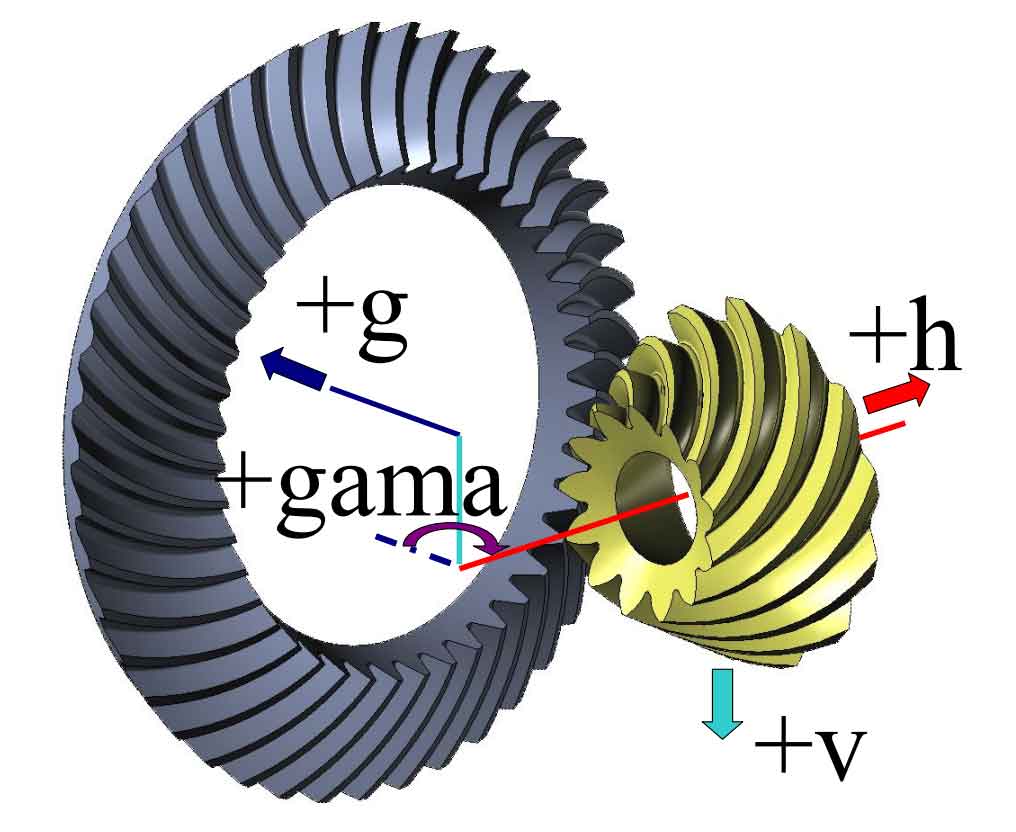

The installation deviation of hypoid gears is mainly divided into four categories. The definition of installation deviation direction is shown in Figure 1. The axial installation deviation of large gears is g, the axial installation deviation of hypoid small wheels is h, the installation deviation of offset distance of large and small gears of hypoid gears is V, and the installation cross angle deviation of large and small gears of hypoid gears is Gama. The ideal installation position of hypoid gears is that all installation deviations are equal to zero (v = H = g = Gama = 0). Using the method of controlling single variable, only one of the installation deviation variables changes during each test, while the other three deviations are equal to zero. For example, when v = 0.2mm, H = g = Gama = 0, and so on. The input resistance moment is 1000nm during comparative analysis.

