Introduction

In the cement industry, the maintenance and repair of critical equipment such as edge transmission open gear mills are paramount to ensuring continuous and efficient production. One of the most challenging aspects of maintaining these mills is the repair of the shell flanges, especially when dealing with cracks and wear that occur during operation. This article delves into the online repair process of the shell flanges of an edge transmission open gear mill, focusing on the methods, challenges, and outcomes of such repairs. The case study presented here is based on a real-world scenario where a cement company successfully repaired the shell flanges of a Φ3.2m×13m edge transmission mill, ensuring its continued operation for over four years without any issues.

Background

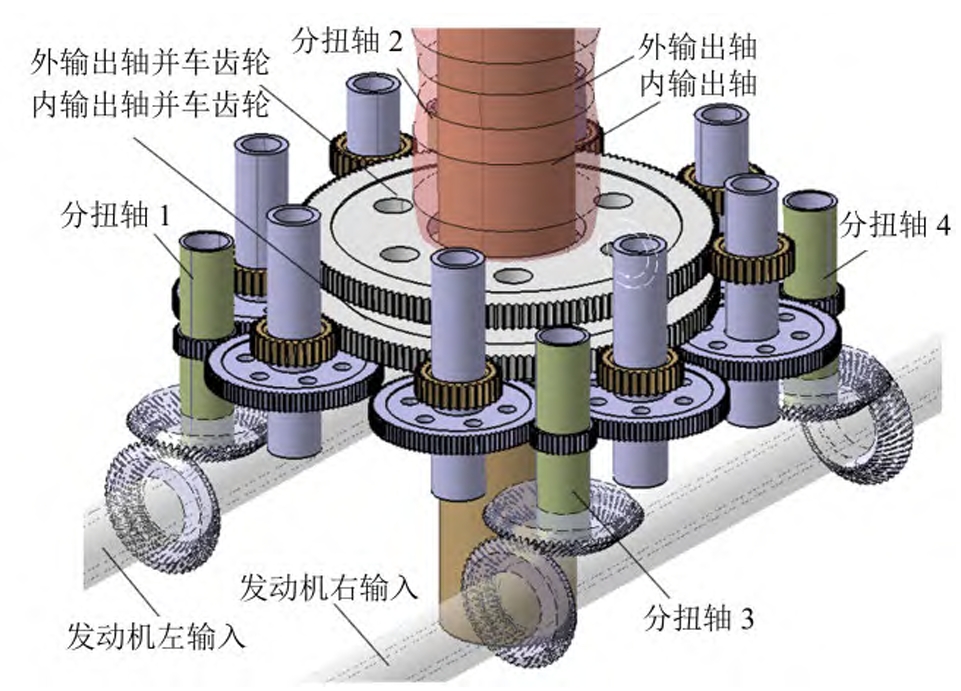

The edge transmission open gear mill is a critical component in the cement production process. It consists of a large gear (bull gear) and a small gear (pinion gear) that work together to rotate the mill shell. The shell flanges, which are part of the mill shell, are subjected to significant stress and wear during operation. Over time, cracks can develop in these flanges, leading to increased vibration, misalignment, and ultimately, equipment failure.

In the case study, the company faced severe vibration issues in their 2# cement mill, which was installed in 2010. Despite various attempts to address the vibration problems, the issues persisted, leading to the eventual cracking of the mill tail shell flange in 2016. The initial repair attempts, which involved welding the cracks, were unsuccessful, and the vibration issues worsened over time. By 2019, the situation had deteriorated to the point where the mill could no longer operate safely, and a comprehensive online repair was necessary.

Problem Analysis

The root cause of the vibration issues and subsequent flange cracking was identified as poor installation and alignment of the bull gear during the initial setup. The radial and axial runout of the bull gear were found to be outside the acceptable limits, leading to improper meshing of the gears and increased stress on the shell flanges. Additionally, the initial repair attempts failed to account for the weight of the mill shell, which caused deformation of the flange during welding, further exacerbating the alignment issues.

Repair Strategy

To address these issues, the company decided to perform an online repair of the shell flange, which involved the following steps:

- Measurement of Bull Gear Runout: The first step was to measure the radial and axial runout of the bull gear flange. This was done by dividing the flange into 16 equal segments and using a dial indicator to measure the runout at each point. The measurements revealed significant variations in the runout, with the maximum axial runout reaching 3.85 mm.

- Welding of the Flange: The next step was to weld the flange to restore its original dimensions. The welding process involved using a CO2 gas-shielded welding technique with CET1T-1 welding wire, which provided good fusion and minimal deformation. The welding was done in multiple layers, with each layer being no more than 1.5 mm thick, to minimize heat input and reduce the risk of deformation.

- Installation of the Turning Device: After welding, a turning device was installed to machine the flange to the required dimensions. The device was mounted above the pinion gear, and the mill shell was rotated using an auxiliary drive system. The turning process was carried out in two stages: a slow initial turning to remove the high points, followed by a faster turning to achieve the final dimensions.

- Measurement and Adjustment: Once the turning was complete, the flange was measured again to ensure that the runout was within acceptable limits. The bull gear and pinion gear were then reinstalled, and the gear meshing was adjusted to ensure proper alignment. The final step was to check the concentricity of the pinion gear, reducer, and motor, with the maximum allowable deviation being 0.2 mm.

Results and Discussion

The online repair of the shell flange was successful, and the mill has been operating without any issues for over four years. The key to the success of the repair was the careful measurement and control of the flange dimensions, as well as the use of appropriate welding and machining techniques. The following table summarizes the key steps and outcomes of the repair process:

| Step | Description | Outcome |

|---|---|---|

| Measurement of Bull Gear Runout | Divided flange into 16 segments and measured radial and axial runout. | Identified significant variations in runout, with maximum axial runout of 3.85 mm. |

| Welding of the Flange | Used CO2 gas-shielded welding with CET1T-1 wire in multiple layers. | Restored flange dimensions with minimal deformation. |

| Installation of Turning Device | Mounted turning device above pinion gear and rotated mill shell. | Achieved precise machining of the flange. |

| Measurement and Adjustment | Reinstalled bull gear and pinion gear, adjusted meshing, and checked concentricity. | Ensured proper alignment and reduced vibration. |

Conclusion

The online repair of the shell flange of an edge transmission open gear mill is a complex but feasible process that can be carried out without the need to disassemble the mill. The key to success lies in careful measurement, controlled welding, and precise machining. By following the steps outlined in this article, cement companies can effectively repair their mills and ensure continued production with minimal downtime.