In the realm of precision mechanical transmission, the demand for specialized motion control has driven the development of non-circular gears. These components, with their varying pitch curves, enable non-uniform transmission ratios essential for advanced machinery. Among the various manufacturing methods for non-circular gears, gear shaping stands out due to its versatility and capability to produce complex internal profiles. This article presents an in-depth exploration of a three-axis linkage gear shaping methodology specifically tailored for non-circular internal gears. I will detail the mathematical foundation, address critical manufacturing challenges such as undercutting and cutter retraction interference, and validate the approach through simulation and physical machining. The core objective is to demonstrate a cost-effective gear shaping strategy that leverages standard three-axis CNC shaping machines, thereby expanding their industrial application without the need for expensive, specialized multi-axis equipment.

The manufacturing of non-circular gears traditionally relies on methods like wire electrical discharge machining, gear hobbing, and gear shaping. Wire cutting, while precise, suffers from low efficiency and programming complexity, making it unsuitable for batch production. Gear hobbing offers high efficiency but fails to machine non-circular external gears with concave pitch curves or non-circular internal gears altogether. Gear shaping, however, effectively overcomes these limitations. The process involves the relative rolling motion between the cutter’s pitch circle and the workpiece’s pitch curve, generating the tooth profile via envelope theory. My focus is on refining this gear shaping process for non-circular internal gears using a standard three-axis CNC machine, where synchronized control of the cutter rotation, workpiece rotation, and center distance is paramount. This approach significantly reduces capital investment compared to four or five-axis solutions, making advanced gear shaping more accessible.

Establishing an accurate kinematic model is the cornerstone of successful gear shaping. For a non-circular internal gear, the pitch curve is defined in polar coordinates as \( r(\phi) \), where \( \phi \) is the polar angle. The fundamental principle of gear shaping is the pure rolling contact between the shaper cutter’s pitch circle (radius \( r_0 \)) and this pitch curve. The mathematical model derives the motion commands for the three axes: the rotational angle of the workpiece \( \Phi \), the rotational angle of the shaper cutter \( \psi \), and the instantaneous center distance \( a \) between them. The derivation utilizes the unit tangent vector \( \mathbf{t} \) and unit normal vector \( \mathbf{n} \) at the contact point \( P \) on the pitch curve.

The coordinates of point \( P \) are:

$$ x_P = r(\phi) \cos \phi $$

$$ y_P = r(\phi) \sin \phi $$

The unit tangent vector is obtained from the derivative:

$$ \mathbf{t} = \frac{1}{\sqrt{\dot{r}(\phi)^2 + r(\phi)^2}} \begin{bmatrix} \dot{r}(\phi) \cos \phi – r(\phi) \sin \phi \\ \dot{r}(\phi) \sin \phi + r(\phi) \cos \phi \end{bmatrix} $$

where \( \dot{r}(\phi) = dr/d\phi \). For an internal gear, the unit normal vector pointing inward is:

$$ \mathbf{n} = \begin{bmatrix} t_y \\ -t_x \end{bmatrix} $$

The center of the shaper cutter \( o_1 \) in the fixed coordinate system is found via the offset along the normal direction:

$$ x_{o_1} = x_P – r_0 t_y $$

$$ y_{o_1} = y_P + r_0 t_x $$

Consequently, the instantaneous center distance \( a \) is:

$$ a(\phi) = \sqrt{x_{o_1}^2 + y_{o_1}^2} = \sqrt{r(\phi)^2 + r_0^2 – \frac{2 r_0 r(\phi)^2}{\sqrt{r(\phi)^2 + (\dot{r}(\phi))^2}}} $$

The rotation angle of the shaper cutter \( \psi \) consists of two parts: the rolling angle \( \theta \) due to the arc length traversed and an adjustment angle \( \beta \). The rolling angle is:

$$ \theta(\phi) = \frac{S(\phi)}{r_0} = \frac{1}{r_0} \int_0^\phi \sqrt{r(\phi)^2 + (\dot{r}(\phi))^2} \, d\phi $$

