This article delves into the crucial topic of helical cylindrical gear modification in the context of meshing dislocation. It comprehensively analyzes the influencing factors of meshing dislocation, including systematic and random errors, and elaborates on the calculation methods for meshing dislocation amounts. Through the design and implementation of gear modification strategies, a series of contrastive analyses are conducted. The research aims to enhance the understanding of gear meshing characteristics, improve the performance of gear transmissions, and provide valuable references for the optimization of gear design and manufacturing processes.

1. Introduction

1.1 Significance of Gear Transmission in Mechanical Systems

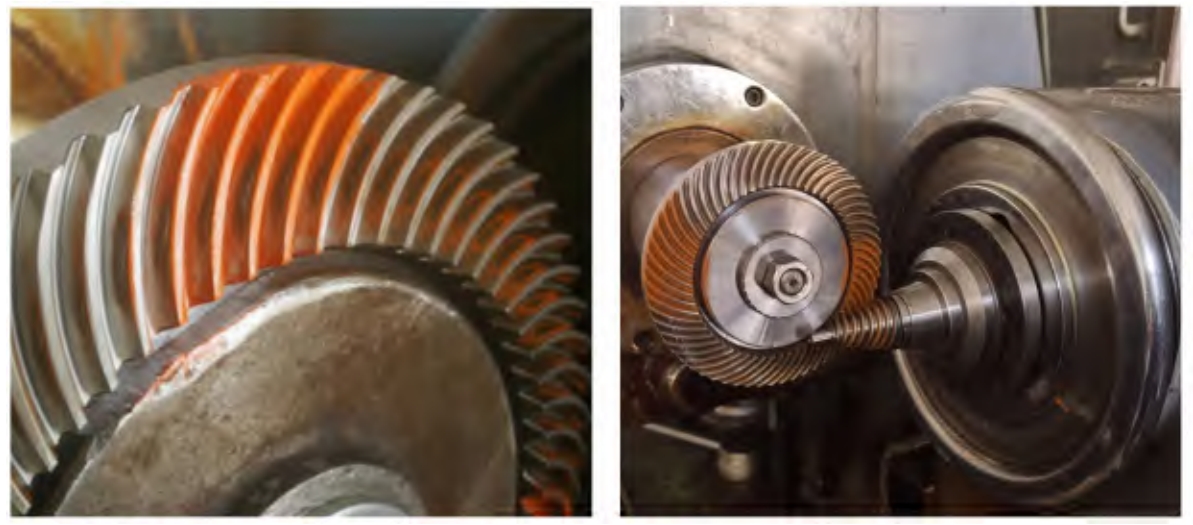

Gear transmission is a fundamental and vital component in mechanical systems, playing a crucial role in countless applications across various industries. In automotive engines, for instance, gears are responsible for smoothly transferring power from the engine to the wheels, ensuring efficient vehicle operation. In industrial machinery like conveyor belts, gear systems enable the precise control of movement and torque distribution, facilitating the seamless flow of production lines. Their ability to transmit motion and power with high efficiency and accuracy makes them indispensable in modern mechanical engineering.

1.2 Challenges Posed by Meshing Dislocation

However, meshing dislocation in gears presents a significant challenge. It disrupts the ideal contact between gear teeth, leading to uneven load distribution. As a result, the tooth surface may experience excessive stress concentration, which not only reduces the service life of the gears but also increases the risk of premature failure. This can cause unexpected breakdowns in mechanical equipment, resulting in costly downtime for repairs and maintenance. Additionally, meshing dislocation can generate vibrations and noise during gear operation, which not only affects the working environment but also potentially indicates underlying mechanical problems that could escalate if left unaddressed.

1.3 Research Objectives and Significance

The primary objective of this research is to develop effective strategies for gear modification to mitigate the negative impacts of meshing dislocation. By accurately analyzing the sources and degrees of meshing dislocation, we can design targeted modification methods. This research is of great significance as it can improve the load – bearing capacity and operational stability of gears, enhance the overall performance of mechanical systems, and reduce maintenance costs associated with gear failures. It also contributes to the advancement of gear design and manufacturing technology, enabling the development of more reliable and efficient gear – based products.

