This paper focuses on enhancing the fertilizer discharging uniformity of the double-gear fertilizer discharger. By modifying the spur gear for fertilizer discharging based on the original structural parameters, a fertilizer discharger with staggered gears is designed. Through parametric modeling and determining the fertilizer-containing volume of the gear teeth, the theoretical fertilizer discharge amount of the discharger is determined by combining theoretical analysis. The EDEM is utilized to simulate the fertilizer discharging process, and the influence of the number of staggered gear pieces and the gap of the fertilizer discharging wheel on the fertilizer discharging uniformity is analyzed through single-factor experiments. The orthogonal simulation experiment is conducted using the L9(3^4) orthogonal table. The experimental results indicate that the primary and secondary order of the influence of the experimental factors on the test indicators is the number of staggered gear pieces and the gap of the fertilizer discharging wheel. When the number of staggered gear pieces is 3 and the gap of the fertilizer discharging wheel is 5 mm, the coefficient of variation of the fertilizer discharging uniformity is 4.69%. The bench test is carried out to compare the double-gear and the fertilizer discharger with staggered gears. The results show that when the rotational speed of the fertilizer discharger with staggered gears is 60 r/min, the coefficient of variation of the fertilizer discharge flow is 4.74%, which is basically consistent with the theoretical value, and the coefficient of variation is reduced by 10.68% compared with that of the double-gear fertilizer discharger. Based on the measured speed-flow curve of the fertilizer discharger, an electronic fertilizer discharge controller is designed and bench tested, with a fertilization accuracy deviation of 3.1%. The optimized fertilizer discharger has good fertilizer discharging uniformity and can achieve precise fertilizer control. The research results can provide a reference for the design and optimization of precise fertilizer dischargers.

1. Introduction

Fertilizer plays an irreplaceable role in grain production. With the development of urbanization and industrialization, the growth trend of future food demand is gradually increasing. How to use fertilizer reasonably and efficiently, improve the fertilization uniformity and utilization efficiency, ensure the future food supply, and increase the grain crop yield has become a highly concerned issue. Currently, the mainstream fertilizer dischargers in the market mainly include the external grooved wheel type and the screw type, but they have problems with poor fertilizer discharging uniformity, making it difficult to achieve precise fertilization. Some scholars have carried out improvement designs for these two types of fertilizer dischargers. For example, Fang Longyu et al. improved the external grooved wheel fertilizer discharger and designed a plug-in vane wheel fertilizer discharger, achieving fertilizer discharge amount control while retaining the advantages of the external grooved wheel fertilizer discharger. ZHANG et al. studied the screw fertilizer discharger, using a spiral grooved wheel instead of a straight grooved wheel, and optimizing the key structural parameters of the spiral grooved wheel. For the single-screw fertilizer discharger, Yang Wenwu et al. used the discrete element method and orthogonal experiments to optimize the angle and length of the fertilizer discharging port, improving the fertilizer discharging uniformity of the screw fertilizer discharger by changing the parameters of the fertilizer discharging port. Yu Chunling designed a double-gear fertilizer discharger, using gears as the fertilizer discharging wheels, and the fertilizer equalizing effect was significantly improved, but there is still room for improvement in its uniformity.

The above studies show that the existing research only conducts improvement designs on the fertilizer discharger, and the main method used is the discrete element simulation technology. This paper aims to address the problem of fluctuating fertilizer discharging uniformity of the double-gear fertilizer discharger, conduct improvement designs, analyze its improvement principle, optimize it using the discrete element simulation experiment, use 3D printing for prototype trial production, conduct a comparison test with the double-gear fertilizer discharger, develop a controller based on the speed-flow curve of the fertilizer discharger to achieve precise fertilizer control, in order to provide a reference for the further optimization of the fertilizer discharger.

