1. Introduction

Metro systems have become an essential part of urban transportation around the world, carrying millions of passengers daily. Ensuring the reliable operation of metro vehicles is crucial for the safety and efficiency of urban transportation. The gearbox, as a core component of the metro vehicle’s bogie, plays a vital role in power transmission. Any malfunction of the gearbox can lead to serious consequences, such as derailment, service disruption, and even endanger the safety of passengers.

Despite the continuous improvement of technology, gearbox failures still occur frequently during the maintenance process. Common problems include oil leakage, paint peeling of the housing, and seal failure. These issues not only affect the normal operation of metro vehicles but also increase maintenance costs. Currently, the maintenance of metro vehicle gearboxes mainly relies on scheduled maintenance. Therefore, it is of great significance to scientifically analyze the causes, impacts, and patterns of failures during maintenance, promote design improvements, and optimize maintenance strategies to reduce failure rates and their impacts, thereby enhancing the operational reliability of gearboxes.

Failure Mode, Effects, and Criticality Analysis (FMECA) is a systematic reliability analysis method. It comprehensively considers the failure modes, failure effects, and failure rates of components or systems, calculates the failure criticality, and quantifies the weak links, which provides a basis for post – failure improvement and pre – failure prevention. FMECA has been widely applied in the design and maintenance guidance of fields such as rail transit, aerospace, and military industry, and has achieved good guiding results. This paper focuses on applying the FMECA method to the reliability research of metro vehicle gearboxes, aiming to provide references for gearbox design improvement and daily maintenance.

2. Metro Vehicle Gearbox Function and Structure

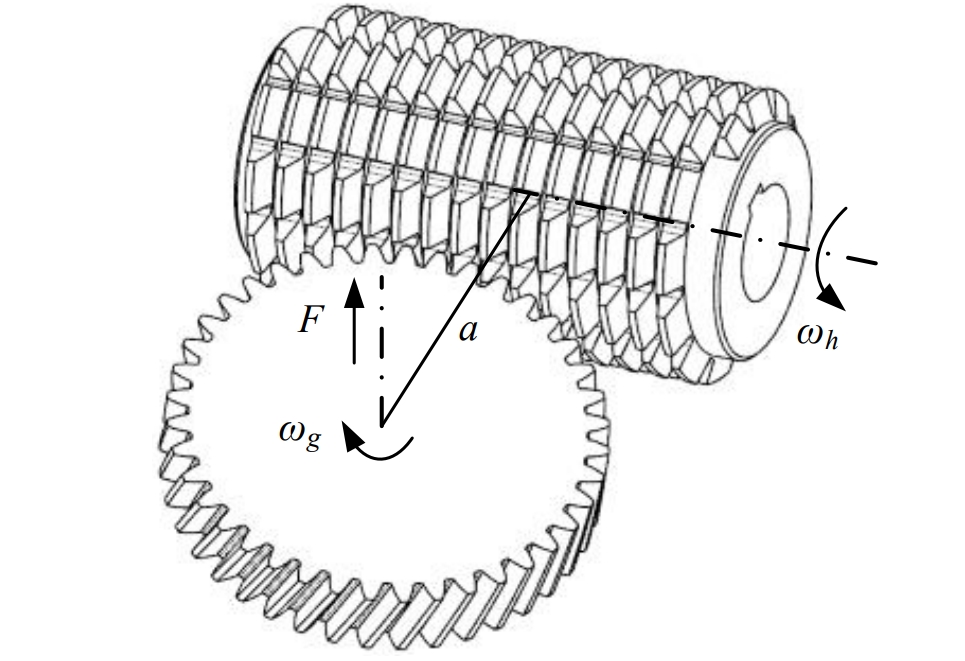

2.1 Gearbox Function

The gearbox serves to transfer the torque of the traction motor from the small gear to the large gear and the axle, driving the train to move. It plays a crucial role in the power – transmission system of metro vehicles, ensuring the smooth operation of the train under different working conditions. Without a properly functioning gearbox, the efficient transfer of power from the motor to the wheels cannot be guaranteed, which may lead to problems such as poor acceleration, abnormal noise, and even complete failure of the vehicle’s propulsion system.

