1. Introduction

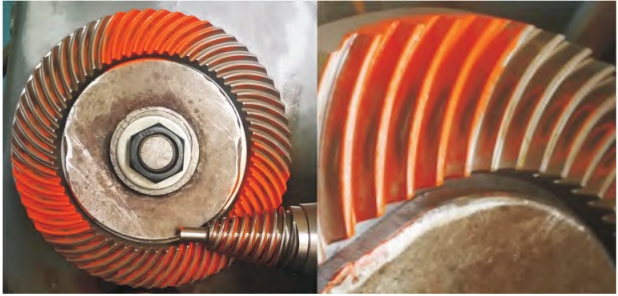

Variable Hyperbolic Circular Arc Tooth Trace (VHCATT) cylindrical gears represent a novel transmission mechanism that combines the advantages of straight, helical, and herringbone gears. Their unique tooth geometry, featuring a hyperbolic arc tooth trace and involute profiles, offers potential improvements in load-bearing capacity and dynamic performance. However, challenges such as uneven load distribution and excessive transmission errors remain critical issues. This paper explores the application of tooth surface modification techniques and load tooth contact analysis (LTCA) to address these challenges, providing insights for optimized gear design.

2. Tooth Surface Modification Techniques

2.1 Cutter Inclination Method (Tooth Trace Direction)

The cutter inclination method modifies the tooth trace by tilting the milling cutter during manufacturing. This approach alters the curvature of the tooth trace, influencing load distribution. Key parameters include the cutter inclination angle (γ) and the radius of the tooth trace (RT). Table 1 summarizes the effects of varying γ on contact characteristics:

| Cutter Inclination Angle (γ) | Contact Area Width | Peak Tooth Load | Transmission Error Amplitude |

|---|---|---|---|

| 0° (Unmodified) | Narrow | High | Large |

| 3° | Slightly Wider | Moderate | Reduced |

| 5° | Wider | Low | Significantly Reduced |

| 7° | Widest | Lowest | Minimal |

Figure 1: Schematic of Cutter Inclination during Milling

2.2 Parabolic Blade Modification (Tooth Profile Direction)

This method employs a parabolic curve to modify the tooth profile, reducing stress concentrations at the tooth tips and roots. The parabolic coefficient (a) and vertex position (u₀) are critical parameters. Table 2 illustrates their effects:

| Parabolic Coefficient (a) | Tooth Tip/ Root Clearance | Load Transition Smoothness | Transmission Error at Engagement |

|---|---|---|---|

| 0 (Unmodified) | Small | Abrupt | High |

| -0.00005 | Moderate | Improved | Moderate |

| -0.00010 | Large | Smooth | Low |

| -0.00050 | Excessive | Overly Smooth | Very Low (Risk of Non-Contact) |

Figure 2: Parabolic Tooth Profile Modification

3. Load Tooth Contact Analysis (LTCA)

3.1 Finite Element Modeling

A finite element model (FEM) was developed using ABAQUS to compute the contact flexibility matrix. The model considers both single and double tooth contact scenarios, as shown in Figure 3. Key steps include:

- Discretization of the tooth surface into nodes.

- Application of distributed loads to simulate real-world operating conditions.

- Calculation of deformations and stress distributions.

Figure 3: FEM Model for Contact Analysis

3.2 Contact Mechanics

The Hertz contact theory was adapted to analyze contact stress distributions. Table 3 compares contact parameters for modified and unmodified gears:

| Parameter | Unmodified Gear | Modified Gear (γ=5°, a=-0.00010) |

|---|---|---|

| Maximum Contact Stress (MPa) | 1200 | 850 |

| Contact Ellipse Length (mm) | 2.5 | 3.8 |

| Load Sharing Ratio | 0.6 (Single Tooth) | 0.8 (Double Tooth) |

Figure 4: Contact Stress Distribution Comparison

4. Results and Discussion

4.1 Influence of Cutter Inclination (γ)

Increasing γ broadens the contact area, reducing peak stresses and transmission errors. Figure 5 shows the relationship between γ and transmission error amplitude:

Figure 5: Transmission Error vs. Cutter Inclination Angle

4.2 Effect of Parabolic Coefficient (a)

Optimizing a improves load transition between single and double tooth contact. However, excessive values lead to non-contact at the tooth tips. Figure 6 illustrates load distribution across the tooth width:

Figure 6: Load Distribution with Varying Parabolic Coefficients

4.3 Impact of Vertex Position (u₀)

Shifting u₀ adjusts the balance between tooth tip and root modifications. Table 4 summarizes the optimal parameters for different applications:

| Application | Optimal γ | Optimal a | Optimal u₀ (mm) |

|---|---|---|---|

| Heavy Load | 5°-7° | -0.00005 to -0.00010 | -3.0 to -1.5 |

| High-Speed Transmission | 3°-5° | -0.00005 | -1.5 to 0 |

| General-Purpose | 5° | -0.00005 | -1.5 |

Figure 7: Vertex Position Effects on Load Distribution

5. Dynamic Performance Evaluation

5.1 Transmission Error Analysis

Transmission error (TE) is a critical indicator of gear dynamics. Figure 8 compares TE profiles for modified and unmodified gears under varying loads:

Figure 8: Transmission Error vs. Load for Modified and Unmodified Gears

5.2 Vibration Response

Modified gears exhibit reduced vibration amplitudes due to smoother load transitions. Figure 9 shows acceleration spectra at 1000 N·m load:

Figure 9: Vibration Spectra Comparison

6. Industrial Applications

VHCATT gears with optimized modifications are suitable for various industries:

- Automotive: Reduced noise and improved torque transmission in differentials.

- Aerospace: High-strength, lightweight solutions for aircraft gearboxes.

- Heavy Machinery: Enhanced durability in mining and construction equipment.

Table 5: Industrial Applications and Benefits

| Industry | Benefit |

|---|---|

| Automotive | Noise reduction, improved fuel efficiency |

| Aerospace | High power density, reliability |

| Heavy Machinery | Extended service life, lower maintenance costs |

7. Conclusion

This study demonstrates that tooth surface modification techniques, combined with LTCA, significantly enhance the performance of VHCATT cylindrical gears. Key findings include:

- Cutter inclination (γ=5°-7°) optimizes contact area and reduces transmission errors.

- Parabolic modification (a=-0.00005 to -0.00010) improves load transition but requires careful clearance management.

- Vertex position (u₀=-3.0 to -1.5 mm) balances tooth tip/root stress distributions.

Future research should explore multi-objective optimization integrating manufacturing constraints and real-world operational conditions.