This article focuses on the importance of detecting the wear state of multi-stage planetary gears in shield machine reducers. It reviews various methods and techniques for gear wear detection, including signal processing and image analysis methods. The article also presents experimental results comparing different detection methods and emphasizes the significance of accurate wear detection for the proper functioning of shield machines.

1. Introduction

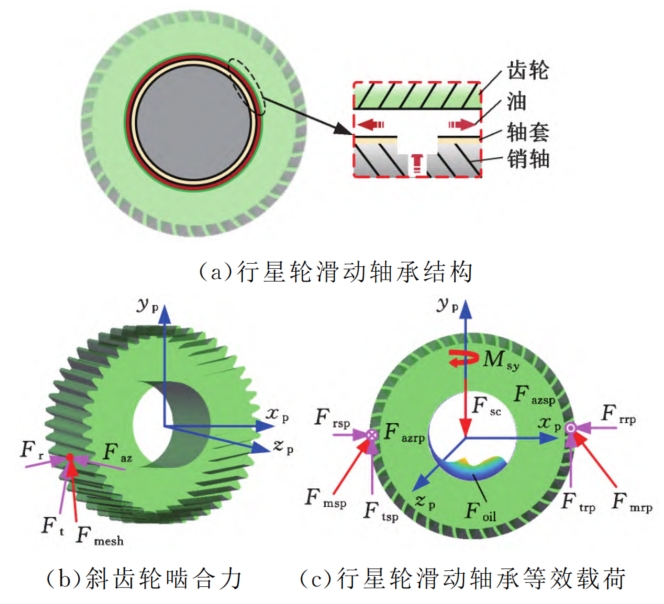

Shield machines play a crucial role in underground engineering construction. The reducer, as a core component of the shield machine, directly affects the performance and safety of the machine. Multi-stage planetary gears, being an important part of the reducer, have a significant impact on its performance and lifespan. Therefore, detecting the wear state of these gears is essential for ensuring the normal operation of the shield machine and improving the safety and efficiency of underground engineering construction.

1.1 Traditional Detection Methods

Traditional methods for detecting the wear state of planetary gears have limitations. For example, monitoring the gear oil index of a fan to evaluate the equipment’s operating state [1] and detecting the meshing wear state of spur gears based on an improved spectral residual method [2] are time-consuming and difficult to implement for real-time detection.

2. Gear Wear Detection Methods

2.1 Vibration Signal Analysis

2.1.1 Noise Reduction

- Importance of Noise Reduction: In planetary gears, vibration signals contain crucial information about the equipment’s operating state. However, these signals are often affected by environmental noise and electromagnetic interference within the equipment, leading to a large amount of noise in the signals. This noise affects the overall stability of the signals and, consequently, the accuracy of wear state detection.

- Translation Invariant Wavelet Denoising: This method utilizes the properties of wavelet transforms to analyze signals at multiple scales, separating noise from useful signals. The process involves several steps:

- Input: The collected planetary gear vibration signal is taken as input.

- Orthogonal Wavelet Transform: Using orthogonal wavelet transform technology, the noisy signal is decomposed into multiple sub-signals, each corresponding to a set of wavelet coefficients that contain noise components and important signal characteristics.

- Cyclic Translation: The planetary gear vibration signal is subjected to multiple cyclic translation processes.

- Soft Threshold Denoising: The soft threshold denoising method in the translation invariant denoising method is used to process the signal.

- Reverse Translation and Averaging: The vibration signal is translated in the opposite direction again, and the average of the processing results is calculated.

- Output: The denoised planetary gear vibration signal is output.

2.2 Gear Image Analysis

2.2.1 Mesh Region Segmentation

- Region Segmentation Method: A mesh region segmentation method that combines region segmentation, region aggregation, and edge correction is used. This method avoids detecting low-gray mesh regions and overcomes the problem of incomplete division caused by pitting on the boundary of the original mesh region.

- Adaptive Local Threshold Calculation: Since the gray features of each small gear wear part are different, an adaptive local threshold segmentation method is used to obtain candidate regions and remove false positive regions according to shape characteristics.

- Mesh Region Candidates: To reduce the segmentation error of the mesh region, this part is segmented based on the division result of the mesh-like region to obtain mesh region candidates and determine whether the segmentation results of the upper and lower regions are correct.

- Verification of Segmentation: The height of the mesh division region is used to determine whether the segmentation is correct. If the segmentation result is incorrect, it needs to be improved.