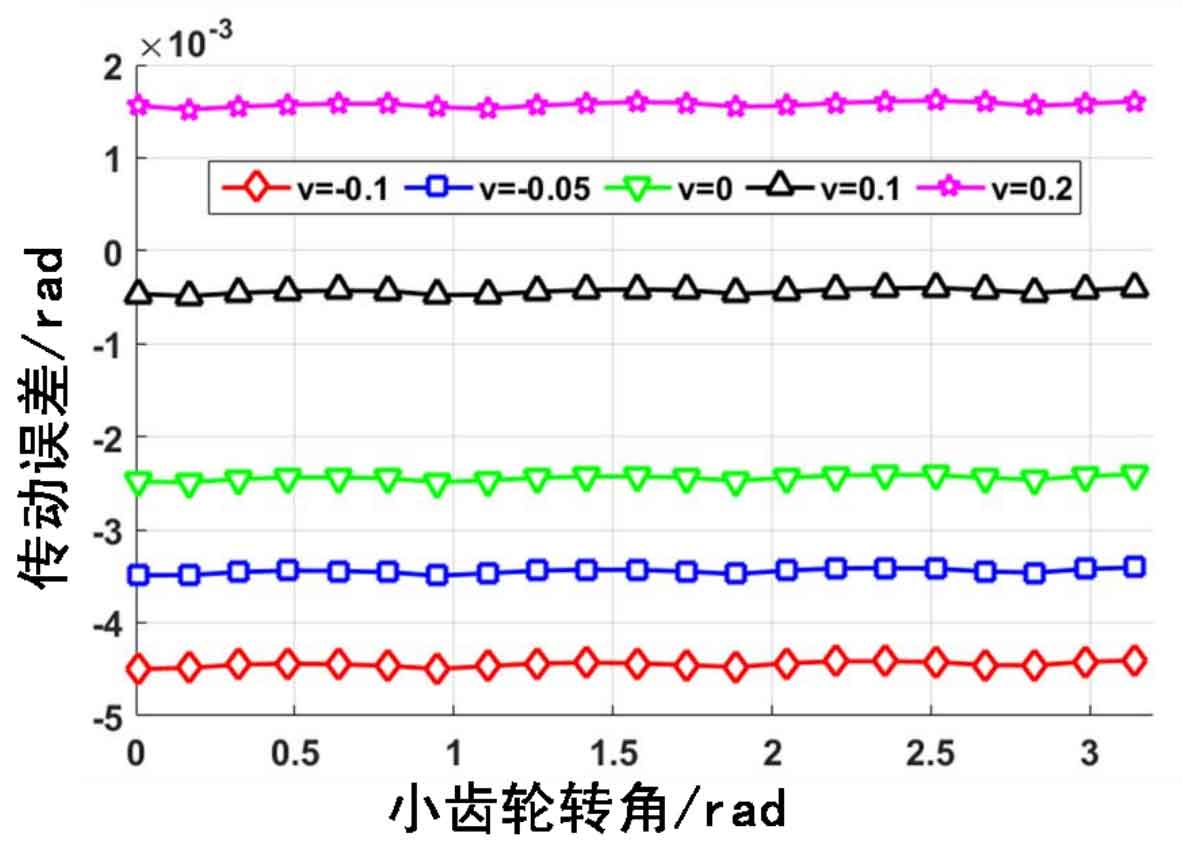

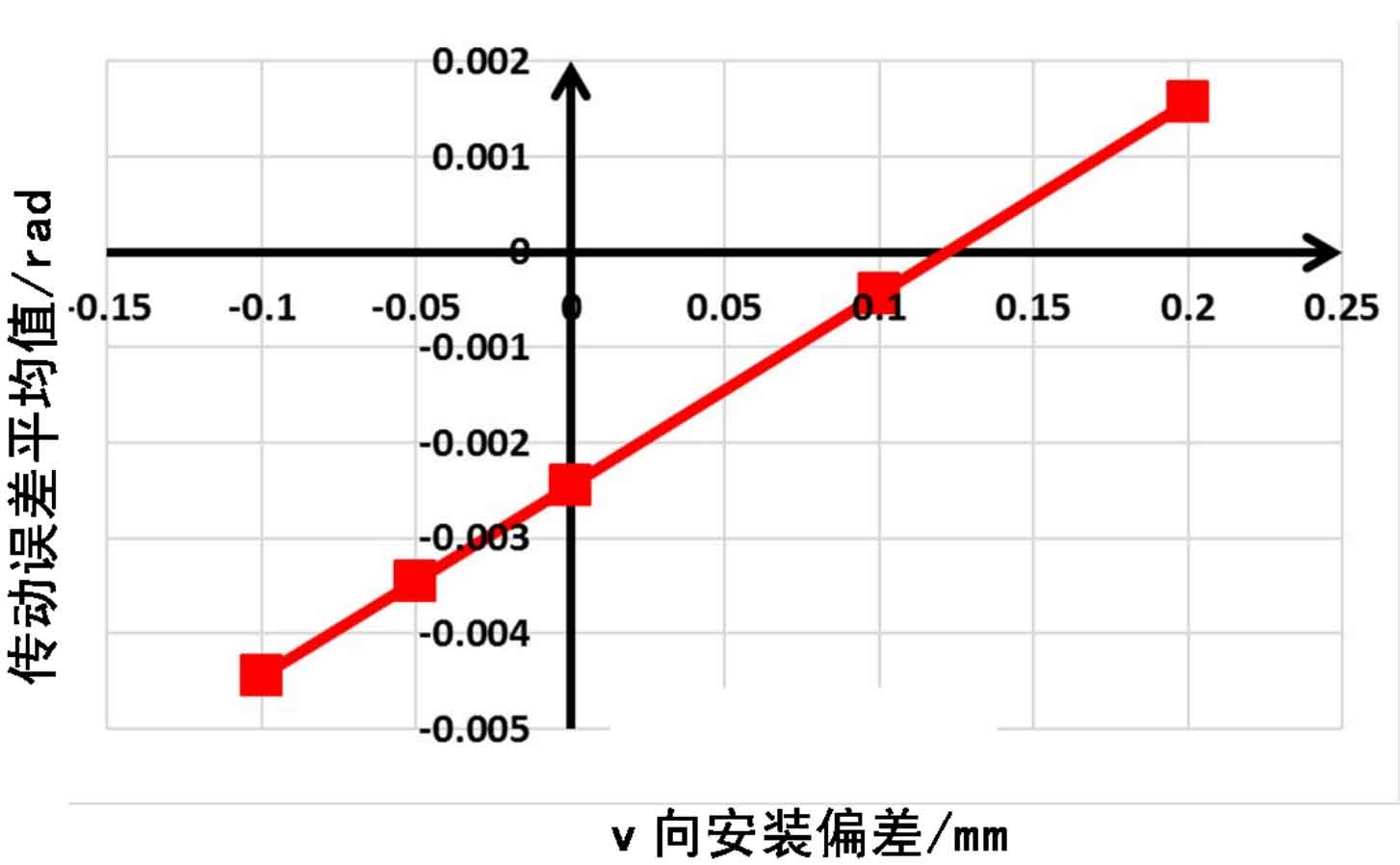

1. Analysis of influence of installation deviation V of offset distance of hypoid gear

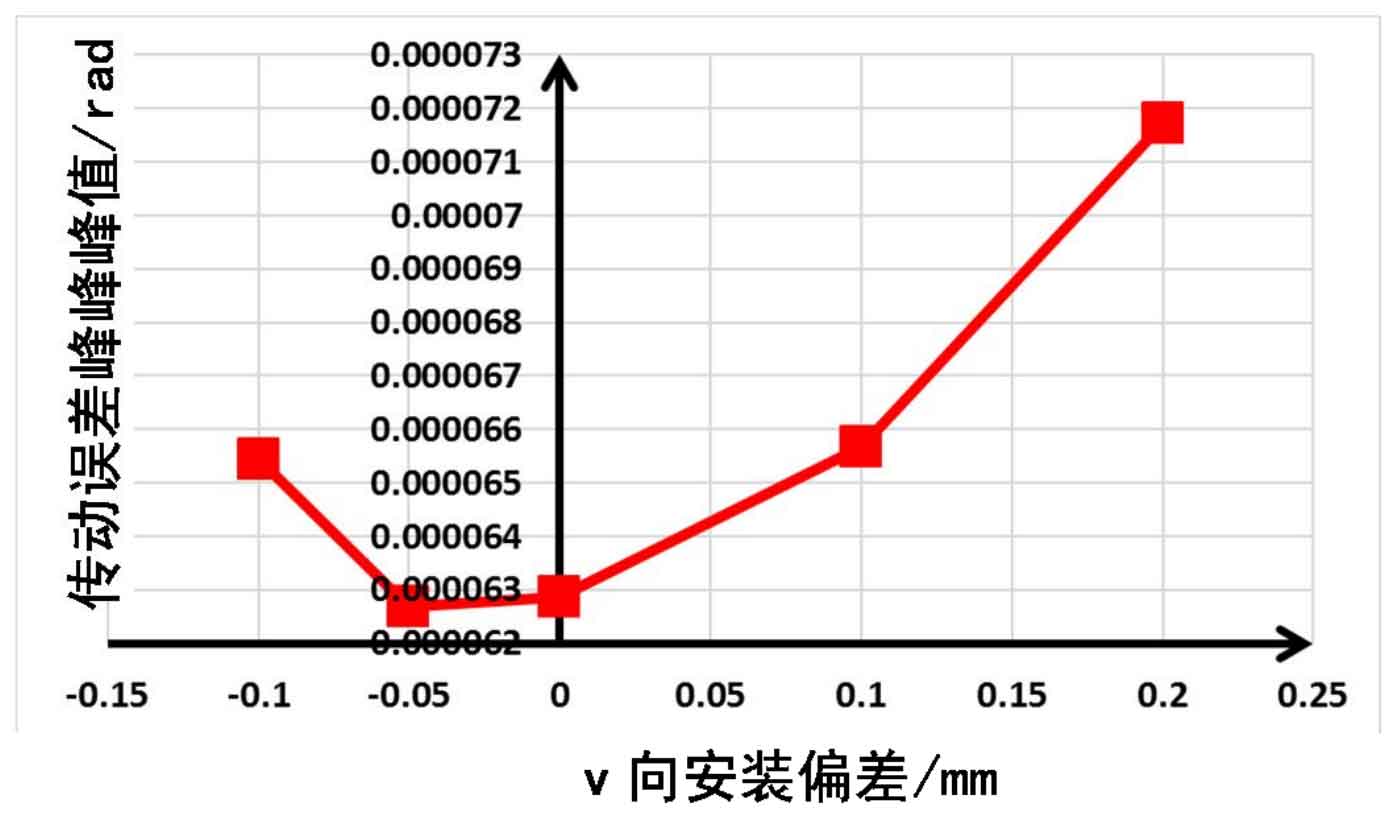

As shown in Fig. 2, when the installation offset deviation of hypoid gear is v = – 0.1mm, -0.05mm, 0mm, 0.1mm, 0.2mm, the influence of the static transmission error of hypoid gear can be seen that when the installation deviation of V direction increases in a positive direction, the average value of transmission error is nearly linearly increased, but the transmission error is positive, as shown in Fig. 3, which means that the rotation speed of the driven gear is faster than that of the driving gear, At this time, the meshing coincidence degree of the hypoid gear is also reduced, which is unfavorable for the smooth transmission of the hypoid gear system. Therefore, the positive installation deviation of the hypoid gear V should be minimized. As shown in Fig. 4, the influence of v-direction installation deviation on the transmission error fluctuation of the hypoid gear can be seen. It can be seen that the influence of v-direction installation deviation on the transmission error fluctuation of the hypoid gear is small. However, careful observation shows that when the v-direction installation deviation is different, the peak position of the transmission error fluctuation is also different, that is, the position of the corresponding gear meshing midpoint is changed. This is because when the value of V increases in the positive direction, the meshing midpoint of hypoid gears moves to the small end, and vice