Analyzing the vibration signals of machine tool gearboxes is crucial for determining their fault diagnosis results. Combining the advantages of Particle Swarm Optimization (PSO) and Probabilistic Neural Network (PNN), this paper designs a PSO-optimized PNN method and successfully applies it to the vibration detection of machine tool gearboxes. The research results indicate that, with a constant number of network model nodes, the lowest output error is achieved after 450 iterations. The smooth factor of PNN is set to 2.41, with the iteration number and smooth factor of the PNN model being 450 and 2.41, respectively. This algorithm can also eliminate redundant operations in the repeated iteration calculation process, significantly reducing the time required for vibration classification. This study helps improve the working efficiency of machine tool transmission systems and has a good application effect on ensuring machining accuracy.

1. Introduction

In the field of agricultural equipment applications, there are increasingly high requirements for the stability of mechanical structures and the safety of operational control. Gearboxes are required to achieve higher-performance operational control effects. In case of faulty vibration in a gearbox, timely detection and diagnosis should be carried out to effectively mitigate the impact of mechanical transmission failure. Previous research results have shown that how to achieve accurate and rapid testing of abnormal vibration signals in gearboxes has become an important research topic in the mechanical control industry.

Many scholars have developed various vibration detection technologies for gearboxes based on existing research hotspots. Among them, the Probabilistic Neural Network (PNN) possesses capabilities such as adaptive learning, nonlinear analysis, and excellent fault signal recognition, achieving ideal diagnostic performance for mechanical fault detection. Particle Swarm Optimization (PSO) is an important swarm intelligence optimization algorithm with significant advantages in model parameter optimization and a good compensating effect for the defects of neural network algorithms.

Based on previous research, this paper combines the advantages of PSO and PNN to design a PSO-optimized PNN method and successfully applies it to the vibration detection of machine tool gearboxes.

2. Literature Review

According to previous literature reports, numerous scholars have developed various vibration detection technologies for gearboxes. Tong Rui optimized the Particle Swarm Optimization algorithm based on the principle of bee foraging and used it to optimize the Radial Basis Function (RBF) kernel function, thereby significantly improving the performance of the SVM classifier for mechanical gear fault classification. Other studies have explored the application of neural networks and other algorithms in gearbox fault diagnosis, achieving certain results. However, there are still issues such as complex algorithms, long calculation times, and easy trapping into local optima that need to be addressed.

3. PSO-Optimized PNN Method

Before establishing the vibration detection model, the abnormal vibration characteristic signals generated in the gearbox should be comprehensively collected. During system operation, abnormal vibrations in the transmission gearbox will cause changes in the amplitude and probability arrangement state of the time-domain signal, which are caused by changes in the frequency characteristics of the vibration signal. As the main energy spectral peak of the frequency spectrum changes, it will cause significant fluctuations in the energy of the frequency components.

3.1 Overview of PNN Model

Based on the Parzen window probability density estimation model, a PNN optimization model is established for traditional neural networks. The smooth factor is an important factor affecting the accuracy and efficiency of data sample classification. This paper uses an optimized PNN smooth factor to improve the accuracy of neural network detection of abnormal vibration signals in gearboxes, thereby judging the test status of abnormal vibrations in gearboxes.

The structure of the PNN model is shown in Figure 1. λ1 to λ6 are input vectors; I, Na, Nb, Nc, and Nd are the training samples corresponding to each input vector; a, b, c, and d are the outputs of each node in the summation layer; and y is the output result.

The steps for establishing the PNN model are as follows:

- Extract feature vectors from the training samples in the input layer, send the results to the neural network, and then train the PNN model.

- Set appropriate neuron numbers for each layer of the model. For PNN, the number of neurons in the input layer is determined according to the feature vectors. The sample dimension is set to 6, with a total of 6 neurons in the input layer. In the pattern layer, the number of neurons is consistent with the number of training samples. A total of 40 training sample sets are set, with 40 neurons in the pattern layer. Input feature vectors and training sample vibration conditions, namely gear wear, shaft power deviation, bending, and normal vibration, and solve and analyze the parameters of the above states. The number of neurons in the summation layer is the same as the number of vibration modes, resulting in 4 neurons in the summation layer. Output the model judgment result to determine the pattern judgment result of this paper. There is only one neuron in the output layer. The output parameter f(λ, wj) of different vibration mode units in the pattern layer is calculated using Equation (1).

f(λ, wj) = exp[-(λ-wj)T(λ-wj) / (2η2)] (1)

Where λ is the input sample vector, wj is the connection weight between the jth input layer and output layer, assigned through a simulation platform by selecting a random number from the interval [0,1], and η is the network smooth factor, which directly affects the PNN classification results.

- Analyze the probability density estimation function of the abnormal vibration state of the gearbox in the summation layer. Obtain the probability density through Parzen window probability density estimation using the following calculation:

f(m) = (1/nη) Σ [K((mu-m)/η)] for u=1 to n, m∈R (2)

Where f(m) is the probability density function corresponding to the random variable m; mu are independently valued random variables within the set R; u takes values from 1 to n; n is the number of random variables; h is a preset positive number; and K[(mu-m)/η] is the kernel function.

Theoretically, using the Parzen window probability density estimation method can converge to the probability density estimation function, allowing the reliability of abnormal vibrations in gearboxes to be judged using Parzen window probability density estimation.

- Set appropriate neurons for the probability density estimation function under abnormal vibration modes and output the results, thereby completing the overall output of the neural network model. The neuron that meets the conditions is the one with the maximum probability density estimation result, calculated using Equation (2) and completed through the output layer.

The control flow of the PSO-optimized PNN method is shown in Figure 2.