- Obtaining the Gear Image Meshing Region: The gear image meshing region is obtained by mapping the depth characteristics of the vibration signals in the source and target domains to the space of the multi-stage planetary gears of the shield machine reducer and minimizing the error between the actual classification and recognition results of the vibration signals and the expected results.

2.2.2 Pitting Area Detection

- Candidate Region Selection: Adaptive local branch segmentation is used to obtain candidate branch regions, and then a formal function is used for the pseudo-candidate regions in the candidate regions.

- Detection Process: The detection process involves reading the data stream, processing the threshold, and finally performing the detection. The main instruments and equipment required for detection are listed in Table 1.

| Name | Model | Performance |

|---|---|---|

| Computer | IBM | – |

| Multi-channel data acquisition system | LMS – SC305 | 16 channels |

| Data analysis system | LMS Test.Lab | Modal Analysis template |

| Signal conditioner | B&K Type 2692 | 4 channels |

| Acceleration sensor | B&K4326A – 001 | Sensitivity 3±15%PC/g |

| Pulse hammer | B&K8202 | Sensitivity 3.97pC/N |

3. Experimental Comparison

3.1 Experimental Setup

- Signal Acquisition: Multiple point excitation and single-point vibration pickup pulse excitation methods are used for signal acquisition. The relevant parameters of the planetary gearbox are shown in Table 2. The frequency of the collected signal is set to 11500Hz, the sampling time is set to 15s, and the spindle speed of the gearbox is set to 19r/min.

| Parameter | Indicator |

|---|---|

| Module/mm | 2.25/2.15/1.75 |

| Number of teeth | 21/19/16 |

| Tooth width/mm | 13/14/16 |

| Addendum coefficient | 1.0 |

| Clearance coefficient | 0.25 |

| Pressure angle/ | 20 |

| Tooth surface machining accuracy | 8 level |

3.2 Detection Results

- Wear Image Comparison: The original gear wear image, the detection results of the method in this article, and the detection results of the control group methods are compared. It can be seen that the method in this article can detect the gear wear state accurately, while the control group methods cannot detect all the wear positions of the gear.

- Detection Accuracy Comparison: By comparing the detection accuracy of different methods with 500 iterations, it is found that the detection accuracy of the method in this article for the gear wear state can reach about 90% on average, while the detection accuracy of the control group methods is about 70% on average, which is lower than that of the method in this article.

4. Significance and Future Directions

4.1 Significance

Accurate detection of the wear state of multi-stage planetary gears in shield machine reducers is crucial for ensuring the normal operation of shield machines and improving the safety and efficiency of underground engineering construction. The method presented in this article has higher accuracy compared to traditional methods, which is beneficial for the maintenance and management of shield machines.

4.2 Future Directions

- Improvement of Detection Methods: Future research could focus on further improving the detection methods, such as exploring more advanced signal processing techniques and image analysis algorithms to enhance the accuracy and efficiency of wear state detection.

- Real-time Monitoring: Developing real-time monitoring systems for gear wear is an important direction. This would enable continuous monitoring of the gear wear state during the operation of the shield machine, allowing for timely maintenance and reducing the risk of equipment failure.

- Integration with Maintenance Strategies: The detection results could be integrated with maintenance strategies to optimize the maintenance schedule and reduce maintenance costs. For example, based on the detected wear state, predictive maintenance could be implemented to replace gears before severe wear occurs.

In conclusion, the wear state detection of multi-stage planetary gears in shield machine reducers is a critical aspect of ensuring the proper functioning of shield machines. The methods and techniques described in this article provide a valuable contribution to this field, and further research and development are expected to bring more advanced and efficient solutions in the future.

5. Gear Wear Mechanisms and Factors Affecting Wear

5.1 Gear Wear Mechanisms

- Adhesive Wear: This occurs when the surfaces of two gears come into contact and there is sufficient force and heat to cause the material to transfer from one surface to another. In a shield machine reducer’s planetary gears, high loads and speeds can contribute to adhesive wear. For example, during the operation of the shield machine, the gears experience continuous meshing and load transfer, which can lead to the formation of microscopic welds between the gear teeth surfaces. These welds can then break, resulting in material transfer and wear.

- Abrasive Wear: Abrasive wear is caused by the presence of hard particles between the gear teeth. These particles can be external contaminants such as dust or debris that enter the gearbox, or they can be generated internally due to wear of other components. In an underground construction environment, there is a higher probability of dust and debris entering the shield machine’s gearbox, which can cause abrasive wear on the planetary gears. The hard particles act like a grinding agent, scratching and wearing away the gear tooth surfaces.