2.2 Gearbox Structure

The gearbox system consists of multiple components, including the housing, large gear, small gear shaft, bearings, hanging devices, etc. The large gear has an interference fit with the axle, ensuring a stable connection during power transmission. The small gear shaft is connected to the traction motor through a coupling, enabling the transfer of torque. The lubricating oil inside the housing plays a vital role in reducing friction and wear between the moving parts, such as the large gear, small gear shaft, and bearings. The housing is connected to the bogie frame through a hanging device, providing support and stability for the gearbox. A functional block diagram of the gearbox is shown in Figure 1.

| Component | Function |

|---|---|

| Housing | Protects internal components, provides a container for lubricating oil, and connects to the bogie frame |

| Large Gear | Transmits torque to the axle |

| Small Gear Shaft | Receives torque from the traction motor and transfers it to the large gear |

| Bearings | Support the rotation of shafts and reduce friction |

| Hanging Device | Connects the gearbox to the bogie frame |

| Lubricating Oil | Lubricates moving parts, reduces friction and wear |

3. Metro Vehicle Gearbox FMECA Analysis

3.1 FMECA Composition

FMECA is composed of Failure Mode and Effects Analysis (FMEA) and Criticality Analysis (CA). FMEA focuses on analyzing the impact of failures on functions and classifying the severity of failure modes, which is convenient for formulating improvement and optimization measures. CA pays more attention to comprehensively analyzing the severity and failure rate of failures, and quantitatively evaluating the impact of failures. By combining these two parts, a comprehensive understanding of the reliability of the gearbox can be achieved.

3.2 Metro Vehicle Gearbox FMEA

3.2.1 Severity Level Classification

In line with the characteristics of rail transit vehicles and referring to relevant national standards such as GB/T 21562 – 2008 “Rail Transit – Reliability, Availability, Maintainability and Safety – Specifications and Examples” and GB/T 7826 – 2012 “System Reliability Analysis Techniques – Failure Mode and Effects Analysis (FMEA) Procedures”, the severity of failure modes is divided into four levels: catastrophic, major, minor, and slight. The specific classification results are shown in Table 1.

| Level | Severity Level | Impact on Environment or People | Impact on Operation |

|---|---|---|---|

| I | Catastrophic | Multiple deaths, and/or multiple serious injuries, and/or significant damage to the environment | System failure |

| II | Major | One death, and/or a single serious injury, and/or obvious damage to the environment | Main system failure |

| III | Minor | Minor injuries and/or obvious impact on the environment | Severe system damage |

| IV | Slight | Possible minor injuries | Minor system damage |

Table 1 Severity Level Classification

3.2.2 Typical Failure Modes and FMEA Results

Typical failure modes of metro vehicle gearboxes include gear tooth breakage and wear, housing cracks, lubricating oil emulsification or darkening, housing oil leakage, abnormal bearing temperature rise, bolt fracture or loosening, and suspension device failure. In practical applications, common failures also include lubricating oil leakage, loss of process plugs, and paint peeling of the housing. Combining industry standards and practical experience accumulated during daily maintenance, the FMEA results of a certain metro gearbox are obtained, as shown in Table 2.

| Failure Mode | Failure Cause | Failure Effect | Impact on Train Operation | Severity Level |

|---|---|---|---|---|

| Bearing Outer Ring Cracking | Excessively long positioning pin of the gland presses the bearing outer ring | Axle locking | Initiate rescue procedures | II |

| End Cover Bolt Fracture | Bolt material strength does not meet the requirements | Components are not firmly installed, and the seal is not tight | Stop for inspection and repair | III |

| Foreign Objects in Lubricating Oil | Inadequate cleaning | Affects lubrication effect | Stop for inspection and repair | III |

| Oil Leakage at the Seal Ring | Seal felt failure, no sealant applied during assembly | Affects lubrication effect | Stop for inspection and repair | III |

| Oil Leakage at the Oil Injection and Drainage Ports | Seal gasket failure | Affects lubrication effect | Stop for inspection and repair | III |

| Loss of Process Plug | Insufficient interference | Process plug contamination | No safety impact | IV |

| Nameplate Falling off | Rivet failure | Unable to read information | No safety impact | IV |

| Housing Paint Peeling | Oil and dirt not cleaned thoroughly before painting | Surface corrosion | No safety impact | IV |

Table 2 Metro Vehicle Gearbox FMEA Results

3.3 Metro Vehicle Gearbox CA

3.3.1 Calculation Theoretical Basis

Criticality Analysis (CA) can quantitatively analyze the impact of failures and comprehensively determine the impact of failure modes. Under a specific severity level, the formula for calculating the criticality of a certain failure mode of a component is:

Where is the failure mode frequency ratio, that is, the ratio of the number of occurrences of the – th failure mode of the component to the total number of failure modes of the product; is the failure mode impact probability, which is the conditional probability that the “initial agreed level” will reach a certain severity level under the condition that the – th failure mode occurs. It is generally judged by analysts based on experience and can refer to Table 3. is the failure rate, which is usually statistically calculated according to the operating mileage, and is the product working time.