2. Analysis of Gear Meshing Dislocation

2.1 Definition and Classification of Meshing Dislocation

According to the ISO 6336 standard, meshing dislocation is defined as the maximum separation between corresponding points of two meshing gears along the tooth width direction, denoted by the symbol . It can be classified into three main types: parallel misalignment (caused by center – distance errors), misalignment parallel to the meshing plane (), and misalignment perpendicular to the meshing plane (). Among them, center – distance errors mainly affect the 重合度 of gear meshing and have a relatively minor impact on tooth – direction load distribution, so they can be neglected in this study. causes the actual contact surface to tilt, reducing the actual contact line length, but its impact on tooth – direction load distribution is minimal and is also ignored here. The focus is on , which is equivalent to helix deviation and can lead to stress concentration at one end of the tooth, exacerbating the problem of uneven load distribution on the tooth surface.

| Type of Meshing Dislocation | Symbol | Impact on Gear Meshing | Significance in This Study |

|---|---|---|---|

| Parallel Misalignment | – | Affects 重合度,minor impact on tooth – direction load distribution | Neglected |

| Misalignment Parallel to the Meshing Plane | Causes stress concentration, worsens tooth – direction load distribution | Main focus | |

| Misalignment Perpendicular to the Meshing Plane | Tilt the contact surface, minor impact on tooth – direction load distribution | Neglected |

2.2 Sources of Meshing Dislocation

The factors contributing to tooth – direction load distribution and meshing dislocation can be broadly divided into two categories: manufacturing and installation errors of gears, and deformation and clearances in components of the transmission system. In the ISO standard, the dislocation caused by manufacturing and installation errors is denoted as , the dislocation caused by the deformation of gears and support shafts is , the dislocation caused by the deformation of the gearbox is , and the dislocation caused by bearing clearances and deformation is . The overall meshing dislocation can be expressed as , where and are correction coefficients for deformation and manufacturing errors, and , are the deformations of the driving and driven wheel shafts respectively.

| Source of Meshing Dislocation | Symbol | Influence on Meshing Dislocation |

|---|---|---|

| Manufacturing and Installation Errors | Contribute to meshing dislocation, affected by factors like helix slope deviation and helix waviness deviation | |

| Deformation of Gears and Support Shafts | Result from load – induced or temperature – related deformations, affect meshing alignment | |

| Deformation of the Gearbox | Can cause the overall structure to shift, leading to meshing dislocation | |

| Bearing Clearances and Deformation | Alter the position and alignment of gears, contribute to meshing dislocation |

2.3 Calculation of Meshing Dislocation Amounts

2.3.1 Calculation of Systematic Meshing Dislocation Amount

ISO 6336 – 1:2006 provides three methods for calculating meshing dislocation: calculation based on experimental measurement results (Method A), calculation based on computer simulation (Method B), and calculation based on influence factor coefficients (Method C). In this study, Method B is employed. First, a global coordinate system for the system is defined, with the origin at the gearbox center. The axes are set as follows: the axis – length direction is the Z – axis (positive to the right), the center – distance direction of the gear pair is the Y – axis (positive from the driving gear to the driven gear), and the normal direction of the YOZ plane is the X – axis (determined by the right – hand rule).

To account for the influence of component stiffness and bearing clearances on gear transmission, a static analysis of the shaft is carried out. The shaft is divided into multiple segments (for example, shaft 1 is divided into 13 segments and shaft 2 into 15 segments, resulting in a total of 30 nodes). The process involves an iterative calculation. Initially, the tooth – surface load is assumed to be uniformly distributed along the tooth width, and the elastic deformation of the shaft is calculated using material mechanics methods as the initial deformation. Then, based on this deformation, the non – uniform load distribution is calculated, and this load distribution is used to calculate a new elastic deformation. This iterative process continues until the calculated deformation displacement or force converges. The total systematic meshing dislocation amount is obtained through equivalent projection transformation of the deformation displacements of each node.

