This article delves deep into the tooth – staggering phase tuning method for spur gear drives, which is a crucial approach in controlling gear vibration and noise. By exploring the meshing principle, calculating the time – varying meshing stiffness, conducting experimental research, and analyzing the results, a comprehensive understanding of this method is achieved. The aim is to provide valuable insights and practical guidance for improving the performance of gear transmission systems.

1. Introduction

1.1 The Significance of Gear Vibration and Noise Control

Gears are fundamental components in mechanical transmission systems, and their vibration and noise levels significantly impact the overall performance, efficiency, and service life of the systems. High – level vibration and noise not only cause discomfort to operators but also lead to increased wear and tear, reduced precision, and potential mechanical failures. For example, in automotive transmissions, excessive gear noise can deteriorate the driving experience, while in industrial machinery, it may indicate impending component failures, resulting in costly downtime. Therefore, the control of gear vibration and noise has become a critical area of research in mechanical engineering.

1.2 Current Vibration Control Methods for Gear Transmission Systems

Currently, several methods are employed to control the vibration of gear transmission systems. These include increasing the contact ratio, gear profile modification, gear shifting, and adding damping elements. Increasing the contact ratio can distribute the load more evenly among the teeth, reducing the impact on individual teeth and thus lowering vibration. Gear profile modification, such as tooth crowning and tip relief, can optimize the meshing process and minimize the generation of dynamic loads. Gear shifting can adjust the gear ratio to avoid resonance frequencies. Damping elements, like rubber mounts or viscous dampers, can absorb and dissipate vibration energy. However, each of these methods has its limitations, and there is a continuous need for new and more effective vibration control techniques.

1.3 The Emergence of the Tooth – Staggering Phase Tuning Method

The tooth – staggering phase tuning method is a relatively new approach that shows great potential in reducing gear vibration. It involves splitting a gear with a certain width into multiple thinner gears and staggering them at specific angles. This simple yet innovative modification can change the meshing characteristics of the gear pair, leading to a reduction in vibration and noise. The concept has attracted the attention of researchers worldwide, and this article aims to comprehensively explore its principles, implementation, and effectiveness.

2. Principle of Tooth – Staggering Phase Tuning

2.1 Tooth – Staggering Phase Tuning Gears

A gear with a width of b is divided into n thinner gears, each with a width of \(\frac{b}{n}\). These thinner gears are then staggered by a specific angle, creating a phase difference between the meshing of each pair of gears. This phase difference can be adjusted to optimize the gear transmission performance. For instance, in a parallel – shaft single – stage transmission system with two meshing pairs, if one side of the gear remains stationary and the other side rotates along the circumferential direction, different phase differences can be achieved. When the rotation angle corresponds to a standard tooth – slot width \(\frac{\pi m_{r}}{2}\), the meshing stiffness function curve of the gear pair is shifted by half a meshing period \(T_{m}/2\) compared to the standard meshing stiffness function curve. The relationship between the tooth – staggering phase P and the tooth – staggering phase angle \(\varphi\) is given by \(p = \frac{\varphi}{2\pi/z}\), where z is the number of teeth of the driving gear.

| Parameter | Definition | Formula |

|---|---|---|

| Tooth – staggering phase P | A measure of the relative phase shift between meshing gears | \(p=\frac{\varphi}{2\pi/z}\) |

| Tooth – staggering phase angle \(\varphi\) | The angle by which the gears are staggered | \(\varphi = mod(\varphi_{0},\frac{2\pi}{z})\) |

| Standard tooth – slot width | A geometric parameter of the gear | \(\frac{\pi m_{r}}{2}\) |

| Meshing period \(T_{m}\) | The time taken for one complete meshing cycle | – |

2.2 Transmission Principle of Tooth – Staggering Phase Tuning Gears

Due to the circumferential staggering of adjacent gears, the corresponding teeth of the two meshing gear pairs do not enter the actual meshing zone simultaneously. For standard spur gears with a contact ratio \(1 < \varepsilon<2\), the meshing process alternates between single – tooth meshing and double – tooth meshing. In the case of tuned spur gears, by adjusting the tooth – staggering phase angle, when one meshing pair is in the single – tooth meshing zone, the other can be in the double – tooth meshing zone, and vice versa. This results in a more continuous and stable meshing process. For example, in a standard spur gear, the contact line length of the meshing pair fluctuates between 2b and b. In a tooth – staggering phase – tuned spur gear pair, the total number of meshing teeth and the contact line length can be adjusted, which is beneficial for reducing vibration.

