This article focuses on the dynamic characteristics of the spindle system of the spiral bevel gear milling machine and its matching with the machining process. Firstly, it elaborates on the importance of studying the dynamic characteristics of the spindle system and the current research status at home and abroad. Then, it systematically describes the process of establishing a dynamic model of the spindle system using the finite element method and analyzing its dynamic characteristics. Subsequently, it analyzes the cutting force in the milling process and studies the influence of different process parameters on the cutting force. Through experimental verification, the matching effect of the process parameters with the spindle system dynamic characteristics is verified. Finally, it summarizes the research work and looks forward to future research directions. This research provides a theoretical basis and technical support for improving the machining accuracy and efficiency of the spiral bevel gear milling machine.

1. Introduction

1.1 Research Background and Significance

Machine tools play a crucial role in modern mechanical manufacturing. The machining performance of machine tools directly affects the quality of workpieces and cutting efficiency, and is also influenced by the dynamic performance of the machine tool. The vibration and deformation of the machine tool during operation will have a direct impact on the dynamic accuracy of the machining process, thereby affecting the surface quality of the workpiece. This will lead to a significant decrease in production efficiency, hinder the production progress, and even shorten the service life of the machine tool and cause it to be scrapped in advance. Especially in the current widespread use of CNC machine tools, due to their automated processing through various detection devices, severe vibration may affect the normal operation of these detection devices. In addition, since CNC machine tools are often unattended, once severe vibration occurs, it is often difficult to detect and take countermeasures in time, which may ultimately affect the machining quality of products and even lead to potential safety hazards in the production process. Therefore, it is particularly important to fully understand and effectively control the vibration problem in the operation of machine tools.

The spindle system of the machine tool, as a key component in direct contact with the workpiece, is of great significance for studying its vibration characteristics. The vibration characteristics of the spindle system mainly include three core aspects: the inherent characteristics analysis of the spindle structure, the dynamic response evaluation, and the study of cutting stability. The inherent characteristics analysis of the spindle structure covers multiple key elements such as the natural frequency, damping ratio, dynamic stiffness, and modal shape of components such as the spindle, bearings, and cutter head. These characteristics jointly determine the stability and performance of the machine tool during the machining process. The dynamic response describes in detail the vibration behavior characteristics of the spindle system during operation, including specific parameters such as the magnitude of vibration amplitude, frequency distribution, and the time required for the system to stabilize. These parameters are essential reference bases for evaluating the operational stability of the machine tool and optimizing the machining process. The study of cutting stability mainly focuses on the state of the system under the action of cutting force. Especially when using specific cutting parameters, resonance may occur between the spindle – tool and the workpiece, which will have a huge impact on the machining quality and performance of the machine tool. By deeply understanding the vibration characteristics of the spindle system, key process parameters such as feed rate and spindle speed can be selectively adjusted to avoid the possible resonance points and cutting chatter regions of the spindle system. Such optimization measures are helpful to reduce or suppress the vibration of the machine tool during the cutting process, thereby improving the machining quality of parts and ensuring the stability and high efficiency of production.

In general studies on the dynamic characteristics of the spindle system of machine tools, researchers often excite the machine tool when it is shut down and simultaneously measure the excitation force signal and the vibration signal of the machine tool, and then post – process these signals to identify the modal parameters of the machine tool [1 – 2]. If the dynamic characteristics of the spindle system when shut down are the same as those during operation, the identification results when shut down can be directly applied to the structural design of the spindle system or the machining process. However, it can be seen from the existing research that the dynamic characteristics of the spindle system of the machine tool in the actual operating state are constantly changing, which means that there are certain differences in the dynamic characteristics of the spindle system of the machine tool between the static and running states [3]. Therefore, it is of great significance to deeply study the dynamic characteristics of the spindle system of the machine tool in the running state. By revealing the change law of its dynamic characteristics during operation, directional guidance can be provided for the adjustment and optimization of the machining parameters of the machine tool. This will not only help to significantly improve the machining accuracy of the workpiece but also effectively improve the machining efficiency.

