This article comprehensively analyzes the influence of bearing clearance on gear modification. It begins with an introduction to the key concepts of bearing clearance and gear modification, followed by a detailed discussion on how bearing clearance affects gear contact and safety factors. Through case studies and software simulations, specific data and trends are presented. Based on these findings, an optimization scheme for gear modification considering bearing clearance is proposed, aiming to enhance the performance and reliability of gear transmissions.

1. Introduction

Gear transmissions play a crucial role in numerous mechanical systems. The performance and reliability of gear systems are affected by various factors, among which bearing clearance and gear modification are of significant importance. Understanding the relationship between them is essential for optimizing gear transmissions.

1.1 Importance of Gear Transmissions

Gear transmissions are widely used in industries such as automotive, aerospace, and industrial machinery. They are responsible for transmitting power and torque efficiently, ensuring the smooth operation of mechanical equipment.

1.2 Significance of Studying Bearing Clearance and Gear Modification

Bearing clearance affects the load distribution, contact stress, and vibration of gears. Gear modification, on the other hand, aims to improve gear performance by adjusting gear tooth profiles and orientations. Studying their interaction can lead to better design and operation of gear systems.

2. Bearing Clearance

2.1 Definition and Types

Bearing clearance refers to the gap between the inner ring, outer ring, and rolling elements of a bearing. It can be classified into three types: initial clearance, assembly clearance, and running clearance.

| Type of Bearing Clearance | Description |

|---|---|

| Initial Clearance | The clearance before the bearing is installed. |

| Assembly Clearance | The clearance in the 配合 state of the bearing’s inner ring and shaft, and outer ring and hole. |

| Running Clearance | The clearance considering factors such as heat generation during actual operation. |

2.2 Factors Affecting Bearing Clearance

Bearing clearance is affected by manufacturing errors, installation errors, 配合 errors, and heat generation during operation. These factors can cause variations in the clearance, which in turn impact the performance of the bearing and the gears it supports.

2.3 Influence of Bearing Clearance on Bearing Performance

Proper bearing clearance is crucial for the normal operation of bearings. Excessive clearance can lead to increased vibration and noise, while insufficient clearance can cause bearing seizure and difficulty in operation.

3. Gear Modification

3.1 Reasons for Gear Modification

In gear transmissions, factors such as variable working conditions, manufacturing errors, and installation errors can cause meshing impacts, uneven load distribution, and vibration. Gear modification is necessary to address these issues and improve gear performance.

3.2 Methods of Gear Modification

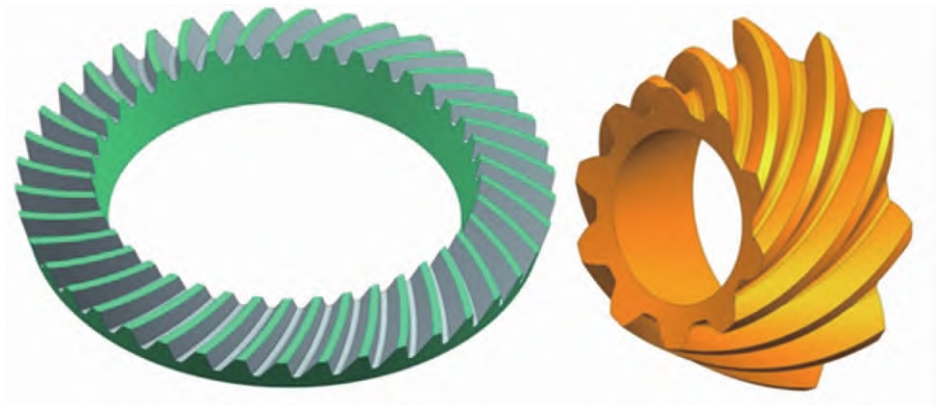

There are two main methods of gear modification: profile modification and orientation modification.

| Method of Gear Modification | Description |

|---|---|

| Profile Modification | Involves the purposeful trimming of the gear tooth profile to reduce meshing impacts caused by elastic deformation and manufacturing errors. |

| Orientation Modification | Removes a portion of material along the tooth width direction to eliminate uneven load distribution caused by system deformation, installation, and manufacturing errors. |

3.3 Influence of Gear Modification on Gear Performance

Gear modification can effectively reduce meshing impacts, improve load distribution, and enhance the service life and performance of gears.

4. Influence of Bearing Clearance on Gear Modification

4.1 Effect on Gear Contact

In an ideal gear meshing condition, the tooth surface load is evenly distributed. However, due to factors such as bearing clearance, the gear shaft may be slightly inclined, resulting in uneven load distribution on the tooth surface.

4.2 Influence on Tooth Surface Load Distribution Coefficient

Bearing clearance can cause changes in the tooth surface load distribution coefficient. As the bearing clearance increases, the tooth surface load distribution coefficient may also change, indicating a shift in the load distribution on the tooth surface.

4.3 Impact on Gear Safety Factors

The changes in the tooth surface load distribution coefficient due to bearing clearance can have an impact on gear safety factors. As the bearing clearance increases, the gear contact and bending safety factors may decrease.