2. Structure Improvement and Fertilizer Discharging Characteristics Analysis

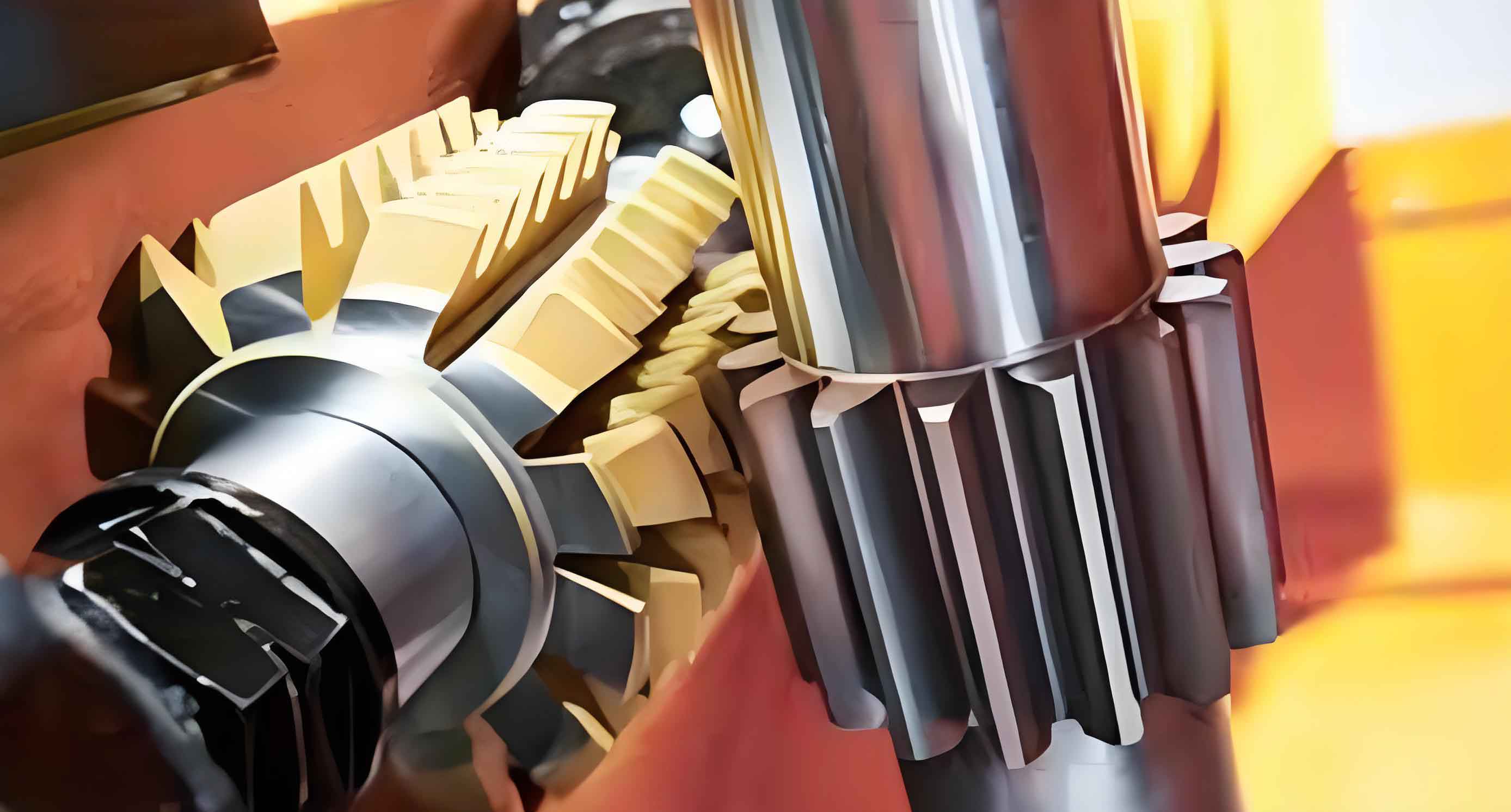

The fertilizer discharging wheel of the double-gear fertilizer discharger uses spur cylindrical gears. When the gears rotate in the middle, the fertilizer is discharged downward from the gap between the two gears. Its structural parameters are a gear tooth number of z = 8, an optimal pressure angle of 20°, and a gap between the two fertilizer discharging gears of 4 mm, with a coefficient of variation of the fertilizer discharging uniformity reaching 15.42%. However, there is still a certain problem of fertilizer discharge flow fluctuation during the alternate fertilizer discharging of the tooth ridges and tooth grooves of the two fertilizer discharging gears. To improve its fertilizer discharging uniformity, the initial concept is to increase the alternate fertilizer discharging space of the tooth grooves and tooth ridges within a unit time to achieve the same gear length, and multiple segmented fertilizer-containing areas alternate fertilizer discharging to reduce the fertilizer discharge flow fluctuation. The fertilizer discharging wheel with staggered gears is designed by using the method of equal-angle staggering of cylindrical gears.