versa. As shown in Fig. 5, the peak to peak value change of transmission error corresponding to the v-direction installation deviation. It can be seen that when v changes in the positive or negative direction, the peak to peak value of transmission error will increase, but this change is not large.

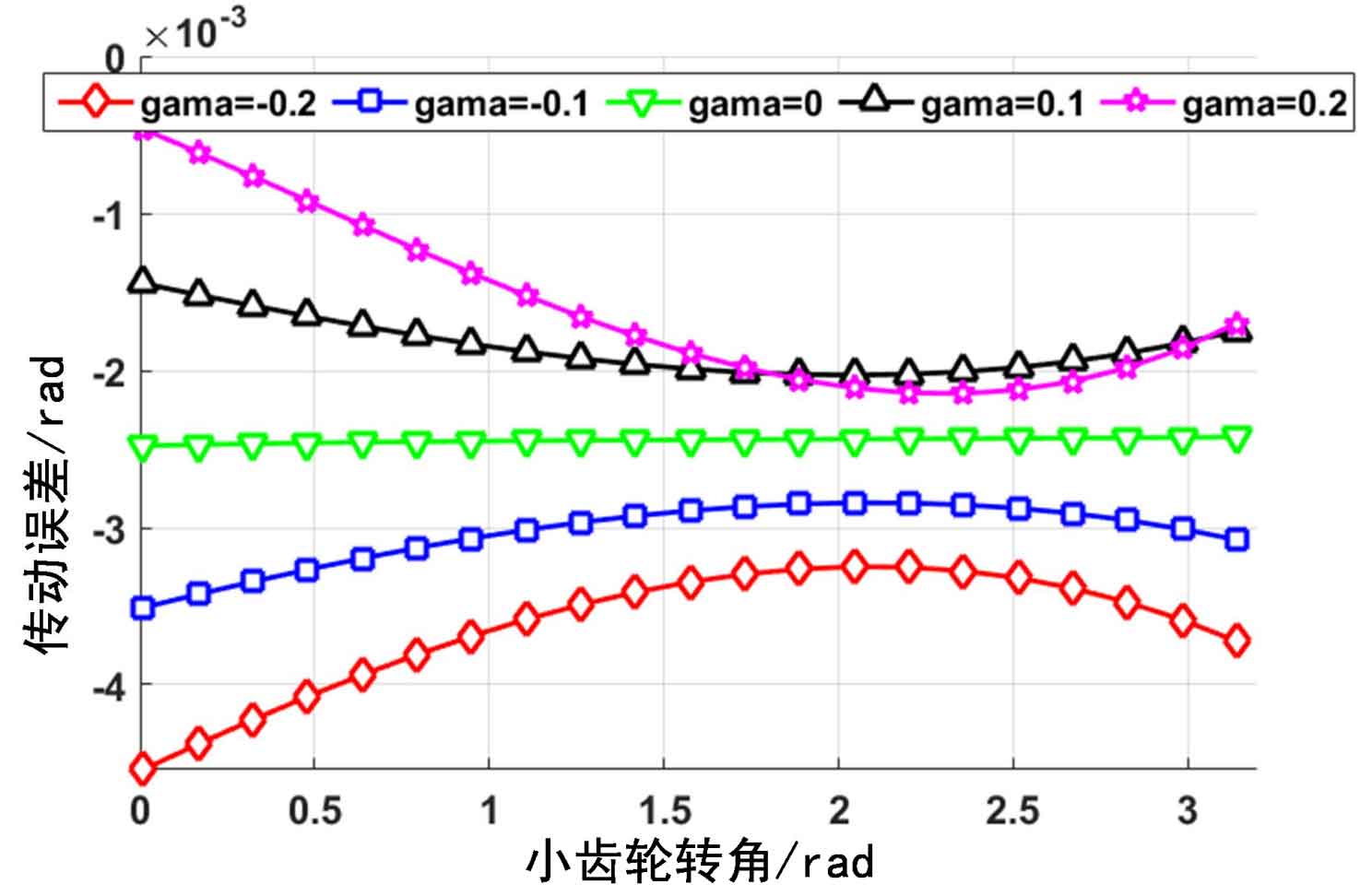

2. Analysis on the influence of Gama on the cross angle installation deviation of hypoid gears

As shown in Fig. 6, the installation deviation Gama = – 0.2 °, – 0.1 °, 0 °, 0.1 °, 0.2 ° of the cross angle of the hypoid gear is affected by the static transmission error of the hypoid gear. It can be seen that different from other types of installation deviation, the average value of the transmission error of the hypoid gear changes with the change of the meshing position of the hypoid gear. This is mainly because the angle installation deviation easily causes abnormal edge contact of the hypoid gear, The unbalance of hypoid gears in the meshing process will bring new excitation to the hypoid gear system. At the same time, it can be seen that the transmission error changes greatly during the meshing process of the hypoid gear, which will generate a large periodic excitation force. Therefore, it is necessary to strictly control the cross angle deviation of the installation of the hypoid gear. In particular, when the installation angle deviation changes in the negative direction, it is easy to cause positive transmission error of the hypoid gear, reduce the meshing coincidence of the hypoid gear, and it is not conducive to the smooth transmission of torque of the hypoid gear.