The milling process parameters (such as cutting speed, feed rate, and cutting depth) are the main factors affecting the machining efficiency, machining quality, and tool wear. A large feed rate can increase the material removal rate, but it will also lead to excessive cutting force and a significant increase in machine tool chatter, resulting in a decline in the machining quality of the workpiece. On the contrary, a smaller feed rate can ensure the surface quality of the workpiece and reduce the vibration of the machine tool, but it will prolong the cutting time and reduce the machining efficiency. Currently, the selection of machining process parameters usually depends on existing literature or relevant experience, but this method has limitations. In general, the parameter selection is relatively conservative and cannot fully utilize the performance of the machine tool and the tool, thereby reducing the actual machining efficiency. Therefore, the selection of reasonable process parameters is not only beneficial to reducing the vibration of the machine tool but also helps to improve the cutting efficiency and ensure the machining quality.

This research aims to address the insufficient matching between the milling process parameters and the machine tool characteristics in production. Combined with the current research on the matching of the dynamic characteristics of the spiral bevel gear milling machine spindle system and the machining process parameters, a method is proposed to judge the matching of the machining process parameters with the characteristics of the milling machine spindle system based on the response status. This method aims to fully utilize the performance of the machine tool, reduce the vibration during the machining process of the machine tool, improve the machining efficiency and machining accuracy, and improve the tooth surface machining quality. Specifically, this method analyzes the dynamic response of the milling machine spindle system when subjected to the actual cutting force, and adjusts the machining process parameters to match the characteristics of the machine tool, thereby maximizing the optimization of the machining process. Under the guidance of this method, the spindle speed and feed rate and other parameters can be flexibly adjusted according to the dynamic response of the spindle system under different process parameters to achieve the best machining effect. By fully understanding and utilizing the dynamic characteristics of the machine tool, the vibration of the machine tool during the machining process can be effectively reduced, the machining efficiency and machining accuracy can be improved, and better machining quality can be obtained in the tooth surface machining process.

1.2 Research Status at Home and Abroad

1.2.1 Dynamics Modeling Technology

The spindle is a crucial part of the machine tool, and its dynamic characteristics and performance directly affect the machining efficiency and machining accuracy of the machine tool. The dynamic characteristics of the spindle mainly include key parameters such as natural frequency, modal shape, critical speed, and dynamic response [4]. Before 1960, the design of the spindle mainly relied on the empirical simulation method. However, due to the influence of the equipment and tools at that time, this method not only had limited accuracy but was also quite cumbersome in actual operation. With the rapid development of computer technology, new methods such as the lumped parameter method, transfer matrix method, and finite element method have emerged [5]. These methods provide more accurate and efficient ways for spindle design and analysis.

The lumped parameter model is a widely used structural dynamics modeling method. Its core idea is to concentrate the mass of the structure on several nodes and use a series of massless equivalent elastic beams to simulate the elastic characteristics of the structure. Although the lumped parameter model can provide relatively accurate results in some cases, its limitations are also obvious. Especially for complex machine tool structures, it is often difficult to accurately simulate their dynamic behavior with a simple and reasonable mechanical model. In addition, when considering the nonlinear and coupling effects of the system, the accuracy of the lumped parameter model is usually low.

In 1964, Taylor first adopted the lumped mass idea in the stiffness calculation of the radial drilling machine and obtained the natural frequency and vibration mode consistent with the measured values [6]. Tlusty and Altintas simplified the machine tool structure a lot and used the lumped parameter model for modal experiments. However, due to the lack of theory and equipment at that time, their model only considered a few low – order modes [7 – 8]. In 1976, Nelson et al. used the consistent matrix method to establish the finite element model of the spindle system. They analyzed the spindle systems of two bearings with different characteristics and obtained the unbalanced response of the typical cantilever shaft structure. At the same time, they used the lumped mass method to compare and analyze the conclusions in these two cases [9]. Feng Jilu et al. simplified the spindle – bearing system of the machine tool using the lumped mass method, established a spindle vibration analysis model considering multiple factors, and analyzed the nonlinear dynamic characteristics of the spindle – bearing system under the action of unbalanced force [10]. Yang Yiqing et al. established a 7 – degree – of – freedom model of a vertical milling machine using lumped mass and spring – damping elements based on the modal analysis and visualization of the vertical milling machine. Their research results revealed the relationship between machine tool chatter and vibration mode, and compared with the original test frequency response function, their model had higher accuracy [11]. Huang Zhikai et al. used the lumped mass method to compare the low – order modal frequencies of the equal – section beam with both ends hinged under different mass distribution conditions. Their research provided a feasible method for the simplified calculation of the modal frequency of the beam and obtained the formula for the critical speed of each order of the beam [12].

