This article comprehensively analyzes the influence of bearing clearance on gear shaping. It begins with an introduction to the basic concepts of bearing clearance and gear shaping, followed by a detailed exploration of how bearing clearance affects gear contact, load distribution, and safety factors. Through case studies and software simulations, specific data and trends are presented. Based on these analyses, an optimization scheme for gear shaping considering bearing clearance is proposed, aiming to improve the performance and reliability of gear transmissions.

1. Introduction

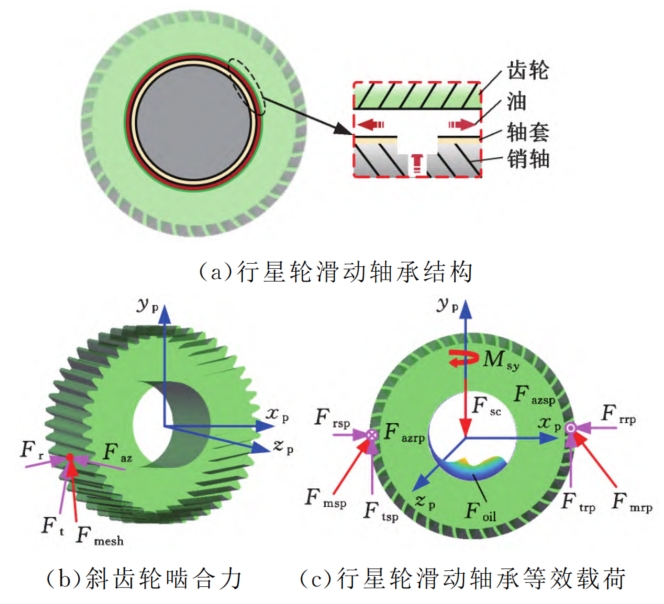

Gear transmissions play a crucial role in various mechanical systems. The performance and reliability of gear transmissions are affected by multiple factors, among which gear shaping and bearing conditions are of great significance. Gear shaping techniques have been widely studied to reduce meshing impacts, load imbalances, and vibrations. However, the influence of bearing clearance on gear shaping has received relatively less attention. Understanding this relationship is essential for further improving gear transmission performance.

2. Bearing Clearance

2.1 Definition and Types

Bearing clearance refers to the gap between the inner ring, outer ring, and rolling elements of a bearing. It can be classified into three types: initial clearance, assembly clearance, and running clearance. Initial clearance is the clearance before bearing installation. Assembly clearance is the clearance in the 配合 state of the bearing’s inner ring with the shaft and the outer ring with the hole. Running clearance takes into account the influence of factors such as heat generation during actual operation.

2.2 Factors Affecting Bearing Clearance

The existence of bearing clearance is due to various factors. Manufacturing errors of the bearing can lead to inconsistent dimensions and thus affect the clearance. Installation errors, such as improper alignment during installation, can also change the clearance. 配合 errors between different components and the occurrence of seizure due to heat generation during actual operation are additional factors contributing to bearing clearance variations.

2.3 Impact of Bearing Clearance on Bearing Performance

The size of the bearing clearance has a significant impact on the performance of the bearing. Excessive bearing clearance can result in large vibrations and noise during operation, while insufficient clearance can cause difficulties in bearing rotation and even seizure. Therefore, a reasonable bearing clearance is crucial for ensuring the normal operation of the bearing.

3. Gear Shaping

3.1 Purpose and Significance

Gear shaping is a technique used to improve the performance of gear transmissions. Due to factors such as variable working conditions, manufacturing errors, and installation errors, gears often experience meshing impacts, load imbalances, and vibrations. Gear shaping aims to address these issues by modifying gear parameters such as tooth profile and tooth orientation.

3.2 Common Gear Shaping Methods

- Tooth Profile Shaping: This involves intentionally trimming a small amount of the tooth profile to deviate from the theoretical tooth profile. By removing a portion of the tooth tip or root, the meshing-in and meshing-out impact phenomena caused by tooth elastic deformation and processing errors during gear meshing can be reduced. Tooth profile shaping includes three elements: shaping amount, shaping length, and shaping curve.

- Tooth Orientation Shaping: It is carried out by removing a part of the material along the tooth width direction to eliminate the tooth load imbalance phenomenon caused by system deformation, installation, and manufacturing errors and to obtain a uniform tooth surface load distribution. Commonly, it adopts the form of spiral angle shaping + tooth end slope.

4. Influence of Bearing Clearance on Gear Shaping

4.1 Influence on Gear Contact

In an ideal gear meshing condition, the tooth surface load is evenly distributed. However, considering factors such as force deformation and assembly accuracy, load imbalance can occur during actual operation. Bearing clearance can cause the shaft to be slightly inclined, which ultimately affects gear meshing. For example, in a gearbox structure with a specific bearing arrangement (such as a combination of cylindrical roller bearings and paired tapered roller bearings on the high-speed shaft), the radial clearance of the cylindrical roller bearing and the axial and radial clearances of the paired tapered roller bearing can lead to a slight inclination of the high-speed shaft under the action of axial force, resulting in load imbalance on the tooth surface during actual operation, causing vibration and noise, and even affecting the service life of the gears.

