1. Introduction

Gear transmission is a fundamental component in a wide range of industries, including construction machinery, vehicles, ships, and aerospace. The dynamic characteristics of gear systems have a profound impact on the overall performance and service life of machinery. Hyperboloidal – type normal circular – arc gears have emerged as a potential solution for specific transmission requirements, especially in applications with large offsets and demanding NVH (noise – vibration – harshness) performance. However, as they are still in the theoretical development stage, in – depth research on their dynamic behavior is crucial. This paper aims to comprehensively analyze the dynamic response of hyperboloidal – type normal circular – arc gears, focusing on the effects of meshing stiffness, transmission error, and backlash.

2. Research Background

2.1 Gear System Dynamics Research Overview

Over the years, significant progress has been made in the study of gear system dynamics. Researchers have considered various factors such as time – varying meshing stiffness, backlash, and damping to establish dynamic models. For example, AlShyyab et al. developed a two – stage spur gear set lumped – parameter dynamic model considering time – varying meshing stiffness and backlash, and solved for the first – order steady – state and forced responses. Lin Tengjiao et al. established a multi – factor bending – torsion coupled nonlinear dynamic model for orthogonal face – gear systems. These studies have laid a solid foundation for understanding the dynamic behavior of different gear types.

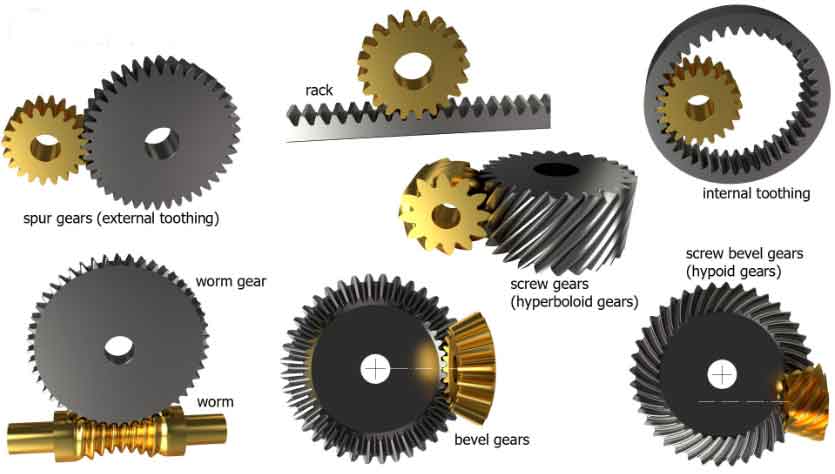

2.2 Development of Hyperboloidal – Type Normal Circular – Arc Gears

Although circular – arc gears were once applied in high – speed and heavy – load parallel – axis transmissions, the emergence of hardened – tooth – surface involute gears hindered their further promotion. In the case of intersecting and staggered axes, the spatial meshing relationship and machining processes of involute straight bevel gears and spiral bevel gears (including hypoid gears) are complex. Hyperboloidal – type normal circular – arc gears were proposed to meet the needs of the vehicle industry for large – offset and excellent NVH – performance staggered – axis transmission technology. Their development requires in – depth research on dynamics to optimize design parameters and diagnose faults.

3. Dynamic Excitations of Gear Pairs

3.1 Time – Varying Meshing Stiffness

3.1.1 Calculation Method Stiffness is defined as the ratio of force to deformation (\(K = \frac{F}{\delta}\)). For hyperboloidal – type normal circular – arc gears, a single – tooth – pair three – dimensional model was constructed based on the tooth – surface mathematical model and design parameters (Table 1). The model was imported into ANSYS for mesh generation. With the gear material set as 45 – steel and a loading torque of 100 Nm, the load and displacement at 32 different meshing positions were simulated and calculated as the small – gear single – tooth rotates from meshing in to meshing out (a rotation angle of 160° with an angular displacement increment of 5°). The single – tooth meshing stiffness was then calculated using the formula. The comprehensive meshing stiffness (\(k=\sum_{i = 1}^{n}K\), where n is the number of instantaneous meshing tooth pairs) was obtained by coupling the single – tooth meshing stiffness in parallel. Considering the number of teeth of the small gear (\(z_1 = 9\)), the single – tooth meshing stiffness of the small gear was shifted and superimposed according to the tooth – dividing angle of 40° to obtain the original comprehensive meshing stiffness curve.