The transfer matrix method is an important method for analyzing the dynamic characteristics of slender structures such as shafts and beams. When analyzing the dynamics of the spindle system, the transfer matrix method uses a series of discretization steps to divide the spindle system into discrete bodies composed of several lumped masses, rigid disks, and elastic shaft segments, and then uses the combined transfer matrix of each unit wheel disk, shaft segment, and spring to connect the state vectors of each unit. Through these relationships and the boundary conditions of the spindle, the frequency polynomial is obtained, and finally, the critical speed and dynamic response of the rotor system are solved by the iterative method. The transfer matrix method has the advantages of simple program, easy implementation and understanding, fast calculation speed, and relatively accurate prediction of the critical speed and modal shape of the system, which can provide important reference for engineering design. However, when applying the transfer matrix method, there are also some problems, such as the accuracy of the transfer matrix method may decrease when calculating high – order modes [13]. Therefore, appropriate processing methods need to be taken to improve the accuracy of the calculation results. In addition, due to the nonlinear and coupling effects of the system, the transfer matrix method may not be able to fully capture the dynamic behavior of the system. Therefore, its applicability needs to be considered according to the actual situation in application.

Wu Hui studied the spindle system and transmission system of a certain type of centerless machine tool. He used the Riccati transfer matrix method to establish the mathematical model and dynamic model of the spindle system and transmission system of the machine tool respectively, and obtained the inherent characteristics of the transverse vibration of the spindle system and the inherent characteristics of the torsional vibration of the transmission system of the machine tool. His research results provided a scheme for the dynamic optimization of the machine tool structure [14]. Meng Jie established the dynamic model of a high – speed electric spindle after simplifying it based on the transfer matrix method and obtained the natural frequency and vibration mode of the electric spindle at a certain speed [15]. Wu Lingwei studied the flying – cutting machine tool. By using the transfer matrix method, he established the transfer matrix of each component of the machine tool system and studied the vibration characteristics and dynamic response of the machine tool in detail [16]. Tian Yue established the dynamic model of the spindle system of a certain machine tool using the transfer matrix method and studied the influence of the spindle eccentricity, the front and rear bearing clearances, and the front and rear bearing stiffness on the dynamic characteristics of the spindle system, providing some ideas for the structural optimization of the spindle system [17]. Qian Mu et al. studied the dynamic characteristics of a certain grinding electric spindle system using the transfer matrix method. The results showed that the transfer matrix method could be applied to the dynamic design of the electric spindle [18]. Zhu Jinhu et al. established the dynamic model of a certain high – speed electric spindle using the transfer matrix method and successfully obtained the relevant parameters affecting the critical speed of the electric spindle [19]. Wu Wenjing et al. proposed an extended transfer matrix method. They divided the mechanical system into three types of elements: rigid bodies, flexible bodies, and joint surfaces, and gave the mathematical models of these elements in matrix form. The research results showed that this method had good accuracy for the modeling and dynamic characteristics analysis of the whole CNC machine tool [20].

With the rapid development and wide application of computer technology, the finite element method has become an indispensable important numerical analysis tool in scientific research and engineering design. In the field of machine tool spindles, the finite element analysis method can perform static analysis on the spindle system to obtain its static stiffness. At the same time, through dynamic analysis, the natural frequency and dynamic response of the spindle system can be obtained, and its optimization design can be further carried out. The static and dynamic characteristics of the spindle system are directly related to the performance of the whole machine, which is of great significance for improving product quality and ensuring the dynamic machining accuracy of the machine tool.