- Fatigue Wear: Fatigue wear is a result of cyclic loading on the gear teeth. The repeated stress and strain cycles during the meshing of the gears can cause microcracks to form on the surface of the teeth. Over time, these microcracks can propagate and lead to the failure of the gear teeth. In a shield machine reducer, the varying loads and speeds during different stages of operation can contribute to fatigue wear. For instance, during the start-up and shutdown phases of the shield machine, the gears experience rapid changes in load, which can accelerate the formation of fatigue cracks.

5.2 Factors Affecting Gear Wear

- Load Conditions: The magnitude and distribution of loads on the gears play a significant role in determining the wear rate. Higher loads can increase the contact stress between the gear teeth, leading to more severe wear. In a shield machine reducer, the load on the planetary gears is influenced by factors such as the thrust force of the shield machine, the resistance of the soil or rock being excavated, and the torque requirements of the cutting head. For example, if the shield machine encounters a particularly hard stratum, the load on the gears will increase, accelerating the wear process.

- Lubrication Conditions: Proper lubrication is essential for reducing friction and wear between the gears. The type and quality of the lubricant, as well as the lubrication system’s performance, can affect the wear rate. In a shield machine reducer, the lubricant needs to have good anti-wear and anti-friction properties to protect the gears. Insufficient lubrication or the presence of contaminants in the lubricant can lead to increased friction and wear. For example, if the lubricant becomes contaminated with water or debris, it can lose its lubricating properties and cause the gears to wear more quickly.

- Operating Speed: The rotational speed of the gears also affects wear. Higher speeds can increase the frequency of meshing and the dynamic loads on the gears, which can contribute to wear. In a shield machine reducer, the operating speed of the planetary gears is determined by the speed of the shield machine’s main drive motor and the gear ratios of the reducer. For example, if the shield machine is operating at a high speed, the planetary gears will experience more frequent meshing and higher dynamic loads, increasing the wear rate.

- Gear Material and Design: The choice of gear material and its design characteristics can impact wear resistance. Materials with higher hardness and strength are generally more resistant to wear. The geometry of the gear teeth, such as the tooth profile, helix angle, and module, can also affect the contact stress and load distribution during meshing. In a shield machine reducer, the selection of appropriate gear materials and designs is crucial for minimizing wear. For example, using a gear material with a higher hardness and a more optimized tooth profile can reduce the wear rate of the planetary gears.

6. Maintenance Strategies for Gear Wear

6.1 Regular Inspection and Monitoring

- Visual Inspection: Regular visual inspections of the gearbox and gears should be carried out. This includes checking for any signs of wear, such as pitting, scoring, or material loss on the gear teeth surfaces. Visual inspection can also detect any signs of lubricant leakage or contamination. In a shield machine reducer, visual inspection can be performed during routine maintenance intervals or when there are signs of abnormal operation. For example, if the operator notices an increase in noise or vibration from the gearbox, a visual inspection should be conducted immediately.

- Vibration Monitoring: Vibration monitoring is an effective method for detecting early signs of gear wear. By installing vibration sensors on the gearbox, the vibration characteristics of the gears can be continuously monitored. Changes in vibration amplitude, frequency, or phase can indicate potential wear or other faults. In a shield machine reducer, vibration monitoring can be integrated with the machine’s control system to provide real-time alerts when abnormal vibrations are detected. For example, if the vibration amplitude exceeds a certain threshold, an alarm can be triggered, indicating that further investigation and maintenance may be required.

- Lubricant Analysis: Analyzing the lubricant in the gearbox can provide valuable information about the wear state of the gears. The lubricant can be tested for contaminants, wear particles, and changes in its chemical properties. An increase in the concentration of wear particles in the lubricant can indicate that the gears are experiencing wear. In a shield machine reducer, lubricant analysis can be performed regularly to monitor the health of the gears. For example, samples of the lubricant can be taken at regular intervals and sent to a laboratory for analysis.

6.2 Preventive Maintenance

- Lubricant Replacement: Regularly replacing the lubricant in the gearbox is an important preventive maintenance measure. The lubricant should be replaced according to the manufacturer’s recommended schedule or when it shows signs of degradation. In a shield machine reducer, the lubricant may need to be replaced more frequently depending on the operating conditions. For example, if the shield machine is operating in a dusty environment, the lubricant may become contaminated more quickly, requiring more frequent replacement.

