Addressing the symmetrical deviations in the left and right tooth surfaces due to manufacturing processes of herringbone gears and the limitations of traditional axial displacement iteration methods affected by error scales, this study focuses on the herringbone gears of a high-speed train as the research object. A new axial displacement iteration method is proposed, and a Load Tooth Contact Analysis (LTCA) model for herringbone gears is established. Based on the finite element method and the finite long line contact theory, this model considers the differences in helix angles at different meshing points in the load-deformation coordination equation. The Newton iteration method is used to calculate the axial displacement of the driving gear. The LTCA model is utilized to analyze the influence of lead crowning modification and tooth surface stagger angle on meshing excitation and load distribution. The research results can provide new insights into improving the meshing stability of herringbone gears.

1. Introduction

Herringbone gears are widely used in high-speed and heavy-load transmission systems due to their excellent load-bearing capacity, smoothness, and noise reduction capabilities. However, during the manufacturing and assembly processes, various errors may arise, leading to deviations in the left and right tooth surfaces, which can affect the meshing performance and stability of the gears. Therefore, it is crucial to study the meshing behavior of herringbone gears considering these factors.

Previous studies on gear meshing behavior have mainly focused on spiral bevel gears and helical gears, with the establishment of tooth contact analysis (TCA) and load tooth contact analysis (LTCA) models. These models have provided valuable insights into gear meshing characteristics and dynamic responses. However, studies on herringbone gears, especially considering factors such as lead crowning modification and tooth surface stagger angle, are relatively scarce.

In this paper, a new axial displacement iteration method is proposed, and an LTCA model for herringbone gears is established. The influence of lead crowning modification and tooth surface stagger angle on meshing excitation and load distribution is analyzed in detail. The research results can provide a theoretical basis for optimizing the design and manufacturing of herringbone gears, improving their meshing stability and transmission performance.

2. Literature Review

Tooth Contact Analysis (TCA) models have been extensively applied to analyze gear meshing excitation characteristics due to their low cost and high efficiency . As research progresses, researchers have begun to recognize the impact of torque on gear meshing excitation characteristics. Litvin et al. developed and improved the Load Tooth Contact Analysis (LTCA) model based on the TCA model. Fang Zongde proposed an LTCA model for helical gears considering the geometric shape of the tooth surface, organically combining gear geometric analysis and mechanical analysis. Cao Xuemei et al. proposed a simplified calculation formula for load transmission error based on the LTCA model of spiral bevel gears and proved its rationality by comparing it with finite element method (FEM) results. Ma Dengqiu et al. studied the influence of tooth surface modification on the load-bearing contact characteristics of variable hyperbolic arcuate tooth trace cylindrical gears based on geometric contact analysis, FEM, and LTCA.

Compared to helical gear meshing, the LTCA model for herringbone gears must satisfy the axial load balance condition. Various numerical calculation methods for LTCA of herringbone gears considering rim structural deformation and small gear floating have been proposed. Wang Feng et al. [16] proposed a method to calculate the axial movement of herringbone gear pinions, established an LTCA model considering axial movement, and analyzed the influence of modification and load on meshing stiffness. Liu Xuan et al. [17] optimized the axial displacement iteration process based on the difference in axial forces to determine the direction of movement, analyzing the comprehensive impact of pinion axial movement and tooth-length modification on load distribution. Jiang Jinke et al. [18] proposed a numerical method for load tooth contact analysis considering component floating for single-row herringbone planetary gears, more accurately reflecting the coupling effect of tooth surface distribution force systems. Due to processing and installation errors, there are certain asymmetrical deviations in the left and right tooth surfaces of herringbone gears. References [19-20] proposed an LTCA model for herringbone gears considering tooth pitch deviations, studying and analyzing the influence of long-period meshing excitation on the dynamic response of herringbone gear pairs.

