This paper focuses on high reduction hypoid (HRH) gears, aiming to comprehensively analyze their geometric modeling, mechanical characteristics, and transmission efficiency. HRH gears play a crucial role in modern mechanical equipment, but their complex topological surfaces pose challenges in research. Through the construction of tooth surface models and ease-off surfaces using the dual equitangent conjugate method, the paper obtains key geometric and kinematic parameters. By establishing coordination equations and conducting loaded tooth contact analysis (LTCA), the load and stress distributions on the tooth surface are determined. Combined with elastohydrodynamic lubrication (EHL) theory, the distributions of oil film thickness, friction coefficient, and friction power consumption are analyzed. Finally, transmission efficiency tests are carried out to verify the proposed models and methods. The research results provide important theoretical and practical references for the design and application of HRH gears.

1. Introduction

In modern mechanical engineering, the demand for high-performance gears is constantly increasing. Gears are essential components in power transmission systems, and their performance directly affects the overall efficiency and reliability of the equipment. HRH gears, with their unique geometric characteristics and transmission capabilities, have attracted significant attention. However, due to their complex topological structures, research on HRH gears faces many difficulties.

Previous studies have explored various aspects of gear design and performance optimization. For example, tooth surface modification techniques have been widely investigated to improve gear meshing performance. Researchers have analyzed the effects of different modification methods and amounts on gear transmission characteristics. In addition, the combination of gear design and tribology has also become a research hotspot. By considering factors such as friction and lubrication, efforts have been made to reduce power consumption and improve gear life. Nevertheless, for HRH gears, there is still a lack of in-depth and systematic research.

This paper attempts to fill this gap by comprehensively studying the geometric modeling, mechanical analysis, and efficiency evaluation of HRH gears. The research not only helps to deepen the understanding of HRH gears but also provides valuable guidance for their engineering applications.