| Gear Type | Meshing Characteristics | Contact Line Length Variation |

|---|---|---|

| Standard spur gear | Single – tooth and double – tooth meshing alternate periodically | Fluctuates between 2b and b |

| Tooth – staggering phase – tuned spur gear | Meshing of different pairs occurs at different times | Can be adjusted to have more stable meshing and different contact line lengths (e.g., 2b, 3b, 4b) |

3. Meshing Stiffness of Tooth – Staggering Phase Tuning Gears

3.1 Definition and Basic Formula of Meshing Stiffness

The meshing stiffness function is defined as the sum of an average value and a variable part, i.e., \(k(t)=\overline{k}+\Delta k(t)\), where \(\overline{k}\) is the average value of the meshing stiffness over one cycle, and \(\Delta k(t)\) is the variable part that changes periodically with time. For a tooth – staggering phase – tuned gear pair, if the meshing stiffnesses of two adjacent gear pairs are \(k^{(1)}(t)\) and \(k^{(2)}(t)\) with initial meshing phases \(p^{(1)}\) and \(p^{(2)}\) respectively, the meshing stiffness of each gear pair after considering the tooth – staggering phase tuning is \(k_{d}(t)=\frac{1}{2}[k^{(1)}(t)+k^{(2)}(t)]\).

3.2 Influence of Tooth – Staggering Phase on Meshing Stiffness

The amplitude J of the variable part of the meshing stiffness of the tooth – staggering phase – tuned gear is related to parameters such as \(\alpha_{1}\), \(\alpha_{2}\), \(\alpha_{3}\), and P. It is found that the meshing stiffness amplitude is not only related to the tooth – staggering phase but also to the original gear contact ratio. For example, for a pair of spur gears with a contact ratio \(\varepsilon_{0}=1.6924\), when the tuning order \(n = 3\), the meshing stiffness fluctuation is the smallest. This is because when the contact ratio proportion coefficient is \(\frac{c}{3}\) (c is an integer), the single – tooth and double – tooth meshing regions are in a multiple relationship. In the case of \(\varepsilon_{0}\approx1.66\) with a proportion coefficient of approximately \(\frac{2}{3}\), the double – tooth meshing region is close to twice the single – tooth meshing region, and a meshing cycle can be divided into three equal time zones.

| Contact Ratio \(\varepsilon_{0}\) | Proportion Coefficient \(\lambda\) | Optimal Tuning Order n | Meshing Stiffness Fluctuation |

|---|---|---|---|

| 1.506 | \(\frac{1}{2}\) | 2 | Reduced |

| 1.66 | \(\frac{2}{3}\) | 3 | Minimized |

| 1.75 | \(\frac{3}{4}\) | 4 | Reduced |

4. Experimental Design for Tooth – Staggering Phase Tuning Vibration Reduction

4.1 Design of Tooth – Staggering Phase Tuning Scheme

To verify the vibration reduction effect of tooth – staggering phase tuning, a variable – tooth – staggering phase parallel – shaft spur gear pair was designed. In the experiment, a spline connection was used to reduce errors introduced by machining and assembly. Three tooth – staggering phase angles \(p = 0\), \(p = 0.2\), and \(p = 0.4\) were selected for research. Given that the number of teeth of a pair of gears is 36 and the tooth – pitch angle is \(10^{\circ}\), a spline with 30 teeth was designed. By adjusting the spline’s tooth – staggering position, different tooth – staggering phase – tuned gears were obtained. For example, when the spline teeth are staggered by 0 teeth, a 0 – tooth – staggering phase – tuned gear is obtained; when staggered by 1 tooth, the tooth – staggering phase is 0.2.

| Spline Tooth Staggering | Tooth – Staggering Phase Angle \(\varphi\) | Tooth – Staggering Phase P |

|---|---|---|

| 0 teeth | \(0^{\circ}\) | 0 |

| 1 tooth | \(12^{\circ}\) (resulting in a \(2^{\circ}\) wheel – tooth stagger) | 0.2 |

| 2 teeth | \(24^{\circ}\) (resulting in a \(4^{\circ}\) wheel – tooth stagger) | 0.4 |