2.3.2 Calculation of Random Meshing Dislocation Amount

For a gear pair with an ISO 7 – level accuracy, the helix slope deviation and helix waviness deviation of the two gears are both ±14μm, and their directions are random. The total random meshing dislocation amount caused by these two errors can be calculated by the formula , where is the working tooth width. The coefficient 2 takes into account the possibility that both gears may have the maximum helix slope deviation and the maximum helix waviness deviation simultaneously. However, since there is no relevant literature on converting this random meshing dislocation amount into an equivalent dislocation amount in the same way as the systematic meshing dislocation amount, a method proposed by Shehata et al. is referenced in the model of Case 3 to introduce this error.

3. Gear Modification Design

3.1 Objectives and Principles of Gear Modification

The main objectives of gear modification are to improve the contact performance of the tooth surface under the influence of meshing dislocation, optimize the load distribution on the tooth surface, and enhance the load – bearing capacity of the gears. The principles of gear modification involve carefully considering the calculated meshing dislocation amounts and the actual working conditions of the gears. By making targeted modifications to the tooth profile and tooth direction, we aim to minimize stress concentration, reduce vibration and noise, and extend the service life of the gears.

3.2 Common Gear Modification Methods

3.2.1 Tooth – Direction Modification

Tooth – direction modification is a key approach in compensating for meshing dislocation. It includes several common methods such as tooth – direction end – face chamfering, tooth – direction inclination, and tooth – direction crowning.

- Tooth – Direction End – Face Chamfering: This method is based on the equivalent dislocation amount along the meshing line of the gear pair. For example, in Case 1 and Case 3, if the right tooth surface of the driving gear has a concentrated load at the II – end, the modification direction is to chamfer from the I – end face to the II – end face. For quenched and tempered steel gears, the ISO provides empirical formulas to calculate the chamfering length and amount.

- Tooth – Direction Inclination: The direction of tooth – direction inclination should be consistent with that of the chamfering. It involves thinning the entire tooth width starting from the left tooth end. Acceptable modification amounts range from 10μm to 25μm. The modification amounts for different cases are determined based on the specific calculated values of meshing dislocation.

- Tooth – Direction Crowning: This modification is focused on the middle part of the tooth width. Since it can only be achieved by removing material, only the crowning amount needs to be determined. The crowning amounts for different cases are calculated considering the systematic and random meshing dislocation amounts.

| Tooth – Direction Modification Method | Modification Principle | Calculation Method for Different Cases |

|---|---|---|

| Tooth – Direction End – Face Chamfering | Based on equivalent meshing – line dislocation | Empirical formulas considering gear material and meshing conditions |

| Tooth – Direction Inclination | Consistent with chamfering direction, full – width thinning | Determined by calculated meshing dislocation and acceptable range |

| Tooth – Direction Crowning | Focus on tooth – width middle, material removal | Calculated considering systematic and random meshing dislocation |

3.2.2 Tooth Profile and Diagonal Modification

For wide – helical gears, although there may be no significant load fluctuations due to single – and double – tooth meshing alternation, to improve the load – bearing capacity, it is necessary to shorten the length of the single – tooth meshing area under full load and make the load change more gradual during double – tooth meshing. Common tooth profile modification methods include tooth – tip/tooth – root chamfering, end – face tooth profile modification, and tooth profile crowning. Diagonal modification, which can be divided into tooth – tip engaging – angle modification () and tooth – root disengaging – angle modification (), can replace tooth profile modification to simplify the modification process. The modification parameters such as the modification starting position, length, and amount are determined based on the tooth – surface load distribution results of the gear pair.