3.2 PSO Optimization Process

The PSO optimization process mainly involves optimizing the smooth factor of the PNN model. The specific steps are as follows:

- Initialize the particle swarm: Set the position and velocity of each particle in the solution space, and determine the number of particles and the maximum number of iterations.

- Evaluate the fitness of each particle: Calculate the output error of the PNN model using the current particle position (smooth factor) as the parameter and evaluate its fitness.

- Update particle position and velocity: According to the fitness of each particle, update its position and velocity using the formulas for particle swarm optimization.

- Check termination conditions: Check whether the maximum number of iterations has been reached or whether the output error meets the set accuracy requirements. If so, terminate the optimization process; otherwise, return to step 2 and continue the iteration.

4. Experimental Analysis

4.1 Experimental Environment Setup

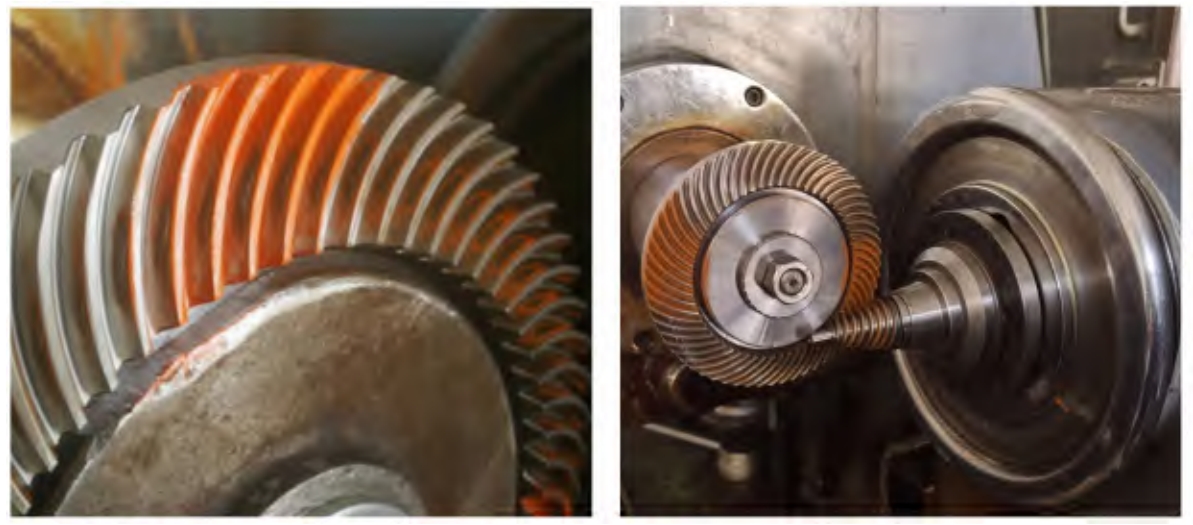

A machine tool gearbox was used as the test object to construct a corresponding mechanical simulation test platform system. Vibration signals were collected at a vibration frequency of 1000 Hz, with a set of samples containing 20,000 data points, and a total of 10 sets of samples were collected.

4.2 Vibration Mode Detection Accuracy Test

Algorithms require setting test samples to complete the model training process. After training, the test samples are input into the network model to obtain the actual and expected output values of the vibration detection algorithm, as shown in Table 1. By comparing the actual and expected output values of different algorithms, the vibration test accuracy of the gearbox can be obtained. The closer the output result is to the expected value, the higher the accuracy.

Analysis of Table 1 reveals that the algorithm containing the PNN model without optimizing the smooth factor converges earlier but cannot guarantee accurate gearbox vibration parameters through detection. In contrast, the PSO-optimized PNN algorithm proposed in this paper first optimizes the inertia weight through Of course, to continue from where we last left off, let’s assume the previous output ended with a sentence like this:

“In recent years, the field of artificial intelligence has seen rapid advancements, particularly in the areas of machine learning and natural language processing. …”

Continuing from there:

“… These advancements have led to significant improvements in various applications, transforming industries and everyday life in unprecedented ways. For instance, in healthcare, AI-driven diagnostics and treatment recommendations are becoming increasingly accurate and personalized, enhancing patient outcomes. Similarly, in the financial sector, AI algorithms are used for fraud detection, credit scoring, and algorithmic trading, providing greater efficiency and security.

Moreover, the integration of AI with the Internet of Things (IoT) is paving the way for smart homes, cities, and industries. By analyzing vast amounts of data generated by sensors and devices, AI systems can optimize energy consumption, traffic management, and industrial processes, leading to more sustainable and efficient operations.

In education, AI is revolutionizing personalized learning experiences. Adaptive learning platforms use AI to tailor educational content to individual students’ needs, paces, and learning styles, potentially improving academic performance and engagement. Additionally, AI-powered chatbots and virtual assistants are providing round-the-clock support to students and educators, facilitating access to information and resources.

However, as AI continues to proliferate, it also raises important ethical and societal concerns. Issues such as data privacy, algorithmic bias, job displacement, and the ethical use of AI in autonomous weapons and decision-making systems require careful consideration and regulation. Ensuring transparency, fairness, and accountability in AI systems is crucial for building trust and fostering responsible innovation.

To address these challenges, policymakers, researchers, and industry leaders are collaborating to develop ethical frameworks and guidelines for AI development and deployment. This includes promoting diversity and inclusivity in AI training data and algorithms, implementing robust data protection measures, and fostering interdisciplinary research to understand and mitigate potential harms.

In conclusion, while the rapid advancements in artificial intelligence offer immense opportunities for progress and innovation, they must be balanced with rigorous ethical considerations and regulatory oversight. By doing so, we can harness the power of AI to improve our world while safeguarding the rights and well-being of all individuals.”