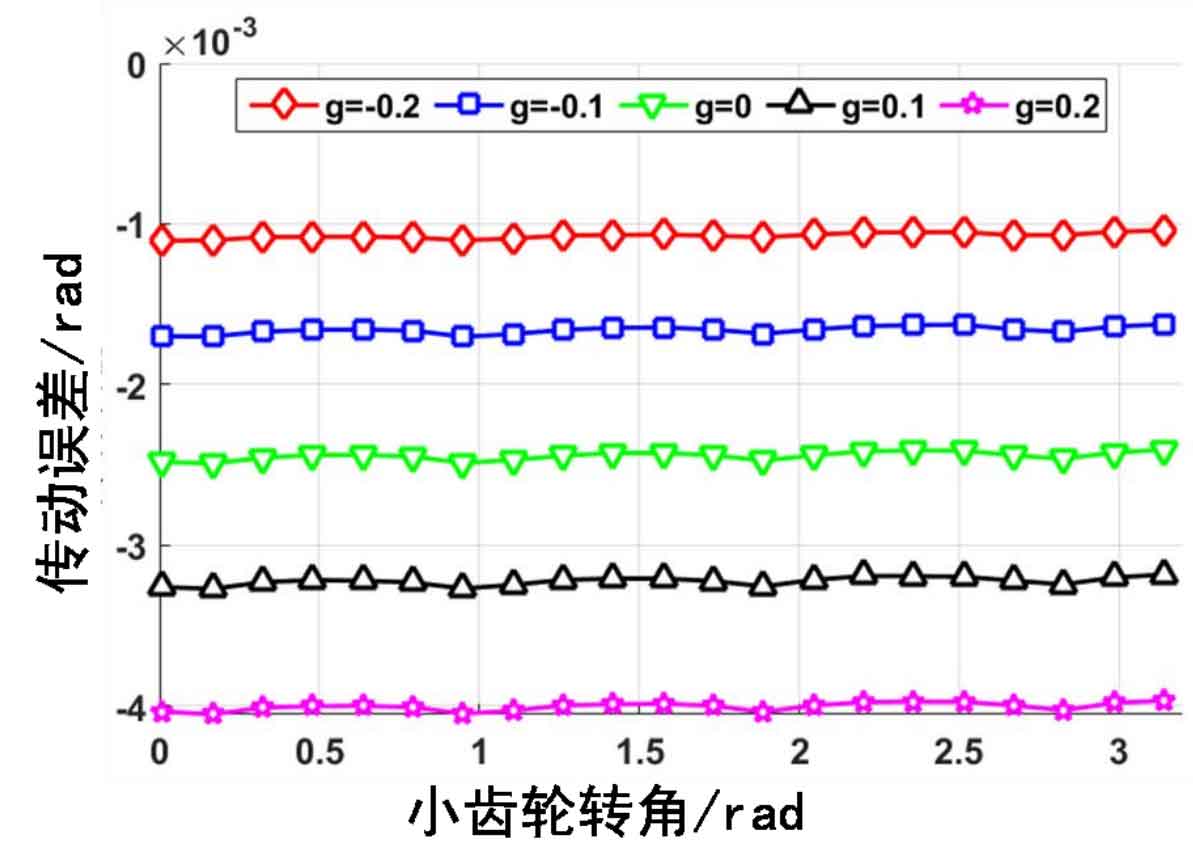

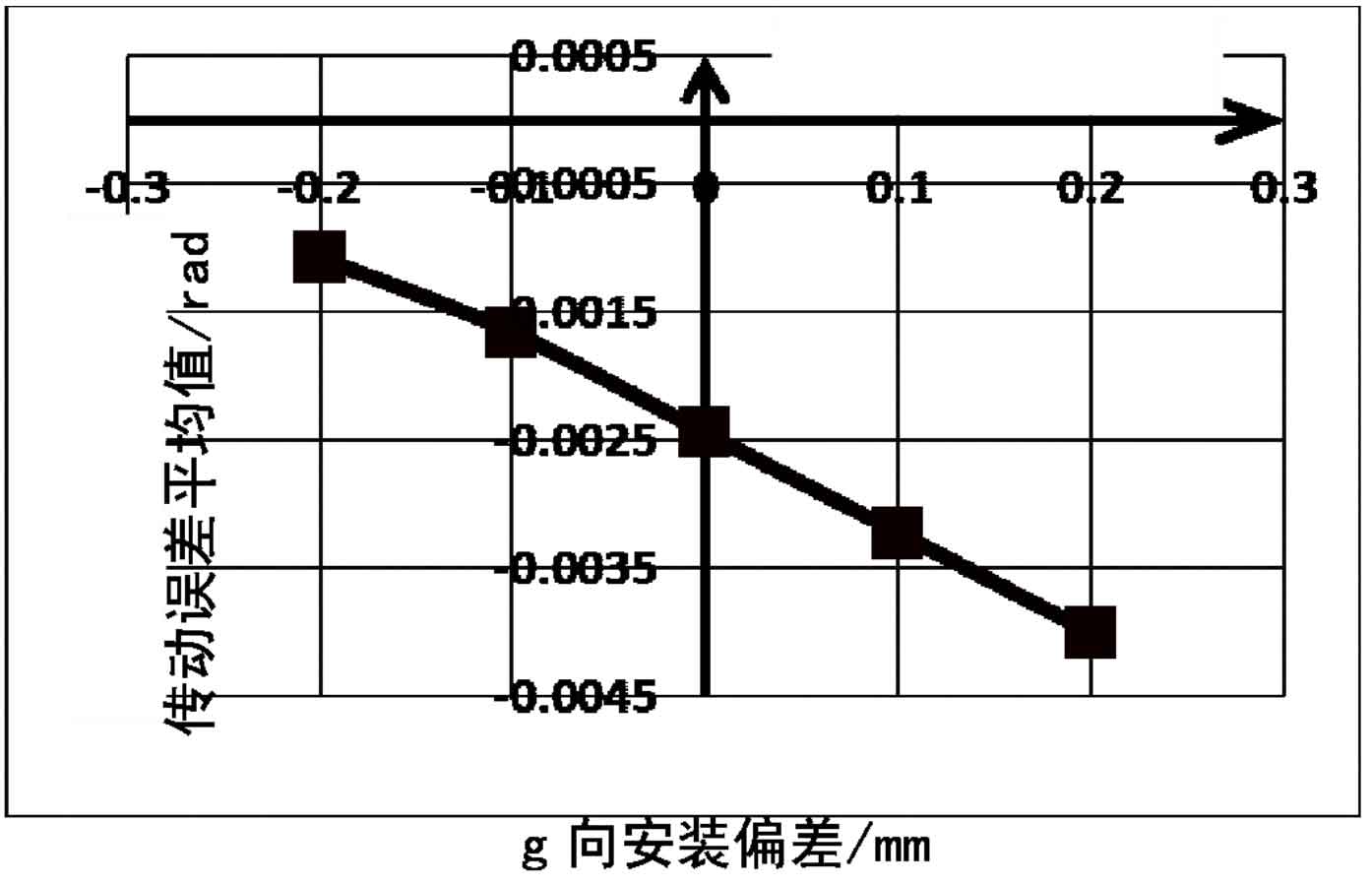

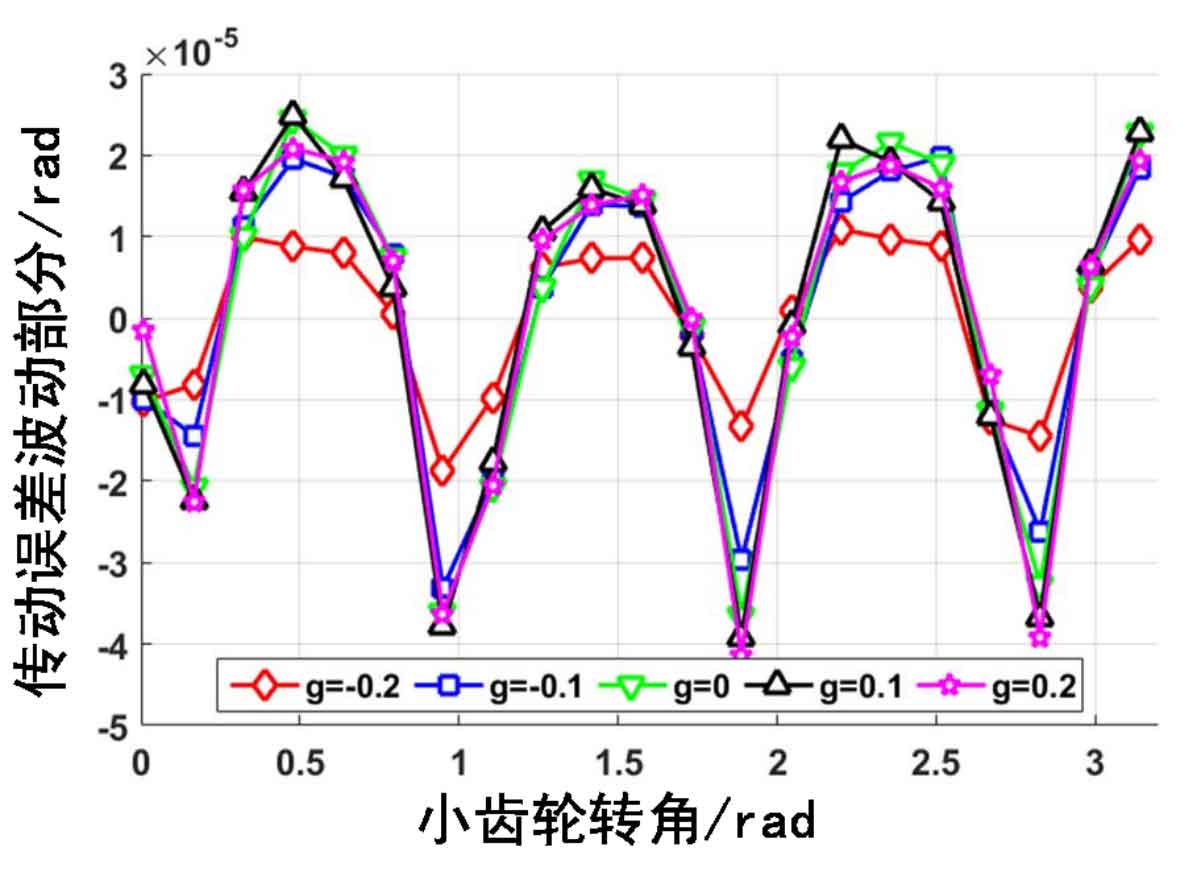

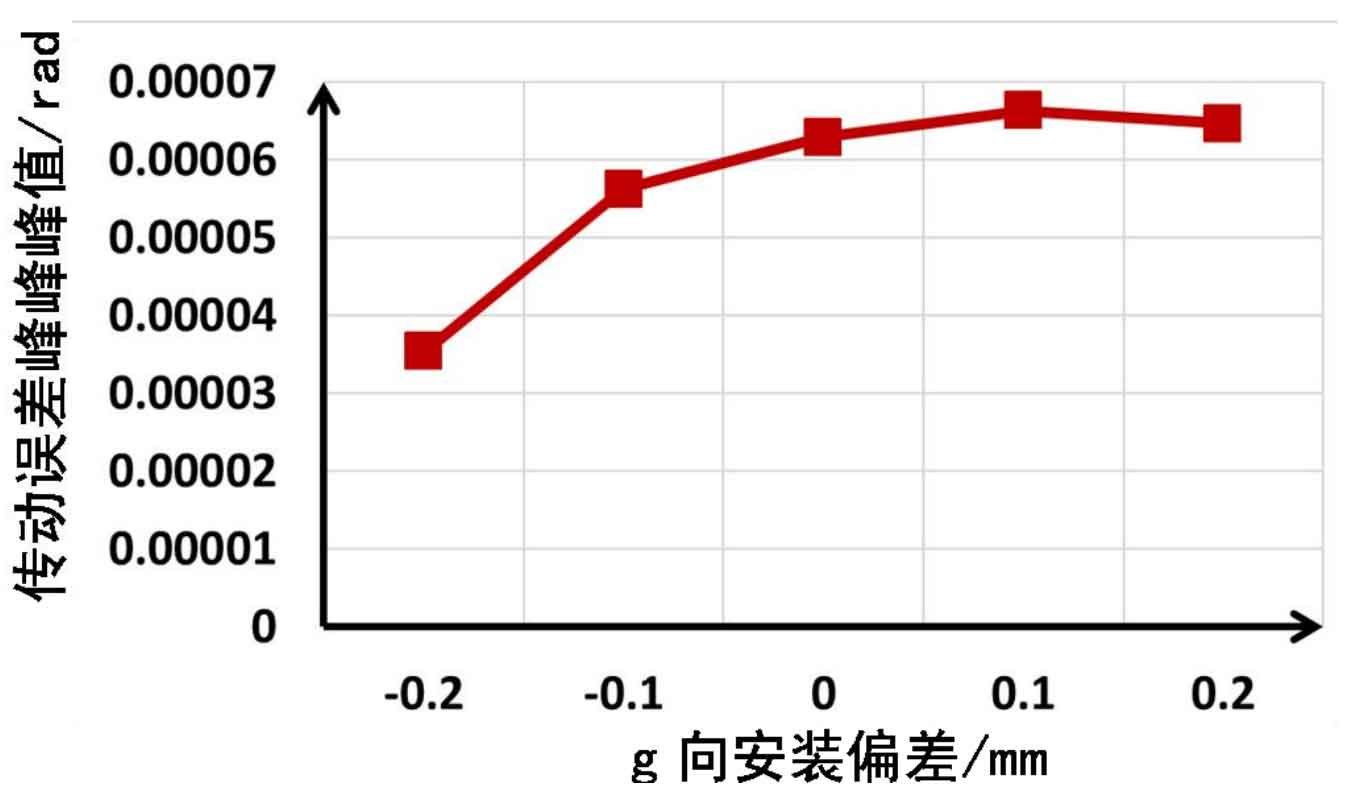

3. Analysis on the influence of the installation deviation g of the hypoid large axle

As shown in Fig. 7, it is the influence of the static transmission error of the hypoid gear when the installation deviation of the hypoid large axle is g = – 0.2mm, -0.1mm, 0mm, 0.1mm and 0.2mm. It can be seen that when the installation deviation of the G direction increases positively, the average value of the transmission error of the hypoid gear moves to the negative direction of the coordinate axis, and the absolute value gradually increases. As shown in Fig. 8, this is the same as the change trend of the average value of the transmission error when the load increases, It shows that the meshing coincidence degree of hypoid gears increases with the positive increase of G value, and vice versa. Fig. 9 corresponds to the transmission error fluctuation part. It can be seen that when the installation deviation increases in the positive direction, the fluctuation peak value of the transmission error changes very little. As shown in Fig. 10, the fluctuation peak value changes with the installation deviation in the G direction. When the installation deviation increases in the negative direction, the transmission error fluctuation will decrease. Comparing different g values, it can be seen that when the g value increases in the positive direction, the meshing coincidence degree of the hypoid gear is increased, which is conducive to the smooth operation of the hypoid gear. Therefore, the meshing coincidence degree of the hypoid gear can be improved by adjusting the installation deviation g of the hypoid gear shaft.