The formula for calculating the failure rate used in this paper is:

Where is the number of failures of a certain component within the statistical period, is the total number of a certain component on the train, and is the annual running kilometer of the train within the statistical period. The annual running mileage of a certain metro train is about 100,000 km, and the unit of the failure rate in this statistical calculation is set as “times/100,000 km”.

| Failure Impact | Value |

|---|---|

| Component is definitely damaged and loses its function | 1.0 |

| Component may be damaged and lose its function | 0.5 |

| Component is rarely damaged and loses its function | 0.1 |

| No impact on the component | 0 |

Table 3 Failure Mode Impact Probability Value Reference

3.3.2 Calculation Results Analysis

Based on the failure data recorded at the maintenance site, the component criticality of the gearbox within 0 – 100,000 km is calculated to be 17.76. The specific failure modes and their criticalities are shown in Table 4.

| Failure Code | Failure Mode | Severity Level | Failure Mode Frequency Ratio | Failure Mode Impact Probability | Failure Rate | Failure Mode Criticality |

| — | — | — | — | — | — |

| F1 | Bearing Outer Ring Cracking | II | 0.052 | 1.0 | 0.007 | 1.04 |

| F2 | End Cover Bolt Fracture | III | 0.034 | 0.5 | 0.003 | 0.15 |

| F3 | Foreign Objects in Lubricating Oil | III | 0.172 | 0.1 | 0.093 | 4.57 |

| F4 | Oil Leakage at the Seal Ring | III | 0.259 | 0.1 | 0.069 | 5.11 |

| F5 | Oil Leakage at the Oil Injection and Drainage Ports | III | 0.190 | 0.1 | 0.102 | 5.54 |

| F6 | Loss of Process Plug | IV | 0.155 | 0.1 | 0.010 | 0.44 |

| F7 | Nameplate Falling off | IV | 0.069 | 0.1 | 0.009 | 0.18 |

| F8 | Housing Paint Peeling | IV | 0.069 | 0.1 | 0.037 | 0.73 |

Table 4 Gearbox Failure Mode CA

According to the criticality analysis results, a gearbox criticality matrix is drawn, as shown in Figure 2. Draw a diagonal line from the origin to the intersection of the maximum criticality and the highest severity level. Draw a horizontal line through the criticality of each failure mode. The horizontal line intersects with the corresponding criticality level to form a point. Draw a perpendicular line from this point to the diagonal line. The farther the foot of the perpendicular is from the origin, the greater the criticality of the failure mode.

From the analysis of the criticality matrix:

- The top 3 failure modes in terms of criticality are oil leakage at the oil injection and drainage ports, oil leakage at the seal ring, and foreign objects in the lubricating oil. These are the key points that should be focused on during inspection and design.

- The bearing outer ring cracking, which ranks first in terms of severity, is a design defect. Attention should be paid to strengthening the control of details in design and production processes to improve the reliability of components from the source.

After the metro vehicle runs 100,000 km, the failures of the gearbox are mainly concentrated in oil leakage at the seal ring and loss of process plugs. The trend of component criticality within one overhaul cycle of the metro vehicle is shown in Figure 3. It can be seen from the figure that the highest – criticality interval of components within one overhaul cycle is 0 – 100,000 km, and the criticality significantly decreases after 100,000 km. This indicates that the first 100,000 km of the gearbox operation is a weak link in reliability, and it is necessary to pay more attention to it during daily maintenance and strengthen inspections.

4. Suggestions for Improving Gearbox Reliability

4.1 Component Design Optimization

- The sealing parts at the oil injection and drainage ports of the gearbox are cast – iron sealing rings with rubber inner rings, and their sealing effect is not as good as that of copper – based sealing rings. It is recommended to consider design – type replacement.

