This paper focuses on the failure analysis and solutions of cylindrical gear transmission in electric tools. It first introduces the importance of cylindrical gear transmission in electric tools and the common failure modes. Then, it deeply analyzes the causes of failure from aspects such as materials, heat treatment processes, and lubrication. Finally, corresponding solutions are proposed to improve the quality and service life of the gears. Through this research, it provides a reference for the design, manufacturing and maintenance of electric tools.

1. Introduction

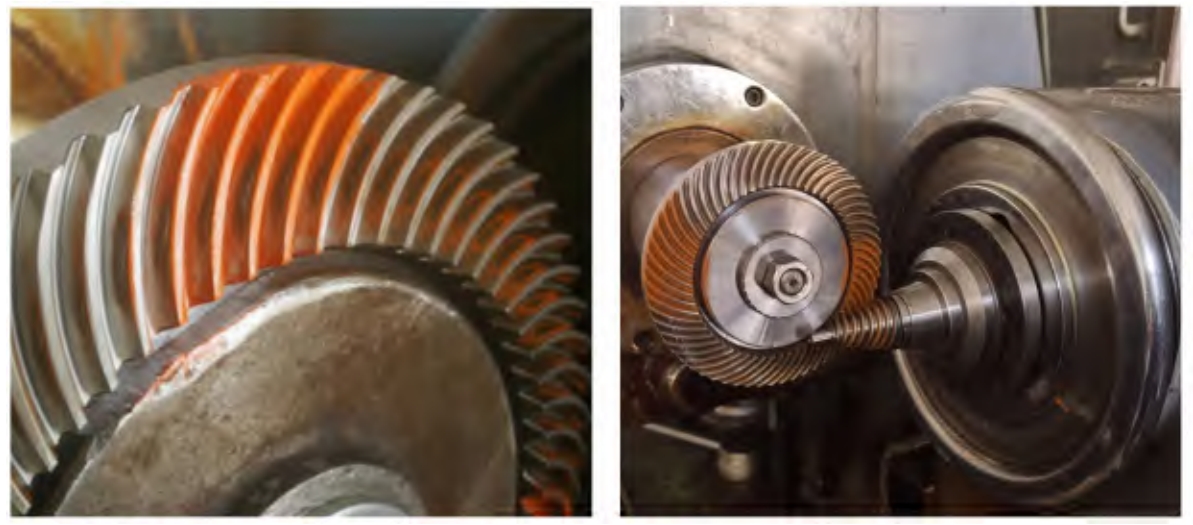

Cylindrical gear transmission is widely used in electric tools to adjust the speed and torque to meet the actual operation requirements. However, due to the high-speed operation and harsh working environment of electric tools, gear failure often occurs, which affects the performance and service life of the tools. Therefore, it is necessary to conduct in-depth research on the failure of cylindrical gear transmission and find effective solutions.

2. Common Failure Modes of Cylindrical Gear Transmission in Electric Tools

2.1 Tooth Surface Plastic Deformation (Fatigue Wear)

Tooth surface plastic deformation is mainly caused by high contact stress and the rolling and sliding of the tooth surface during meshing in continuous high-speed transmission. This is a form of permanent deformation of the gear teeth. It usually occurs on gears with low hardness, but can also occur on high-hardness gears under heavy loads.

| Causes of Tooth Surface Plastic Deformation | Description |

|---|---|

| Improper lubricating grease selection | The lubricating grease has poor extreme pressure resistance, temperature resistance and adhesion, resulting in poor lubrication effect, dry grinding and heating of the tooth surface, and finally plastic deformation. |

| Excessive clearance | Excessive clearance between the two tooth surfaces of the cylindrical gear or between the gear inner hole and the shaft causes plastic deformation wear due to mutual or relative sliding friction or impact stress. |

| Abrasive substances | When abrasive substances such as sand particles and iron filings fall into the meshing tooth surface during gear assembly, the tooth surface will gradually wear out and become scrapped. |

2.2 Tooth Breakage

Tooth breakage has various forms. Under normal working conditions, it is mainly tooth root bending fatigue breakage. When the gear teeth are loaded, the bending stress at the tooth root is the largest. Coupled with the stress concentration caused by the sudden change of the cross-section at the tooth root transition part and the machining tool marks, fatigue cracks will be generated at the tooth root after repeated loading of the gear teeth and gradually expand, resulting in fatigue breakage of the gear teeth.

