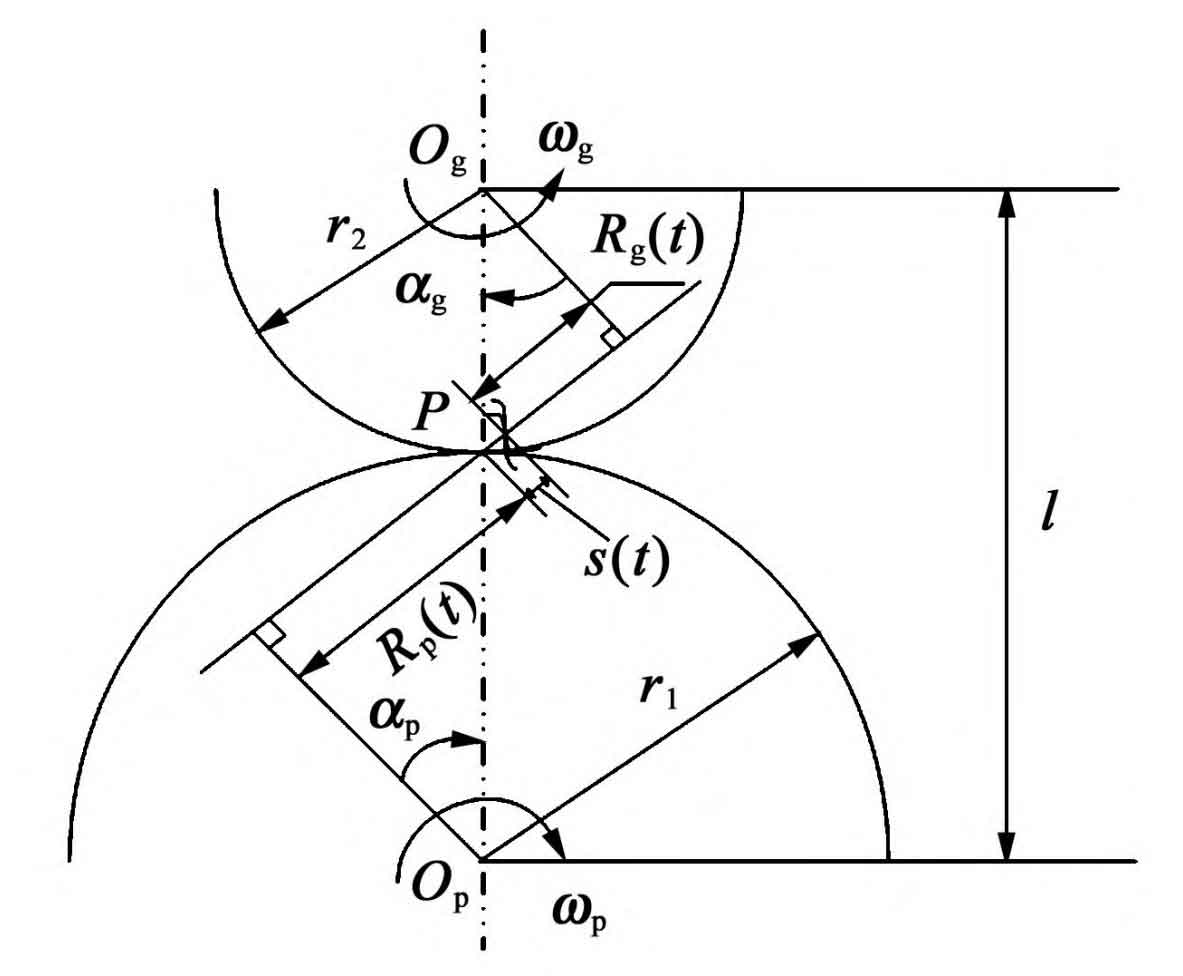

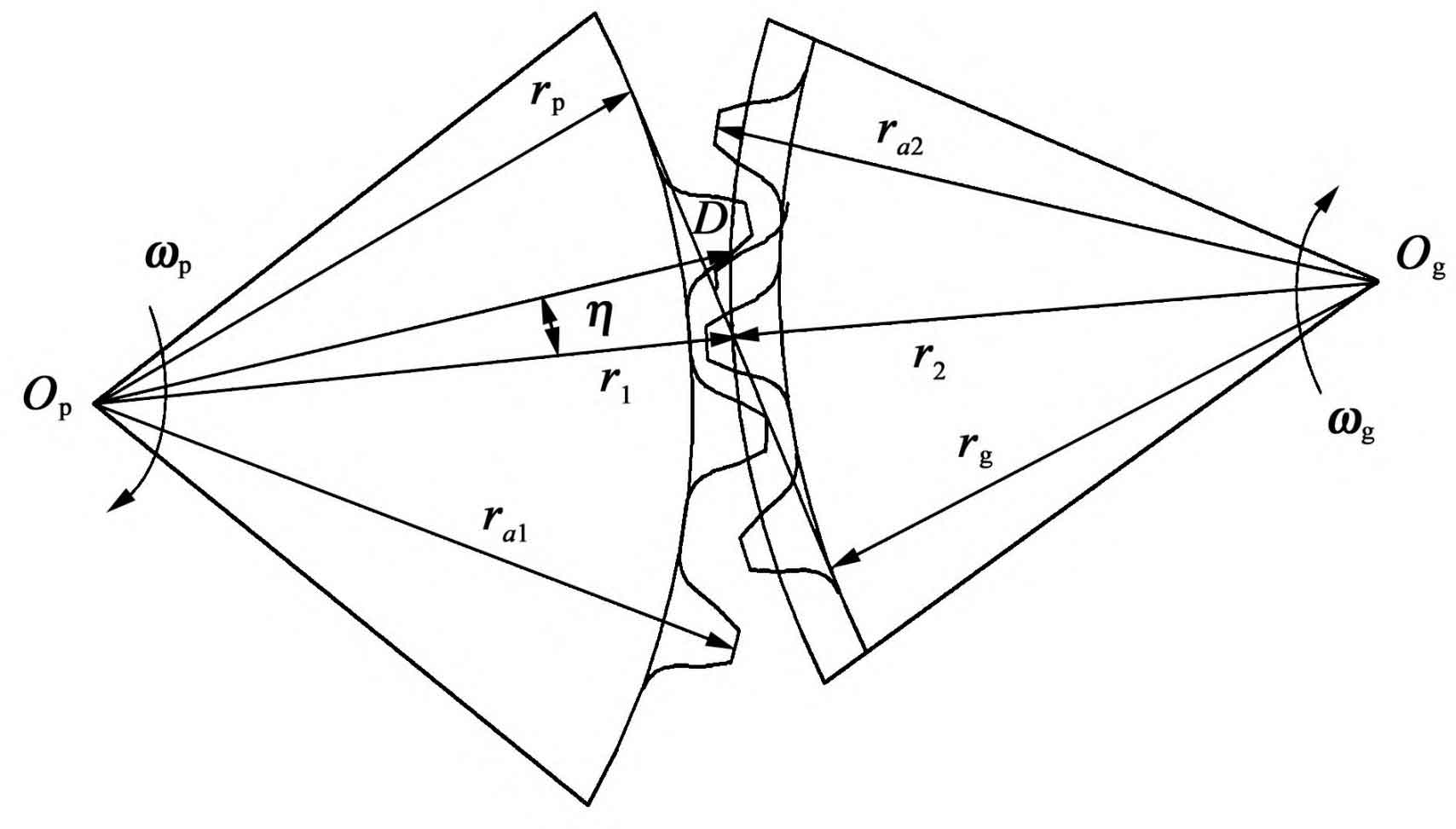

The actual meshing state of spur gear is shown in Figure 1, and the distance from the node to the instantaneous meshing point is s (T). According to the previous assumptions, the surface roughness follows the Gaussian random distribution, and the random part of S (T) also follows the Gaussian distribution, including:

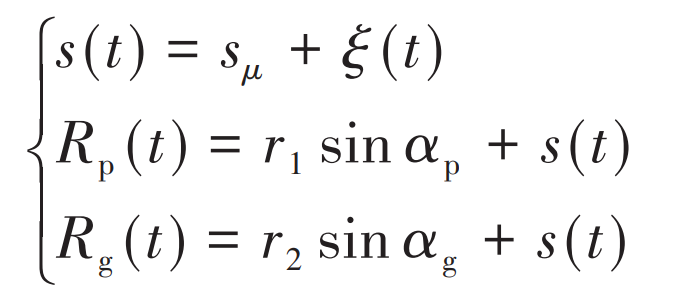

Where, s μ In order to solve the mean value of the distance from the instantaneous meshing point on the spur gear profile to the pitch circle of the spur gear by using the geometric relationship, the calculation model is shown in Figure 2.

