Introduction

Gear transmission systems are widely used in industry, and the meshing and dynamic characteristics of gear transmission are related to the smoothness and reliability of the entire equipment. The large number of manufacturing and installation errors in engineering can cause changes in the contact state of the tooth surface, thereby affecting the development of tooth surface damage (such as peeling, wear, and bonding),Cylindrical Gear and further affecting the dynamic behavior of the gear system. Numerous studies have focused on the impact of manufacturing errors or tooth surface damage on the meshing and response characteristics of gears. Accumulated tooth pitch error is a common gear manufacturing error, and many scholars at home and abroad have analyzed the impact of tooth pitch error on the dynamic characteristics of the system. The influence of tooth pitch deviation on the dynamic characteristics of spur gear rotor system was studied, and the results showed that tooth pitch deviation would cause sideband frequency to appear near the meshing frequency. A dynamic model of helical gears considering accumulated tooth pitch error was established based on the contact analysis method of gear teeth, and it was extended to herringbone gears. During gear operation, wear on the tooth surface is inevitable. The research on wear can mainly be divided into quasi-static assumptions and dynamic assumptions. Based on the Archard wear model, a wear prediction model for spur gear pairs under quasi-static conditions was established,Cylindrical Gear and the influence of misalignment and torque on wear was studied. A dynamic wear prediction model was established by coupling the wheel dynamics model with the Archard wear model, revealing the interaction between wear and dynamic behavior.Cylindrical Gear An improved dynamic wear prediction model for gear pairs was established, and the effectiveness of the wear prediction model was verified through experiments.

A dynamic wear model considering tooth pitch error

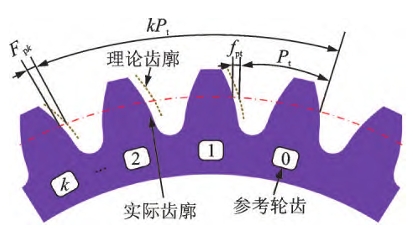

Due to machining errors, the actual tooth profile often deviates from the theoretical involute tooth profile, causing meshing teeth to participate in meshing earlier or later. The schematic diagram of accumulated tooth pitch error is shown in Figure 1. Pt is the theoretical tooth pitch, fpt is the tooth pitch error, and Fpk is the accumulated tooth pitch error corresponding to the k-th gear tooth. A tooth pitch error greater than zero indicates that the actual tooth thickness is greater than the theoretical tooth thickness, Cylindrical Gear while conversely, it indicates that the actual tooth thickness is less than the theoretical tooth thickness. The contact analysis method for gear tooth load balancing accuracy and solving efficiency, and effectively considering various forms of tooth profile errors, this paper adopts the LTCA method to obtain the load distribution of gear pairs containing tooth profile deviations. The core idea of the LTCA method is to separate the overall deformation and contact deformation during gear meshing.Cylindrical Gear The contact deformation is calculated using analytical formulas to improve calculation efficiency, and the overall deformation is calculated using the finite element method.

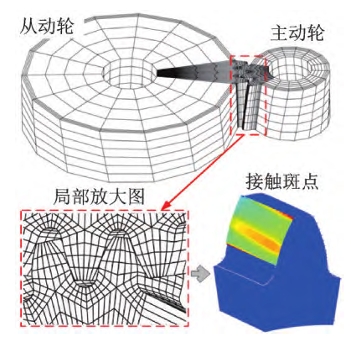

In order to improve the universality and computational efficiency of the program, Cylindrical Gear the finite element calculation process is implemented in the MATLAB environment. The finite element mesh constructed in MATLAB.

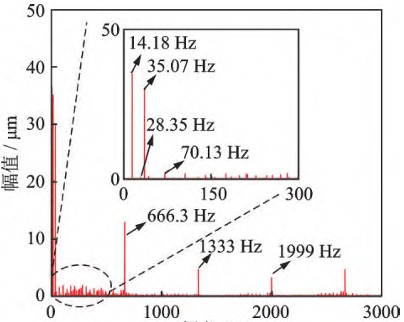

Model validation

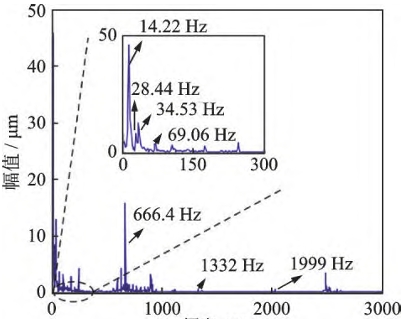

The experimental results of the dynamic transmission error of the helical gear pair with accumulated tooth pitch error verify the effectiveness of the model proposed in this paper.Cylindrical Gear For the convenience of comparing with the experimental results in the literature, the tooth profile deviation parameters consistent with the experiments in the literature are adopted,Cylindrical Gear and the forms of tooth profile deviation included include: tooth profile modification, tooth direction modification, cumulative tooth pitch error, and geometric eccentricity. The rotational frequency component caused by the cumulative error of tooth pitch is very obvious, showing a very obvious sideband near the meshing frequency. Cylindrical Gear The spectral characteristics obtained from the model and the experiments in the literature are very similar, indicating the effectiveness of the simulation model.