The angle \( \beta \) between the normal vector and the line connecting centers is:

$$ \beta(\phi) = \arccos\left( \frac{r_0 \sqrt{r(\phi)^2 + (\dot{r}(\phi))^2} – r(\phi)^2}{a(\phi) \sqrt{r(\phi)^2 + (\dot{r}(\phi))^2}} \right) $$

Thus, the cutter rotation is:

$$ \psi(\phi) = \theta(\phi) + \beta(\phi) – \pi $$

The rotational angle of the workpiece \( \Phi \) is derived from the polar angle \( \phi \) and the angle \( \gamma \) of the line \( oo_1 \):

$$ \gamma(\phi) = \arctan\left( \frac{y_{o_1}}{x_{o_1}} \right) = \arctan\left( \frac{r(\phi) \sin \phi + r_0 t_x}{r(\phi) \cos \phi – r_0 t_y} \right) $$

$$ \Phi(\phi) = \phi – \gamma(\phi) $$

The complete three-axis linkage gear shaping model is summarized by the following system of equations, which are fundamental for CNC programming:

$$ \begin{aligned}

a(\phi) &= \sqrt{ r(\phi)^2 + r_0^2 – \frac{2 r_0 r(\phi)^2}{\sqrt{r(\phi)^2 + (\dot{r}(\phi))^2}} } \\

\Phi(\phi) &= \phi – \arctan\left( \frac{r(\phi) \sin \phi + r_0 t_x}{r(\phi) \cos \phi – r_0 t_y} \right) \\

\psi(\phi) &= \frac{1}{r_0} \int_0^\phi \sqrt{r(\phi)^2 + (\dot{r}(\phi))^2} \, d\phi + \arccos\left( \frac{r_0 \sqrt{r(\phi)^2 + (\dot{r}(\phi))^2} – r(\phi)^2}{a(\phi) \sqrt{r(\phi)^2 + (\dot{r}(\phi))^2}} \right) – \pi

\end{aligned} $$

This model encapsulates the precise coordination required for the gear shaping process. To facilitate understanding and application, the key parameters and their relationships are summarized in the table below.

| Parameter | Symbol | Description | Formula/Relation |

|---|---|---|---|

| Pitch Curve | \( r(\phi) \) | Polar equation of non-circular gear | Input design function |

| Shaper Cutter Radius | \( r_0 \) | Pitch circle radius of cutter | \( r_0 = m z_0 / 2 \) |

| Contact Point | \( P \) | Tangency point on pitch curve | \( (x_P, y_P) \) |

| Unit Tangent Vector | \( \mathbf{t} \) | Direction of curve at \( P \) | Derived from \( r(\phi) \) |

| Unit Normal Vector | \( \mathbf{n} \) | Inward normal at \( P \) for internal gear | \( \mathbf{n} = (t_y, -t_x)^T \) |

| Center Distance | \( a(\phi) \) | Distance between workpiece and cutter centers | Varies with \( \phi \) |

| Workpiece Rotation | \( \Phi(\phi) \) | Angular position of non-circular gear | \( \Phi = \phi – \gamma \) |

| Cutter Rotation | \( \psi(\phi) \) | Angular position of shaper cutter | \( \psi = \theta + \beta – \pi \) |

| Rolling Arc Angle | \( \theta(\phi) \) | Cutter rotation due to pure rolling | Integral of arc length |

Prior to initiating the gear shaping process, it is crucial to verify that the designed non-circular internal gear will not suffer from undercutting. Undercutting occurs when the tool removes material from the dedendum of the gear tooth, weakening the tooth structure. This phenomenon is most likely at the point on the pitch curve with the minimum radius of curvature \( \rho_{\text{min}} \). The radius of curvature at any point is given by:

$$ \rho(\phi) = \frac{ \left( r(\phi)^2 + (\dot{r}(\phi))^2 \right)^{3/2} }{ r(\phi)^2 + 2(\dot{r}(\phi))^2 – r(\phi)\ddot{r}(\phi) } $$

where \( \ddot{r}(\phi) = d^2r/d\phi^2 \). The condition to avoid undercutting during gear shaping is derived from the geometry of the generating process, analogous to that for circular gears. For a standard shaper cutter with module \( m \), pressure angle \( \alpha \), addendum coefficient \( h_{a0}^* \) (typically 1), and number of teeth \( z_0 \), undercutting is prevented if the following inequality holds:

$$ m^2 h_{a0}^* (z_0 + h_{a0}^*) \leq \rho_{\text{min}} (\rho_{\text{min}} + m z_0) \sin^2 \alpha $$

