1. Introduction

Gear mechanisms are widely used in machinery due to their high transmission efficiency, long service life, and stable transmission ratio. However, gear failure, such as wear and pitting, can lead to shortened gear life, increased clearance, reduced efficiency, and noise. Therefore, understanding the contact stress during gear transmission is crucial for gear design and performance optimization.

1.1 Background

Previous studies have focused on various aspects of gear contact problems. For example, PUNEETH and MALLESH analyzed the contact process of a pair of spur gears using finite element software and applied the results to gear design. Hu et al. calculated the ratio of maximum contact stress to node contact stress for standard gear transmission. Tang et al. analyzed the impact problem caused by the change of transient contact speed during gear meshing. Yang applied the finite element method to calculate gear contact deformation and stress. ZHAO et al. established a fractal surface contact model for rough tooth surfaces. LIU et al. studied the bearing capacity of face-hobbed and face-milled hypoid gears.

1.2 Research Objectives

This study aims to calculate the maximum contact stress of modified involute spur gears during transmission, analyze the position of maximum contact stress, and derive the stress ratio function. The effects of the number of teeth of the pinion and the transmission ratio on the stress ratio will be investigated, and a method for precise contact strength calculation will be provided.

2. Gear Meshing and Hertz Stress Calculation

2.1 Gear Parameters and Meshing Process

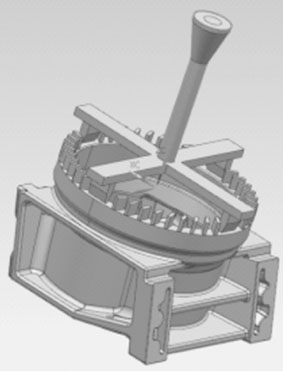

Consider a pair of modified involute spur gears with torque , rotational speed , load correction coefficient , normal force of a single pair of teeth , tooth width , tangential force , module , transmission ratio , number of teeth and , base circle radii and , radii of any meshing point on the tooth profiles and , pressure angles and , pitch circle radii and , pitch circle pressure angle , and meshing angle . The contact process of a pair of teeth is shown in Figure 1.

2.2 Hertz Stress Formula

According to the Hertz formula, the contact stress at any point on the tooth profile is given by:

where and . The comprehensive curvature at any contact point is , where and . The combined elastic influence coefficient of the two gears is . After substitution, the contact stress can be expressed as .

2.3 Analysis of Contact Stress Variation

The variation of the contact stress mainly depends on the function . By analyzing the variation of with , it is found that the comprehensive curvature is larger near the limit meshing point of the meshing line, and has a minimum value at the midpoint of the limit meshing line. The contact stress is larger near the endpoints of the actual meshing line, but the maximum contact stress occurs near the limit meshing point of the pinion, at the boundary point between the single-tooth meshing area and the double-tooth meshing area.

3. Calculation of Maximum Contact Stress

3.1 Maximum Contact Stress at a Specific Point

Let the limit meshing line of the gears be . When the tooth profile contacts at point , the contact stress at this point can be calculated by substituting the relevant parameters into the formula. The result is

3.2 Contact Stress at the Node

When the gears are in node meshing, the distance from the node to the meshing limit point of the gear is . By substituting this into the relevant formula, the contact stress at the node is

4. Stress Ratio and Its Analysis

4.1 Definition of Stress Ratio

The ratio of the maximum contact stress (at point ) to the contact stress at the node is defined as the stress ratio

4.2 Expression of Maximum Contact Stress in Terms of Stress Ratio

The maximum contact stress can be expressed as

4.3 Analysis of Stress Ratio for Different Gear Types

4.3.1 Isometric Modified Gear Transmission

For isometric modified gear transmission, when the number of teeth of the driving gear is less than , as increases, the stress ratio and the maximum contact stress increase. As the transmission ratio increases, the stress ratio and the maximum contact stress also increase. When the transmission ratio is greater than or equal to 3 and the number of teeth of the small gear is greater than or equal to 13 (less than 17), the maximum contact stress is 8% or more greater than the node contact stress.

4.3.2 Unisometric Modified Gear Transmission

For positive transmission in unisometric modified gear transmission, as the number of teeth of the small gear increases, the stress ratio increases, while as the modification coefficient increases, the stress ratio decreases. The same trend is observed for negative transmission.

4.3.3 Standard Gear Transmission

In standard gear transmission, when , the stress ratio decreases as the number of teeth of the small gear increases, and increases as the transmission ratio increases.

5. Conditions for Precise Contact Strength Design

If the design criterion for gear contact strength is that the maximum contact stress is 8% or more greater than the node contact stress, then precise design according to the maximum contact stress is required. The conditions for requiring precise contact fatigue strength design calculations are provided in Table 1. When the number of teeth of the small gear and , precise contact fatigue strength design calculations according to the maximum contact stress are not required.

6. Example Analysis

6.1 Design of Gear Transmission Based on Contact Strength

Given the input power , transmission ratio , and rotational speed of the small gear for an external meshing modified involute spur gear transmission, along with other material and parameter information, the gear transmission is designed according to contact strength. The number of teeth of the small gear is selected, and the modification coefficients and are determined. The stress ratio is calculated. The calculated results show that the gear pitch circle diameters designed according to node meshing and maximum stress are different, and the corresponding moduli are and respectively.

6.2 Verification of Stress Ratio Calculation Formula

The Abaqus finite element software is used to simulate the contact stress of the gear transmission in the above example. The geometric dimensions and parameters of the gears are set, and the contact stresses at the boundary point and the node are calculated. The stress ratio obtained from the simulation is compared with the calculated stress ratio, and the relative error is 1.34%, indicating that the calculated results are in good agreement with the simulation results.