4. Analysis on influence of axial installation deviation h of quasi double curved surface small wheel

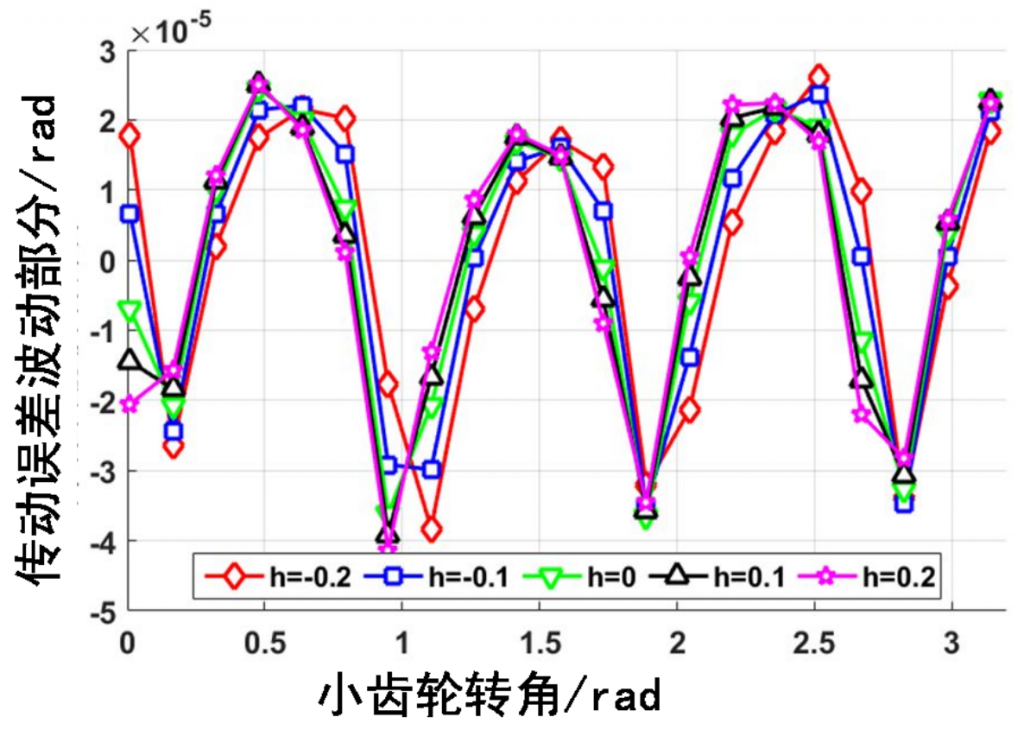

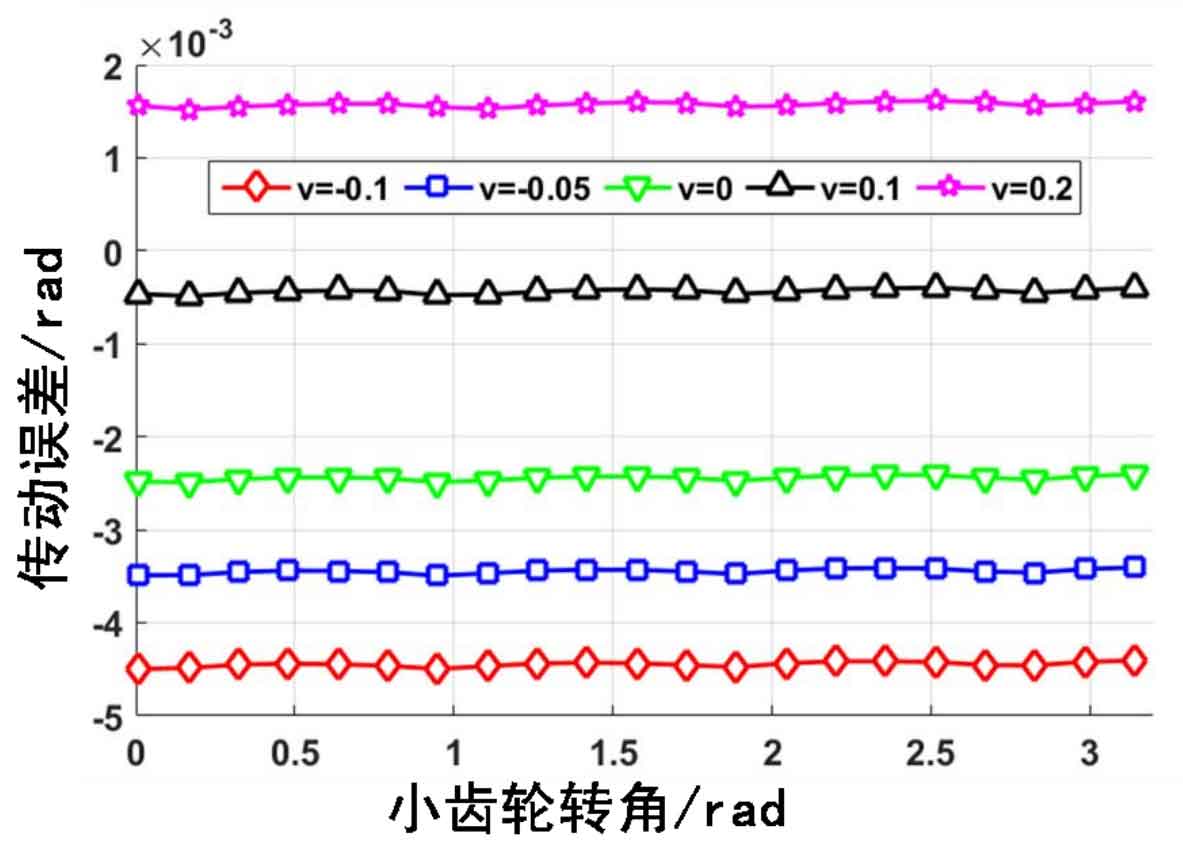

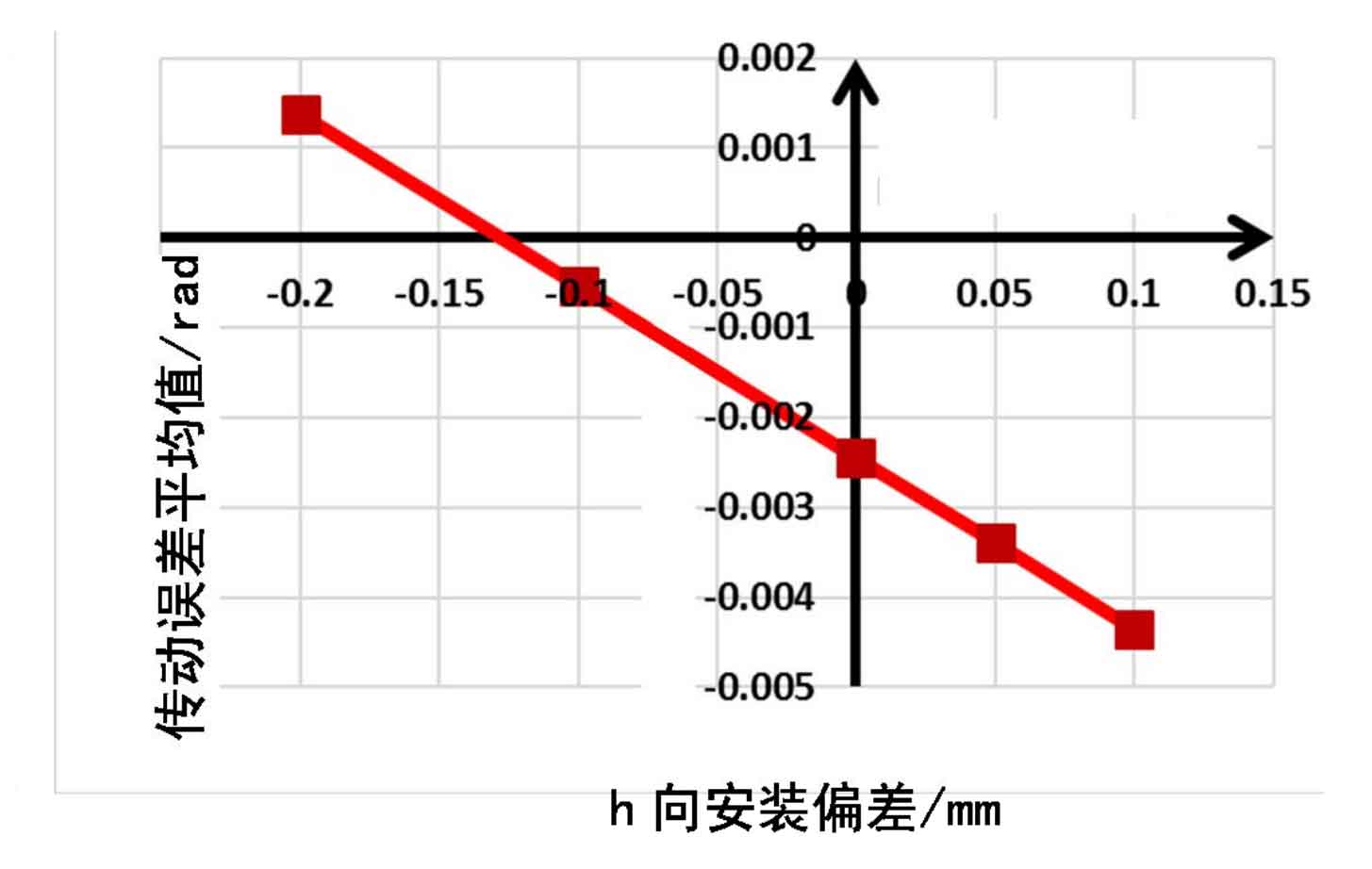

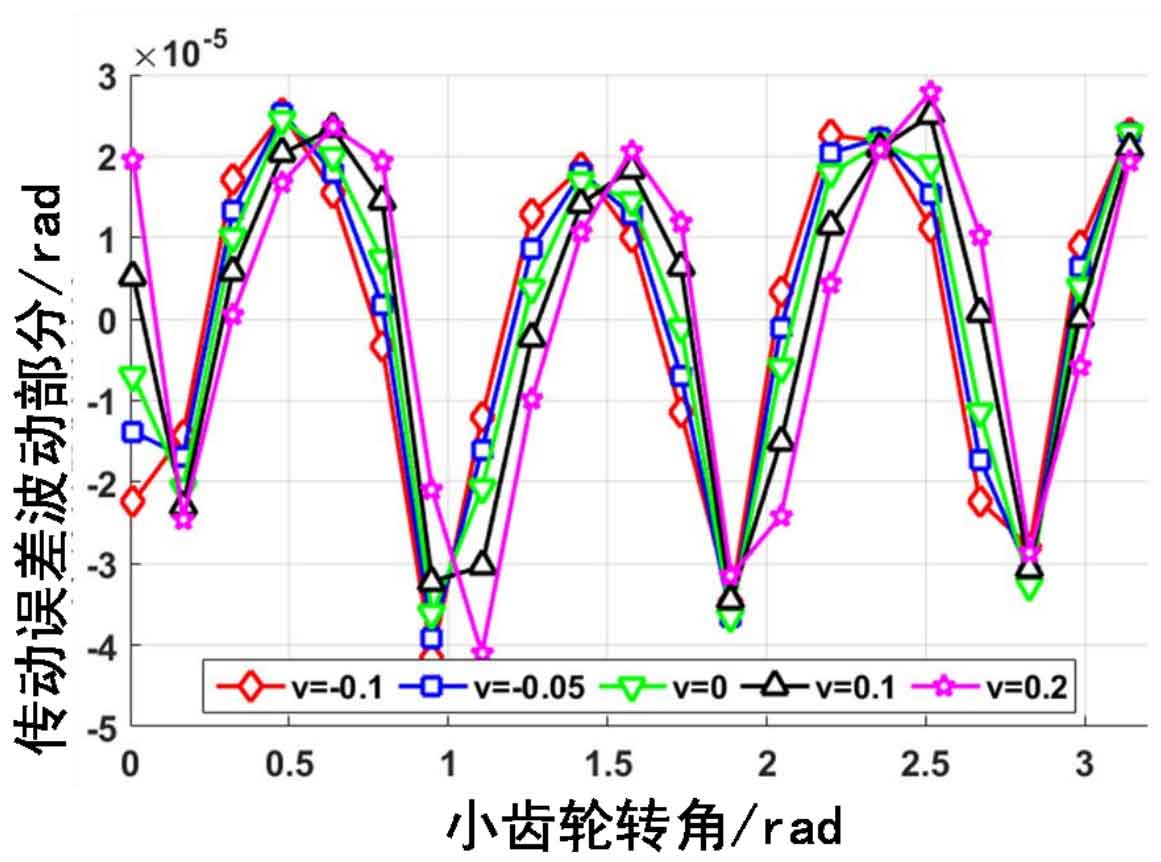

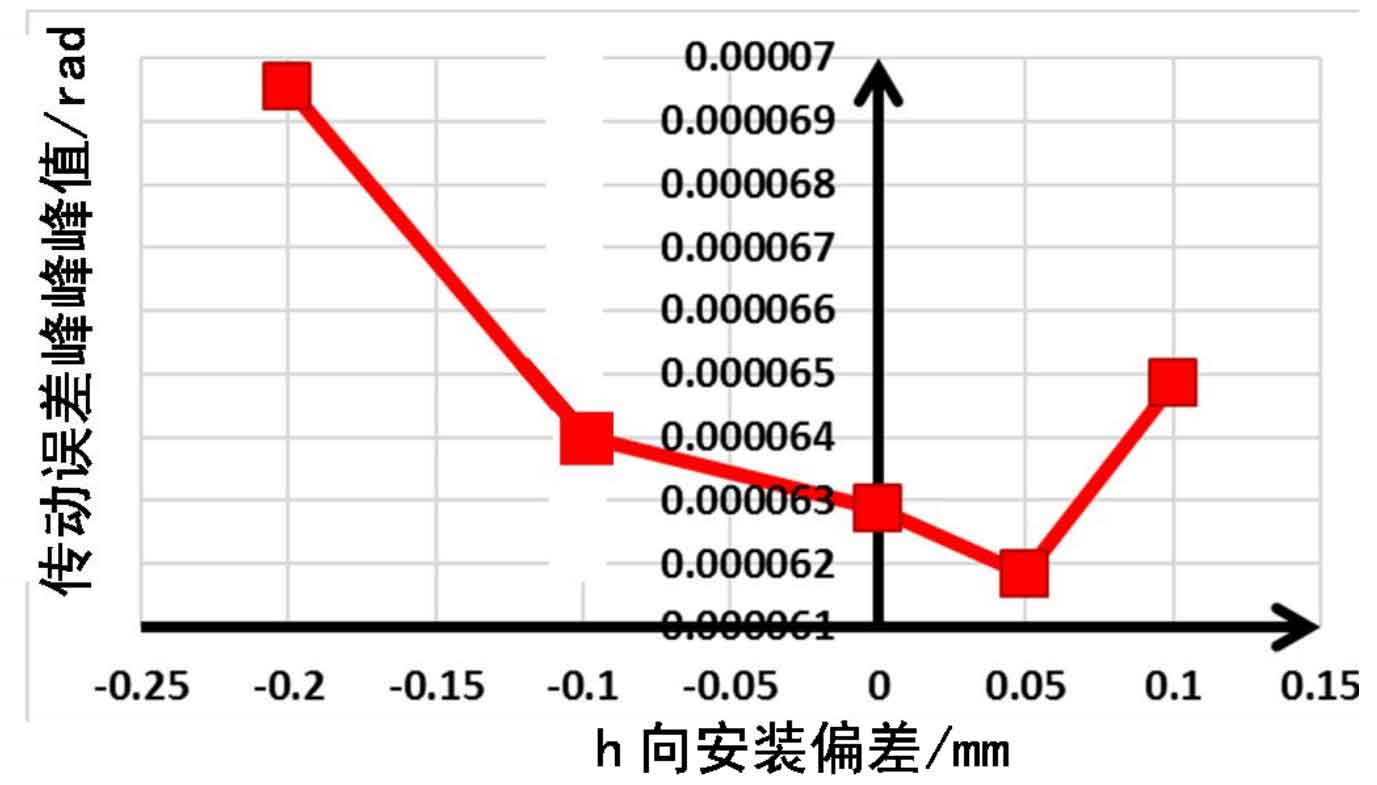

As shown in FIG. 11, it is the influence of the static transmission error of the hypoid gear when the axial installation deviation of the hypoid pinion is h = – 0.2mm, -0.1mm, 0mm, 0.1mm, 0.2mm, and its trend is just opposite to the change trend of the v-direction installation deviation. It can be seen that when the value of H increases in the positive direction, the average value of the transmission error of the hypoid gear moves in the negative direction, which is close to a linear change. However, when the value of H increases in the negative direction, the average value of the transmission error of the hypoid gear appears positive, as shown in FIG. 12. This will lead to the reduction of the meshing coincidence and is not conducive to the smooth operation of the hypoid gear. Therefore, the installation deviation of the hypoid gear pinion in the negative direction of H should be minimized. As shown in Figure 13, the installation deviation fluctuation of the hypoid gear shows that when the H value is different, the transmission error fluctuation is basically the same, but the peak position changes slightly. This is because the hypoid gear meshes from the big end to the small end. When the H value increases in a positive direction, the meshing midpoint of the hypoid gear moves to the big end. As shown in FIG. 14, the