For standard parameters (\( \alpha = 20^\circ \), \( h_{a0}^* = 1 \)), this simplifies to a practical relation between the module and the minimum curvature radius:

$$ m \leq \frac{0.68 \, \rho_{\text{min}} }{ \sqrt{0.1156 z_0^2 + 4 z_0 + 4} – 0.34 z_0 } $$

This formula provides a direct guideline for selecting an appropriate module during the design phase to ensure a viable gear shaping operation. Adherence to this condition guarantees that the gear shaping process will produce a full, uncut tooth profile.

A significant challenge in the gear shaping of non-circular internal gears on a three-axis machine is the phenomenon of cutter retraction interference. Standard three-axis CNC gear shaping machines typically employ a fixed-direction retraction mechanism, where the cutter moves away along the line connecting the gear and cutter centers during the non-cutting return stroke. For non-circular pitch curves, this retraction direction may not align with the local normal direction, potentially causing the cutter to gouge into a previously machined tooth flank—a failure known as retraction interference. This issue is particularly acute in gear shaping processes where the geometry is non-uniform.

The criterion for retraction interference is based on the angle \( \Delta_1 \) between the center line and the pitch curve normal at the contact point. From the model, \( \Delta_1 = \pi – \beta \). Interference is avoided if the cutter retracts within a ±20° range around the normal direction. Therefore, the non-interference condition for successful gear shaping is:

$$ \Delta_1 = \pi – \arccos\left( \frac{r_0 \sqrt{r(\phi)^2 + (\dot{r}(\phi))^2} – r(\phi)^2}{a(\phi) \sqrt{r(\phi)^2 + (\dot{r}(\phi))^2}} \right) \leq 20^\circ $$

If \( \Delta_1 > 20^\circ \) at any point during the gear shaping cycle, interference will occur. To circumvent this, an active retraction strategy must be integrated into the CNC program. The proposed method involves, at the bottom of each cutting stroke, commanding an additional offset \( \Delta a \) along the center line, effectively moving the cutter to a position where its center lies on the normal line of a neighboring point \( P_1 \) on the pitch curve with polar angle \( \epsilon \). The coordinates of the offset cutter center \( o_1′ \) are:

$$ x_{o_1′} = x_{o_1} – \Delta a \cos \gamma $$

$$ y_{o_1′} = y_{o_1} – \Delta a \sin \gamma $$

The point \( P_1 \) with coordinates \( (r(\epsilon)\cos\epsilon, r(\epsilon)\sin\epsilon) \) must satisfy the condition that the vector \( \overrightarrow{o_1′ P_1} \) is perpendicular to the tangent vector \( \mathbf{T} \) at \( P_1 \):

$$ \mathbf{T} \cdot \overrightarrow{o_1′ P_1} = 0 $$

Solving this equation yields the value of \( \epsilon \), and the corresponding axis motions \( a \), \( \Phi \), and \( \psi \) can be computed from the main model to execute a safe retraction. This method allows standard three-axis machines to perform continuous gear shaping of non-circular internal gears without requiring hardware modifications or special cutters.

| Interference Aspect | Condition | Description | Solution in Gear Shaping |

|---|---|---|---|

| Undercutting | \( m > m_{\text{max}} \) from formula | Tooth root material excessively removed | Redesign module or pitch curve to satisfy \( m \leq \) condition |

| Retraction Interference | \( \Delta_1 > 20^\circ \) | Cutter gouges finished tooth on return stroke | Implement calculated offset \( \Delta a \) and solve for \( \epsilon \) to reposition cutter |

| Machine Limitation | Fixed retraction direction | Standard three-axis machine constraint | Software-based adaptive retraction integrated into CNC code |