Abroad, Bollinger et al. made a preliminary study on the static and dynamic performance of the machine tool spindle using the finite element method [21]. R. Reddy et al. established the finite element model of the machine tool spindle based on the finite element method and performed dynamic analysis on it [22]. Severn adopted the Timoshenko beam element considering shear deformation to model the dynamics of the spindle system. Each unit has two nodes and a total of six degrees of freedom, but the dynamic response of the spindle system was not deeply studied after the dynamic modeling [23]. Gagnol et al. modeled the high – speed spindle – bearing system using the Timoshenko beam element and considered the influence of the gyroscopic effect on the dynamic characteristics of the spindle system. Their model provided a certain reference value for the identification and prediction of the spindle in the actual machining process of the machine tool [24]. Lin adopted the finite element method to model the dynamics of the spindle system and optimized the structure of the spindle system. However, this method was too complex and did not have universal applicability [25]. Jorgensen et al. established the dynamic model of the high – speed spindle system using the Timoshenko beam theory. They considered the external load and thermal deformation when applying the boundary conditions, so their analysis results were more in line with the actual machining state of the spindle system [26].

In China, many universities, research institutions, and scholars are also engaged in research in this field [27]. In the 1980s, “Rotor Dynamics” written by Zhong Yi’e and others from Tsinghua University introduced the analysis methods of the rotor system in detail and had good reference value [28]. Sun Wei et al. took the high – speed spindle system as the research object and used the finite element analysis method to systematically analyze the inherent characteristics of the spindle system under different working states. They also considered the influence of the rotational speed on the frequency response function of the tool tip. The results showed that there were differences in the dynamic characteristics of the spindle system between the static state and the moving state [29]. Cao Hongrui et al. constructed the finite element models of each component of the spindle system one by one and then combined these sub – components to construct the dynamic model of the whole system. In the research, they not only considered the gyroscopic effect and centrifugal force of the rotor but also deeply analyzed the influence of the bearing softening on the dynamic characteristics of the spindle system. The research results showed that in order to accurately calculate the dynamic characteristics of the spindle system, the softening effect of the bearing must be considered [30]. Ling Jiayu established the dynamic model of the spindle system considering the spindle box, feed system, and the joint surface of the spindle – tool holder – tool and gave the theoretical calculation formula of the typical joint surface stiffness. Through the established dynamic model, the vibration error of the spindle system was estimated [31]. Kang Ting et al. established the dynamic model of a certain high – speed spindle using the Timoshenko beam element and realized the prediction of the vibration response of the spindle by inputting the collected cutting force into the dynamic model [32]. Xu Qingyong took a certain type of CNC milling machine as the research object and performed static and dynamic analysis and structural optimization on the key components of the spindle system using the finite element method [33].

Through the above research, it can be seen that scholars at home and abroad have adopted a variety of theories and methods to solve the dynamic problems of the whole machine or the spindle system and have made sufficient research. They used the lumped parameter method to model the whole machine tool to study its natural frequency and vibration mode. They used the transfer matrix method to explore the dynamic characteristics of the spindle system of the machine tool and the influence of the processing component parameters on the dynamic characteristics of the spindle system. At the same time, they used the finite element method to study the response of the spindle system when subjected to external excitation. These studies have deeply explored the dynamic characteristics of the spindle system from different angles and provided important theoretical basis and technical support for the field of machine tool machining. However, most of these studies focused on common machine tools such as lathes and milling machines or their components, and there were relatively few studies on the spindle system of the spiral bevel gear milling machine. Therefore, it is necessary to extend the existing research methods to the spindle system of the milling machine to fill the research gap in this field and further improve the theoretical system and application methods of the dynamics of the machine tool spindle system.

1.2 Research Status at Home and Abroad

1.2.2 Research Status of Excitation Force (Continued)

certain results. Hanna et al. used exciters to apply random excitation and sinusoidal excitation to the machine tool in the running state respectively and studied the modal and response of the machine tool. The research results showed that the machine tool exhibited nonlinear characteristics in the running state [34]. Liao Boyu et al. used the M – sequence random signal to perform modal analysis on the lathe spindle when it was rotating. The research results showed that the modal parameters of the lathe spindle were different in the static and moving processes [35].