Analysis of meshing characteristics

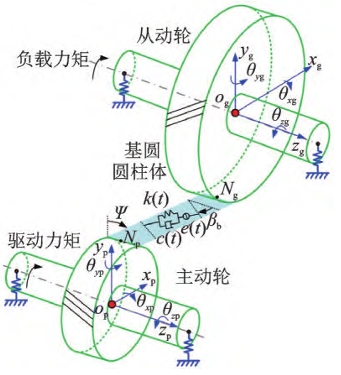

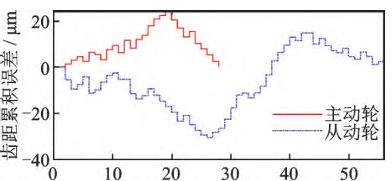

The diameters of the driving shaft and the driven shaft are 60 mm and 100 mm, respectively. Cylindrical Gear The length of the shaft is 300 mm. Bearing stiffness, ignoring shaft damping. The cumulative error of tooth pitch between the driving wheel and the driven wheel is based on the measured results in China.

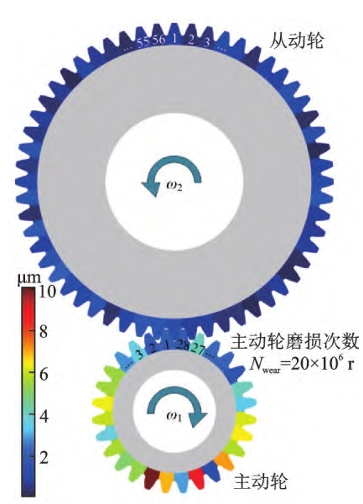

Accumulated wear depth of the middle surface of the active gear tooth width under different operating times. The node position has zero wear due to its zero relative slip velocity. Cylindrical Gear There is significant wear at the root and top of the teeth. As the number of runs increases, due to severe wear at the root and top of the teeth, the contact stress in this area decreases and the wear rate slows down. For gear pairs without accumulated pitch error, the meshing stiffness within each meshing cycle is the same. Cylindrical Gear The introduction of cumulative error in tooth pitch will result in different meshing stiffness within each meshing cycle, showing an overall fluctuation trend during the chasing tooth cycle. Cylindrical Gear And the tooth pitch error only affects the meshing stiffness of the double tooth zone, while the meshing stiffness of the single tooth zone is independent of the accumulated tooth pitch error. After 400 × 106 runs, the stiffness between the single and double tooth meshing areas became smoother, and the length of the double tooth area decreased, that is, the overlap of the gear pair decreased.

Vibration characteristic analysis

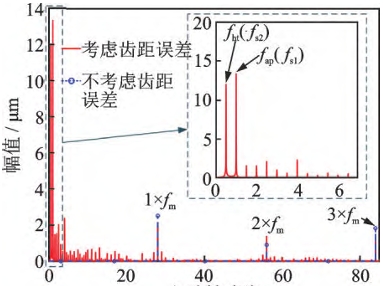

If the meshing non-uniformity caused by accumulated tooth pitch errors is not considered, the spectrum of worn gears only contains the meshing frequency component. The wear gear spectrum obtained by considering the cumulative error of tooth pitch contains a richer frequency component. In the low frequency range,Cylindrical Gear obvious components such as chasing tooth frequency and combination state frequency can be observed, and there is also sideband frequency modulation phenomenon near the meshing frequency and its harmonics. Due to the particularity of the number of teeth in this example, the chasing tooth frequency fht is equal to the rotational frequency fs2 of the driven shaft,Cylindrical Gear and the combined state frequency fap is equal to the rotational frequency fs1 of the active shaft.

The dynamic load coefficient is defined as the ratio of the maximum dynamic meshing force to the static meshing force during the steady-state vibration cycle. In the early wear stage (running in stage), Cylindrical Gear grinding Loss can improve the smoothness of meshing, mainly due to slight wear that can alleviate tooth interference during the process of alternating single and double teeth, playing a role in running in and passive shaping. As the number of runs increases, the meshing clearance (no-load transmission error) caused by wear becomes larger and larger, Cylindrical Gear and the gear system shows a clear trend of performance degradation, with a linear increase in vibration. Although both the model in this article and the traditional model (without considering tooth pitch error) can predict this performance degradation process, the traditional model will underestimate the dynamic load coefficient by about 10%.

Analysis of Uneven Wear

Traditional wear simulation analysis is based on uniform load distribution between teeth, resulting in the same amount of wear on each tooth.Cylindrical Gear However, in reality, due to the accumulation of tooth pitch errors, the wear morphology of each tooth surface is often different. After considering the cumulative error of tooth pitch, the model can effectively simulate the wear non-uniformity caused by uneven load between teeth.

Conclusion

A method considering tooth pitch accumulation is proposed based on the contact analysis method of gear teeth, gear rotor dynamics model, and Archard wear model

A gear dynamic wear prediction model based on product error. The effectiveness of the model was verified by comparing the simulated spectrum with literature experiments.Cylindrical Gear Based on the above The model was described and the impact of accumulated tooth pitch error on response characteristics and wear distribution was analyzed. The main conclusions are as follows:

(1) The cumulative error of tooth pitch will introduce shaft rotation frequency, chasing tooth frequency, and combination shape to meshing stiffness, transmission error, and vibration response Rich frequency components such as state frequency.Cylindrical Gear However, the spectrum obtained from traditional dynamic models generally only contains the meshing frequency component.

(2) This model can evaluate the unevenness of inter tooth wear caused by accumulated errors in tooth pitch, and improve the traditional wear models The idealized assumption is that the amount of tooth wear is equal. Mild wear can help alleviate uneven load distribution between teeth,Cylindrical Gear but severe wear can worsen even load distribution Characteristics, leading to increased vibration.

(3) The dynamic wear model in this article can establish a mapping relationship between the chase tooth coefficient and the wear non-uniformity coefficient. Adopting chasing teeth design Calculation can reduce the coefficient of uneven wear by about 30%. Cylindrical Gear When the accumulated error of tooth pitch is small, the requirement for chasing tooth design can be appropriately relaxed.