To validate the developed gear shaping model and interference avoidance strategy, a comprehensive computer-aided engineering system was developed. This system integrates numerical analysis and graphical simulation capabilities to automate the CNC code generation for gear shaping. The workflow begins with inputting the non-circular gear parameters (pitch curve equation, number of teeth, module) and shaper cutter specifications. The system first checks for undercutting using the derived condition. It then calculates the three-axis motion trajectories based on the linkage model. Subsequently, a dynamic simulation of the gear shaping process is performed, visually verifying tooth generation and checking for potential retraction interference. If interference is predicted, the system automatically incorporates the corrective offset algorithm into the motion plan. Finally, standard G-code is generated for the three-axis CNC gear shaping machine.

An engineering case study involved machining a pair of third-order sinusoidal non-circular gears. The driving gear had a pitch curve given by \( r_1(\phi) = \frac{a}{1 + i_{12}(\phi)} \) with 34 teeth, module \( m = 2 \, \text{mm} \), and pressure angle \( 20^\circ \). The transmission ratio function was \( i_{12}(\phi) = 0.3 \sin \phi – 2.015 \). The mating non-circular internal gear had a pitch curve \( r_2(\phi_2) = a – r_1(\phi) \) and 102 teeth. A standard shaper cutter with \( z_0 = 13 \) and \( m = 2 \, \text{mm} \) was selected, satisfying the non-undercutting condition. The gear shaping model equations were computed, and the motion data revealed regions where \( \Delta_1 \) exceeded 20°, indicating necessary retraction intervention.

