitations

Traditional analysis of gear transmission mainly focuses on parameters such as gear ratios, velocities, and torques. While these parameters are important, they do not fully capture the dynamic behavior of the nodes. For example, in some cases, the accelerations of the nodes may be overlooked, leading to inaccurate predictions of the system’s performance.

6.2 How the New Property Complements Traditional Analysis

The acceleration property of nodes complements traditional analysis by providing additional information about the dynamic behavior of the gears. It allows engineers and researchers to consider the accelerations of the nodes, which can have a significant impact on the overall performance of the gear system. By combining the traditional analysis methods with the consideration of the node acceleration property, a more comprehensive and accurate understanding of the gear transmission can be achieved.

7. Experimental Verification

To further confirm the validity of the acceleration property of nodes, experimental verification can be carried out.

7.1 Experimental Setup

An experimental setup can be designed to measure the accelerations of the nodes in a gear transmission system. This can involve using accelerometers attached to the gears or gear racks at the nodes. The gears can be driven by a motor, and the motion of the system can be recorded and analyzed.

7.2 Results and Discussion

The experimental results should show that the projections of the accelerations of the nodes on the common tangent direction are approximately equal, within a reasonable margin of error. Any discrepancies between the experimental results and the theoretical predictions can be analyzed and attributed to factors such as measurement errors, manufacturing tolerances, or simplifications in the theoretical model.

8. Conclusion

In this article, we have explored an important acceleration property of nodes in gear transmission. We have defined the node, explained its velocity relationship, and proved the acceleration property both geometrically and analytically. We have also provided examples and applications of this property and compared it with traditional analysis methods. Finally, we have discussed the experimental verification of the property.

8.1 Summary of Key Findings

- The node in gear transmission is an important concept, and its velocity at the pitch point is equal for meshing gears or gear racks.

- The acceleration property of nodes states that the projections of the nodes’ accelerations on the direction of the common tangent of the nodes are equal regardless of the motion of the gear or rack.

- This property can be proved geometrically and analytically and has been illustrated through examples.

- It has applications in gear design and analysis and can complement traditional analysis methods.

8.2 Future Research Directions

Future research can focus on further exploring the implications of this property for more complex gear systems, such as those involving multiple gears and non-standard gear geometries. Additionally, research can be done to improve the experimental verification methods and to develop more accurate theoretical models that take into account various factors affecting the node accelerations.