1. Introduction

Bevel gears play a crucial role in mechanical transmission systems, being widely used in various fields such as aerospace, automotive, and construction machinery. The quality of their tooth surfaces is a vital indicator for evaluating the performance of meshing transmission. In the three – dimensional measurement of bevel gears, traditional contact – based measurement methods using 45 discrete grid points have low efficiency and are difficult to obtain full – tooth – surface data. With the development of optical measurement technology, it has effectively compensated for the shortage of tooth – surface measurement points.

However, the quality assessment of bevel gears often relies on complex tooth – surface mathematical models. These models are influenced by both the design parameters of bevel gears and the machine adjustment parameters. In practical quality evaluation, it is often difficult to obtain these process parameters, making it challenging to establish the theoretical mathematical model of the tooth surface. Therefore, the relative evaluation method emerges as a more ideal choice. This article will deeply explore the relative method evaluation in the three – dimensional measurement of bevel gears, including its principles, measurement systems, experimental verification, and future research directions.

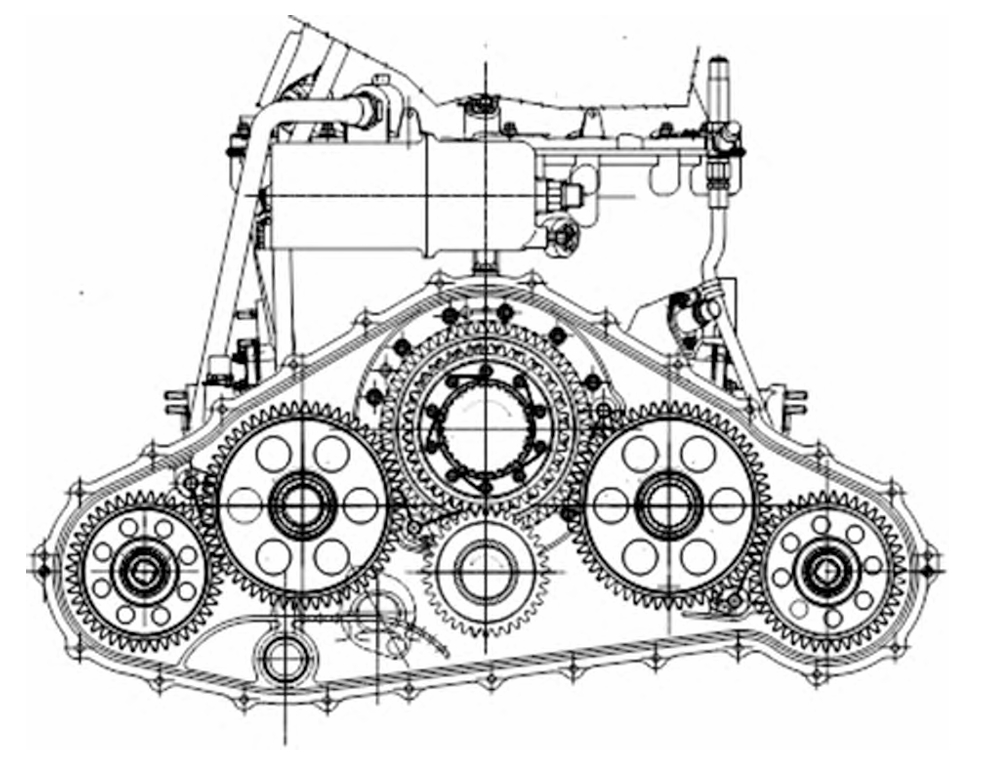

Figure 1: Applications of Bevel Gears in Different Industries [Insert an image showing bevel gears in aerospace engines, automotive differentials, and construction machinery]

2. Relative Method Evaluation Principles

2.1 Theoretical Tooth Surface of Bevel Gears

The three – dimensional coordinate system of bevel gears is established with the z – axis coinciding with the gear’s rotation axis, and the xOy plane perpendicular to the z – axis and coinciding with the large – end end – section of the bevel gear. The origin o is located at the intersection of the z – axis and the large – end end – section of the gear. The tooth – surface equation of bevel gears can be expressed in a general form, which serves as the theoretical basis for understanding the geometric shape of bevel gear tooth surfaces. Although we avoid complex mathematical formulas here, this equation is fundamental for further research on tooth – surface evaluation.