| Gear | Normal Module (mm) | Number of Teeth | Tooth Width (mm) | Pressure Angle (°) | Tooth Profile Radius (mm) |

|---|---|---|---|---|---|

| Small Gear | 4 | 9 | 44.3 | 30 | 6.0 |

| Large Gear | 4 | 41 | 26.0 | 30 | 6.6 |

3.1.2 Fitting of Meshing Stiffness Curve To balance the complexity of the Fourier series expansion and the fitting accuracy, a third – order Fourier series was used to fit the original meshing stiffness curve. The comprehensive meshing stiffness can be expressed as \(k(t)=\sum_{j = 0}^{3}(a_{j}\cos(j\omega t)+b_{j}\sin(j\omega t))\), where j is the order of the Fourier series, \(a_{j}\) and \(b_{j}\) are Fourier coefficients (Table 2), and \(\omega\) is the meshing angular frequency (\(\omega=\frac{2\pi}{T_{z}} = 2\pi\omega_{i}z_{i}=\frac{\pi n_{i}z_{i}}{30}\)).

| Order | \(a_{j}\) | \(b_{j}\) |

|---|---|---|

| 0 | \(-1.09\times10^{9}\) | – |

| 1 | \(-9.36\times10^{7}\) | \(-1.79\times10^{7}\) |

| 2 | \(-5.23\times10^{7}\) | \(-1.77\times10^{6}\) |

| 3 | \(-3.92\times10^{7}\) | \(-8.73\times10^{6}\) |

3.2 Static Transmission Error

3.2.1 Composition of Static Transmission Error Static transmission error is mainly composed of tooth – load – induced deformation and gear manufacturing errors. Tooth – load – induced deformation includes tooth – surface contact deformation and tooth bending deformation, while manufacturing errors mainly include pitch error and profile error. It is generally expressed as \(e(t)=\delta(t)+e_{m}(t)\), where \(\delta(t)\) is the sum of tooth – surface contact and bending deformations, and \(e_{m}(t)\) is the gear manufacturing error.

3.2.2 Calculation of Static Transmission Error The deformation \(\delta(t)\) was obtained through finite – element contact simulation. The mean value of tooth deformation was about 4 μm, and the single – tooth deformation curve was consistent with the deformation theorem. For manufacturing errors, considering the significant influence of pitch error, the pitch cumulative tolerance was used as the manufacturing error value. Since the error is time – varying, it was represented by a harmonic function \(e_{m}(t)=(e_{1} + e_{2})\sin(\omega t+\gamma)\), where \(e_{1}\) and \(e_{2}\) are the pitch cumulative tolerance values of the small and large gears (36 μm and 63 μm respectively for 7 – grade circular – arc gears), and \(\gamma\) is the initial phase angle (usually 0). After considering the main factors, the static transmission error was finally expressed as \(e(t)=99\sin(0.3\pi n_{1}t)\).

3.3 Backlash

Backlash was set as \(0.06m\) (assuming half of the backlash is b). The nonlinear clearance displacement function of the hyperboloidal – type normal circular – arc gear pair is \(f(x)=\begin{cases}x(t)-b, & x(t)>b\\0, & -b\leq x(t)\leq b\\x(t)+b, & x(t)< – b\end{cases}\), where \(x(t)\) is the normal transmission error during gear transmission.