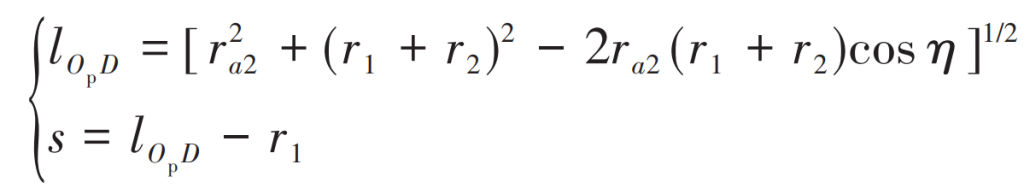

According to the meshing principle and geometric relationship, according to the geometric model established in the early stage, it is improved, s is calculated by formula, and the mean s of S is calculated μ:

Where R1 is the pitch circle radius of driving wheel; R2 is the pitch circle radius of the driven wheel; Ra2 is the radius of the top circle of the driven tooth of spur gear.

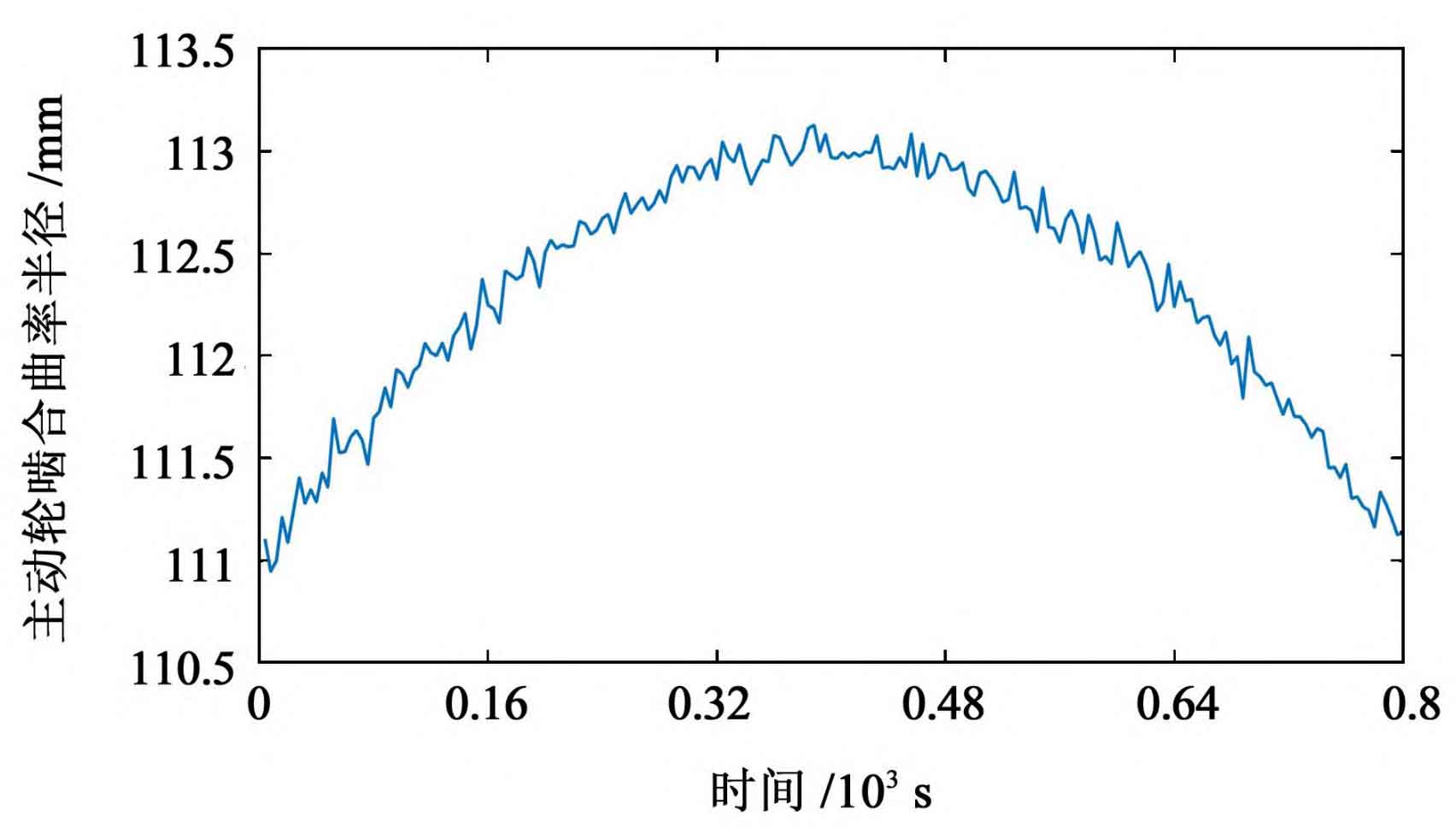

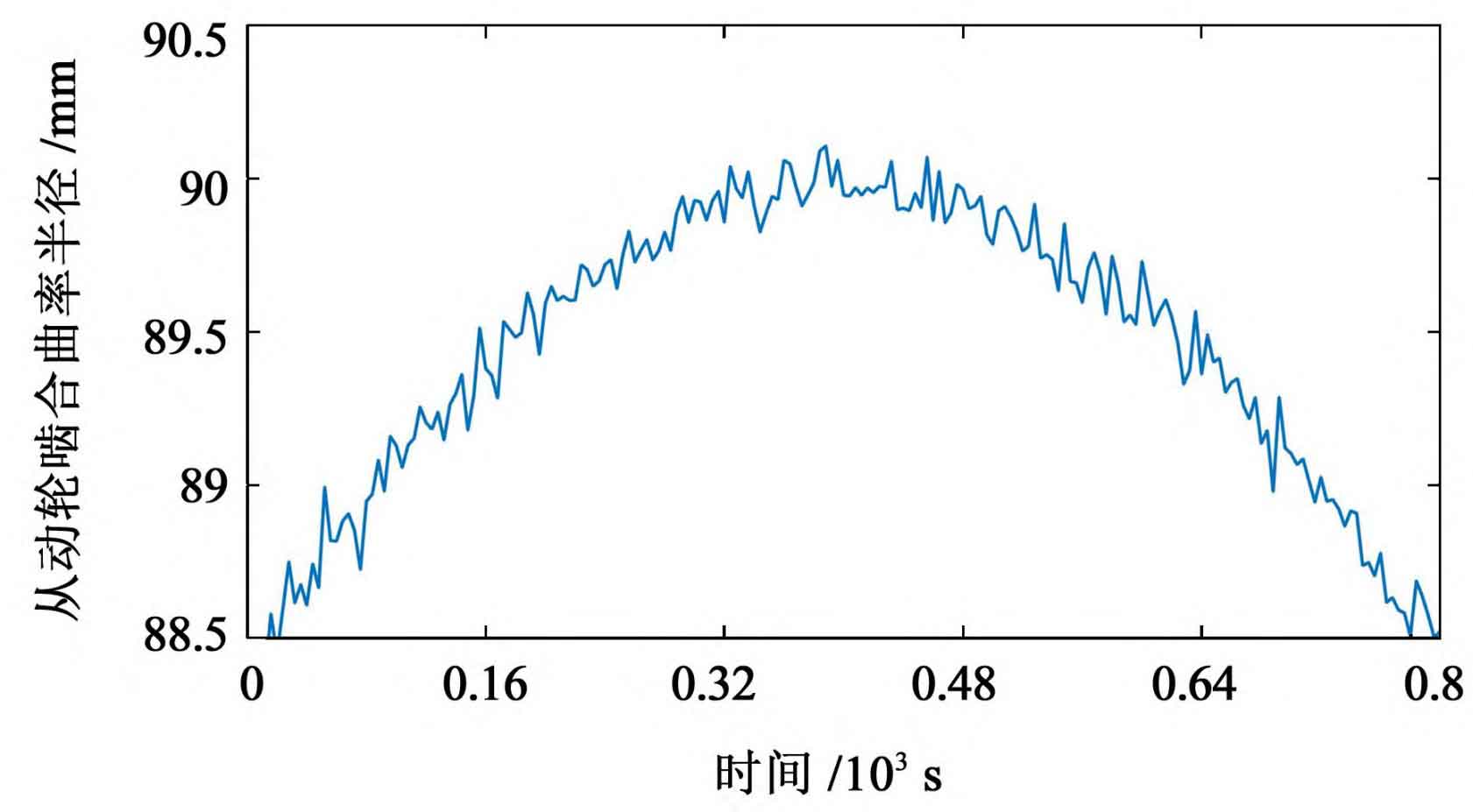

According to the simultaneous formula, the time-domain response curve of meshing curvature radius of spur gear is obtained, as shown in Figure 3.