This fertilizer discharging wheel is improved on the basis of the cylindrical gear. Using the Maddi 3D design tool plugin of SolidWorks to generate the cylindrical gear, taking the case of 3 pieces of staggered gears as an example, the cylindrical gear is axially divided into 3 equal parts at equal distances, and the divided entities are circumferentially rotated to make the 3 cylindrical gears mutually staggered, and finally combined into a whole. After the improvement, each fertilizer discharging space can be finely divided, thereby improving the fertilizer discharging uniformity. The structures of the fertilizer discharging wheel before and after improvement are shown in Figure 1.

The structure of the improved fertilizer discharger with staggered gears is shown in Figure 2, which consists of a left-handed fertilizer discharging wheel, a right-handed fertilizer discharging wheel, a housing, and a transmission gear. The two fertilizer discharging wheels mesh through the fixed transmission gear. During operation, the two fertilizer discharging wheels rotate inward in the middle, driving the fertilizer to flow out of the fertilizer discharging port along the gap formed by the tooth ridges and tooth grooves. Due to the staggered structure of the gears, the gap meshing space during the rotation of the fertilizer discharging wheels remains basically unchanged, and the fertilizer in the tooth grooves is continuously discharged, avoiding the intermittent fertilizer discharging phenomenon and improving the fertilizer discharging uniformity.

3. Fertilizer Discharging Performance Analysis of the Fertilizer Apparatus with Staggered Gears

To clarify the influencing factors of the fertilizer discharge amount of the fertilizer discharger with staggered gears, theoretical analysis is conducted on the fertilizer discharging performance and fertilizer discharge amount of the fertilizer discharger with staggered gears.

Figure 3 shows the meshing state of two staggered gears with a single piece center as the section. The two gears operate from the meshing to the non-meshing state, and the fertilizer enters and exits from the gap between the two gears. The main parameters of the fertilizer discharger with staggered gears include the number of gear teeth, the module m, the pressure angle a, the number of gear staggering pieces, and the center distance of the gap meshing of the two gears. The fertilizer-containing space between the tooth ridges and tooth grooves of the two staggered gears directly affects the quality of fertilization operations, and it is necessary to calculate the fertilizer-containing space of the staggered gears to obtain the specific structural parameters that affect the quality of fertilization operations. As shown in Figure 4, the area of the fertilizer-containing region of the tooth ridges and tooth grooves of the left and right staggered gears is equal to the area of a single tooth groove minus the area of the overlapping region of the two gears, and the plane shape of the overlapping region is approximately an isosceles trapezoid, then the area of the overlapping region is S2 = hl (1), where S2 is the area of the overlapping region, in mm2; h is the length of the midline of the trapezoid, in mm; and l is the height of the isosceles trapezoid, in mm.

When the gear size parameters are fixed, the smaller the center distance between the two staggered gears, the smaller the gap between the two staggered gears, while l and h increase, the area of the overlapping region increases, the area of the fertilizer-containing region decreases, affecting the fertilizer discharge amount and thereby affecting the fertilizer discharging uniformity.

Select a pair of meshing intervals of a single gear piece to calculate its fertilizer-containing space volume. Use SolidWorks to conduct 3D modeling of the shadow part of a single piece of staggered gear, select the fertilizer-containing space for volume recognition, and obtain the volume data of the model.

The rotational speed n of the fertilizer discharging wheel is equal to the magnitudes of n1 and n2. When the tooth ridge or tooth groove of the left-handed fertilizer discharging wheel is opposite to the tooth groove or tooth ridge of the right-handed fertilizer discharging wheel, it is a meshing. The number of coincidences of the two fertilizer discharging wheels in one rotation cycle is the total number of gear teeth of the fertilizer discharging wheel. Therefore, the total volume r of the fertilizer particles discharged by the fertilizer discharger with staggered gears in one rotation cycle can be calculated according to Equation (2).

V = (v1 * k * n * t * 10^-4 * e) / 6 (2)

k = 2 * z (3)

In the equation, v1 is the fertilizer-containing space volume of a single piece of staggered gear, in cm3; k is the number of coincidences in one rotation cycle of the fertilizer discharging wheel; t is the operation time of the fertilizer discharging wheel, in s; z is the number of gear teeth of the fertilizer discharging wheel; and e is the number of staggering pieces of the fertilizer discharging wheel, e = 3.

