Abstract This article focuses on the acoustic signal aided detection method of spiral bevel gear based on PSO – MCKD. It begins with an introduction to the importance and challenges of spiral bevel gear detection. Then, it delves into the principles of PSO – MCKD, including the Maximum Correlated Kurtosis Deconvolution (MCKD) and Particle Swarm Optimization (PSO). The experimental setup and procedures for collecting and analyzing acoustic signals of spiral bevel gear is described in detail. The results of the experiments, such as the analysis of different axial deviations on gear meshing acoustic signals, are presented and discussed. The article also includes a comparison and verification of tooth surface imprint to further validate the method. Finally, the conclusions highlight the effectiveness and advantages of the proposed method in spiral bevel gear detection.

1. Introduction

Spiral bevel gear is widely used in complex mechanical equipment due to their large contact ratio, smooth meshing, and high load – carrying capacity. However, in the actual operation process, factors such as installation errors can affect the transmission accuracy and stability of the entire system. Traditional methods for detecting the transmission accuracy of spiral bevel gear, such as observing contact imprints, are often subjective and inaccurate. Therefore, exploring new methods for detecting the transmission accuracy of spiral bevel gear is of great significance.

In recent years, scholars have conducted in – depth research on the contact imprints of spiral bevel gear. Some studies have focused on qualitative analysis of contact imprints, while others have explored the relationship between installation errors and contact imprints. However, these methods still have limitations in accurately assessing the transmission accuracy of spiral bevel gear.

Acoustic detection technology has emerged as a promising approach for gear detection. By analyzing the sound signals generated during gear transmission, it is possible to accurately detect gear performance. The Maximum Correlated Kurtosis Deconvolution (MCKD) method has been proposed to process sound signals and extract periodic impulse components. However, the performance of MCKD depends on input parameters, and accurate selection of filter length and shift number is crucial. Particle Swarm Optimization (PSO) has been used to search for MCKD parameters to improve its signal processing ability.

In this article, we propose an acoustic signal – aided detection method for spiral bevel gear based on PSO – MCKD. This method combines a gear rolling inspection machine with an acoustic signal acquisition system to design a real – time acoustic signal acquisition experiment. By analyzing the amplitude of the meshing frequency and its harmonics in the frequency spectrum, we can assess the transmission accuracy of the gears.

2. Spiral Bevel Gear Contact Imprint

The contact imprint is an important indicator for evaluating the meshing quality of spiral bevel gear. It is formed by the contact of the tooth surfaces during gear transmission and reflects the meshing state of the gears. Axial deviation during gear installation can lead to abnormal contact imprints, resulting in increased vibration and noise and affecting the transmission accuracy of the gears.

| Axial Deviation | Impact on Contact Imprint | Impact on Gear Transmission |

|---|---|---|

| Large Wheel Axial Deviation | Unreasonable contact imprint shape, size, and position | Vibration and noise increase, affect transmission stability |

| Small Wheel Axial Deviation | Similar to large wheel axial deviation | Similar to large wheel axial deviation |

In practice, methods such as empirical judgment or multiple adjustments are often used to evaluate the meshing performance of gears. However, these methods are time – consuming and inaccurate. In this study, we introduce an acoustic measurement method to assist in evaluating the rationality of the contact imprint and improve the accuracy of meshing performance assessment.

3. PSO – MCKD – Based Gear Acoustic Signal Processing Method

3.1 Basic Principles

3.1.1 Maximum Correlated Kurtosis Deconvolution (MCKD)

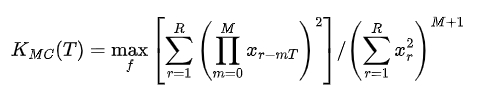

The MCKD method aims to find a finite impulse response filter by maximizing the correlated kurtosis of the input signal. Given an input signal y(u)=h(u)x(u)+e(u), where y(u) is the input signal, h(u) is the transmission response, x(u) is the periodic pulse, and e(u) is the noise component. The maximum correlated kurtosis is defined as:

where T is the deconvolution period and M is the maximum shift number. The optimal filter f can be calculated using specific formulas.

3.1.2 Particle Swarm Optimization (PSO)

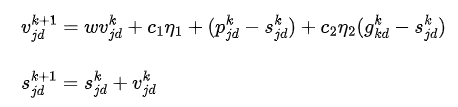

The PSO algorithm searches for the optimal solution by relying on the cooperation and information sharing among particles. Each particle has a velocity (v) and a position (s) and can independently explore the optimal solution. The velocity and position of particles are updated using the following formulas:

where is the inertia weight, and are learning factors, and and are random numbers in the range of . To balance the search ability and improve the overall performance of the algorithm, the inertia weight and learning factors are dynamically adjusted.

