Abstract

The space surface of high reduction hypoid gear (HRH) is complex, making it difficult to control the meshing quality through conventional machining calculation methods. This paper establishes a coordinate system for space gear meshing transmission and presents the general form of the space meshing equation. The surface equation of the trimming cutter head is deduced, and a tooth profile modification method is proposed to solve the problem of tooth surface curvature correction for HRH gears. Based on the principle of close surfaces, a simulation model for HRH gear machining parameter calculation and meshing is established by integrating the production surface, small wheel surface, and ease-off difference surface. The geometric parameter control method of the ease-off difference surface and the process for HRH gear machining parameter calculation and meshing simulation are provided, enabling the control of tooth surface differential structure and meshing quality. The meshing quality of the tooth surface is tested through contact spots and dynamic performance.

1. Introduction

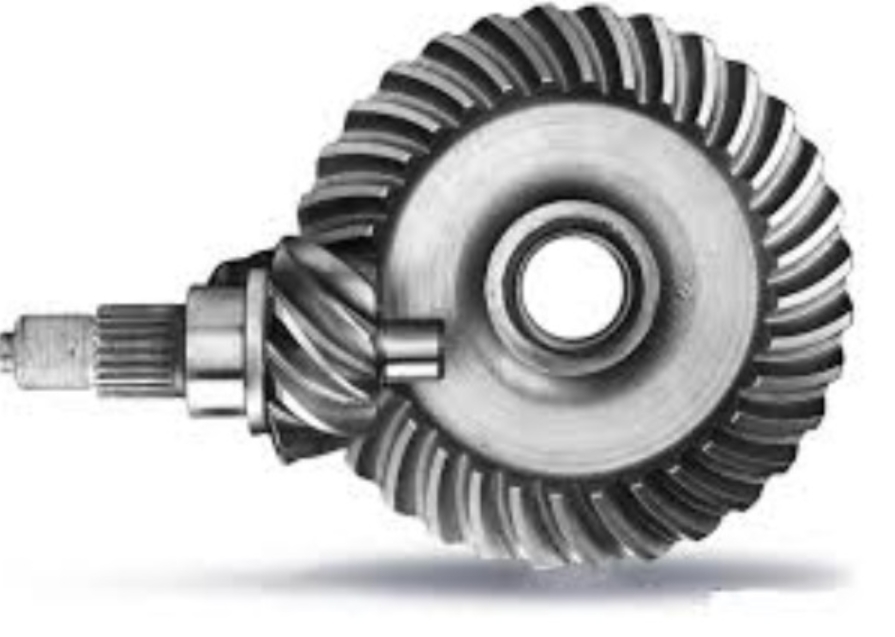

Power density and efficiency have always been primary objectives pursued in the field of mechanical transmission, where gears with a reduced number of teeth are crucial for achieving these goals. High reduction hypoid gears (HRH) offer advantages such as high contact ratio, reduced number of teeth, lightweight design, and high efficiency, making them promising candidates for highly integrated electromechanical power transmission applications.

| Literature | Key Contributions |

|---|---|

| [2] | Designed a three-tooth spiral bevel gear using the “non-zero variation” principle. |

| [3-4] | Studied the geometric evolution of HRH gears through meshing simulations. |

| [4] | Researched a one-tooth HRH gear. |

| [5] | Established a reverse adjustment optimization model for spiral bevel gear tooth profile error correction. |

| [6] | Proposed a digital true tooth surface model for spiral bevel gears with tooth profile and installation errors. |

| [7-8] | Studied the conversion of mechanical milling machine processing parameters to NC grinding machine motion parameters. |

| [9] | Provided a tooth surface modification method based on high-order machine tool coordinate motion principles. |

| [10-11] | Introduced a tooth surface processing and error correction method directly for 6-axis CNC machines. |

| [12] | Conducted comparative analyses of spiral bevel gears with fourth-order transmission errors using tooth bearing contact analysis and tooth surface relative modification (ease-off) maps. |

| [13-14] | Presented tooth surface correction methods for spiral bevel gears with high-order transmission errors based on ease-off surface topology principles. |

2. General Form of the Space Gear Meshing Equation

Assuming a crossed-axis gear spatial transmission (Σ(1), Σ(2)), the coordinate system. The fixed coordinate system related to gears 1 and 2 is 12S S, with three spatial fixed coordinate systems: 00000(,,)S O x y z −, S d, and S D. The 0z-axis of the S 0 coordinate system coincides with the rotation axis 2z of gear 2. The S d coordinate system differs from the S 0 coordinate system by a translation of 0[0]d EG =−O O. The S p coordinate system differs from the S d coordinate system by a translation of [00]d p P =O O and a rotation of 90γ°−. The instantaneous rotation angles of the large and small wheels are 12ϕϕ, and the angular velocities are 2ω and 1ω, respectively.