By determining the total volume r of the discharged fertilizer particles and the stacking density ρ of the fertilizer particles, the total mass m0 of the fertilizer discharged by the fertilizer discharger with staggered gears in one rotation cycle can be calculated through Equation (4).

m = ρ * V (4)

From Equation (4) and volume recognition, it can be known that the number of gear teeth z, the module m, the pressure angle α, the addendum height coefficient ha*, the center distance and gap of the fertilizer discharging gear are closely related to the size of the fertilizer-containing space. Based on the engineering practice and the size parameters of the existing fertilizer dischargers in the market, considering comprehensively, it is determined that the number of teeth of the staggered gear is z = 8, the module is m = 8, the pressure angle is α = 20°, the addendum height coefficient is ha* = 1, the top clearance coefficient is c* = 0.25, the length of the fertilizer discharging wheel is 60 mm, and the minimum center distance a2 of the fertilizer discharging wheel is 68 mm. For the existing planting mode, the theoretical fertilizer discharge amount of the fertilizer discharger with staggered gears can reach the requirement of the general minimum 75 kg of urea fertilization amount per hectare when the minimum rotational speed of the fertilizer discharging wheel is 30 r/min. Excessive number of gear pieces is prone to crushing the fertilizer, so the influence of the structural parameters of the fertilizer discharger can be simplified as the relationship between the fertilizer-containing space and the number of staggering pieces of the fertilizer discharging wheel. Therefore, this paper intends to conduct the combined optimization of the two parameters: the number of staggering pieces of the staggered gear and the gap between the two fertilizer discharging wheels horizontally separated.

3.1 Simulation Parameter Settings

3.1.1 Fertilizer Parameter Settings

The test fertilizer is urea produced by Anyang Zhongying Chemical Fertilizer Co., Ltd., with a particle size of 1.73 to 3.74 mm. Randomly select 150 urea particles for testing, with an average length of 3.07 mm, an average width of 2.92 mm, an average height of 2.71 mm, an average radius of 1.64 mm, and a radius standard deviation of 0.199 mm. Calculate the equivalent particle size D and sphericity Sp of the fertilizer particles according to Equations (5) and (6).

D = (L * B * H)^(1/3) (5)

Sp = (D / L) * 100% (6)

In the equation, L is the length of the urea particle, in mm; B is the width of the urea particle, in mm; and H is the height of the urea particle, in mm.

It can be calculated that the equivalent particle size D of the fertilizer particles is 3.28 mm, and the sphericity Sp is 94.66%. Since Sp > 90%, a sphere with a diameter of 3.28 mm is selected as the simulation particle model.

3.1.2 Simulation Model Parameter Settings

Considering that the urea particles do not adhere to each other during fertilization, the Hertz-Mindlin (no slip) contact model is used as the contact model between the urea particles and between the urea particles and the fertilizer discharger. Based on the existing research basis, determine the parameters of the urea particles, the fertilizer discharger, and the contact mechanics, as shown in Table 1.

3.1.3 Test Method

Import the 3D model of the fertilizer discharger with staggered gears into EDEM, and set the parameters according to Table 1. Build a particle factory at the fertilizer inlet, with a particle diameter of 3.28 mm and a total number of 80,000 particles. Refer to the double-gear fertilizer discharger, set the rotational speed of the fertilizer discharging wheel to 60 r/min, and place the data area grid on the fertilizer collecting plate. Since the fertilizer particles have the same movement law in each fertilizer discharging cycle of the fertilizer discharging wheel, set the fertilizer collecting plate to move longitudinally with a moving speed of 1 m/s, and the total simulation time is 10 s. The simulation model is shown in Figure 5.

3.1.4 Fertilizer Discharging Performance Evaluation Method

According to “DB21T 1519-2016 Intertillage Fertilizer Applicator”, the test evaluation index is the coefficient of variation of the fertilizer discharging uniformity. The smaller the coefficient of variation value, the better the fertilizer equalizing performance of the fertilizer discharger.