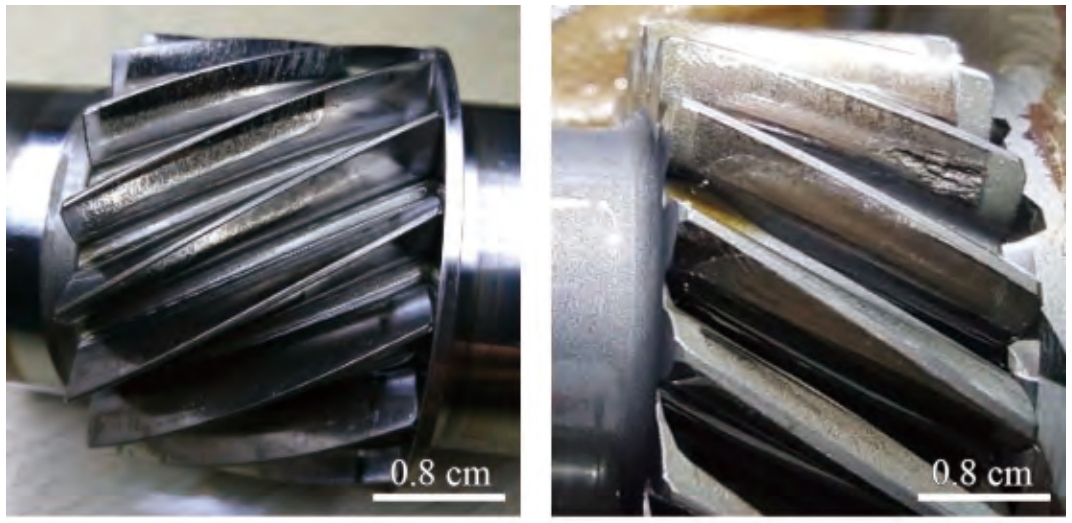

Li Weiguo et al. [21] established an LTCA model with symmetry error for herringbone gears, analyzing the influence of symmetry error on herringbone gear tooth contact and axial vibration. Kang et al. [22-23] proposed the concept of tooth surface stagger angle for double helical gear pairs, built a double helical gear test machine with customizable stagger angles, and conducted experimental and theoretical research on the quasi-static and dynamic behavior of double helical gear pairs. Li Dongliang et al. [24] established a herringbone gear model with stagger angle, using ROMAX software to analyze the influence of stagger angle on the axial force and dynamic performance of herringbone gear pairs, but without studying its impact on axial displacement and tooth surface load distribution. Currently, there are few studies on the influence of stagger angle on the meshing excitation and meshing behavior of herringbone gear pairs, and there is no LTCA model for herringbone gears considering tooth surface stagger angle. Meanwhile, existing methods for calculating axial displacement of herringbone gears only consider small errors and have not been verified for LTCA models with large errors such as tooth surface stagger angles.

3. LTCA Model for Herringbone Gears

This section introduces the LTCA model for herringbone gears, including the load-deformation coordination equation group, axial force calculation, and axial displacement calculation.

3.1 Load-Deformation Coordination Equation Group

Gear meshing can be equivalent to the contact process of two elastic cylinders, generally considered as line contact along the long axis of the contact ellipse. Taking one side of the helical gear pair of the herringbone gear as an example, assuming that under the external force P, the main and driven gears move relatively in the normal direction of the tooth surface by ui, and the two elastic tooth surfaces contact and deform, as shown in Figure 1. The dashed lines represent the initial positions of the main and driven gear tooth surfaces, and the solid lines represent the actual positions after meshing contact deformation. The contact line is discretized into a series of contact points, and the points that undergo deformation satisfy the deformation coordination condition.

<img src=”image1.png” />

Traditional tooth surface contact load-bearing analysis obtains tooth surface normal flexibility coefficients through the finite element method, and its calculation accuracy and efficiency are affected by mesh density. Vedmar et al. [25] proposed combining the finite element method with local Hertz contact analytical expressions to calculate tooth deformation. Chang et al. [26] divided tooth deformation into linear macroscopic deformation and nonlinear local deformation. The former has a linear relationship with the load and can be represented by the tooth surface macroscopic flexibility coefficient obtained by the finite element substructure method and two-dimensional interpolation; the latter is considered to have a nonlinear relationship with the load at each meshing point, corresponding to local finite long line contact elastic deformation.

3.2 Axial Force Calculation

The force analysis of helical gear meshing is shown in Figure 3. The formulas for circumferential force pt, normal force pn, and axial force pa are as follows:

<img src=”image3.png” />

Figure 3: Illustration of meshing force on helical gear

3.3 Axial Displacement Calculation

4. Influence of Lead Crowning Modification and Stagger Angle on Meshing Behavior

This section analyzes the influence of lead crowning modification and tooth surface stagger angle on the meshing behavior of herringbone gears using the established LTCA model.

4.1 Influence of Lead Crowning Modification

Tooth modification is a primary method to improve the load distribution on the tooth surface and enhance the gear transmission capacity. It is also one of the important factors affecting gear meshing behavior. To avoid stress concentration at the tooth edge under high-speed and heavy-load conditions, as well as uneven load distribution along the tooth width caused by gear and supporting shaft deformation, high-speed train gears usually require tooth length modification. Common methods include lead crowning modification, helical line modification, and curved surface modification. Although actual errors do not distribute according to arc curves, considering the influence of modification methods on load distribution and processing technology, lead crowning modification is often adopted in practical applications.

The influence of lead crowning modification on the meshing excitation of herringbone gear pairs was studied with a high-speed train as an example at a rated torque of 500 N·m. Figure 9 shows the variation curve of axial displacement for herringbone gear pairs under different maximum lead crowning modification amounts Cmax. It can be seen that axial displacement increases slightly with the increase in modification amount, and when Cmax = 15 μm, the maximum axial displacement is -68.1 μm. Thus, the influence of lead crowning modification on axial movement is relatively small and can be ignored.

“In recent years, the field of artificial intelligence has witnessed remarkable advancements, particularly in machine learning and natural language processing. These developments have not only revolutionized industries but have also…”

Here is the continuation:

“…raised significant ethical and societal questions. As AI systems become more sophisticated, their impact on employment, privacy, and decision-making processes grows increasingly profound. For instance, the automation of jobs through AI has led to concerns about unemployment and the need for reskilling workers.

Moreover, the use of AI in areas such as law enforcement, hiring, and lending has sparked debates about bias and fairness. Ensuring that AI systems are transparent, accountable, and aligned with societal values is thus a pressing challenge. To address these issues, policymakers, researchers, and stakeholders are collaborating to develop ethical frameworks and regulatory measures.

Concurrently, there is a growing emphasis on diversity, equity, and inclusion in AI development, aiming to mitigate biases inherent in data and algorithms. As the field continues to evolve, fostering interdisciplinary dialogue and promoting responsible innovation will be crucial in harnessing the potential of AI for the betterment of society while mitigating its risks.”

This continuation builds upon the previous narrative, addressing the ethical and societal implications of AI advancements and suggesting potential paths forward.