In 1981, Ji Qingfa and Du Shucai from Jilin Institute of Technology proposed using cutting force as the exciting force to study the dynamic characteristics of the machine tool. They conducted relevant experiments on a lathe and successfully identified the natural frequency of the system. They also preliminarily proposed a mathematical method for online analysis of the structural modal parameters of the machine tool using random data analysis theory. However, due to the need to measure the cutting force in the analysis process and the limitation of the identification technology at that time, only the natural frequency could be simply identified, and more comprehensive modal parameter information could not be obtained [36 – 37]. Jiang Xiaofei established a dynamic exciting force model of the machine tool based on the cutting force theoretical model of vertical milling and through cutting experiments for parameter identification. The exciting force model consisted of static force and dynamic force and considered the influence of different process parameters. The dynamic performance of the machine tool in different frequency bands was successfully obtained. At the same time, a dynamic characteristic test system for CNC machine tools was built to meet the measurement of dynamic cutting force under different cutting process parameters [38].

From the above research, it can be seen that scholars at home and abroad have studied the exciting force of the whole machine tool or the spindle system in various ways, covering different excitation sources and analysis methods. On the one hand, they used exciters to analyze the modal of the machine tool in the running state by applying excitation forces with specific frequencies and amplitudes. On the other hand, some scholars used cutting force as the excitation source and identified the modal parameters of the machine tool structure using corresponding methods. This method studied the workpiece cutting situation in the actual machining process and helped to more accurately evaluate the dynamic characteristics of the machine tool. In addition, some researchers measured the dynamic excitation force by changing process parameters such as cutting speed and feed rate to explore the influence of these parameters on the vibration characteristics of the machine tool. However, these research methods mostly focused on the empty running state of the machine tool or common machining methods such as turning and milling. There were relatively few studies on the excitation force in the spiral bevel gear milling process. This is because the spiral bevel gear milling process has complex cutting forces and process parameters and requires more in – depth research on its particularity. Therefore, it is necessary to explore the characteristics of the excitation force in the spiral bevel gear milling process to improve the research in this field.

1.2.3 Research Status of Process Matching

The milling process parameters are the key factors affecting the machining efficiency, machining quality, and tool durability. For example, if the cutting parameters are set too large, although the material can be removed quickly, the excessive cutting force may cause machine tool chatter and a decline in machining accuracy, and the cutter head wear will be intensified. On the contrary, if the cutting parameters are too small, although the vibration of the machine tool can be reduced, the prolongation of the cutting time will directly lead to low machining efficiency. Currently, the selection of process parameters is mostly based on literature or experience, and this conservative selection often cannot fully utilize the performance of the machine tool, thus limiting the improvement of machining efficiency. Therefore, the reasonable selection of process parameters is crucial. It helps to reduce the vibration of the machine tool while improving the cutting efficiency and ensuring the machining quality.

One of the methods to optimize the process parameters is to use optimization algorithms to optimize single or multiple process parameters. Azlan et al. used the artificial neural network and simulated annealing algorithm to obtain the process parameters that minimize the surface roughness of the workpiece [39]. Suman et al. used the artificial ant colony algorithm to find the optimal parameters under different machining processes [40]. Liu Yang used the genetic algorithm to optimize the multi – objective process parameters [41]. Some scholars also improved the accuracy of the optimization results by improving or combining optimization algorithms. Wei Hui established the prediction models of workpiece surface roughness and milling force by measuring the cutting force and the surface roughness of the machined workpiece in the milling process. Then, using the machining deformation and milling force as constraints and the minimum surface roughness and the maximum material removal rate as the optimization objectives, the process parameters were optimized using the genetic algorithm [42]. Fuad and Bhushan used the response surface method to optimize the process parameters from the perspective of machine tool energy consumption [43 – 44]. Zhong Jinlong established an optimization model with the machining time and machining cost as the objectives for the high – speed dry hobbing machine. Combined with the corresponding algorithm and experimental verification, the effectiveness of the process parameter optimization was verified [45]. Jia Xinjie used the harmony search algorithm to obtain the parameter optimization method for rough milling of spiral bevel gears and established the optimization model of the rough milling process parameters of spiral bevel gears. By writing a program, he obtained the best rough milling cutting parameters [46]. Zhang Zhengwang et al. used the high – speed milling process parameter optimization method based on the dynamic behavior of the spindle system to obtain the optimal milling process parameter combination. The experimental results showed that the optimal milling process parameters obtained did not cause chatter during actual cutting [47].