Statistically calculate the number of fertilizer particles within the length of 250 mm on the fertilizer collecting plate, calculate the standard deviation and average value of the number of fertilizer particles, and calculate the coefficient of variation of the fertilizer discharging uniformity. Set the machine speed based on the fertilizer discharging time of one rotation and 1/4 of the total length of the grid, divide the monitoring area into 5 grids, and statistically calculate the fertilizer within each grid. Calculate the average value of the results of three fertilizer discharging cycles at the same rotational speed.

Calculate the average value of the fertilizer particles according to Equation (7).

k_bar = (1 / φ) * Σ ki (7)

In the equation, k_bar is the average number of fertilizer particles in the statistical area; φ is the number of statistical times; and ki is the number of fertilizer particles at the statistical moment i.

Calculate the standard deviation x of the number of fertilizer particles in the statistical area according to Equation (8).

x = √((1 / (φ – 1)) * Σ (ki – k_bar)^2) (8)

Calculate the coefficient of variation σ of the fertilizer discharger’s fertilizer discharging uniformity according to Equation (9).

σ = (x / k_bar) * 100% (9)

3.2 Results and Analysis

3.2.1 Comparison of the Fertilizer Discharging States Before and After Improvement

Compare the fertilizer discharging uniformity of the fertilizer dischargers before and after improvement, as shown in Figure 6. When the cylindrical gear fertilizer discharger is working, the fertilizer-containing space is the entire gap in the axial direction of the gear, and the tooth grooves and tooth ridges of the fertilizer discharging wheel alternate and mesh intermittently, and the fertilizer particles are discharged alternately in the gap, showing an intermittent fertilizer discharging state. In the fertilizer discharging process of the fertilizer discharger with staggered gears, the overall fertilizer discharge amount is divided into 3 parts, making up for the gap of intermittent fertilizer discharging, and the fertilizer continuously falls in the entire fertilizer discharging process.

The number of fertilizer particles discharged at different times by the improved fertilizer discharger is shown in Figure 7. Within 1 to 9 s, the distribution of red particles is more concentrated, and the distribution of black particles is more dispersed. The fertilizer discharge amount fluctuation of the fertilizer discharger with staggered gears is reduced compared to that of the cylindrical gear fertilizer discharger, and the fluctuation range is significantly reduced, representing that the fertilizer discharge flow fluctuation of the improved fertilizer discharger is smaller, and its fertilizer discharge flow is more uniform. At the same time, through the statistics of the number of particles, calculate the coefficient of variation of the number of particles, which is 2.68% and 5.85% respectively, and the fertilizer equalizing property of the staggered gear is improved by an average of 54.19% compared to the cylindrical gear.

3.2.2 Relationship Between the Number of Staggered Gear Pieces and the Fertilizer Discharging Uniformity

Fix the gap between the two staggered gears at 5 mm, and conduct a single-factor test with 2, 3, and 4 pieces of staggered settings respectively, and extract the time series diagram of the number of fertilizer particles in the particle number monitoring area at the fertilizer discharging port, as shown in Figure 8.

It can be seen from Figure 8 that when there are 3 pieces of staggered gears, the fluctuation range of the number of particles is the smallest, and when there are 4 pieces, the fluctuation is the largest. Statistically calculate the number of fertilizer particles in the stable fluctuation stage of 1 s within 0.75 to 1.75 s, and calculate the coefficient of variation of the number of particles, which is 3.23%, 2.98%, and 3.35% for 2, 3, and 4 pieces respectively. The coefficient of variation of the number of particles of the 3 pieces of staggered gears is smaller than the other two, the fertilizer flow is more uniform, and the fertilizer discharging effect is better.

3.2.3 Relationship Between the Fertilizer Discharging Gap and the Fertilizer Discharging Uniformity

Based on 3 pieces of gear staggering, select 3 sets of fertilizer discharging wheels with fertilizer discharging gaps of 4, 5, and 6 mm for a single-factor test, and extract the time series diagram of the number of fertilizer particles in the particle number monitoring area at the fertilizer discharging port respectively, as shown.