3.2 Spiral Bevel Gear Acoustic Signal Processing Flow

The PSO – optimized MCKD process involves initializing the PSO algorithm, calculating the particle fitness function value, and iteratively updating the particle position and velocity until the optimal solution is obtained. The parameters corresponding to the global optimal particle are the optimal solution for MCKD.

The acoustic signal detection process for spiral bevel gear includes inputting the collected sound signal, using PSO to optimize MCKD to find the optimal parameters and , setting the MCKD parameters to process the sound signal, and analyzing the Hilbert envelope spectrum to identify and analyze the relevant characteristic information.

4. Experimental Verification and Result Analysis

4.1 Acoustic Signal Measurement Experiment

A real – time acoustic signal acquisition test bench for spiral bevel gear was designed, consisting of a numerically controlled Y9550 bevel gear rolling inspection machine and an acoustic signal acquisition system. The acoustic signal acquisition system includes hardware and software components. The hardware mainly consists of a sound sensor and a data acquisition card, and the software is responsible for real – time display and data storage of time – domain and frequency – domain signals.

| Hardware Component | Specification |

|---|---|

| Sound Sensor | COINVINV9206 single – directional sound pressure sensor, with good sensitivity, directivity, working temperature, and dynamic range |

| Data Acquisition Card | PCI – 1742U data acquisition card of Advantech Technology |

Before the experiment, the hardware devices were checked to ensure they were in good working condition. The sound sensor was fixed above the spindle box, and the sampling frequency and sampling duration were set. Different axial installation errors were set during the experiment, and the audio signals of the gear meshing were collected and analyzed.

4.2 Measured Acoustic Signal Analysis

4.2.1 Gear Set Forward Deviation Acoustic Signal Analysis

For gear sets with different positive axial deviations (, , ), the time – domain and frequency – domain characteristics of the meshing sound signals were analyzed. In the time – domain signal without deviation, the periodic pulse was not obvious, so the frequency – domain analysis was mainly carried out. The results showed that as the axial deviation increased positively, the amplitude of the meshing frequency and its harmonics increased, while the meshing frequency and its harmonics themselves did not change significantly.

| Gear Set | 1 – fold Frequency Amplitude | 2 – fold Frequency Amplitude | 3 – fold Frequency Amplitude |

|---|---|---|---|

| A – F () | 0.171 | 0.036 | 0.029 |

| A1 – F1 () | 0.172 | 0.042 | 0.040 |

| A2 – F2 () | 0.257 | 0.087 | 0.073 |

4.2.2 Gear Set Negative Deviation Acoustic Signal Analysis

For gear sets with different negative axial deviations (, , ), similar analyses were carried out. The results showed that as the axial deviation increased negatively, the amplitude of the meshing frequency and its harmonics also increased, while the meshing frequency and its harmonics themselves did not change significantly.

| Gear Set | 1 – fold Frequency Amplitude | 2 – fold Frequency Amplitude | 3 – fold Frequency Amplitude |

|---|---|---|---|

| A – F () | 0.154 | 0.037 | 0.032 |

| A – F () | 0.163 | 0.068 | 0.029 |

| A – F () | 0.473 | 0.079 | 0.085 |

5. Tooth Surface Imprint Comparison Verification

To verify the feasibility and accuracy of the proposed method, a high – precision spiral bevel gear pair was used as an example. The tooth surface imprints were detected using a numerically controlled Y9550 bevel gear rolling inspection machine. The tooth surfaces of the large and small wheels were colored, and the axial deviation was adjusted according to the data. The contact imprints were observed and compared with the results of the acoustic signal – aided detection method.

The results showed that as the axial deviation increased, the shape and area of the contact imprints changed significantly, which was consistent with the results of the acoustic signal – aided detection method. This verified the feasibility and accuracy of the proposed method in assessing the transmission accuracy of spiral bevel gear.

6. Conclusions

In this article, an acoustic signal detection experiment for spiral bevel gear was designed, and an acoustic signal – aided detection method for the transmission accuracy of spiral bevel gear based on PSO – MCKD was proposed. The following conclusions were obtained:

- The designed acoustic signal detection experiment scheme can accurately detect the transmission accuracy and running state of spiral bevel gear, improving the accuracy and efficiency of detection and reducing the risk of false positives and false negatives.

- The proposed PSO – MCKD – based acoustic signal processing method effectively improves the accuracy and filtering and noise reduction performance of the MCKD algorithm. It can effectively extract continuous transient impacts of weak signals and has achieved good results in the processing of spiral bevel gear acoustic signals.

- The analysis of measured signals shows that an increase in axial deviation leads to an increase in the amplitude of the meshing frequency and its harmonics. The method provides effective auxiliary support for evaluating the transmission accuracy of gears based on tooth surface contact imprints.

Overall, the proposed method overcomes the limitations of traditional detection methods and provides a more accurate and efficient way to detect the transmission accuracy of spiral bevel gear.