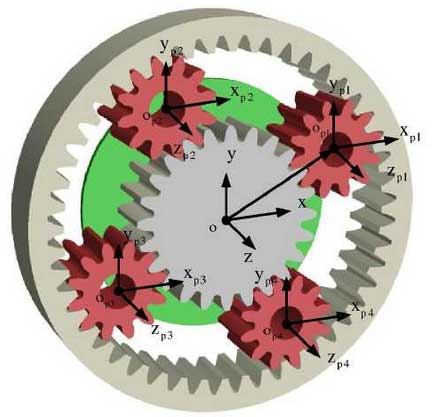

Planetary gear systems are widely recognized for their compact structure, high power density, and load-sharing capabilities. However, vibration and noise during operation remain critical challenges affecting transmission performance. This study investigates the relationship between structural parameters (e.g., tooth counts, input configurations) and dynamic characteristics to optimize planetary gear systems for noise reduction.

1. Fundamental Constraints in Planetary Gear Design

Design parameters must satisfy three essential conditions:

| Constraint | Mathematical Expression |

|---|---|

| Adjacency Condition | $$2a_{12} \sin\left(\frac{\pi}{n_p}\right) > d_{12}$$ |

| Coaxiality Condition | $$\frac{z_1 + z_2}{\cos\alpha_{12}} = \frac{z_3 – z_2}{\cos\alpha_{23}}$$ |

| Assembly Condition | $$\frac{z_1 + z_3}{n_p} \in \mathbb{Z}$$ |

Where \( z_1, z_2, z_3 \) represent sun gear, planet gear, and ring gear teeth counts, respectively. \( n_p \) denotes the number of planet gears.

2. Key Performance Metrics

2.1 Transmission Error (TE)

TE quantifies positional deviations between actual and ideal gear meshing:

$$TE = \left(\phi_x – \phi_x^{(0)}\right) – \left(\phi_t – \phi_t^{(0)}\right) \frac{z_1}{z_3 + z_1}$$

Where \( \phi_x, \phi_t \) denote angular displacements of carrier and sun gear.

2.2 Meshing Stiffness

Time-varying meshing stiffness significantly influences vibration:

$$K_n = \frac{F_n}{\delta_n}$$

$$K_t = \frac{F_n r_b^2}{\delta}$$

Total stiffness combines bending (\( K_b \)), shear (\( K_s \)), compression (\( K_a \)), and Hertzian contact (\( K_h \)) components:

$$K_e = \frac{1}{\frac{1}{K_{bs}} + \frac{1}{K_{ss}} + \frac{1}{K_{as}} + \frac{1}{K_{kp}} + \frac{1}{K_{sp}} + \frac{1}{K_{ap}} + \frac{1}{K_h}}$$

3. Parameter Optimization Strategy

Using Kisssoft software, 78 tooth combination schemes were evaluated under identical operating conditions. Critical optimization rules were identified:

| Optimal Condition | Effect on Performance |

|---|---|

| Sun-planet and planet-ring tooth counts are coprime | Reduces TE by 46.2% |

| Sun gear teeth ≠ integer multiple of planet count | Decreases contact stress by 53.5% |

| Carrier as input component | Improves load distribution uniformity |

4. Simulation and Experimental Validation

Comparative analysis of seven tooth combination schemes revealed:

| Parameter | Original Design | Optimized Design | Improvement |

|---|---|---|---|

| Transmission Error (µm) | 1.847 | 0.292 | 84.2% |

| Maximum Contact Stress (MPa) | 1335.5 | 998.3 | 25.3% |

| Normal Stiffness (N/µm) | 383.5 | 325.7 | 15.0% |

Physical prototype testing confirmed vibration reduction through input configuration optimization:

$$TE_{\text{carrier-input}} = 0.157\,\mu\text{m} \quad (46.2\% \text{ reduction vs sun-input})$$

5. Conclusion

This study establishes three critical principles for planet gear system optimization:

- Coprime tooth relationships between meshing pairs minimize TE fluctuations

- Non-integer sun-gear/planet-count ratios prevent resonance excitation

- Carrier-input configuration enhances load distribution and reduces bending stresses

The methodology provides a systematic approach for designing low-noise planetary gear transmissions in industrial applications.