| Causes of Tooth Breakage | Description |

|---|---|

| Bending fatigue | Under normal load conditions, due to the stress concentration at the tooth root, fatigue cracks are generated and gradually expand, resulting in tooth breakage. |

| Sudden overload or stall | When the gear is suddenly overloaded or stalled, such as when using a single-stage reduction electric drill or impact electric drill to screw screws, or during gear stall tests, or when the drill bit is suddenly stuck during drilling, or when the reciprocating machinery of the jigsaw fails suddenly during high-speed operation, the shaft gear may be overloaded and broken or sheared. |

| Severe wear | After severe wear of the gear teeth, the tooth thickness is too thin and will break under normal impact loads. |

3. Analysis of Failure Causes

3.1 Material Factors

The material properties of gears directly affect their strength and wear resistance. If the hardness of the gear material is too low, it is easy to cause tooth surface plastic deformation. On the contrary, if the hardness is too high and the toughness is insufficient, it is easy to cause tooth breakage. In addition, the quality of the material itself, such as the presence of inclusions and defects, will also reduce the performance of the gear.

3.2 Heat Treatment Process

Improper heat treatment process will lead to uneven hardness distribution of the gear, which may cause stress concentration and reduce the strength of the gear. For example, if the quenching temperature is too high or the cooling rate is too fast, it may cause cracks on the gear surface.

3.3 Lubrication Problems

The selection of lubricating grease is very important. If the lubricating grease does not match the working conditions of the gear, it cannot provide good lubrication and cooling effects, resulting in increased friction and wear between the gears, and even causing gear failure.

4. Solutions

4.1 Solutions for Tooth Surface Plastic Deformation

- Reasonable Hardness Definition: According to the actual working conditions and selected materials of the gears, the hardness of the gears should be reasonably defined. The hardness of the small gear should be one grade higher than that of the large gear, that is, more than 5 degrees.

- Proper Lubricating Grease Selection: High-viscosity or composite lubricating grease containing extreme pressure additives should be used to help slow down or prevent the plastic deformation of the gear teeth.

- Optimal Gear Clearance: The gear clearance should be reasonably selected, and the fit between the gear and the output shaft can adopt transition fit and interference fit to reduce the friction or abnormal impact on the tooth surface caused by relative sliding.

- Strengthening Process Control: For the abrasive wear caused by the falling of abrasive substances on the meshing tooth surface during product assembly, the process control should be strengthened to ensure that the gear machining tooth surface is cleaned, the heat treatment and transportation processes are protected, and the assembly site meets the 5S requirements.

4.2 Solutions for Tooth Breakage

- Improving Tooth Root Strength: For the shaft gears of most single-stage reduction electric drills, impact electric drills and jigsaws, which usually have a small number of teeth and a small module, it is recommended to increase the radius of the tooth root transition fillet and eliminate the machining tool marks to reduce the stress concentration at the tooth root.

- Enhancing Shaft and Support Rigidity: Increase the rigidity of the shaft and support, that is, use a bevel transition between the tooth part and the bearing section to improve the strength of the shaft gear tail.

- Appropriate Increase of Modification Coefficient: Appropriately increase the modification coefficient of the shaft teeth to increase the tooth root thickness and the diameter of the tooth root circle, thereby improving the bending strength of the tooth root.

- Material and Heat Treatment Optimization: For electric tools that are often used under extreme overload or stall conditions, it is recommended to change the shaft gear material from ordinary medium carbon steel materials such as 40Cr or 42CrMo to low-carbon alloy materials such as 20CrMo or 20CrMnTi, and use carburizing or carbonitriding heat treatment methods to make the tooth core material have sufficient toughness.

5. Conclusion

In conclusion, the failure of cylindrical gear transmission in electric tools has a significant impact on the performance and service life of the tools. By analyzing the common failure modes and causes, and proposing corresponding solutions, it can effectively improve the quality of the gears and the reliability of the electric tools. In the future design and manufacturing process, continuous attention should be paid to the selection of materials, the optimization of heat treatment processes and the improvement of lubrication conditions to ensure the normal operation of the cylindrical gear transmission in electric tools and meet the needs of users.