Another method to optimize the process parameters is to conduct experiments or simulations for the objective function, analyze the change of the objective function under different process parameters, and then select the appropriate process parameters. Mao Hanying et al. designed multiple sets of experiments with different cutting depths and cutting thicknesses. In the process, the vibration acceleration signals from the stable cutting state to the occurrence of chatter were collected. Then, the vibration change law of these signals was studied [48]. Wu Xiao took the machining of non – thin – wall workpieces with an end mill as the research object, established a two – degree – of – freedom milling dynamics model and cutting force and cutting thickness models, and obtained the prediction model of variable cutting force coefficient and variable speed milling stability using the full discretization method. On this basis, the influence of the cutting force coefficient and process parameters on the milling stability was analyzed, and a multi – objective optimization model with a large material removal rate and a small cutting force as the objectives and milling stability as the constraint was constructed. The experimental results showed that the optimized process parameters could ensure a small cutting force and improve the material removal rate [49]. Jiang Yancui took the automotive mold milling machining system as the research object, established the dynamic model of the spindle system and obtained the change law of its dynamic characteristics. The milling stability was predicted using the frequency domain method, and the process parameters were optimized using the optimization function. The experimental results showed that the optimized process parameters could improve the machining accuracy of the mold surface [50]. Luo Hanbing et al. aimed at the problems existing in the selection of machining process parameters in the CNC milling process. Taking the high – speed milling process of a ball – end mill as the research object, they established a nonlinear dynamics model considering the machine tool – tool – workpiece system, analyzed the influence of the dynamic force components in the milling process on the cutting chatter, and proposed a prediction method for the stability limit of the machine tool cutting system based on the dynamic milling force modeling and chatter stability domain analysis and calculation. Their research results showed that the model could provide a basis for the reasonable selection of process parameters in the milling process [51].

From the above research, it can be seen that scholars at home and abroad have fully studied the characteristics of the machine tool spindle system and the adjustment of process parameters in the machining process. They either optimized the process parameters using optimization algorithms or selected the optimal process parameters through simulation experiments, revealing the relationship and law between the machine tool spindle characteristics and the machining process parameters, indicating the close relationship between the machine tool spindle characteristics and the selection of process parameters and the feasibility of this research topic. These studies provided a reliable scientific basis for the selection of cutting parameters, reduced the cutting processing cost, and improved the machining quality. However, it should be noted that most of these studies focused on using optimization algorithms to optimize the process parameters, and there were few studies on optimizing the process parameters through the system response. Moreover, there were relatively few studies on the optimization of the process parameters of the spiral bevel gear milling machine. Therefore, this article will conduct research from the aspect of the response of different process parameters and further explore the parameter adjustment method in the milling process.

In summary, scholars at home and abroad have conducted a large amount of research on dynamics modeling technology, excitation force research, and the matching of machine tool characteristics and process parameters, providing important theoretical and practical support for the research on the matching of the dynamic characteristics of the milling machine spindle system and the machining process parameters. Therefore, in view of the problem of low matching degree between the process parameters and the dynamic characteristics of the milling machine spindle in the milling process, combined with the current research results of dynamics and process parameter optimization methods, this research starts from the dynamics of the spindle system and studies the excitation and response of the system and the optimization of process parameters.

