1. Introduction

In the realm of aviation engine technology, the continuous pursuit of higher performance and efficiency has led to a significant increase in turbine inlet temperatures. As a result, the cooling of turbine components, especially turbine guide vanes, has become a crucial area of research. Traditional cooling methods using high – pressure air from the compressor have limitations, such as increased cooling air consumption, which negatively impacts engine performance and complicates the cooling structure.

The advent of non – air cooling media cooling technologies has brought new possibilities. Heat pipe technology, in particular, has gained increasing attention in the aviation industry. A heat pipe is a highly efficient heat transfer device that can transfer heat over long distances with a small temperature difference. In the context of turbine guide vanes, integrating heat pipe technology offers the potential to enhance cooling efficiency and reduce the reliance on traditional cooling air.

However, the current research on turbine guide vane heat pipes still has some shortcomings. In numerical simulations, simplifications like treating heat pipes as high – thermal – conductivity materials or reducing the flow dimension of the working fluid deviate from the actual situation, making it difficult to accurately evaluate the performance of the thermal protection system. Additionally, the flow resistance generated by the condenser section of the turbine blade heat pipe in the bypass duct increases the bypass duct pressure drop, affecting engine performance and limiting the height of the condenser section and its heat transfer capacity.

This study aims to address these issues by optimizing the structure of the turbine guide vane heat pipe condenser section. Through methods such as twisting the blade angle and changing the cross – sectional shape, the flow resistance is reduced, allowing for an increase in the condenser section height and heat transfer area without increasing the bypass duct pressure drop. The numerical simulation results of the optimized and traditional structures are compared to evaluate the improvement in thermal protection performance.

2. Physical Model

2.1 Turbine Guide Vane Heat Pipe Model

Based on the structure of the al – 31F engine, a 1:1 three – dimensional model of the turbine guide vane heat pipe and the duct was established. The turbine guide vane heat pipe extends directly from the inner duct to the outer duct. Due to the limitation of the gas flow pressure drop in the outer duct, the height of the condenser section does not exceed 10% of the total outer duct height, and the effective condenser area is only \(1886~mm^{2}\).

2.2 Optimized Model

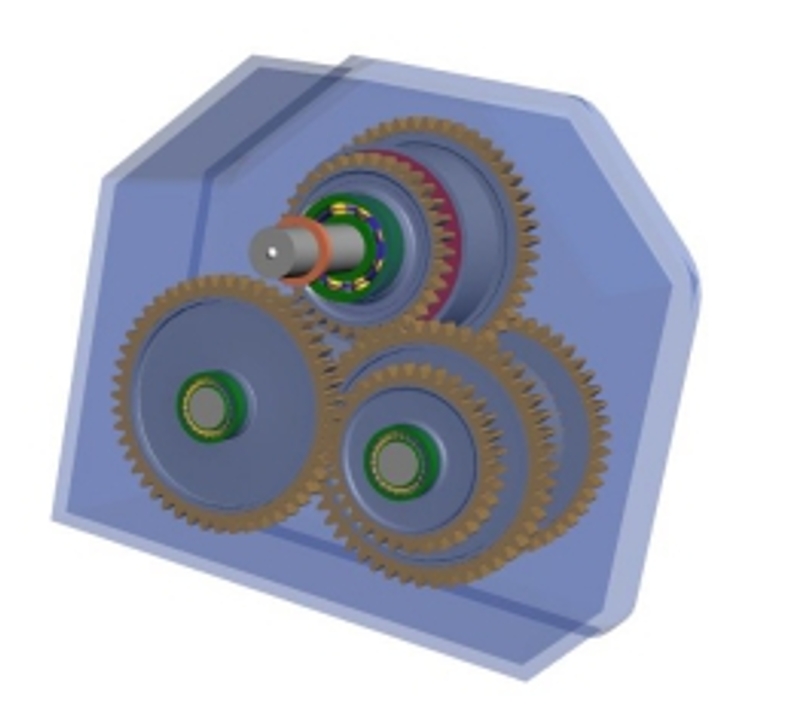

To minimize the impact of the condenser section on the downstream flow field of the outer duct, the structure of the condenser section in the outer duct part was optimized. First, the blade was twisted to reduce the angle between the blade and the incoming gas. Then, the blade cross – section was replaced with a droplet – shaped cross – section. Figure 2 shows the improved model (hereinafter referred to as the “optimized structure”). To minimize the impact of the structure shape on the working fluid flow in the vapor chamber and the wick, a smooth curved surface was used to connect the evaporation section and the condenser section in the adiabatic section, ensuring the continuity of the longitudinal isoparametric curves on the two surfaces.

The droplet – shaped cross – section is composed of two semi – ellipses. The shape of the condenser section cross – section is shown in Figure 3, and its profile equation is as follows.

Due to the reduction in flow resistance, the impact of the condenser section on the downstream is reduced, so the height of the condenser section can be increased to expand the condenser area. After optimization, the condenser section runs through the entire outer duct, with a height of 140 mm and an effective condenser area of \(18914~mm^{2}\), which is 10 times the original area. The specific physical parameters of the duct and the heat pipe are shown .