- Since the problem of process plug loss persists throughout the overhaul cycle, it is advisable to apply fastening glue during factory installation.

- The reason for the fracture of the end – cover bolts is the insufficient strength of the bolt material. During the design process, more attention should be paid to strengthening the material strength verification and analysis.

- The nameplate falls off due to rivet failure. It is recommended to change to screw fastening and apply fastening glue on the back of the nameplate.

- The cause of the bearing outer ring cracking is the excessively long positioning pin of the end cover. It is necessary to ensure that the gap between the inclined surface of the positioning pin and the bottom of the stop groove is greater than 0.3 mm.

| Component | Problem | Suggested Optimization |

|---|---|---|

| Oil Injection and Drainage Port Sealing Parts | Poor sealing effect | Replace with copper – based sealing rings |

| Process Plug | Prone to loss | Apply fastening glue during installation |

| End – Cover Bolts | Fracture due to insufficient material strength | Strengthen material strength verification |

| Nameplate | Falling off due to rivet failure | Change to screw fastening and apply glue |

| Bearing Outer Ring | Cracking due to long positioning pin | Ensure proper gap of positioning pin |

4.2 Production Process Optimization

- Regarding the problem of oil leakage at the seal ring, it is recommended to apply sealant at the seals of the end cover, cup sleeve, etc. during gearbox assembly to improve the sealing effect.

- The presence of foreign objects in the lubricating oil is due to inadequate cleaning of impurities in the housing during assembly. The housing cleaning process should be optimized, and comprehensive and in – depth cleaning should be carried out during assembly.

- Housing paint peeling is concentrated at the joints of the rib plates, which are difficult – to – clean areas. It is recommended to strengthen the cleaning and inspection of these areas before painting to ensure that the surface is dry and free of oil.

| Problem | Root Cause | Optimization Measure |

|---|---|---|

| Oil Leakage at the Seal Ring | Poor sealing | Apply sealant during assembly |

| Foreign Objects in Lubricating Oil | Inadequate cleaning during assembly | Optimize housing cleaning process |

| Housing Paint Peeling | Difficult – to – clean areas | Strengthen cleaning and inspection before painting |

4.3 Maintenance Strategy Optimization

- Since the failure criticality of the gearbox is relatively high during the first 100,000 km of operation, during operation, it is necessary to strengthen the inspection of items such as lubricating oil and the appearance condition in combination with train inspections. If necessary, a noise – monitoring inspection can be set up when the train returns to the depot. After 100,000 km, the inspection cycle can be appropriately extended.

- During equal – time maintenance, it is necessary to promptly clean the dust on the seal ring, drain hole, oil – level mirror, etc., which is convenient for train inspection operations to detect failures in a timely manner.

- After completing the lubricating oil replacement operation, it is necessary to promptly clean the oil stains at the oil injection and drainage ports with a cloth to avoid misjudging failures.

| Maintenance Stage | Suggested Action |

|---|---|

| First 100,000 km | Strengthen inspections, set up noise – monitoring |

| After 100,000 km | Extend inspection cycle |

| During Equal – Time Maintenance | Clean relevant parts |

| After Lubricating Oil Replacement | Clean oil injection and drainage ports |

4.4 Optimization Measures Effect Analysis

A certain brand of gearbox in Zhengzhou Metro optimized the design and production process based on the weak links obtained from FMECA. For the gearboxes that were rectified on – site and newly produced in subsequent projects, no similar problems occurred again, indicating that the optimization effect is obvious, which verifies the effectiveness of the optimization measures. The maintenance strategy optimized with reference to the FMECA results, when implemented in daily maintenance, can effectively avoid missed inspections, missed repairs, or misdiagnoses of gearbox failures, and at the same time improve the operation efficiency.

5. Conclusion

This paper takes a certain metro vehicle gearbox as the research object, analyzes its failure modes, failure causes, criticalities, and their changing trends over time by using the FMECA method, and puts forward optimization and improvement suggestions for the design, manufacturing, and maintenance strategies of the gearbox.

- Failure modes such as oil leakage at the oil injection and drainage ports, oil leakage at the seal ring, and foreign objects in the lubricating oil rank high in terms of criticality. During design and production, corresponding optimizations should be carried out from aspects such as material selection, applying sealant, and timely cleaning to improve the operational reliability of the gearbox.