4.2 Principle and Structure of the Test Bench

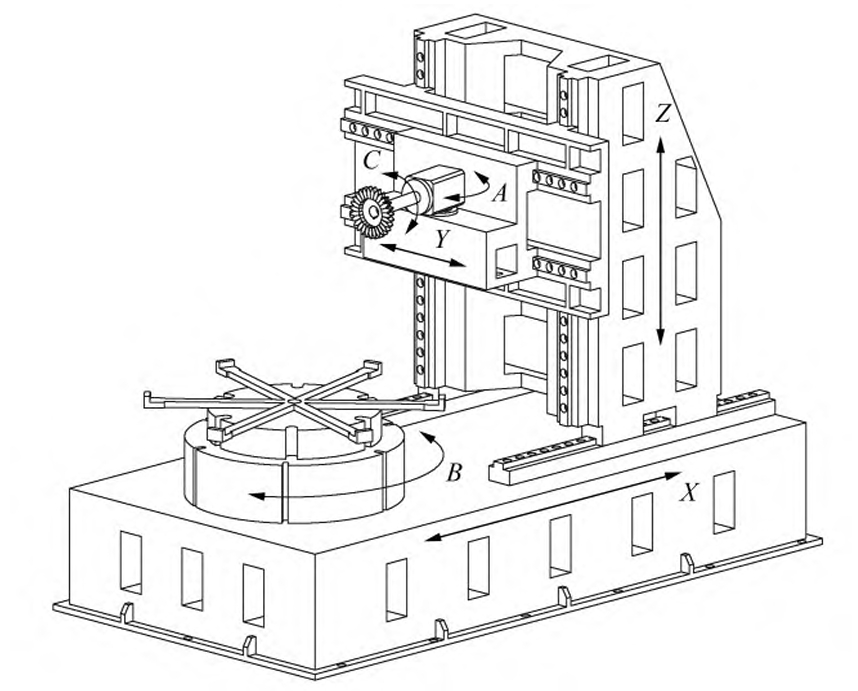

The test bench consists of a servo – drive motor, couplings, torque – speed sensors, bearing seats, grating sensors, a test gearbox, a load motor, and a test bench frame. The servo – drive motor provides the driving force, and the load motor applies the load. The torque – speed sensors measure the torque and speed, while the grating sensors are used to measure the rotational position. The test bench has specific input and load – end parameters, such as the motor torque range from 0 – 140 N·m and the speed range from 0 – 8000 r/min at the input end.

| Component | Function | Parameter Range (Input End) |

|---|---|---|

| Servo – drive motor | Provide driving force | Torque: 0 – 140 N·m Power: – Speed: 0 – 8000 r/min |

| Torque – speed sensor | Measure torque and speed | Torque range: 20/4 N·m |

| Grating sensor | Measure rotational position | – |

| Test gearbox | House the gear pair for testing | – |

| Load motor | Apply load | Torque: – Speed: 0 – 2500 r/min |

4.3 Sensor Arrangement

To accurately measure the vibration parameters of the drive shaft in the radial direction, vibration displacement sensors are fixed on the test bench through a Z – shaped bracket in two mutually perpendicular directions. Vibration acceleration sensors are arranged at the input and output ends. The signal acquisition card has a sensitivity of 8 mV/μm and a range of 2 mm, while the displacement sensor has a sensitivity of 8.0 V/mm and a range of ± 10 V.

| Sensor Type | Installation Location | Sensitivity | Range |

|---|---|---|---|

| Vibration displacement sensor | At four points in two perpendicular directions on the test bench | 8.0 V/mm | ± 10 V |