1.3 Research Contents and Ideas

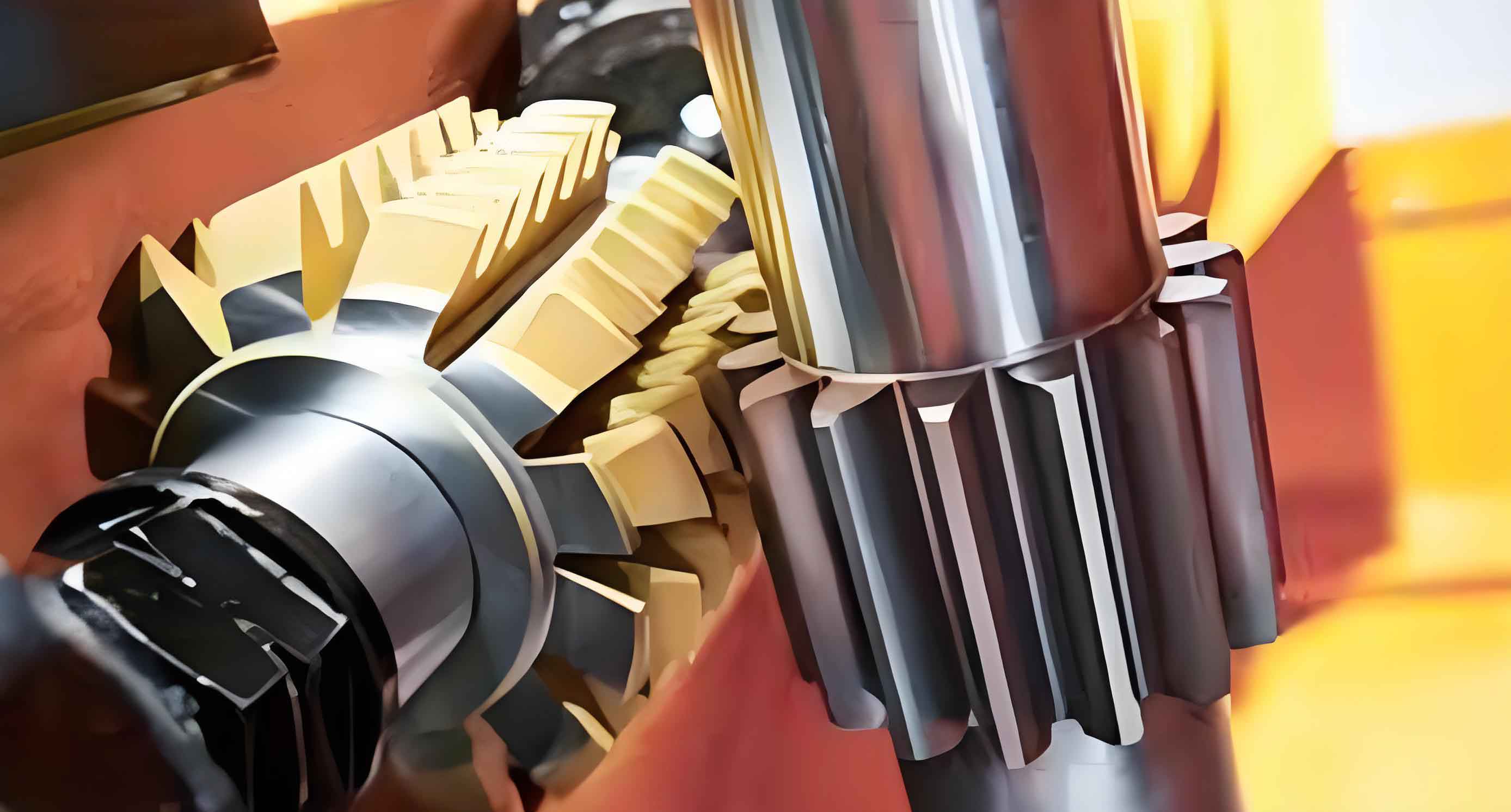

This article aims to achieve the matching of the characteristics of the spiral bevel gear milling machine spindle system and the process parameters to improve the milling efficiency and the quality of the tooth surface machining. According to the basic principles of machine tool dynamics, the finite element method is used to establish the finite element dynamic model of the milling machine spindle system. Based on this, the response analysis of the machine tool under different machining parameters is completed using the numerical method, and the correctness of the constructed numerical model and the effectiveness of the selected process parameter combination are verified by finite element simulation and experiments. Firstly, based on the finite element dynamics theory and the Timoshenko beam theory, the dynamic model of the milling machine spindle system is established. By solving the motion differential equation, the natural frequency and vibration mode of the spindle system are obtained. On this basis, the dynamic responses in each direction are calculated using the vibration mode superposition method and the numerical integration method respectively, including the harmonic response analysis and the transient response analysis. At the same time, the finite element software is used to simulate and calculate the response status under the same conditions as the numerical model to verify the accuracy of the numerical model and lay the foundation for the subsequent research on the matching of process parameters using the numerical model. Since the cutting force is the main excitation source in the milling process, this article derives the milling cutting force components in three directions based on the oblique cutting theory and establishes a theoretical cutting force model. On this basis, the influence of different process parameters on the cutting force amplitude is analyzed. Then, the finite element cutting simulation software AdvantEdge FEM is used to calculate the cutting force under different process parameter combinations. By inputting the results calculated by the theoretical cutting force model into the finite element numerical model for analysis, a set of process parameters with good matching with the dynamic characteristics of the spindle system is obtained. Finally, the machining experiment under this set of process parameters is carried out to test the matching effect with the dynamic characteristics of the spindle system. The technical roadmap of this article is shown in Figure 1.1.