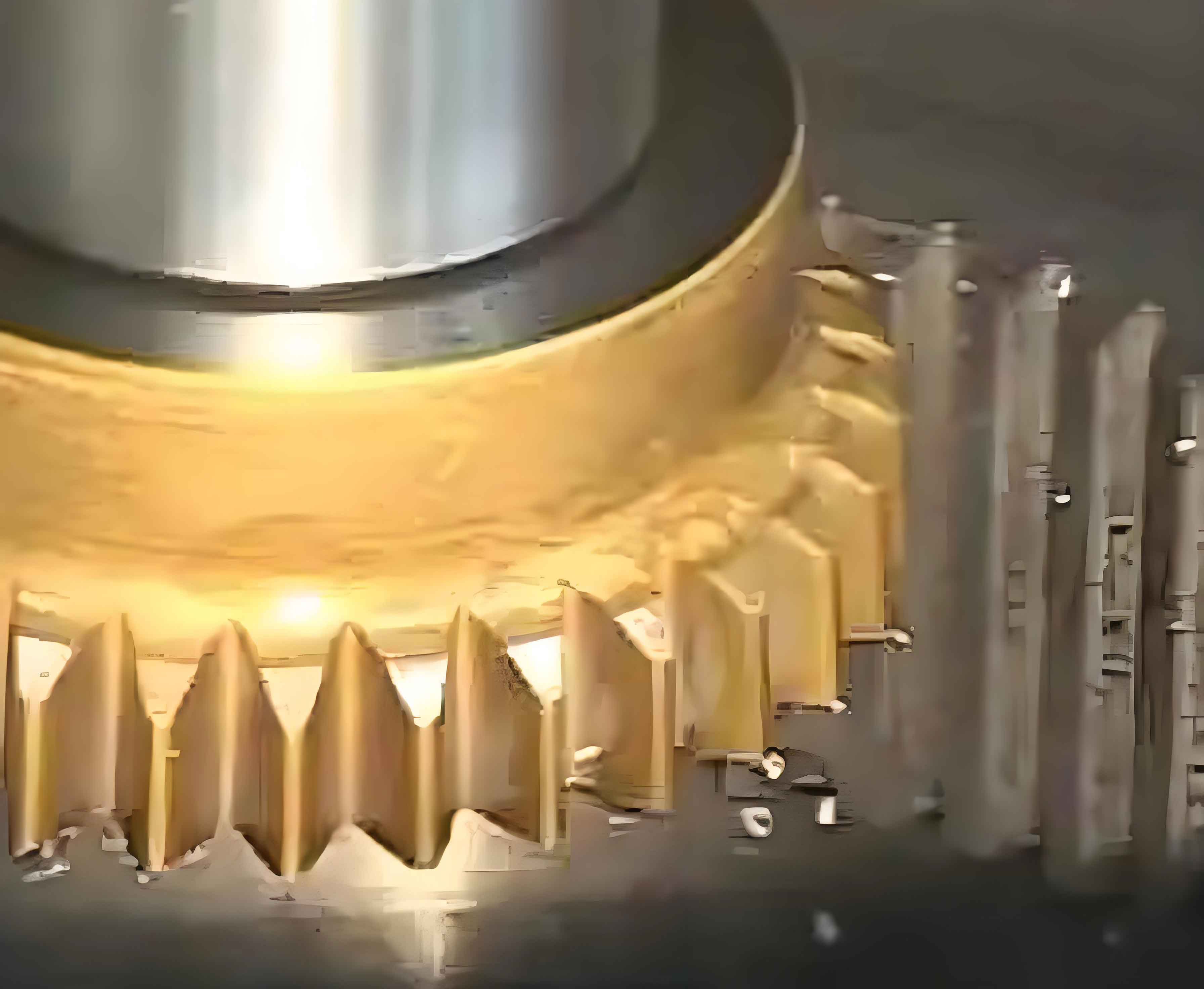

The simulation system successfully generated the tooth profiles via the envelope method. The graphical results showed complete, healthy tooth forms for both the external and internal gears, confirming the correctness of the basic gear shaping model. The simulated internal gear profile matched the expected geometry without signs of gouging, proving the effectiveness of the retraction algorithm. The final step was physical machining on a standard three-axis CNC gear shaping machine. The generated G-code was uploaded, and machining parameters such as cutting speed, feed rate, and retraction amount were set. The gear shaping process involved several roughing and finishing cycles, similar to cylindrical gear machining.

The machined non-circular internal gear exhibited a precise and smooth tooth form, with no evidence of retraction interference or undercutting. Surface roughness measurements on the tooth flanks yielded \( R_a \) values between 0.7 and 0.9 μm, meeting design specifications. Furthermore, coordinate measurement machine (CMM) data points from a machined tooth were plotted against the theoretically simulated tooth profile. The close alignment between the measured and simulated profiles provided strong empirical validation of the entire gear shaping methodology, from mathematical modeling to practical CNC execution.

This research establishes a robust framework for the gear shaping of non-circular internal gears. The primary contribution is a concise yet comprehensive mathematical model for three-axis linkage gear shaping, derived from the pitch curve normal vector. This model is computationally efficient and directly applicable to CNC programming. Secondly, clear analytical conditions for preventing undercutting at the design stage and for identifying retraction interference during the gear shaping process have been formulated. Most importantly, a practical software-based solution for retraction interference has been proposed and verified, enabling the use of cost-effective, general-purpose three-axis gear shaping machines. This eliminates the need for expensive multi-axis machines or specially modified cutters with offset centers. The developed automatic programming and simulation system not only validates the process offline but also enhances the functionality of standard machines, supporting small-batch, economical production of high-precision non-circular internal gears. Future work may explore the extension of this gear shaping philosophy to more complex spatial non-circular gears or the integration of real-time monitoring to further optimize the cutting process.

The gear shaping process, as detailed in this investigation, proves to be an exceptionally versatile method for producing non-circular internal gears. The successful implementation hinges on the precise synchronization of rotational and linear axes governed by the derived equations. The interference avoidance strategy is a critical component that transforms a theoretical model into a practical manufacturing solution. By addressing both geometric generation and kinematic constraints, this work demonstrates that advanced gear shaping is achievable without prohibitive investment, paving the way for broader adoption of non-circular gears in innovative mechanical systems. The repeated focus on gear shaping throughout this study underscores its centrality as a viable and efficient manufacturing pathway for these specialized components.