4. Orthogonal Experiment

4.1 Experimental Design

According to the theoretical analysis of the fertilizer discharging process, the difference between the center distance of the gap meshing of the two fertilizer discharging wheels and the center distance in the meshing state, that is, the size of the gap of the fertilizer discharging wheel, directly affects the fertilizer discharge amount. If the gap is too large, the fertilizer will fall directly; if it is too small, the fertilizer will be stuck, affecting the normal operation. Since the number of staggered gear pieces is a discrete quantity, the orthogonal experiment method is used to design the experiment. The gap of the fertilizer discharging gear is set as the experimental factor, and the setting range is about 2 times the diameter of the fertilizer particle, that is, 4 – 6 mm. The number of staggered gear pieces of the fertilizer discharging wheel is set as the experimental factor, and the number of staggered gear pieces of the fertilizer discharging wheel is determined to be 2 – 4 pieces. The factor levels are shown in Table 2.

4.2 Experimental Scheme and Result Analysis

The L9(3^4) orthogonal table is selected for the orthogonal experiment. The experimental factors are the number of staggered pieces of the fertilizer discharging wheel A and the gap of the fertilizer discharging wheel B, and the experimental index is the coefficient of variation of the fertilizer discharging uniformity σ. Range analysis is carried out on the experimental results, and variance analysis is also carried out using Design – Expert 8.0.6. The results are shown in Table 3 and Table 4.

From Table 3, it can be seen that the primary and secondary relationship affecting the coefficient of variation is: the number of staggered pieces of the fertilizer discharging wheel, the gap of the fertilizer discharging wheel. A2B2 is the best parameter combination scheme, that is, the number of staggered pieces of the fertilizer discharging wheel is 3, and the gap of the fertilizer discharging wheel is 5 mm.

As can be seen from Table 4, the number of staggered gear pieces of the fertilizer discharging wheel has a highly significant impact on the coefficient of variation of the fertilizer discharging uniformity (P = 0.001 < 0.01); the gap of the fertilizer discharging gear has a significant impact on the coefficient of variation of the fertilizer discharging uniformity (0.01 < P = 0.0102 < 0.05).

5. Bench Test

According to NY/T 1003 – 2006 “Technical Specifications for Quality Evaluation of Fertilizer Application Machinery”, a bench test is carried out on the fertilizer discharger with staggered gears to verify the reliability and feasibility of the fertilizer discharger.

5.1 Experimental Materials and Methods

The experimental site is the Intelligent Agricultural Machinery Equipment Engineering Laboratory of Harbin Cambridge University, and the time is March 2023. Urea produced by Anyang Zhongying Chemical Fertilizer Co., Ltd. is selected as the experimental fertilizer. The gap of the fertilizer discharging wheel c = 5 mm, the number of staggered gear pieces e = 3, the number of gear teeth of the fertilizer discharging wheel z = 8, the diameter of the addendum circle of the fertilizer discharging wheel d = 80 mm, and the length of the fertilizer discharging wheel is 60 mm. A 3D printer is used to process the fertilizer discharger with staggered gears, and an experimental bench is built. The rotational speed of the motor is adjusted by the controller to drive the fertilizer discharger. A fertilizer collecting box is placed on the conveyor belt of the experimental bench to collect the discharged fertilizer. After the fertilizer discharging is completed, the fertilizer collected in the fertilizer collecting box is statistically analyzed. The experimental bench is shown in Figure 10. The double – gear fertilizer discharger (the cylindrical gear parameters are the same as those of the staggered gear) is replaced for a comparative test.

5.2 Results and Analysis

5.2.1 Comparative Test Results

The fertilizer discharging uniformity of the fertilizer discharger with staggered gears and the double – gear fertilizer discharger is compared. Set the same rotational speed of the fertilizer discharging wheel at 60 r/min, the test time at 2 s, and conduct 3 repetitions. Statistically analyze the relationship between the test uniformity and the fertilization amount. The experimental results show that the fertilizer discharge amount of the fertilizer discharger with staggered gears is 377.62 g, and the coefficient of variation is 4.74%. The average fertilizer discharge amount of the double – gear fertilizer discharger is 339.21 g, and the coefficient of variation is 15.42%. The relative error between the experimental and simulated fertilizer discharge amounts of the optimized fertilizer discharger with staggered gears is 4.19%. It is analyzed that the fertilizer discharger with staggered gears made by 3D printing is made of hard plastic, and the friction with the fertilizer particles is small, making it easy for the fertilizer to be discharged and the flow rate to increase, resulting in a larger fertilizer discharge amount. However, its relative error is less than 5%, indicating reliability. The relative error between the experimental and simulated coefficients of variation is 1.07%, verifying the correctness of the simulation optimization. Under the same conditions, the coefficient of variation of the fertilizer discharger with staggered gears is reduced by 10.68 percentage points compared with that of the double – gear fertilizer discharger, and the fertilizer discharging uniformity is effectively improved.

