The essence of swing rolling is a special two roll rolling. In the process of rotary forging, although the swing head is only in partial contact with the workpiece, the workpiece as a continuous whole, and the non-contact part is also passively stressed.

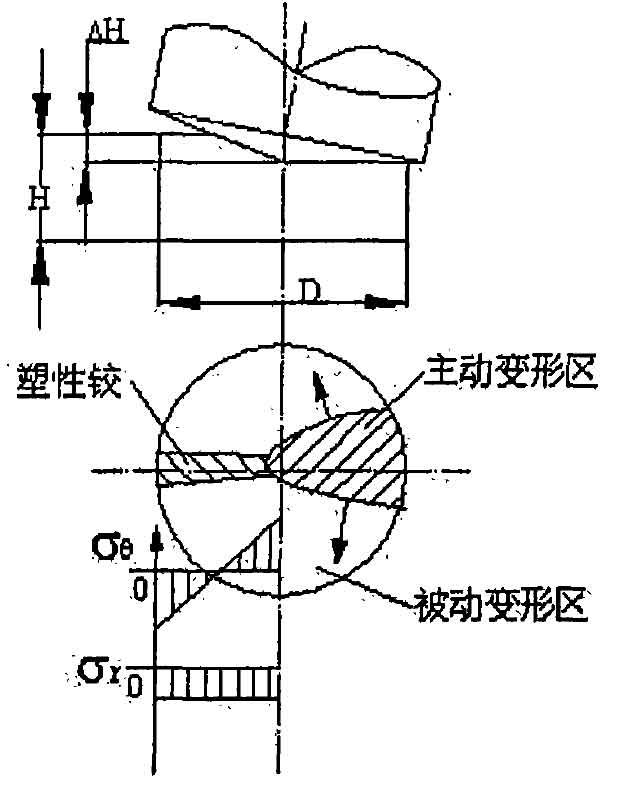

The machined surface of the workpiece can be divided into contact area and non-contact area. The contact area directly bears the rotary rolling pressure and produces plastic deformation, so it is called the active deformation area: the non-contact part bears the side pressure brought by the active deformation area, because the active deformation area extends tangentially under the rolling pressure and produces side pressure on the non-contact area, so the non-contact area is called the passive deformation area. The deformation of the workpiece is composed of these two parts, as shown in Figure 1:

1 Deformation of active deformation zone

The non-contact part bears the side pressure brought by the active deformation area, because the active deformation area extends tangentially under the rolling pressure and generates side pressure on the non-contact area, so the non-contact area is called the passive deformation area. The deformation of the workpiece is composed of these two parts, as shown in Figure 1. The metal flow trend can be roughly divided into two parts: the part close to the free side The metal flows radially, and the rest of the metal mainly flows tangentially. Its strain characteristics are as follows:

2 Deformation of passive deformation zone

Due to deformation of active deformation zone εθ> 0. The active deformation zone is equivalent to a wedge applying side pressure to the passive deformation zone, so the passive deformation zone generates resistance to hinder the deformation of the active deformation zone. The resistance will change with the deformation of the active deformation zone, and its value is related to the relative thickness of the processed workpiece and the relative feed of axial rolling.

Under the lateral pressure of the active deformation zone, the deformation of the passive deformation zone can be in the following three cases:

1) Small elastic deformation;

2) . large elastic deformation, elastic instability, resulting in warpage or wrinkling;

3) When the workpiece (preform) is thin, a so-called “plastic hinge” is formed at the radial symmetrical part of the active deformation area, as shown in Fig. 2.

At thisAt this time, the inner side of the plastic hinge is in tension, σθ> 0, lateral compression σθ< 0. In this way, it is easy to cause the inner layer to become thinner, ε Z < 0, the outer layer becomes thicker, ε z> 0. The deformation zone outside the plastic hinge is elastic deformation. When the workpiece (preform) is thick, there is no plastic hinge in the passive deformation zone.