3. Mathematical Model

3.1 Control Equations

This study is based on a large – scale commercial computational fluid dynamics (CFD) program and uses user – defined functions (UDF) to model the flow and heat transfer characteristics of high – temperature sodium heat pipes. The following assumptions are made for the model:

- During the entire process, the gas – liquid interface remains stationary, and the evaporation and condensation processes only occur at the gas – liquid interface.

- The wick is completely filled with liquid, and the vapor chamber is only filled with vapor.

- Sodium vapor is an ideal gas.

- In the initial working condition and the calculation process, the fluid near the gas – liquid interface is in a saturated state.

3.2 Boundary Conditions

The numerical model of the high – temperature heat pipe has no velocity inlet boundary condition. In this study, mass source terms and momentum source terms are added to the first – layer grids on both sides of the gas – liquid interface to simulate the gas – liquid two – phase flow in the heat pipe, artificially creating “inlet and outlet” at the gas – liquid interface. The mass source term at the gas – liquid interface defines the “inlet and outlet mass flow rate”, the momentum source term defines the “inlet and outlet velocity”, and the interface temperature defines the “inlet and outlet temperature”.

The evaporation section of the heat pipe is the high – temperature gas in the inner duct, the condenser section is the low – temperature gas in the outer duct, and the convective heat transfer coefficient is automatically calculated by the software. The middle transition section is an adiabatic boundary. In the simulations of different models, the gas flow rates in the inner and outer ducts are set with reference to the same working condition of the engine, and their respective temperatures and incoming flow velocities are shown .

3.3 Working Fluid Physical Properties

The density of the vapor chamber and the wick can be expressed by the following formulas: \(\rho_{g}=\frac{P_{eq}}{R T_{g}}\) \(\rho_{1}=\frac{M_{1}^{0}+\Delta t \sum \dot{m}_{i}}{\varepsilon \sum V_{1}}\) where \(M_{1}^{0}\) represents the total mass of the liquid in the wick in the previous iteration step, and \(V_{1}\) is the volume of the grid unit in the wick.

3.4 Calculation Process

To calculate the physical parameters such as mass flow rate, temperature, and pressure at the interface and the density at each time step, UDF is programmed. Figure 4 shows the complete calculation process.

- Initialize the calculation parameters, including the physical properties of the working fluid, the geometric parameters of the model, and the boundary conditions.

- Use the Simple algorithm to solve the momentum equation, pressure correction equation, and energy equation iteratively.

- In each iteration, calculate the mass and momentum source terms at the gas – liquid interface using the relevant formulas, and update the physical parameters such as temperature, pressure, and density.

- Check whether the calculation results converge. If they converge, end the calculation; otherwise, continue the iteration.

4. Result Analysis

4.1 Outer Duct Flow Field

Figure 5(a) shows the velocity streamline diagram of the outer duct flow field of the traditional structure. The upper part of the flow field is almost unaffected by the condenser section, but the lower part of the flow field is very disordered due to the presence of the condenser section, with a maximum velocity of 105.56 m/s. Figure 5(b) shows the velocity streamline diagram of the outer duct flow field of the optimized structure. In the entire flow field, the outer duct gas flows stably through the drag – reducing structure of the condenser section, with a maximum velocity of 66.52 m/s.

During the flow process, the flow rate of the outer duct remains unchanged. The impact of the condenser section on the downstream can be directly represented by the pressure drop at the inlet and outlet of the outer duct calculation domain. The pressure drop at the inlet and outlet of the traditional – structure outer duct is 704.9 Pa, while that of the optimized structure is 338.4 Pa. The structural optimization of the turbine guide vane heat pipe effectively reduces the pressure drop of the outer duct, having a smaller impact on engine performance.

| Structure | Maximum Velocity in Outer Duct (m/s) | Outer Duct Inlet – Outlet Pressure Drop (Pa) |

|---|---|---|

| Traditional Structure | 105.56 | 704.9 |

| Optimized Structure | 66.52 | 338.4 |

4.2 Turbine Guide Vane Heat Pipe and Optimized Structure

Figure 6 shows the distribution of the average wall temperature along the height of the heat pipe for the two structures. The horizontal axis is the ratio of the heat pipe height to the total heat pipe height (dimensionless height). The average temperature of the inner – channel blade of the traditional structure is 1581 K, and the total heat transfer is 1680 W. The average temperature of the inner – channel blade of the optimized structure is 1342 K, and the total heat transfer is 7100 W.

Due to the short condenser section of the traditional structure, the temperature difference of the heat pipe wall in the condenser section is large, and the overall operating temperature is significantly higher than that of the optimized structure. After structural optimization, the condenser area of the outer – duct condenser section increases, resulting in an increase in total heat transfer. The overall temperature difference of the heat pipe increases, effectively reducing the blade temperature.

5. Conclusions

This study improved and optimized the turbine guide vane heat pipe model based on the droplet – shaped drag – reducing shape. Using the CFD method, numerical simulations of the traditional turbine guide vane heat pipe structure and the proposed optimized structure were carried out. By comparing the external duct pressure drop, wall temperature, vapor chamber velocity, and pressure distribution, the following conclusions were obtained:

- The application of the droplet – shaped drag – reducing structure in the condenser section of the outer duct can reduce the outer duct pressure drop from 704.9 Pa to 338.4 Pa, effectively reducing the impact of the condenser section on the downstream of the outer duct. At the same time, the effective condenser area is increased to 10 times the original.