4. Dynamics Analysis of Gear Pairs

4.1 Dynamics Model

A discrete mathematical model of the gear – pair meshing was established using the lumped – mass method. The two gears were regarded as rigid bodies, and the tooth – contact situation was represented by spring, damping element, error element, and clearance parameters, corresponding to time – varying meshing stiffness, meshing damping, static transmission error, and backlash respectively. Based on Newton’s second law, the two – degree – of – freedom dynamics differential equation of the gear pair was obtained: \(\begin{cases}I_{1}\ddot{\theta}_{1}+R_{dr1}c_{m}\dot{x}(t)+R_{dr1}k(t)f(x)=T_{1}\\I_{2}\ddot{\theta}_{2}-R_{d2}c_{m}\dot{x}(t)-R_{dr2}k(t)f(x)= – T_{2}\end{cases}\) where \(\theta_{i}\) is the angular displacement, \(I_{i}\) is the moment of inertia (\(I_{1}=2.42\times10^{-3}kg\cdot m^{2}\), \(I_{2}=3.69\times10^{-2}kg\cdot m^{2}\)), \(R_{dai}\) is the directional turning radius (\(R_{dr1}=1.559\times10^{-2}m\), \(R_{d2}=7.101\times10^{2}m\)), \(c_{n}\) is the average meshing damping (0.79 Ns/m), and \(T_{i}\) is the torque. After rearrangement, it can be transformed into \(m_{e}\ddot{x}(t)+c_{m}\dot{x}(t)+k(t)f(x)=m_{e}(\frac{R_{dr1}T_{1}}{I_{1}}+\frac{R_{d2}T_{2}}{I_{2}}-\ddot{e}(t))\), where \(m_{e}=\frac{1}{R_{dr1}^{2}/I_{1}+R_{dz2}^{2}/I_{2}}\) is the equivalent mass. In the absence of friction, the meshing force \(F_{mech}=k(t)f(x)+c_{m}\dot{x}(t)\).

4.2 Solution of Dynamics Equation

Due to the time – varying and strongly nonlinear nature of the gear – transmission dynamics differential equation caused by time – varying meshing stiffness and static transmission error, it is difficult to obtain an exact solution by analytical methods. The fourth – order Runge – Kutta method was used for numerical solution. The initial displacement and velocity were set based on the equation, and the second – order differential equation was reduced to a system of first – order differential equations. The initial – value problem of the dynamics model was expressed as: \(\begin{cases}x_{1}(t)=x(t)\\x_{2}(t)=\dot{x}_{1}(t)\\\dot{x}_{2}(t)=(\frac{R_{di}T_{1}}{I_{1}}+\frac{R_{d2}T_{2}}{I_{2}}-\ddot{e}(t))-\frac{c_{m}x_{2}(t)+k(t)f(x_{1})}{m_{e}}\\x_{1}(0)=0\\x_{2}(0)=0\end{cases}\) A calculation program was compiled using MATLAB with an integration step – size of \(1\times10^{-6}s\) to solve the nonlinear differential equation.

4.3 Dynamic Response

With the small – gear speed of the hyperboloidal – type normal circular – arc gear pair set as 2000 r/min (referring to automotive working conditions), the vibration displacement response curve and dynamic meshing – force curve of the gear pair were obtained by solving the dynamics model. The root – mean – square values of the vibration displacement response (\(x_{rms}\)) and dynamic meshing force (\(F_{rms}\)) were 0.11989 mm and \(1.3091\times10^{5}N\) respectively. The dynamic – response curves showed large – amplitude fluctuations during the start – up phase from rest, and then tended to be stable with an obvious periodic pattern, indicating that the gear pair entered a stable transmission state. In a rotation period of 0.03 s, there were approximately 9 meshing periods, which was consistent with the number of teeth of the small gear, verifying the rationality of the numerical calculation.