4. Contact Analysis and Comparison

4.1 Evaluation Indicators for Gear Meshing Quality

To assess the effectiveness of gear modification in compensating for meshing dislocation, several evaluation indicators are used, including transmission error, contact spots on the working tooth surface of the driving gear, and tooth – root stress of the driving gear. Transmission error reflects the smoothness of gear meshing, with smaller values indicating more stable operation. Contact spots and tooth – root stress distributions can directly reflect the load – bearing conditions and stress states of the gear teeth, providing important information for evaluating the performance of gear modification.

4.2 Results and Analysis of Contact Analysis for Different Cases

Four different cases are analyzed: Case 1 represents a gear pair with systematic – error – induced dislocation but without modification; Case 2 has systematic meshing dislocation and is modified; Case 3 includes random – error – induced dislocation without modification; and Case 4 has both types of dislocations and is modified.

The transmission error curves of the gear pairs in different cases show that Case 1 has a relatively large transmission error and obvious fluctuations, indicating unstable meshing. After modification in Case 2, although the overall transmission error value may increase slightly due to material removal, the fluctuation is significantly reduced, improving the smoothness of gear meshing. Case 3 shows that the random – error – induced dislocation has a relatively small impact on the transmission error, and Case 4 also demonstrates an improvement in transmission performance compared to Case 3.

Regarding the contact spots and tooth – root stress, Case 1 exhibits a typical non – uniform load distribution, with the maximum load on the right – hand side of the tooth surface and stress concentration at the meshing – in end of the gear. After modification in Case 2, the load distribution on the tooth surface becomes more uniform, and the tooth – root stress is significantly reduced and shifted towards the middle of the tooth width. Case 3 has a similar stress distribution pattern to Case 1, with only a slight increase in numerical values. In Case 4, although the stress amplitude is reduced and the stress distribution becomes more uniform after modification, the modification effect is not as good as that in Case 2, indicating that gear modification has limited compensation for random – error – induced meshing dislocation.

| Case | Transmission Error (μm) | Contact Spot Characteristics | Tooth – Root Stress (MPa) |

|---|---|---|---|

| Case 1 | Max: 10.66, Mean: 9.71, Fluctuation: 1.71 | Uneven, concentrated on one side | 275.5 (concentrated at meshing – in end) |

| Case 2 | Higher than Case 1, Fluctuation: 1.03 | More uniform distribution | 180.6 (shifted towards middle) |

| Case 3 | Max: 10.67, Mean: 9.71, Fluctuation: 1.79 | Similar to Case 1 | Slightly higher than Case 1 |

| Case 4 | Improved compared to Case 3 | More uniform, but less effective than Case 2 | Reduced, more uniform but less effective than Case 2 |

5. Conclusion

5.1 Summary of Key Findings

In this research, several important findings have been obtained. Among the systematic factors, bearing deformation has the most significant impact on the meshing dislocation amount, and the effects of different systematic factors can either superimpose or offset each other. Among the random factors, helix deviation has the greatest influence on meshing dislocation, and the effects of random factors are cumulative. Systematic – factor – induced meshing dislocation is the dominant factor affecting the smoothness and load – bearing capacity of gear transmission. The combined modification method of tooth – direction modification and diagonal modification can effectively compensate for the impact of systematic – factor – induced meshing dislocation, but has little effect on compensating for the load – unevenness caused by random meshing dislocation.

5.2 Implications for Gear Design and Manufacturing

These findings have important implications for gear design and manufacturing. In the design stage, more attention should be paid to reducing the influence of systematic factors, especially bearing – related factors, to minimize meshing dislocation. When manufacturing gears, stricter control over helix – related errors can help reduce random meshing dislocation. Additionally, the application of appropriate gear modification methods can improve the performance of gear transmissions, enhance the reliability of mechanical systems, and reduce production and maintenance costs.

5.3 Future Research Directions

Future research can focus on further exploring more accurate methods for calculating and compensating for random meshing dislocation. Developing new gear modification techniques or optimizing existing ones based on advanced materials and manufacturing processes can also be potential research directions. Moreover, studying the long – term effects of meshing dislocation and gear modification on gear fatigue life and system durability will provide more in – depth understanding and contribute to the continuous improvement of gear – based mechanical systems.