2. HRH Gear Geometry Modeling

2.1 Dual Equitangent Conjugate Principle

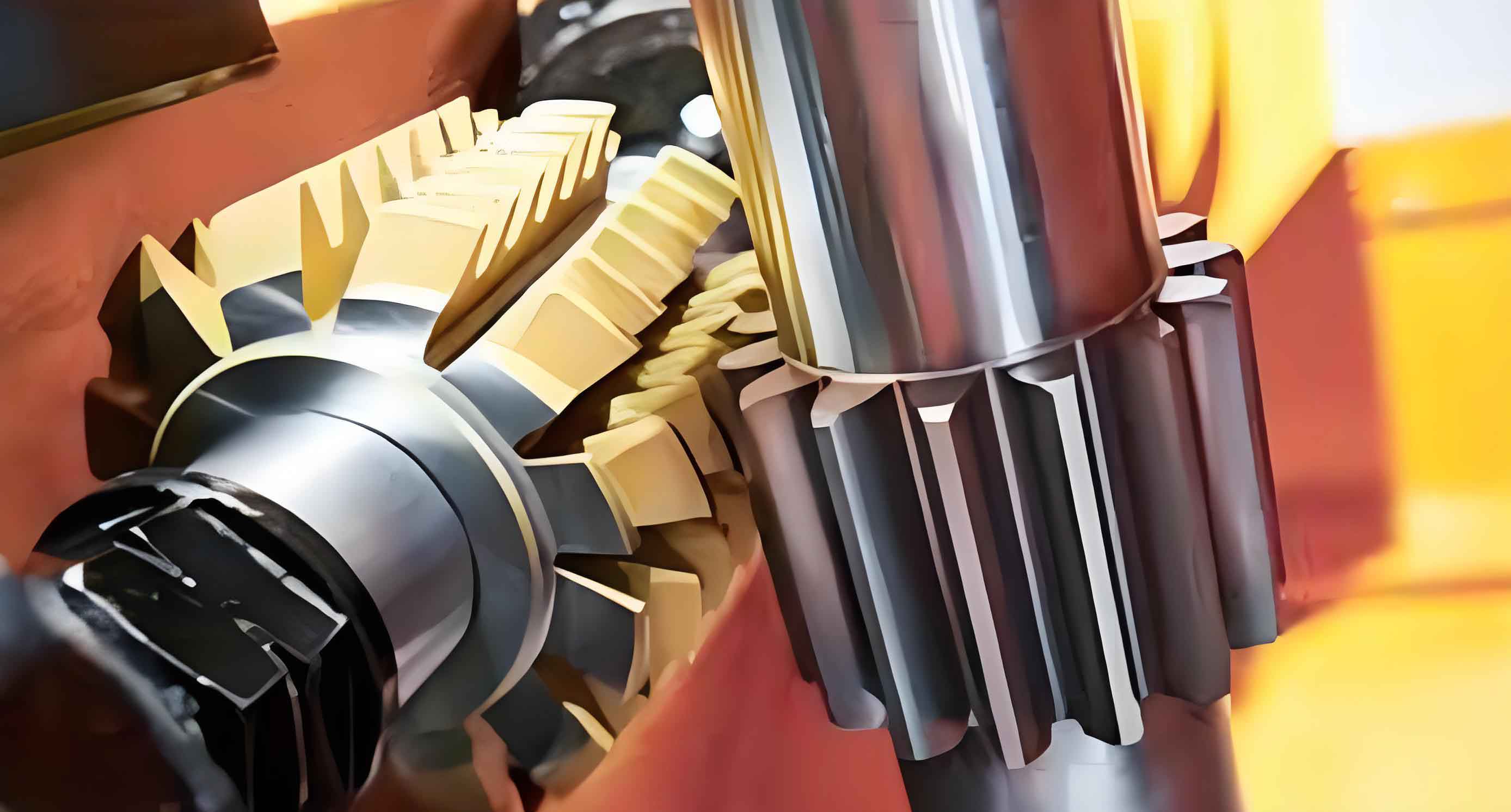

The dual equitangent conjugate method is the foundation for HRH gear geometry modeling. As shown in Figure 1, by establishing a specific coordinate system relationship, the meshing process of the gears can be accurately described. The small gear coordinate system is placed in the large gear processing coordinate system, and the cutter head coordinate system is located in the first quadrant of the cradle coordinate system . The initial position of the cradle coordinate system coincides with the machine tool coordinate system .

During the gear generation process, the small gear rotates around the axis, and the rotation angle is related to the rotation angle of the generating gear by the roll ratio . The meshing equation of the small gear and the generating gear is established based on the geometric relationship and vector analysis. By solving this equation, the conjugate tooth surface equation of the small gear can be obtained.

| Coordinate System | Relationship Description |

|---|---|

| and | The cutter head cuts the gear tooth surfaces based on the conjugate relationship. |

| and | The initial coincidence provides a reference for the gear machining process. |

| and | The transformation matrix reflects the coordinate transformation during the meshing process. |

2.2 Tooth Surface Processing Parameters and Modeling Example

Taking a pair of 3:60 HRH gears as an example, the specific processing parameters are shown in Table 1. The large gear has an outer diameter of 145mm, the small gear has a downward offset of 40mm, and the gear width is 20mm. Both gears are modified in two directions to ensure point contact.

Based on these parameters, the tooth surface is digitally solved. The cutter cone surface and the modified tooth surfaces of the large and small gears have an equitangent conjugate relationship. By calculating the relevant equations, the actual tooth surface equation of the small gear can be obtained. Subsequently, the ease-off surface is constructed, which reflects the deviation between the conjugate tooth surface and the actual tooth surface. The analysis of the ease-off surface can provide important information about the meshing characteristics of the gears, such as the contact trace points and the clearance of the contact line.

| Parameter | Value |

|---|---|

| Gear Ratio | 3:60 |

| Large Gear Outer Diameter | 145mm |

| Small Gear Offset | 40mm |

| Gear Width | 20mm |

3. Geometric Motion Parameter Calculation

3.1 Curvature of the Large Gear Tooth Surface

The large gear is processed by the forming method. The vector function of the tooth surface is , and the two tangential directions of the curved coordinates are the two principal directions. The principal curvatures and can be directly obtained from the cutter head equation. and , where and are related parameters in the machining process. The accurate calculation of the curvature is of great significance for understanding the geometric shape and stress distribution of the tooth surface.

3.2 Contact Point Differential Curvature

The comprehensive curvature of the contact point is an important parameter related to geometry, mechanics, and lubrication. The two principal value directions and are determined. The differential curvature in the direction can be obtained from the difference curve, and the induced normal curvature in the direction is calculated using the second-order characteristic function and the characteristic vector. By considering the curvature of the ease-off surface at the contact point in this direction, the comprehensive curvature in the direction is obtained. The distribution of the comprehensive curvature radius in the direction shows a certain trend, which is smaller at the small end and the tooth root and larger at the large end and the tooth top.

3.3 Relative Motion Velocity

The rotational motion velocities of the two gears are and , respectively. The relative linear velocity . Considering the coordinate relationship of the gears in space, the relative linear velocity can also be expressed as . By projecting the motion velocity onto the direction in the tangential plane, the relative sliding velocity can be obtained. The entrainment velocity and the slide-roll ratio are also calculated. The distribution of the entrainment velocity and the slide-roll ratio on the contact line shows that the slide-roll ratio of the HRH tooth surface is relatively uniform, which is a significant characteristic of its meshing transmission.