7. Conclusions

7.1 Summary of Research Results

- The calculation method for the maximum contact stress of modified gears during transmission is obtained. The maximum contact stress can be expressed as the product of the stress ratio and the node contact stress.

- The variation law of the stress ratio with the number of teeth of the small gear and the transmission ratio is analyzed. When , the stress ratio increases with the increase of the number of teeth of the small gear and the transmission ratio, and reaches the maximum when .

- The conditions for precise contact strength design are provided. If the maximum contact stress is 8% or more greater than the node contact stress, precise design according to the maximum contact stress is required.

7.2 Significance and Future Research Directions

This study provides a theoretical basis for the precise design of modified gears and helps to improve the reliability and performance of gear transmissions. Future research could focus on further investigating the influence of other factors on gear contact stress, such as surface roughness and lubrication conditions, and exploring more accurate calculation methods and optimization strategies for gear design.

In conclusion, understanding the contact stress in the transmission process of modified involute spur gears is essential for gear design and performance optimization. The research results presented in this paper contribute to the development of more reliable and efficient gear transmissions.

| Table 1: Conditions for Requiring Precise Contact Fatigue Strength Design Calculations | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Small Gear Teeth Number | 23 | 22 | 21 | 20 | 19 | 18 | 17 | 16 | 15 | 14 | 13 | 12 |

| Transmission Ratio (≥) | 11.2 | 5.3 | 4.3 | 3.2 | 2.6 | 2.2 | 1.8 | 2 | 2.6 | 2.7 | 3.1 | 6.4 |

| Stress Ratio (≥) | 1.080 | 1.080 | 1.083 | 1.080 | 1.081 | 1.082 | 1.080 | 1.080 | 1.080 | 1.081 | 1.080 | 1.080 |

8. Gear Contact Stress in Practical Applications

8.1 Importance in Industrial Machinery

In industrial machinery, such as manufacturing equipment, conveyor systems, and power transmission units, gears play a crucial role. The contact stress directly affects the lifespan and performance of gears. High contact stress can lead to premature wear, pitting, and even failure of gears, resulting in costly downtime and maintenance. Understanding and controlling the contact stress is essential for ensuring the smooth operation of industrial machinery.

8.2 Influence on Gear Design and Selection

The knowledge of contact stress is also vital for gear design and selection. Engineers need to consider the contact stress when determining the appropriate gear materials, tooth profiles, and lubrication methods. For example, if the contact stress is expected to be high, stronger and more wear-resistant materials may be chosen. The tooth profile can be optimized to distribute the contact stress more evenly. Lubrication is also crucial as it can reduce friction and wear, thereby reducing the contact stress.

9. Factors Affecting Gear Contact Stress

9.1 Gear Geometry

The geometry of gears, including the number of teeth, module, pressure angle, and tooth profile, has a significant impact on the contact stress. As discussed earlier, the number of teeth and the transmission ratio affect the stress ratio, which in turn determines the maximum contact stress. The module and pressure angle also influence the contact stress through their effects on the tooth geometry and the load distribution.

9.2 Load Conditions

The load applied to the gears is another important factor. Higher loads generally result in higher contact stresses. The type of load, whether it is static or dynamic, also matters. Dynamic loads can cause additional stress fluctuations and fatigue damage to the gears.

9.3 Lubrication and Surface Finish

Lubrication and surface finish play a crucial role in reducing the contact stress. A good lubricant can form a protective film between the gear teeth, reducing friction and wear. A smooth surface finish can also help in reducing the contact stress by minimizing the asperities on the tooth surfaces that can cause stress concentrations.

10. Methods for Reducing Gear Contact Stress

10.1 Gear Modification

Gear modification techniques, such as profile modification and lead modification, can be used to reduce the contact stress. These modifications can help in optimizing the load distribution and reducing the stress concentrations at the tooth contacts.

10.2 Lubrication Optimization

Optimizing the lubrication system can significantly reduce the contact stress. This includes selecting the appropriate lubricant, ensuring proper lubricant supply, and maintaining the correct lubricant temperature and viscosity.

10.3 Material Selection

Choosing the right gear materials with good mechanical properties and wear resistance can also help in reducing the contact stress. Materials with high hardness and toughness can withstand higher stresses and resist wear.

11. Future Trends in Gear Contact Stress Research

11.1 Advanced Simulation Techniques

With the development of computer technology, more advanced simulation techniques are expected to be used in gear contact stress research. These techniques can provide more accurate predictions of the contact stress and help in optimizing the gear design.

11.2 Multidisciplinary Approaches

Future research is likely to involve multidisciplinary approaches, combining mechanical engineering with materials science, tribology, and other fields. This will enable a more comprehensive understanding of the factors affecting the contact stress and lead to more effective solutions for reducing it.

11.3 Real – Time Monitoring and Control

Real – time monitoring and control of gear contact stress is another potential area of research. This can involve the use of sensors to measure the contact stress during gear operation and the development of control strategies to adjust the gear parameters in real time to maintain the contact stress within acceptable limits.

12. Conclusion

Gear contact stress is a critical factor in the performance and lifespan of gears. Understanding the factors affecting it and the methods for reducing it is essential for the design and operation of reliable gear transmissions. Future research in this area is expected to bring more accurate predictions and better control of the contact stress, leading to more efficient and reliable gear systems. The research presented in this paper provides a foundation for further exploration and development in the field of gear contact stress.