2.2 Establishing the Datum Tooth Surface

To establish the datum tooth surface, a workpiece gear with better tooth – surface quality is selected from the same batch of bevel gears as the datum gear. A special U – V – W coordinate system is established on the tooth surface. The U – direction is from the tooth root to the tooth tip, the V – direction is from the large end to the small end of the bevel gear, and the W – direction represents the 序号 of each tooth.

The discrete point – cloud data of the tooth surface of the datum gear can be expressed as a structured three – dimensional model. After obtaining the discrete data, all the tooth surfaces of the datum gear are averaged to form the datum tooth surface. Then, the NURBS (Non – Uniform Rational B – Spline) surface fitting method is used to fit the datum tooth surface. This fitting method can better approximate the actual tooth – surface shape, providing a more accurate reference for subsequent relative evaluations.

Table 1: Comparison of Different Coordinate Systems for Bevel Gear Tooth – Surface Representation

| Coordinate System | Definition | Advantage | Disadvantage |

|---|---|---|---|

| U – V – W | U: from tooth root to tooth tip; V: from large end to small end; W: tooth number | Easy to describe the position of points on the tooth surface | Not commonly used in general mechanical design |

| Cartesian Coordinate System (\(x – y – z\)) | Standard Cartesian coordinates | Compatible with general geometric calculations | Difficult to directly reflect the characteristics of bevel gear tooth surfaces |

2.3 Relative Evaluation

After establishing the datum tooth surface, the three – dimensional tooth – surface information of the actual bevel gear is obtained through optical measurement methods. The actual gear’s data point set is then compared with the datum tooth surface by placing them in the same position in the gear coordinate system.

The relative position relationship between the actual tooth surface and the datum tooth surface is used to calculate the normal deviation. This normal deviation reflects the difference between the actual tooth surface and the datum tooth surface, which can be used as an important indicator for evaluating the quality of the bevel gear tooth surface. A smaller normal deviation indicates that the actual tooth surface is closer to the datum tooth surface, and the quality of the bevel gear is relatively better.

Figure 2: Schematic Diagram of Relative Evaluation between Actual and Datum Tooth Surfaces [Insert an image showing the actual and datum tooth surfaces in the gear coordinate system with arrows indicating the normal deviation]

3. Gear Three – Dimensional Measurement System

3.1 Experimental Device

The experimental device for bevel gear three – dimensional measurement consists of a gear measurement center equipped with a line – structured light sensor. The measured gear is installed on the instrument’s rotary spindle and rotates at a certain speed. The line – structured light sensor is installed on the base of the linear moving axis through a fine – tuning platform, which can adjust its spatial position and pose.

During the measurement process, the rotation angle signal of the spindle serves as an external trigger source to trigger the sensor to collect signals, enabling real – time acquisition of tooth – surface contour data. The selected Keyence LJ – V7000 series line – structured light sensor has excellent performance, with a nominal distance of 60mm, a measurement line width range of 13.5 – 15mm, a height measurement range of ± 8mm, and a repeat accuracy of 0.4μm.

Table 2: Technical Parameters of Keyence LJ – V7000 Series Line – Structured Light Sensor

| Parameter | Value | Significance |

|---|---|---|

| Nominal Distance | 60mm | Determines the working distance between the sensor and the measured gear |

| Measurement Line Width Range | 13.5 – 15mm | Affects the width of the measured area on the tooth surface |

| Height Measurement Range | ± 8mm | Limits the range of height values that can be measured on the tooth surface |

| Repeat Accuracy | 0.4μm | Reflects the precision of repeated measurements |

3.2 Coordinate System Establishment

Three coordinate systems are established in the measurement system: the gear coordinate system \(O_{g}-x_{g}y_{g}z_{g}\), the world coordinate system \(O_{0}-x_{0}y_{0}z_{0}\), and the sensor coordinate system \(o – x_{s}y_{s}z_{s}\). The \(z_{g}\) – axis of the gear coordinate system coincides with the gear axis and rotates with the gear. The \(z_{0}\) – axis and the origin \(o_{0}\) of the world coordinate system coincide with the \(z_{g}\) – axis and the origin \(O_{g}\) of the gear coordinate system respectively. The origin \(O_{s}\) of the sensor coordinate system is located at the center point of the emitted laser line, and the plane \(x_{s}O_{s}y_{s}\) is parallel to the laser plane.