5.2.2 Development of Controller Verification Test

The single – factor test method is used to verify the adjustment effect of the fertilizer discharge amount of the fertilizer discharger with staggered gears designed in this paper. The rotational speeds of the fertilizer discharging wheel are 20, 30, 40, 50, and 60 r/min, a total of 5 levels. The fertilizer discharge amount of the fertilizer discharger working stably for 10 s is measured, and the fertilizer discharge amount per second is calculated as the test index. The test is repeated 5 times, and the average data is taken.

Origin software is used to linearly fit the rotational speed and the fertilizer discharge amount. The fitting equation is y = 5.26x + 45.03, and the determination coefficient R² = 0.99. The fertilizer discharge amount increases with the increase of the rotational speed of the staggered gear, and the fitting result of the two shows a linear positive correlation, as shown in Figure 11. To achieve precise fertilizer control, a fertilization controller is designed based on this function equation. This controller can real – time monitor the operation speed of the machine through the Beidou and GPS modules, and then control the fertilization amount through the rotational speed adjustment. To verify the fertilizer control performance of the controller, 3 rotational speeds are randomly selected for 3 repeated verification tests. The test results are averaged and compared with the preset values. The results are shown in Figure 12. It can be seen that the average deviation between the fertilizer discharge amount of the fertilizer discharger controlled by the electronic control system and the preset value is 3.1%, proving that the electronic control system can improve the fertilizer discharging uniformity through rotational speed control and achieve precise fertilizer control.

6. Conclusion

In this paper, based on the double – gear fertilizer discharger, a fertilizer discharger with staggered gears is designed. Aiming to improve the fertilizer discharging uniformity, combined with the discrete element method, single – factor test, and orthogonal test methods, the fertilizer discharging simulation analysis of this fertilizer discharger is carried out. The best parameter combination of the entity is obtained and verified. At the same time, a fertilization controller is developed to achieve precise fertilization. The main conclusions are as follows:

- The fertilizer discharging wheel with gears is improved by using the method of slicing and staggering. The fertilizer discharging wheel with staggered gears is designed. Using EDEM software to establish a discrete element simulation model, comparing and analyzing the fertilizer discharge flows of the two fertilizer dischargers, the fertilizer discharging wheel with staggered gears has an obvious fertilizer equalizing effect on the fertilizer discharger, which has research significance. Through theoretical analysis and parametric modeling volume identification, the number of staggered gear pieces and the gap of the fertilizer discharging wheel are determined to be the main factors affecting the fertilizer discharging uniformity.

- Combined with the previous research results of the team, single – factor tests and orthogonal tests are carried out to determine that the optimal structural parameter combination of the fertilizer discharger is 3 pieces of staggered gears and a gap of the fertilizer discharging wheel of 5 mm.

- The bench test is carried out with the optimal structural parameters. The results show that the coefficient of variation of the fertilizer discharging uniformity of the test is 4.74%, and the coefficient of variation of the fertilizer discharging uniformity of the double – gear fertilizer discharger under the same conditions is 15.42%. The fertilizer discharge amount of the test is almost the same as that of the simulation, verifying the reliability and feasibility of the fertilizer discharger with staggered gears. Based on the fertilizer discharger with staggered gears of the optimal parameters, Origin software is used to fit the fertilizer discharge amount data under different rotational speeds of the fertilizer discharging wheel, confirming that the fertilizer discharge amount can be linearly adjusted by controlling the rotational speed of the fertilizer discharging wheel.

- According to the fitting equation of the rotational speed – flow curve, a fertilization controller is developed. This controller can identify the instantaneous speed through GPS and Beidou to achieve the purpose of accurately controlling the actual fertilizer discharge amount. The results show that the deviation between the test value and the preset value is 3.1%, which can achieve precise fertilizer control.

The research results of this paper can provide a reference for the design and optimization of precise fertilizer dischargers, and have certain guiding significance for improving the level of agricultural fertilization. Future research can further explore the application of the fertilizer discharger with staggered gears in different fertilizers and soil conditions, and continuously optimize its performance to meet the actual needs of agricultural production.