This article delves into the calculation of meshing stiffness for spur bevel gears, a crucial aspect in gear design and analysis. A novel slice calculation method considering tooth pair coupling is presented. By comparing with traditional analytical methods and finite – element methods, its advantages in terms of accuracy and efficiency are demonstrated. The impact of assembly errors on meshing stiffness is also explored, providing valuable insights for practical engineering applications.

1. Introduction

1.1 Importance of Spur Bevel Gears

Spur bevel gears are key components in numerous mechanical systems, widely used in automotive, precision machine tools, aerospace, and other fields. Their ability to transmit power between intersecting shafts makes them indispensable in many applications .

1.2 Significance of Meshing Stiffness Calculation

The time – varying meshing stiffness of spur bevel gears is a critical factor in evaluating their transmission performance. Precise calculation of this stiffness is essential for ensuring the stability of gear transmission. Inaccurate stiffness values can lead to issues such as excessive vibration, noise, and reduced service life of the gears .

1.3 Research Background

Over the years, researchers have made significant efforts in calculating the meshing stiffness of gears. For cylindrical gears, the calculation methods are relatively mature. However, for space bevel gears like spur bevel gears, the research is still in progress. Many scholars have used finite – element methods to analyze the meshing stiffness, while others have adopted traditional analytical approaches. Each method has its own limitations. The finite – element method offers high accuracy but is time – consuming and affected by various factors. Traditional analytical methods, on the other hand, are quick but cannot account for the coupling effect between tooth pairs, resulting in large calculation errors for multi – tooth meshing stiffness .