Through the transformation matrix related to the gear rotation angle \(\varphi\) and the sensor pose parameters \([\alpha,\beta,x,a,b,c]\), the measured three – dimensional tooth – surface data of the bevel gear can be obtained. This coordinate system establishment is crucial for accurately measuring and analyzing the tooth – surface shape of bevel gears.

Figure 3: Schematic Diagram of the Coordinate Systems in the Measurement System [Insert an image showing the three coordinate systems and their relationships]

4. Experimental Verification

4.1 Obtaining the Datum Tooth Surface

A high – quality workpiece gear is selected from a batch of bevel gears with the same parameters as the datum gear. The three – dimensional data point cloud of the nine tooth surfaces of the datum gear is obtained, which is then used as the basis for subsequent comparisons. This datum tooth – surface data provides a reference standard for evaluating the quality of other bevel gears in the same batch.

Figure 4: Three – Dimensional Data Point Cloud of the Datum Tooth Surface [Insert an image showing the point cloud of the datum tooth surface]

4.2 Obtaining the Measured Tooth Surface

The measured bevel gear is placed in the three – dimensional measurement experimental device. The original data of the actual tooth surface of the gear is measured, and after coordinate transformation, the three – dimensional point cloud of the measured bevel gear is obtained.

Due to the influence of factors such as the offset of the line – structured light sensor in the x – axis direction, the curvature of the bevel gear tooth surface, and laser re – reflection, only one side of the tooth surface can be measured at a time. In this experiment, the convex surface of the bevel gear tooth is selected for measurement, with each tooth surface having approximately 3.2 million points. The data in the z – axis direction is concentrated between – 3mm and 3mm. To obtain the point – cloud data of both sides of the bevel gear tooth surface, the sensor can be symmetrically moved along the xc – axis and equidistantly moved along the z – axis.

Table 3: Characteristics of Measured Tooth – Surface Data

| Characteristic | Value | Impact |

|---|---|---|

| Number of Measured Points per Tooth Surface | Approximately 3.2 million | Affects the accuracy of tooth – surface reconstruction |

| z – axis Data Concentration Range | – 3mm – 3mm | Reflects the range of height values on the measured tooth surface |

| Measurement Side | Convex surface | Determines the area of the tooth surface being evaluated |

4.3 Deviation Calculation and Analysis

To facilitate the comparison and analysis between the actual tooth surface and the datum tooth surface, all the discrete points on the tooth surface are projected onto the axial section. By matching the point – cloud coordinates of the two tooth surfaces, the normal deviation of the actual tooth surface relative to the datum tooth surface is calculated.

The maximum normal deviation value and the minimum normal deviation value are obtained, which can directly reflect the deviation degree of the actual tooth surface from the datum tooth surface. In addition, five bevel gears with the same parameters in the same batch are randomly selected for relative quality evaluation. The results show that the relative evaluation results of the selected gears are consistent, indicating that the production process of this batch of bevel gears is stable.

Table 4: Normal Deviation Results of Five Measured Bevel Gears (μm)

| Gear Number | Maximum Normal Deviation Value | Minimum Normal Deviation Value |

|---|---|---|

| Gear 1 | 2.026 | – 3.105 |

| Gear 2 | 2.146 | – 2.057 |

| Gear 3 | 2.441 | – 2.295 |

| Gear 4 | 2.555 | – 2.209 |

| Gear 5 | 2.496 | – 1.634 |

Figure 5: Comparison of Normal Deviation Results of Different Gears [Insert a bar chart showing the maximum and minimum normal deviation values of the five gears]

5. Conclusion and Future Research Directions

This article has studied the relative evaluation method in the three – dimensional measurement of bevel gears. By using a high – quality workpiece gear in the same batch as the datum gear and combining it with line – structured light gear three – dimensional measurement technology, the normal deviation and evaluation results of the measured bevel gear can be obtained.

Experimental results show that when it is difficult to construct the theoretical tooth surface, the relative evaluation method of bevel gear quality is an ideal solution. It overcomes the problems of relying on complex theoretical models and insufficient information acquisition in traditional measurements and can reflect the stability of the bevel gear production process.

In future research, efforts should be made to expand the information collection and quality evaluation of the full tooth width. This can better represent the quality of the entire tooth surface and more reliably monitor the stability of the production process on – site. Additionally, further research can be carried out on improving the accuracy of measurement systems and optimizing the relative evaluation method to make it more adaptable to different production scenarios and gear types.