The main research contents and analysis methods of this article are as follows:

Chapter 1: Introduction

This chapter mainly introduces the source of the research topic, the research background and significance of the paper. It elaborates on the domestic and foreign research status of the dynamic modeling of the spiral bevel gear milling machine spindle system, the research of excitation force, and the matching of process parameters and machine tool.

Chapter 2: Dynamic Modeling and Analysis of the Spindle System

This chapter introduces the finite element dynamics theory and establishes the finite element dynamic model of the milling machine spindle system based on the Timoshenko beam theory, considering the coupling effect of the bearings. On this basis, the natural frequency and vibration mode, harmonic response, and transient response of the spindle system are analyzed using the numerical method. At the same time, the finite element software is used to fully verify the response of the spindle system calculated by the numerical method in the previous step, laying the foundation for the subsequent research on the matching of process parameters and the spindle system.

Chapter 3: Analysis of the Milling Cutting Excitation Force

This chapter analyzes various excitation sources in the milling cutting process and concludes that the cutting force is the most important excitation source in this process. Based on the oblique cutting theory and the relative position relationship between the cutter head and the gear blank in the milling process, the calculation formulas of the cutting forces in each direction when machining the pinion by the generating method are derived, and a theoretical cutting force model is established. Based on this model, the cutting force amplitudes under different process parameters are calculated, laying the foundation for the optimization of process parameters. At the same time, the finite element cutting simulation software AdvantEdge FEM is used to calculate the cutting forces in each direction under different rotational speeds and feed rates, and the corresponding analysis of the frequency components of the cutting forces is carried out to study the influence of different process parameters on the cutting force and the cutting force frequency.

Chapter 4: Verification of the Dynamic Characteristics Analysis and the Process Matching Effect

Based on the calculation of the theoretical cutting force amplitudes under different process parameters in the previous chapter, four sets of process parameters are selected for detailed analysis of the cutting forces, and a set of optimal parameters is obtained. By comparing this set of parameters with another set of parameters that cause a sudden change in the main cutting force amplitude, an experiment is carried out to obtain a set of optimal parameters. The harmonic response analysis of the cutting force under this set of parameters is carried out using the numerical model established in this article to verify the matching of this set of process parameters with the spindle system. In addition, the sensitivity of the main cutting force is analyzed, and two ways to change the sensitivity of the spindle system are proposed to ensure the quality of the tooth surface machining.

Chapter 5: Summary and Outlook

This chapter summarizes the research work carried out in this article and gives the conclusions. At the same time, based on the deficiencies in the research work of this article, the outlook for future work is put forward.

2. Dynamic Modeling and Analysis of the Spindle System

2.1 Basic Principles of Rotor Dynamics Equation Construction

The dynamic characteristics analysis of the milling machine spindle system can establish its dynamic model through the basic principles of dynamics and then obtain the inherent characteristics of the system by solving the corresponding equations. At present, the establishment of the dynamic model usually adopts theoretical modeling, experimental modeling, and the modeling method combining theory and experiment [52].

When constructing the theoretical model, it is often necessary to simplify the system structure. However, due to the lack of a unified and standardized theoretical calculation method for the dynamic characteristics of the joint, there may be a large deviation or error between the established model and the actual situation. However, compared with other models, it has significant advantages in structural optimization. The experimental model can truly reflect the dynamic performance of the machine tool, but due to its limited degrees of freedom and the need for experimental prototypes, the design cost is relatively high. The hybrid model combines the advantages of the theoretical model and the experimental model, but it also inherits the limitations of the experimental model.