2. Meshing Stiffness Calculation Model of Spur Bevel Gears

2.1 Spur Bevel Gear Slice Model

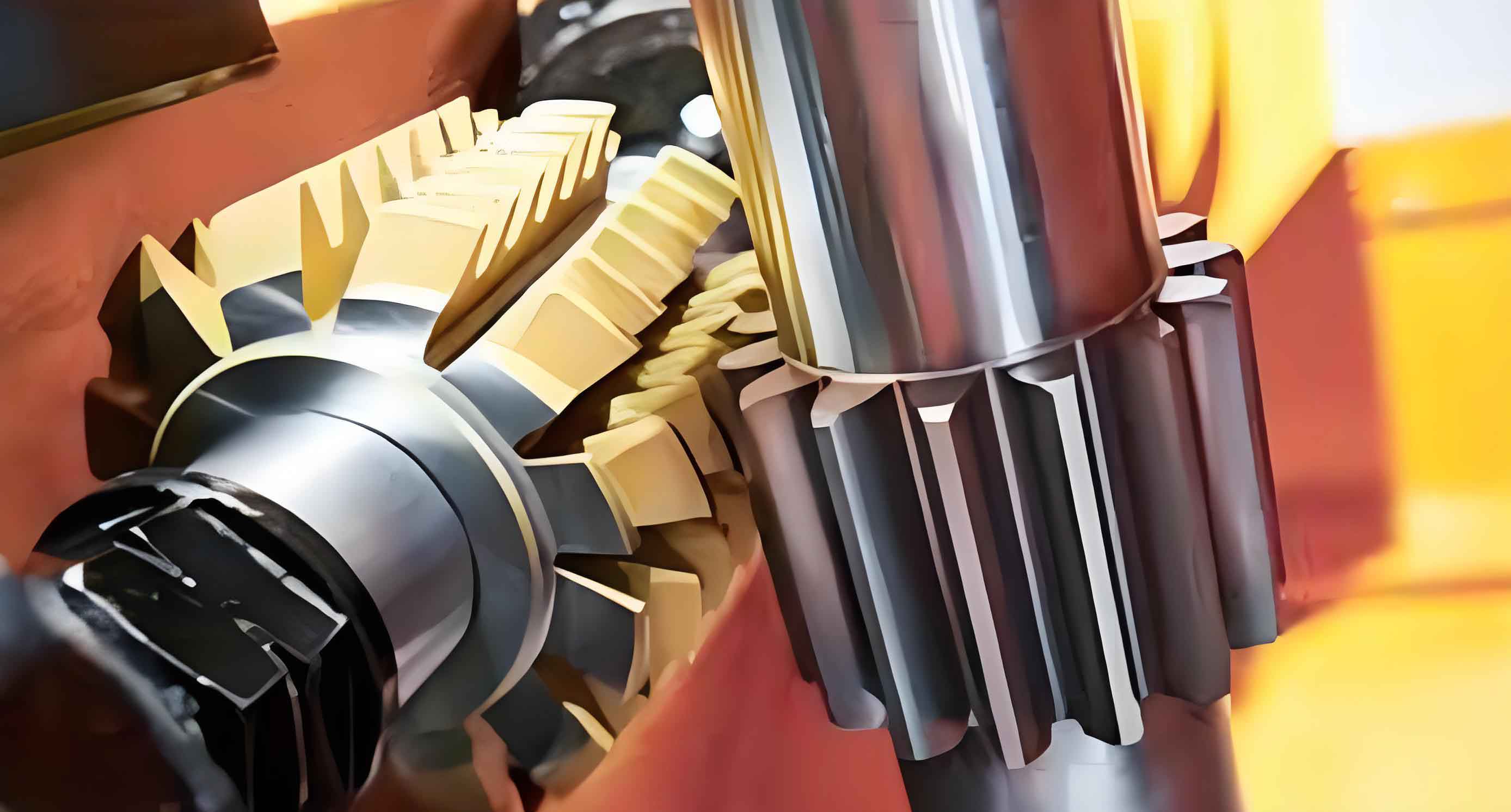

2.1.1 Discretization Principle

To account for the complex 3D structure and meshing characteristics of spur bevel gears, the gear teeth are discretized along the tooth width direction using the back cone, and the gear body is discretized along the axis direction. This results in a series of thin – slice bevel gears with equal tooth widths. Based on the back – cone equivalence principle, when the slice width is small enough, each thin – slice bevel gear can be approximated as a spur gear. Figure 1 shows the slice model of a spur bevel gear.

| Symbol | Definition |

|---|---|

| \(d_{b}\) | Width of the thin – slice tooth |

| \(r_{j}\), \(r_{aj}\), \(r_{fj}\) | Pitch circle radius, addendum circle radius, and dedendum circle radius of the bevel gear respectively |

| \(\delta_{j}\) | Pitch cone angle of the bevel gear |

| B | Tooth width |

| R | Outer cone distance |

| \(r_{k}\) | Bore radius |

2.1.2 Equivalent Parameters

The equivalent parameters of the i – th slice, such as the equivalent number of teeth \(z_{ij}\), equivalent pitch circle radius \(r_{ij}’\), equivalent addendum circle radius \(r_{aij}’\), and equivalent dedendum circle radius \(r_{fij}’\), can be calculated using the following formulas.

2.2 Thin – Slice Meshing Stiffness Calculation

2.2.1 Components of Meshing Stiffness

Each thin – slice can be approximated as a spur gear. The equivalent meshing stiffness of a spur bevel gear considering wheel tooth deformation includes Hertz contact stiffness, bending stiffness, shear stiffness, and radial compression stiffness. Additionally, the gear body deformation also contributes to the equivalent meshing stiffness, known as the gear body stiffness. The single – tooth linear meshing stiffness \(k_{ii}^{d}\) of the i – th slice can be expressed as.

2.2.2 Considering Tooth Pair Coupling

Traditional analytical methods for calculating multi – tooth meshing stiffness simply sum up the single – tooth meshing stiffness of each tooth pair, leading to large errors. This is because they only consider single – tooth meshing when calculating the gear body stiffness and ignore the coupling effect between tooth pairs. In this study, a gear body stiffness correction coefficient is introduced in the calculation of double – tooth meshing stiffness. The double – tooth linear meshing stiffness \(k_{li}^{s}\) is expressed as.