4.2 Influence on Tooth Surface Load Distribution Coefficient

The load imbalance on the tooth surface is mainly reflected in the tooth surface load distribution coefficient in gear strength calculations. By analyzing the tooth surface load distribution coefficient, the impact on the gear safety coefficient can be accurately determined. Through specific case studies and software simulations (using ROMAX software, for example), it has been found that with the increase in bearing running clearance, the tooth surface load shows an imbalance trend. As shown in Table 1, under different clearance conditions, the tooth surface load distribution coefficient and safety coefficient change.

| Work Condition | Tooth Orientation Load Distribution Coefficient | Pinion Contact Safety Coefficient | Pinion Bending Safety Coefficient |

|---|---|---|---|

| Work Condition 1 (0.05mm) | 1.1167 | 1.436 | 2.123 |

| Work Condition 2 (0.1 mm) | 1.1486 | 1.416 | 2.071 |

| Work Condition 3 (0.15mm) | 1.1878 | 1.392 | 2.009 |

4.3 Influence on Gear Safety Coefficient

As the bearing clearance increases, the gear contact and bending safety coefficients generally show a downward trend. This indicates that the bearing clearance has an impact on the safety of the gear. Therefore, it is necessary to consider this factor when designing and using gears to ensure the reliability of the gear transmission system.

5. Case Studies and Analyses

5.1 Case Description

In a specific case, the gear shaft and gear materials are selected as 18CrNiMo7 – 6, and heat treatment is carried out using carburizing and quenching. The gear analysis software ROMAX is used for modeling. The high-speed shaft bearing is selected as a cylindrical roller bearing NU2240 and a paired tapered roller bearing 30240 + 32240 combination configuration. The running clearances of the cylindrical roller bearing are set to 0.05 mm, 0.1 mm, and 0.15 mm for analysis.

5.2 Results and Discussions

- Tooth Surface Contact Stress Cloud Diagrams: The tooth surface contact stress cloud diagrams under different clearance conditions (shown in Figures 1 – 3) clearly show the changes in tooth surface load distribution. As the clearance increases, the load imbalance becomes more obvious.

- Analysis of Tooth Surface Load Distribution Coefficient and Safety Coefficient: As mentioned earlier, with the increase in clearance, the tooth surface load distribution coefficient changes, and the safety coefficient decreases. This indicates that the bearing clearance has a significant impact on the gear’s mechanical properties.

- Adjustment of Spiral Angle Shaping: To address the issue of load imbalance caused by different clearances, the spiral angle shaping method is adjusted. By keeping the shaping parameters of Work Condition 1 unchanged and adjusting the spiral angle shaping amounts of Work Condition 2 and Work Condition 3, the results show that the tooth surface load distribution coefficient and safety coefficient can be effectively adjusted, as shown in Table 2.

| Work Condition | Spiral Angle Shaping Increase Amount | Tooth Orientation Load Distribution Coefficient | Pinion Contact Safety Coefficient | Pinion Bending Safety Coefficient |

|---|---|---|---|---|

| Work Condition 1 (0.05mm) | 0 | 1.1167 | 1.436 | 2.123 |

| Work Condition 2 (0.1mm) | 0.015 | 1.1149 | 1.437 | 2.126 |

| Work Condition 3 (0.15mm) | 0.030 | 1.1174 | 1.435 | 2.122 |

6. Optimization Scheme for Gear Shaping Considering Bearing Clearance

6.1 Principle and Basis

Based on the analysis of the influence of bearing clearance on gear shaping, an optimization scheme is proposed. The principle is to adjust the gear shaping parameters according to the actual bearing clearance to ensure that the gear can operate in an ideal state. The basis for this optimization is the relationship between bearing clearance, gear contact, and safety factors obtained from previous analyses.

6.2 Specific Optimization Methods

- Adjusting Spiral Angle Shaping: As demonstrated in the case studies, adjusting the spiral angle shaping amount can effectively correct the load imbalance caused by different bearing clearances. By accurately determining the appropriate adjustment amount according to the actual clearance situation, the tooth surface load distribution can be optimized, and the safety coefficient can be maintained or improved.

- Combining with Other Shaping Methods: In addition to adjusting the spiral angle shaping, other shaping methods such as tooth profile shaping can also be combined as needed. For example, if there are still issues with meshing impacts after adjusting the spiral angle shaping, tooth profile shaping can be further considered to address these problems comprehensively.

6.3 Verification and Evaluation of the Optimization Scheme

The effectiveness of the optimization scheme can be verified and evaluated through further simulations and practical applications. By comparing the performance of gears before and after optimization (such as comparing the tooth surface load distribution coefficient, safety coefficient, and vibration and noise levels), the superiority of the optimization scheme can be determined. If the optimized gears show better performance in terms of load distribution, safety, and vibration reduction, it indicates that the optimization scheme is effective.

7. Conclusion

Bearing clearance is an important factor affecting gear shaping and gear transmission performance. Through detailed analyses of its influence on gear contact, load distribution, and safety factors, and through case studies and simulations, we have a more comprehensive understanding of this relationship. The proposed optimization scheme for gear shaping considering bearing clearance provides a practical approach to improving the performance and reliability of gear transmissions. In actual design and use, it is necessary to pay attention to the selection and adjustment of bearing clearance and the application of appropriate gear shaping methods to ensure the normal operation and long-term stability of gearboxes. Future research can focus on further refining the optimization scheme and exploring more effective methods to address the influence of bearing clearance on gear shaping.