4. Contact Point Load Calculation

4.1 Loaded Tooth Contact Analysis (LTCA)

In the LTCA of HRH gears, considering the clearance on the contact line, the deformation of the tooth surface under the action of the load is analyzed. Assuming that the load is borne by several teeth and units, the deformation of each unit is related to the total deformation and the clearance. By establishing the deformation-load relationship equation and using the minimum deformation energy as the convergence condition, the meshing stiffness and load distribution can be calculated. The load distribution on the tooth surface is mainly concentrated in the middle part, which is obtained by traversing the contact line sequence at different rotation angles.

4.2 Contact Stress Calculation

When calculating the contact stress, considering that the instantaneous contact deformation of the tooth surface may deviate from the Hertz point contact state, a differential unit method is adopted. The deformation region is divided into small cylindrical units along the contact line. By approximating the contact problem of each unit as the contact between a cylinder and a plane and using the Hertz contact stress formula, the contact stress distribution on the tooth surface can be obtained. The maximum contact stress can reach 1050 MPa, which indicates the high stress level during the meshing process of HRH gears.

5. Tooth Surface EHL Friction Power Consumption Calculation and Analysis

5.1 Minimum Oil Film Thickness Calculation

Due to the complexity of the contact line parameters of HRH gears, the line contact EHL model cannot be directly applied. By subdividing the EHL interface based on the contact stress calculation unit, the point contact problem is transformed into a micro-unit line contact problem. Using the Dowson and Hamrock classical formula, the longitudinal minimum oil film thickness of each contact line unit is calculated. The distribution of the oil film thickness shows that except for the obvious increase at both ends of the contact line, the overall distribution is relatively uniform, with a thickness ranging from 0.4 to 0.5μm, indicating the significant EHL effect of the HRH tooth surface.

5.2 Friction Coefficient Calculation Formula

According to the film thickness ratio , the lubrication state is divided into three cases: boundary lubrication, mixed elastohydrodynamic lubrication, and full elastohydrodynamic lubrication. Different formulas are used to calculate the friction coefficient in different lubrication states. The friction coefficient distribution on the contact line shows that due to the absence of pure rolling points on the HRH tooth surface, the friction coefficient is larger in the middle of the contact line and smaller at both ends, which is different from the general involute cylindrical gears.

5.3 Friction Power Consumption Calculation

The meshing friction loss of the tooth surface is caused by the relative sliding of the contact points. The power consumption of each unit on the contact line is calculated by . The power consumption distribution on the contact line is consistent with the friction coefficient distribution law. The total power consumption at any instant is the accumulation of the power consumption of all contact line units of multiple pairs of teeth. The calculation results show that the instantaneous meshing power consumption of HRH gears has a small fluctuation.

6. HRH Transmission Efficiency Test

6.1 Contact Quality Inspection

Before the transmission efficiency test, the meshing quality of the 3:60 HRH gears is inspected. The contact spots on the tooth surface left by the rolling inspection on the rolling inspection machine are observed. From the convex surface of the large gear, the contact spots are elliptical and located in the middle of the tooth surface near the small end, without edge contact, which is consistent with the ease-off modification result and meets the inspection standards of bevel gears.

6.2 Transmission Efficiency Test

The HRH gear transmission efficiency test bench is set up as shown in Figure 2. High-precision torque sensors JC1A (input end, accuracy ±0.1%) and JC2C (output end, accuracy ±0.2%) are used, and the dynamic error is ±0.18%. The test is carried out under different rotational speeds () and load ranges (). The torque meters at the input and output ends are placed in the same window, and the data is read by camera to ensure synchronization. The test results show that the transmission efficiency of the HRH gearbox is consistent with the theoretical calculation trend, increasing with the increase of rotational speed and decreasing with the increase of load. In the given load range, the test efficiency is 76.8% – 82.1%, with an average value of 79.45%, and the theoretical calculation efficiency is 75.0% – 84.3%, with an average value of 79.65%. The error between the two is within a reasonable range, considering factors such as bearing friction, sealing friction, and flow resistance.

7. Conclusion

This paper comprehensively studies HRH gears from the aspects of geometric modeling, mechanical analysis, and transmission efficiency testing. The following conclusions are obtained:

- The proposed ease-off surface analysis, deformation coordination equation, and contact line differential unit method can effectively solve the geometric contact, motion, and mechanical parameters of the gears, facilitating the parameterization and programming of LTCA analysis.

- The contact line differential unit method combined with the EHL friction coefficient empirical formula successfully solves the problems of load distribution calculation and EHL parameter solution, and obtains the distribution laws of tooth surface load stress, oil film thickness, friction coefficient, and friction power consumption.

- The transmission efficiency test verifies the correctness of the proposed HRH gear meshing efficiency calculation model and analysis method. The average transmission efficiency of HRH gears is 79.45%, with a small average error of 0.2% and a maximum error of 2.8% compared with the theoretical calculation results.

Future research can further explore the optimization of HRH gear design based on the obtained results, such as improving the gear meshing performance and reducing power consumption, to meet the higher requirements of modern mechanical equipment for gear transmission.