In the process of constructing the real tooth surface of digital hypoid gear, in order to quickly and accurately describe the wear condition of hypoid gear tooth surface, it is necessary to divide the discrete data points of hypoid gear tooth surface into blocks, judge the wear area of hypoid gear tooth surface, and accurately describe the wear area by using local interpolation algorithm, so as to reduce the amount of interpolation calculation of hypoid gear tooth surface. The traditional data block method is often based on the regular geometric features of parts, which is not applicable to the free-form surface describing the real tooth surface of hypoid gear. A non feature based discrete data block technology is proposed to accurately identify the wear area of hypoid gear tooth surface.

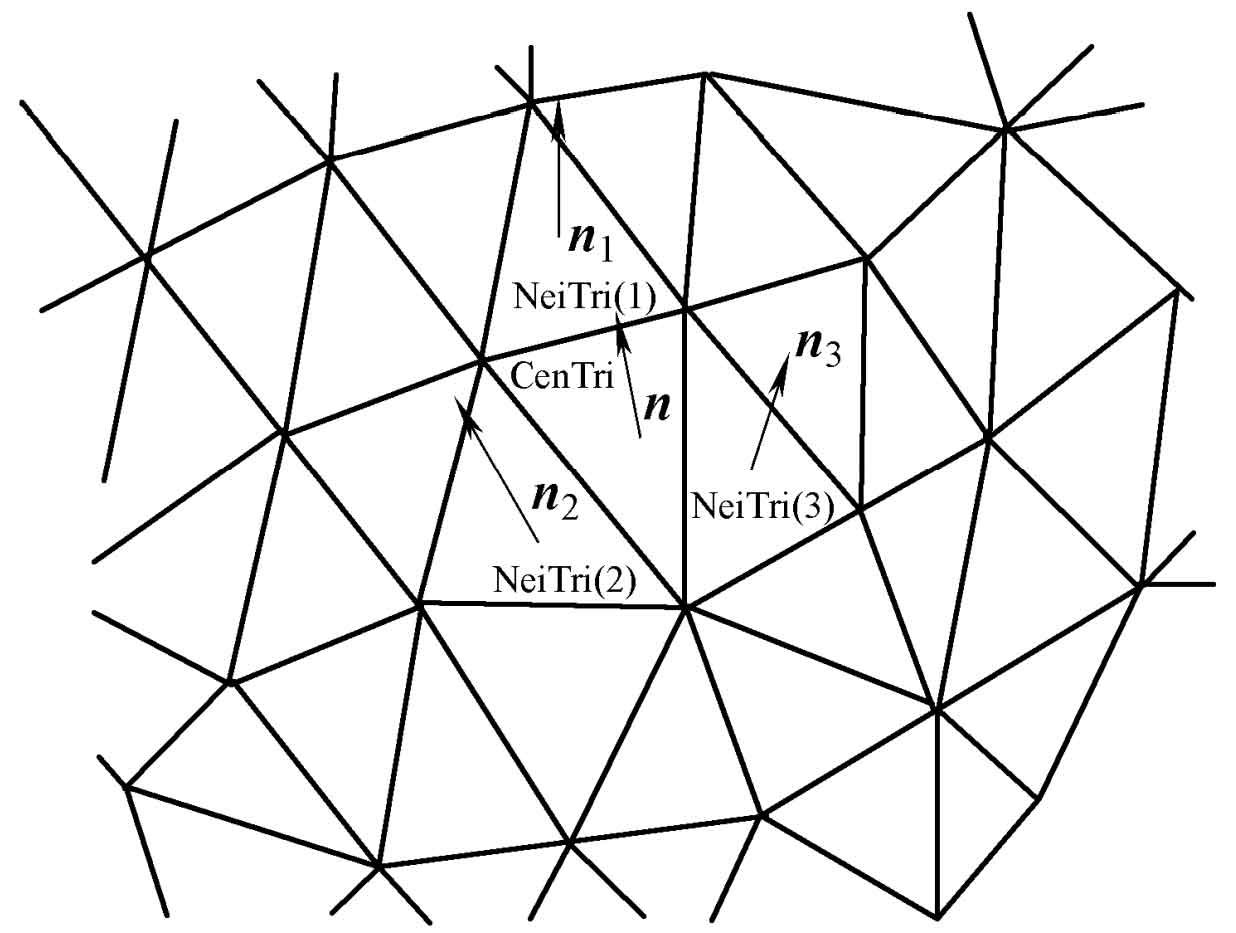

Let any triangle on the tooth surface Σ of digitally fitted hypoid gear be taken as the central triangle centri, its normal vector is n, and its adjacent triangle neitri (I) normal vector is Ni, I = 1,2,3. The included angle between the central triangle centri and the adjacent triangle neitri (I) is δ i 。 Traverse all central triangles, calculate the T value of each central triangle according to the formula, and select the central triangle with the smallest t value as the starting triangle statri, as shown in Figure 1.