- Gear Replacement: In some cases, when the wear on the gears reaches a certain level, it may be necessary to replace the gears. The decision to replace the gears should be based on factors such as the severity of the wear, the remaining useful life of the gears, and the cost of replacement compared to the cost of continued operation with worn gears. In a shield machine reducer, the replacement of planetary gears can be a complex and costly process, but it is necessary to ensure the proper functioning of the reducer. For example, if the wear on the planetary gears is severe enough to affect the performance of the shield machine, replacement should be considered.

6.3 Predictive Maintenance

- Data Analytics and Modeling: Predictive maintenance uses data analytics and modeling techniques to predict the future wear state of the gears. By collecting and analyzing data from various sources such as vibration sensors, lubricant analysis, and operating parameters, a model can be developed to predict when the gears will reach a critical wear state. In a shield machine reducer, predictive maintenance can be used to optimize the maintenance schedule and reduce unplanned downtime. For example, a machine learning algorithm can be used to analyze the data and predict the wear rate of the planetary gears based on current operating conditions.

- Condition Monitoring Systems: Condition monitoring systems are used to continuously monitor the health of the gears and provide real-time alerts when maintenance is required. These systems typically include sensors for vibration, temperature, and lubricant condition, as well as a data acquisition and analysis unit. In a shield machine reducer, condition monitoring systems can be integrated with the machine’s control system to provide a comprehensive monitoring solution. For example, if the condition monitoring system detects an abnormal increase in temperature or a decrease in lubricant level, an alarm can be triggered, indicating that maintenance is required.

7. Impact of Gear Wear on Shield Machine Performance

7.1 Reduced Efficiency

- Increased Friction and Power Loss: Gear wear leads to increased friction between the gear teeth, which in turn causes an increase in power loss. In a shield machine reducer, this means that more energy is required to drive the shield machine, reducing its overall efficiency. For example, if the planetary gears in the reducer are worn, the friction between the teeth will increase, and more power will be dissipated as heat, resulting in a decrease in the efficiency of the shield machine’s propulsion system.

- Altered Gear Ratios and Torque Transmission: Wear on the gears can also change the gear ratios and affect the torque transmission. This can lead to improper functioning of the shield machine’s cutting head and other components. In a shield machine reducer, if the planetary gears are worn, the gear ratios may change, and the torque transmitted to the cutting head may not be sufficient to cut through the soil or rock effectively. This can result in slower excavation speeds and reduced productivity.

7.2 Increased Noise and Vibration

- Noise Generation: Gear wear can cause an increase in noise levels. The worn gear teeth surfaces can produce a rattling or screeching sound during meshing. In a shield machine reducer, this increased noise can be a nuisance to the operators and can also indicate potential problems with the gears. For example, if the noise level from the gearbox increases significantly, it is likely that the gears are experiencing wear or other faults.

- Vibration Amplification: Wear on the gears can also amplify vibrations. The uneven wear on the gear teeth surfaces can cause an imbalance in the rotational forces, leading to increased vibrations. In a shield machine reducer, these vibrations can be transmitted to the entire shield machine, causing discomfort to the operators and potentially damaging other components. For example, if the vibrations are too strong, they can cause loosening of bolts and other fasteners, leading to a safety hazard.

7.3 Safety Risks

- Component Failure: Severe gear wear can lead to component failure. If the gears in a shield machine reducer fail, it can cause the shield machine to stop working, which can be a serious safety hazard in an underground construction environment. For example, if the planetary gears fail, the torque transmission to the cutting head will be interrupted, and the shield machine may become stuck in the soil or rock, endangering the lives of the operators.

- Reduced Control and Stability: Gear wear can also affect the control and stability of the shield machine. The altered gear ratios and increased vibrations can make it difficult to control the direction and speed of the shield machine. In a shield machine reducer, if the planetary gears are worn, the operator may have difficulty maintaining a straight path during excavation and may need to make frequent adjustments to the machine’s controls. This can increase the risk of accidents and reduce the overall safety of the operation.

8. Conclusion

The wear state of multi-stage planetary gears in shield machine reducers is a critical factor that affects the performance and safety of the shield machine. Accurate detection of gear wear is essential for implementing effective maintenance strategies and ensuring the proper functioning of the shield machine. The methods and techniques described in this article, including vibration signal analysis, gear image analysis, and experimental comparison, provide valuable insights into gear wear detection. Additionally, understanding the gear wear mechanisms, factors affecting wear, maintenance strategies, and the impact of wear on shield machine performance is crucial for optimizing the operation and maintenance of shield machines. Future research should focus on further improving gear wear detection methods, developing real-time monitoring systems, and integrating maintenance…