For this spatial meshing motion, considering the gear meshing angle and the relative position of the axes as six variables: 12(,,,,,)E P G ϕϕγ, it corresponds to six degrees of freedom. According to gear meshing relationships or the needs of generating processing, a maximum of three degrees of freedom can be achieved for meshing transmission. Here, only single-freedom meshing is used—with fixed relative positions of the axes, and 21ϕϕ as a functional relationship.

3. Machining of the Large Wheel Tooth Surface

3.1. Large Wheel Forming Method

Based on the relationship between the various coordinate systems involved in large wheel machining, the tooth surface equation Σ2 of the large wheel and the respective vectors can be determined.

3.2. Modification of the Close Surface

When using a straight-profile tool for forming the large wheel, it leads to insufficient tooth profile curvature, preventing the large and small wheels from forming the correct meshing relationship. To avoid curvature interference and ensure the correct point contact relationship between the large and small wheels, the small wheel must adopt either the hypoid format tilt (HFT) or hypoid generating modified method (HGM) for tooth profile correction. However, these two methods are not suitable for HRH gears with smaller moduli. Therefore, a general hobbing method is proposed for the small wheel, while the large wheel adopts tool modification to compensate for the insufficient tooth profile curvature.

Table: Modification Parameters for the Large Wheel

| Modification Type | Equation |

|---|---|

| Transverse Modification (yH) | 210100.5()'()w a u u w a u u =−=− |

| Longitudinal Modification (xL) | 20()arctan L θθθ=+′ |

4. Topological Modification Control for Surface Synthesis

Assuming the small wheel has two generating wheels, one is the close surface obtained by synthesizing the ease-off surface with the large wheel tooth surface, and the other is the generating surface of the machining machine. Since both produce the same small wheel tooth surface, they should share common characteristics. The former is taken as the target tooth surface of the small wheel for surface synthesis.

4.1. Determination of the ease-off Gradient Ellipse

Based on the principle of conjugate motion, a given ease-off on the surface corresponds to a given tooth surface modification gradient. The gradient ellipse equation is given by:

22221 4 a b x x a b +=

The ease-off difference curvature is:

2 2 88a b k k a b δδΔ= Δ=

4.2. Determination of the Close Surface

Substituting the difference curvature into the Euler formula, the principal axis direction close surface normal curvature of the ease-off ellipse can be obtained.

5. Contact Simulation

Using the designed parameters in Table 1, surface synthesis and tooth surface contact simulations were performed based on the motion relationship between the large and small wheels, obtaining the ease-off difference surface and the ease-off gradient represented by a chromaticity map. The tooth surface modification shows a clear elliptical gradient expanding outward from the base point.

Table 1: Machining Parameters for a Pair of 3:60 Tooth Ratio HRH Gears

| Parameter | Concave Surface | Convex Surface | Large Wheel |

|---|---|---|---|

| Wheel Mounting Angle γm /(°) | 10.991 9 | 10.991 9 | 74.763 9 |

| Bed Position X b /mm | ‒1.525 3 | ‒1.540 0 | 0 |

| Vertical Wheel Position E m /mm | 39.884 3 | 40.227 8 | 0 |

| Horizontal Wheel Position X G /mm | ‒0.336 7 | ‒0.946 7 | 5.342 8 |

| Angular Tool Position q /(°) | 75.842 4 | 81.526 2 | 42.214 3 |

| Radial Tool Position S r /mm | 52.086 2 | 51.678 2 | 53.151 3 |

| Rolling Ratio m 12 | 20.015 2 | 19.747 6 | — |

| Cutter Head Radius r c0/mm | 77.725 | 72.644 | 37.3/38.9 |

| Tool Pressure Angle α/(°) | 20.0 | 28.0 | 21.0 |

The mismatch amounts at the four vertices of the tooth surface were obtained as 34 μm, 149 μm, 31 μm, and 196 μm. The chromaticity map illustrates the ease-off gradient, demonstrating that the tooth surface modification exhibits a distinct elliptical gradient expanding outward from the base point. By interpreting the ease-off surface, the contact line gaps and transmission errors (TE) were acquired.

The contact path designed in a large internal diagonal pattern, aligning with the characteristics of high modification and contact ratio for HRH gears. The maximum gaps at the ends of the contact lines are 128 μm and 166 μm, ensuring no load concentration occurs at the lower edge during load bearing. The six transmission error plots represent five teeth, with the middle plot corresponding to the currently engaged tooth pair. The five intersection points with the adjacent plots indicate a contact ratio exceeding five. Specifically, the contact ratio for the front face is 5.2.

The aforementioned contact simulations reveal that the shape and orientation of the tooth surface modification gradient, the contact path/lines, and the transmission error (TE) control are in line with expectations. This confirms the accuracy of the calculated processing parameters and the appropriateness of the tooth surface curvature modification.