5. Influence of Dynamic Excitations on Gear – Pair Dynamic Response

5.1 Influence of Time – Varying Meshing Stiffness

When other parameters remained unchanged, the influence of meshing – stiffness changes on the dynamic response was calculated by setting the time – varying meshing stiffness as 80%, 90%, 100%, 110%, and 120% of the original value. As the meshing stiffness increased, the vibration displacement response of the gear pair decreased, while the dynamic meshing force increased, and the waveforms remained unchanged. Through quantitative analysis of the root – mean – square values of the vibration displacement response and dynamic meshing force, it was found that when the meshing stiffness increased by 10%, the change rate of the vibration displacement response was only about 0.15%, while that of the dynamic meshing force was about 10%. This indicates that the time – varying meshing stiffness has a relatively small impact on the vibration displacement response but a significant impact on the dynamic meshing force.

| Time – Varying Meshing Stiffness | Vibration Displacement Response (mm) | Relative Change Rate of Vibration Displacement Response (%) | Dynamic Meshing Force (\(10^{5}N\)) | Relative Change Rate of Dynamic Meshing Force (%) |

|---|---|---|---|---|

| 80% \(k(t)\) | 0.12024 | 0.29193 | 1.05 | 19.777 |

| 90% \(k(t)\) | 0.12007 | 0.15014 | 1.18 | 9.869 |

| 100% \(k(t)\) | 0.11989 | 0 | 1.31 | 0 |

| 110% \(k(t)\) | 0.11976 | 0.10843 | 1.44 | 9.877 |

| 120% \(k(t)\) | 0.11965 | 0.20018 | 1.57 | 19.762 |

5.2 Influence of Static Transmission Error

By calculating with the static transmission error set as 80%, 90%, 100%, 110%, and 120% of the original value while keeping other parameters constant, it was observed that as the static transmission error increased, the waveform of the vibration displacement response was slightly longitudinally stretched, and its fluctuation range gradually increased, but the change was small. The difference in the dynamic meshing force was not obvious. The relative change rates of the vibration displacement response and dynamic meshing force were both less than 0.02% when the static transmission error increased by 10% incrementally, indicating that the static transmission error had little impact on the mean values of the vibration displacement response and dynamic meshing force. However, a larger static transmission error led to greater fluctuations in the vibration displacement response of the gear pair.

| Static Transmission Error | Vibration Displacement Response (mm) | Relative Change Rate of Vibration Displacement Response (%) | Dynamic Meshing Force (\(10^{5}N\)) | Relative Change Rate of Dynamic Meshing Force (%) |

|---|---|---|---|---|

| 80% \(e(t)\) | 0.12 | 0.00834 | 1.31 | 0.00764 |

| 90% \(e(t)\) | 0.12 | 0.01670 | 1.31 | 0.01530 |

| 100% \(e(t)\) | 0.12 | 0 | 1.31 | 0.00 |

| 110% \(e(t)\) | 0.12 | 0 | 1.31 | 0.00764 |

| 120% \(e(t)\) | 0.12 | 0.00834 | 1.31 | 0.00 |

5.3 Influence of Backlash

When the backlash was set as 80%, 90%, 100%, 110%, and 120% of the original value for calculation, it was found that as the backlash increased, both the vibration displacement response and the dynamic meshing force increased significantly. When the backlash increased by 10% incrementally, the change rates of the vibration displacement response and dynamic meshing force were both about 10%, indicating that the backlash had a great influence on the vibration displacement response and dynamic meshing force and was the main factor causing their increase.

| Backlash | Vibration Displacement Response (mm) | Relative Change Rate of Vibration Displacement Response (%) | Dynamic Meshing Force (\(10^{5}N\)) | Relative Change Rate of Dynamic Meshing Force (%) |

|---|---|---|---|---|

| 80% b | 0.09620 | 19.740 | 1.05 | 19.746 |

| 90% b | 0.10807 | 9.859 | 1.18 | 9.862 |

| 100% b | 0.11989 | 0.000 | 1.31 | 0.000 |

| 110% b | 0.13171 | 9.859 | 1.44 | 9.862 |

| 120% b | 0.14353 | 19.718 | 1.57 | 19.716 |

6. Conclusions

Based on the dynamics model and dynamics differential equation, this paper investigated the effects of time – varying meshing stiffness, static transmission error, and backlash on the dynamic response of hyperboloidal – type normal circular – arc gear pairs. The results show that the backlash has the greatest impact on the vibration displacement response, followed by the time – varying meshing stiffness. Although the static transmission error has little impact on the mean value of the vibration displacement response, it significantly changes its fluctuation range.