- Due to the short condenser section and limited condenser area of the traditional structure, the total heat transfer is small. After structural optimization, the total heat transfer increases from 1680 W to 7100 W, and the average temperature at the hot end of the blade decreases from 1581 K to 1342 K. The change in structure reduces the hot – end temperature of the blade by 239 K, improving the thermal protection effect.

- When the heat pipe operates stably, parameters such as the wall temperature of the heat pipe and the velocity and pressure of the internal gas are greatly affected by the structure. The heat pipe structure, vapor density, total heat transfer, and other parameters lead to significant differences in the distribution and magnitude of the velocity in the vapor chambers of the two structures.

In general, the optimized structure proposed in this study shows obvious advantages in reducing the outer duct pressure drop and improving the thermal protection performance of the turbine guide vane heat pipe, providing a new idea for the design and optimization of turbine guide vane cooling structures in aviation engines. Future research can further explore the influence of different working conditions and heat pipe materials on the performance of the optimized structure to further improve the reliability and efficiency of the heat pipe cooling system.

6. Future Research Directions

6.1 Influence of Different Working Conditions

The current study focuses on a specific set of working conditions. However, in real – world applications, aviation engines operate under a wide range of conditions. Future research can investigate how the optimized turbine guide vane heat pipe structure performs under different engine loads, altitudes, and flight speeds. For example, at high altitudes, the air density and temperature change significantly, which may affect the heat transfer and flow characteristics of the heat pipe. By conducting numerical simulations or experiments under various working conditions, a more comprehensive understanding of the structure’s performance can be obtained. This will help in further optimizing the design to ensure its effectiveness across different operating scenarios.

6.2 Effect of Heat Pipe Materials

The choice of heat pipe materials plays a crucial role in its performance. In this study, 316 stainless steel is used as the tube wall material and sodium as the working fluid. Future research can explore the use of other high – performance materials. For instance, advanced alloys with better heat – transfer properties and higher temperature resistance can be considered for the tube wall. New working fluids with improved heat – transfer coefficients and phase – change characteristics may also be investigated. By changing the materials, the heat – transfer efficiency, durability, and overall performance of the heat pipe can be enhanced, potentially leading to even better thermal protection for turbine guide vanes.

6.3 Integration with Other Cooling Technologies

Although the optimized heat pipe structure shows promising results, combining it with other cooling technologies may further improve the cooling performance. For example, integrating it with thin – film cooling or transpiration cooling techniques can create a more comprehensive cooling system. Thin – film cooling can provide an additional layer of cooling on the surface of the turbine guide vane, while transpiration cooling can enhance heat transfer by allowing a cooling fluid to permeate through the porous surface of the vane. Studying the synergy between the heat pipe and these other cooling methods can lead to the development of more efficient and reliable cooling solutions for aviation engines.

6.4 Experimental Validation

While numerical simulations are a powerful tool for studying the heat pipe structure, experimental validation is essential to confirm the accuracy of the results. Future research should focus on conducting experiments to measure the actual performance of the optimized turbine guide vane heat pipe. This can involve building physical models of the heat pipe and testing them under controlled conditions in a laboratory or in an engine test rig. By comparing the experimental data with the numerical simulation results, any discrepancies can be identified and addressed. Experimental validation will not only enhance the confidence in the numerical models but also provide valuable insights for further improving the design of the heat pipe structure.

7. Significance of the Research

7.1 Improving Engine Performance

The reduction in outer – duct pressure drop and the enhancement of thermal protection performance achieved by the optimized heat pipe structure have a direct positive impact on engine performance. With less pressure drop in the outer duct, the engine can operate more efficiently, reducing the energy loss associated with gas flow. Lowering the temperature of the turbine guide vanes helps to maintain the structural integrity of the components, preventing premature failure due to high temperatures. This, in turn, improves the overall reliability and durability of the engine, leading to increased engine life and reduced maintenance costs.

7.2 Meeting the Demands of Future Aviation

As the aviation industry continues to evolve, there is a growing need for more efficient and powerful engines. The development of advanced cooling technologies, such as the optimized turbine guide vane heat pipe, is crucial for meeting these demands. By improving the cooling efficiency, engines can operate at higher temperatures, enabling higher thrust – to – weight ratios and better fuel efficiency. This is particularly important for next – generation aircraft, which aim to reduce emissions and improve environmental friendliness while also enhancing performance.

7.3 Contribution to Heat Pipe Technology Development

The research on the turbine guide vane heat pipe contributes to the broader field of heat pipe technology. The findings and design strategies developed in this study can be applied to other heat – transfer applications, not only in aviation but also in areas such as power generation, electronics cooling, and space technology. The understanding of how to optimize heat pipe structures for better performance can inspire new designs and improvements in heat – pipe – based systems, promoting the overall development of heat – transfer technology.