5. Case Studies and Software Simulations

5.1 Case Study Setup

A specific gear transmission case is considered, with details of the gear shaft, gears, and bearing configurations provided. The gear materials and heat treatment methods are also specified.

| Gear Transmission Parameters | Values |

|---|---|

| Transmitted Power (kW) | 4000 |

| Gear Shaft Rotation Speed (r/min) | 1200 |

| Transmission Ratio | 4.1852 |

| Gear Modulus (mm) | 9 |

| Number of Teeth (Gear Shaft/Gear) | 27/113 |

| Helix Angle (°) | 13 |

| Pressure Angle (°) | 20 |

| Tooth Width (mm) | 210/205 |

5.2 Simulation Results with Different Bearing Clearances

Using software such as ROMAX, simulations are carried out with different bearing clearances (0.05 mm, 0.1 mm, and 0.15 mm). The tooth surface contact stress nephograms and corresponding data are obtained.

| Bearing Clearance (mm) | Tooth Surface Contact Stress Nephogram | Tooth Surface Load Distribution Coefficient | Small Gear Contact Safety Factor | Small Gear Bending Safety Factor |

|---|---|---|---|---|

| 0.05 | [Show the relevant nephogram] | 1.1167 | 1.436 | 2.123 |

| 0.1 | [Show the relevant nephogram] | 1.1486 | 1.416 | 2.071 |

| 0.15 | [Show the relevant nephogram] | 1.1878 | 1.392 | 2.009 |

5.3 Analysis of Results

From the simulation results, it can be observed that as the bearing clearance increases, the tooth surface load distribution becomes more uneven, and the gear safety factors decrease. This indicates the significant influence of bearing clearance on gear modification and performance.

6. Optimization of Gear Modification Considering Bearing Clearance

6.1 Adjustment of Helix Angle Modification

Based on the analysis of different bearing clearance cases, it is found that adjusting the helix angle modification can be an effective way to adapt to different bearing clearances. By increasing the helix angle modification amount, the tooth surface load distribution can be improved, and the gear safety factors can be maintained or increased.

| Bearing Clearance (mm) | Helix Angle Modification Increase Amount | Tooth Surface Load Distribution Coefficient | Small Gear Contact Safety Factor | Small Gear Bending Safety Factor |

|---|---|---|---|---|

| 0.05 | 0 | 1.1167 | 1.436 | 2.123 |

| 0.1 | 0.015 | 1.1149 | 1.437 | 2.126 |

| 0.15 | 0.030 | 1.1174 | 1.435 | 2.122 |

6.2 Overall Optimization Scheme

An overall optimization scheme for gear modification considering bearing clearance is proposed. This includes selecting appropriate bearings with suitable clearances, accurately measuring and controlling the bearing clearances during installation, and applying proper gear modification methods based on the actual bearing clearances.

7. Conclusion

Bearing clearance has a significant impact on gear modification and the performance of gear transmissions. By understanding this influence and implementing appropriate optimization measures, the performance and reliability of gear transmissions can be effectively improved. Future research may focus on further exploring the relationship between bearing clearance and other factors affecting gear performance, as well as developing more advanced optimization methods and techniques.

7.1 Summary of Key Findings

- Bearing Clearance Basics: It is a crucial parameter in bearings, classified into initial, assembly, and running clearances. Its size is affected by multiple factors and has a significant impact on bearing performance.

- Gear Modification Essentials: Necessary to address issues in gear transmissions caused by various factors. Profile and orientation modifications are the main methods, improving gear performance.

- Interaction Impact: Bearing clearance affects gear contact, load distribution coefficient, and safety factors. As clearance increases, load distribution worsens and safety factors decrease.

- Optimization Approaches: Adjusting helix angle modification and a comprehensive scheme involving bearing selection, clearance control, and proper gear modification methods can mitigate the negative effects.

7.2 Implications for Gear Transmission Design

The findings of this study have several implications for the design of gear transmissions:

- Bearing Selection: Designers must carefully consider the bearing clearance requirements during the bearing selection process. Choosing bearings with appropriate clearances for the specific application can help to ensure optimal gear performance.

- Installation Precautions: During installation, precise measurement and control of the bearing clearance are essential. Any deviation from the recommended clearance values can lead to suboptimal gear operation.

- Gear Modification Planning: Based on the expected bearing clearance, a proper gear modification plan should be formulated. This includes determining the appropriate modification methods and parameters to achieve the best possible gear performance.

7.3 Future Research Directions

While this study has provided valuable insights into the influence of bearing clearance on gear modification, there are still several areas that warrant further investigation:

- Multi-Factor Interaction: The interaction between bearing clearance and other factors such as lubrication, temperature, and load variations needs to be explored in more detail. Understanding these complex interactions can lead to more comprehensive optimization strategies.

- Advanced Optimization Techniques: Research could focus on developing more advanced optimization techniques for gear modification considering bearing clearance. These techniques could potentially improve the accuracy and efficiency of the optimization process.

- Experimental Validation: Further experimental studies are needed to validate the simulation results obtained in this study. This would provide more reliable data for practical applications and enhance the credibility of the proposed optimization methods.

8. References

[1] Cheng Daxian. Mechanical Design Manual: Second Volume. Beijing: Chemical Industry Press, 2007.

[2] Gears – Cylindrical involute gears and gear pairs – Concepts and geometry:DE – DIN.DIN ISO 21771. 2014.