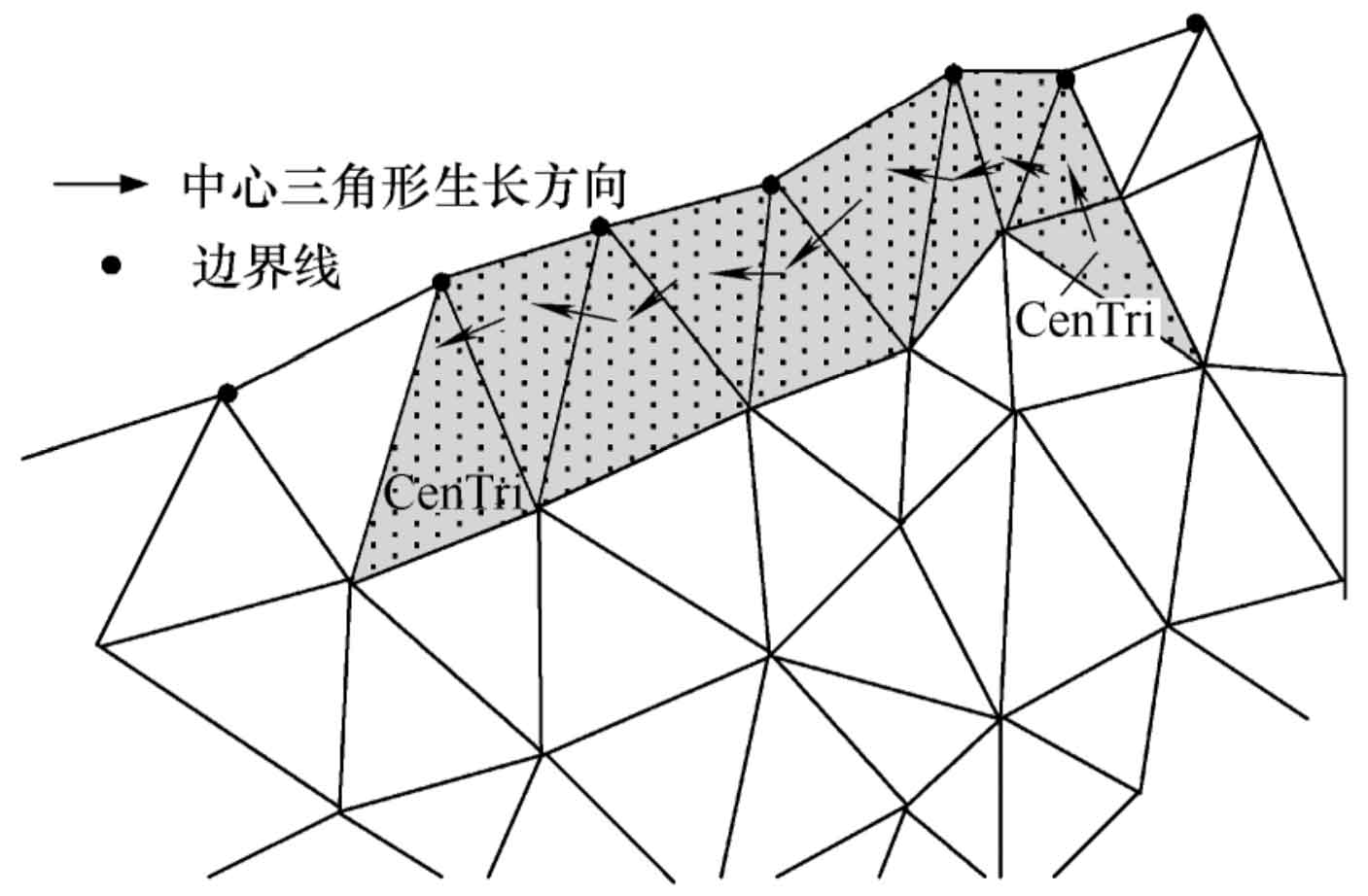

The adjacent triangle neitri (I) with the smallest angle with the normal vector of the starting triangle sitri is taken as the central triangle centri. If the formula can be satisfied, the adjacent triangle neitri (I) with the smallest angle with the normal vector of the central triangle centri in addition to the starting triangle sitri is taken as the central triangle centri; Otherwise, the starting triangle statri is re selected, and the blocking process based on non characteristic discrete data is shown in Figure 2.