| Vibration acceleration sensor | At the input and output ends | – | – |

| Signal acquisition card | – | 8 mV/μm | 2 mm |

5. Experimental Research on Tooth – Staggering Phase Tuning Gear Vibration Reduction

5.1 Vibration Displacement Measurement Results

When the input speed is 500 r/min and the load is 20 N·m, the vibration displacements at the input and output ends of the parallel – shaft spur gear pair with different tooth – staggering phases are measured. The root – mean – square (RMS) values of the vibration displacement at the input end for \(p = 0\), \(p = 0.2\), and \(p = 0.4\) are 23.0 μm, 11.8 μm, and 10.1 μm respectively. Compared with \(p = 0\), the vibration displacements at \(p = 0.2\) and \(p = 0.4\) are reduced by approximately 48.7% and 56.1% respectively. At the output end, the RMS values are 22.9 μm, 10.3 μm, and 11.9 μm, with reductions of about 55.0% and 48.0% compared to \(p = 0\). From the frequency – domain diagrams, the rotational frequency \(f_{x}\) and its harmonics are the main excitation frequencies, and the amplitudes of these frequencies are reduced with the increase of the tooth – staggering phase.

| Tooth – Staggering Phase P | Input End Vibration Displacement RMS (μm) | Reduction Percentage Compared to \(P = 0\) | Output End Vibration Displacement RMS (μm) | Reduction Percentage Compared to \(P = 0\) |

|---|---|---|---|---|

| 0 | 23.0 | – | 22.9 | – |

| 0.2 | 11.8 | 48.7% | 10.3 | 55.0% |

| 0.4 | 10.1 | 56.1% | 11.9 | 48.0% |

5.2 Vibration Acceleration Measurement Results

The vibration accelerations at the input and output ends are also measured under the same conditions. At the input end, the vibration accelerations for \(p = 0\), \(p = 0.2\), and \(p = 0.4\) are \(6.89m/s^{2}\), \(5.17m/s^{2}\), and \(4.22m/s^{2}\) respectively, with RMS reductions of about 24.9% and 38.8% compared to \(p = 0\). At the output end, the values are \(5.85m/s^{2}\), \(4.98m/s^{2}\), and \(4.08m/s^{2}\), with RMS reductions of about 14.9% and 30.3% compared to \(p = 0\). The meshing frequency \(f_{m}\) and its harmonics are the main excitation frequencies of vibration acceleration, and their amplitudes are reduced when \(p = 0.2\) and \(p = 0.4\).

| Tooth – Staggering Phase P | Input End Vibration Acceleration (\(m/s^{2}\)) | Reduction Percentage of RMS Compared to \(P = 0\) | Output End Vibration Acceleration (\(m/s^{2}\)) | Reduction Percentage of RMS Compared to \(P = 0\) |

|---|---|---|---|---|

| 0 | 6.89 | – | 5.85 | – |

| 0.2 | 5.17 | 24.9% | 4.98 | 14.9% |

| 0.4 | 4.22 | 38.8% | 4.08 | 30.3% |

5.3 Influence of Load Torque on Vibration Acceleration

The vibration accelerations at the input and output ends of the parallel – shaft spur gear pair with different tooth – staggering phases and different load torques are measured. It is found that regardless of the tooth – staggering phase, the vibration accelerations at both the input and output ends increase with the increase of the load torque. However, for \(p = 0.2\) and \(p = 0.4\), the vibration accelerations are always smaller than those of \(p = 0\). The experimental results and simulation results show good consistency in the vibration reduction trend, although the experimental results are slightly larger due to factors such as installation errors, shaft misalignment, and bearing clearances during the machining and assembly of the experimental parts.

| Tooth – Staggering Phase P | Average Reduction Percentage of Input End Vibration Acceleration (Experimental) | Average Reduction Percentage of Input End Vibration Acceleration (Simulation) | Average Reduction Percentage of Output End Vibration Acceleration (Experimental) | Average Reduction Percentage of Output End Vibration Acceleration (Simulation) |

|---|---|---|---|---|

| 0.2 | 15.9% | 19.4% | 18.2% | 19.1% |

| 0.4 | 28.6% | 32.3% | 30.4% | 31.9% |

6. Conclusion

6.1 Summary of Research Findings

This research has established a calculation model for the meshing stiffness of tooth – staggering phase – tuned gear pairs, revealing that the time – varying meshing stiffness is related to both the contact ratio and the tooth – staggering phase P. By studying the vibration responses of parallel – shaft gear pairs at different tooth – staggering phases, the optimal tooth – staggering phase for the gear pair has been determined. The experimental study on different tooth – staggering phase schemes of parallel – shaft gear pairs has shown that the tooth – staggering phase vibration reduction theoretical model is in good agreement with the experimental results in terms of the vibration reduction trend.