installation deviation in H direction corresponds to the peak to peak change of transmission error. It can be seen that when h changes in the positive or negative direction, the peak to peak value of transmission error will increase. Compared with v-direction installation deviation, the influence of h-direction installation deviation on the peak value of transmission error is smaller than v-direction installation deviation.

5. Comparison of influence degree of installation deviation on static transmission error of alignment hypery gear

By comparing the influence of the above installation deviation on the transmission error, it can be seen that the installation deviation has a small influence on the fluctuation part of the transmission error of the hypoid gear, and a large influence on the average part. The comprehensive analysis results can be summarized as follows:

(1) The positive increase of V value, the positive increase of Gama value, the negative increase of G value and the negative increase of H value will easily lead to the positive transmission error of the hypoid gear, which will reduce the meshing coincidence of the hypoid gear. Therefore, in order to ensure the stable operation of the hypoid gear, it is necessary to control the installation deviation in these directions.

(2) Comparing the sensitivity of installation deviation to the mean value of transmission error, it can be found that the axial installation deviation h of hypoid gear small wheel and the installation deviation V of offset distance of hypoid gear large and small wheel have the same sensitivity to transmission error, and the axial installation deviation g of hypoid gear large wheel has relatively weak influence on transmission error.

(3) The installation of the cross angle Gama will make the mean value of the transmission error no longer constant, but will change with the different meshing positions of the hypoid gears, which will cause new periodic excitation in the meshing process of the hypoid gears. This periodic component will make the transmission error fluctuate greatly in the meshing process of the hypoid gears, and may cause the forward transmission error of the hypoid gears, So that the hypoid gears cannot mesh normally. Therefore, it is necessary to strictly control the cross angle and installation deviation of hypoid gears.

(4) When the pinion axial installation deviation h and the hypoid gear installation offset distance deviation V change, the peak to peak value of the hypoid gear transmission error will increase, but the response of the v-direction installation deviation to the peak to peak value is larger than that of the h-direction installation deviation. For the installation deviation g of the hypoid gear in the axial direction, when G increases in the positive direction, the peak value of the transmission error is basically unchanged, and when G increases in the negative direction, the peak value of the transmission error decreases. Therefore, the average value of transmission error can be increased in the negative direction and the peak value is basically unchanged by adjusting the installation deviation g of the hypoid gear in the axial direction. This can improve the meshing coincidence of gears and improve the power transmission of hypoid gears.