2.2.3 Torsional Meshing Stiffness

The time – varying meshing stiffness can also be evaluated through torsional meshing stiffness. According to the relationship between linear and torsional meshing stiffness , the torsional meshing stiffness of the bevel gear is.

2.3 Calculation of Gear Body Stiffness Correction Coefficient

2.3.1 Finite – Element Model Establishment

To calculate the gear body stiffness correction coefficient, a 3D finite – element model of each thin – slice bevel gear is established in the finite – element software Ansys. Figure 2 shows the finite – element model of the i – th thin – slice.

2.3.2 Calculation Process

The elastic modulus of the gear teeth in the thin – slice is set to 10,000 times that of the gear body. In this way, the gear teeth can be regarded as a relatively rigid region compared to the gear body, and the displacements caused by local Hertz contact and gear tooth elastic deformation can be ignored [12]. A mass21 element is established at the mid – point of the tooth width along the axis of the thin – slice, coupled with the inner – ring nodes and fully constrained. Forces \(F_{ij}\) are applied along the \(x_{1}\) axis at the double – tooth meshing position \(O_{ij}\), and \(F_{2j}(F_{1j}=F_{2j} = 0.5N)\) are applied along the \(x_{2}\) axis at the position \(O_{2j}\). The displacements at \(O_{ij}(i = 1,2;j = 1,2)\) along the action line are measured.

3. Meshing Stiffness Calculation Model of Error Tooth Profiles

3.1 Tooth Profile Deviations of Each Thin – Slice Caused by Assembly Errors of Bevel Gears

3.1.1 Types of Assembly Errors

Among the many factors affecting the meshing stiffness of spur bevel gears, installation errors have a significant impact. This study focuses on the tooth profile position deviations (thin – slice back – cone error tooth profiles) caused by installation errors and establishes a meshing stiffness model for them. According to national standards, installation errors can be divided into shaft – intersection angle errors and shaft – intersection point errors [13]. Figure 3 shows the relationship diagram of the assembly error coordinate system.

| Symbol | Definition |

|---|---|

| \(\theta\) | Shaft – intersection angle error |

| \(\varepsilon\) | Shaft – intersection point error |

| \(S_{1}(O_{1}-x_{1}y_{1}z_{1})\), \(S_{2}(O_{2}-x_{2}y_{2}z_{2})\) | Coordinate systems fixed to the driving and driven gears respectively |

| \(S_{1i}(O_{1i}-x_{1i}y_{1i}z_{1i})\), \(S_{2i}(O_{2i}-x_{2i}y_{2i}z_{2i})\) | Auxiliary coordinate systems at the i – th thin – slice |

| \(\delta_{1}\), \(\delta_{2}\) | Angles between \(z_{1i}\), \(z_{2i}\) and \(z_{1}\), \(z_{2}\) respectively |

3.2 Meshing Stiffness Model of Bevel Gears with Error Tooth Profiles

3.2.1 Meshing Process under Error Conditions

Under installation error conditions, the axes of bevel gears may shift and skew, resulting in different meshing conditions for each thin – slice tooth pair. This often leads to edge contact, seriously affecting the transmission performance of the gears. Therefore, when calculating the meshing stiffness under error conditions, it is necessary to determine whether each thin – slice participates in meshing. Figure 4 shows the load – bearing contact process of the bevel gear thin – slice under error conditions.

| Symbol | Definition |

|---|---|

| \(E_{i}\) | Tooth profile deviation of the i – th thin – slice |

| \(E_{i}’\) | Sum of the deformation of the thin – slice under load and the tooth profile deviation |

| \(e_{i}\) | Angular deviation of the thin – slice |

| e | Sum of the angular displacement of the thin – slice under load and the angular deviation under error conditions |

| T | Applied external torque |