1. Introduction

In the realm of modern manufacturing, spiral bevel gear machines play a crucial role in the production of various mechanical components. The electric spindle, as a key component of these machines, directly impacts their performance, precision, and productivity. This article delves into the in – depth exploration of electric spindle applications on spiral bevel gear machines, covering aspects such as the importance of electric spindles, the challenges faced in their operation and maintenance, and innovative solutions developed to overcome these challenges.

1.1 Significance of Electric Spindles in Spiral Bevel Gear Machines

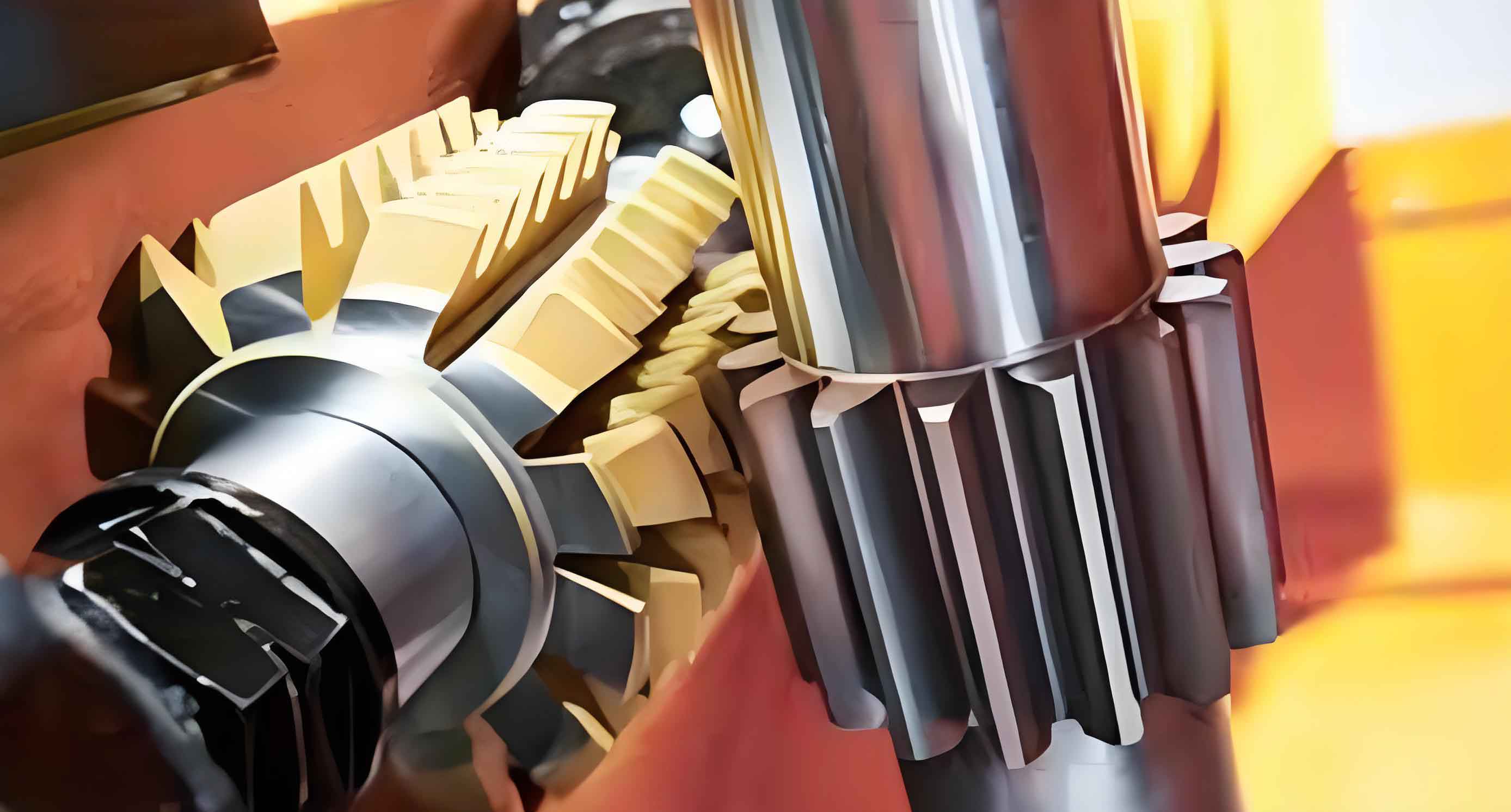

Electric spindles are the heart of spiral bevel gear machines. They provide the necessary rotational power for cutting tools and workpieces, enabling the precise machining of spiral bevel gears. In high – end manufacturing, the accuracy and stability of electric spindles are essential for producing gears with tight tolerances. For example, in the automotive industry, where spiral bevel gears are widely used in differential systems, the quality of the gears directly affects the vehicle’s performance, durability, and noise levels. A well – functioning electric spindle ensures that the gears are machined with high precision, reducing vibration and noise during operation.

1.2 Challenges in Electric Spindle Operation and Maintenance

However, the operation and maintenance of electric spindles on spiral bevel gear machines are not without challenges. One of the common issues is the occurrence of failures such as water leakage, 堵塞 (blockage), and overheating, which can lead to electric spindle burnout. These failures not only cause downtime but also result in significant economic losses. For instance, in a large – scale manufacturing plant, the breakdown of an electric spindle can halt an entire production line, leading to delays in product delivery and potential loss of business opportunities. Additionally, the complexity of electric spindle systems, including their integration with servo drives and control systems, makes troubleshooting and maintenance a daunting task.

2. Overview of Spiral Bevel Gear Machines and Electric Spindles

2.1 Structure and Working Principle of Spiral Bevel Gear Machines

Spiral bevel gear machines are designed to cut and shape spiral bevel gears. They typically consist of multiple axes, including the tool drive system, workpiece drive system, and base angle drive system. The tool drive system controls the rotation and movement of the cutting tool, while the workpiece drive system positions and rotates the workpiece. The base angle drive system adjusts the angle of the workpiece for proper gear cutting. Table 1 provides a summary of the main components and functions of spiral bevel gear machines.

| Component | Function |

|---|---|

| Tool Drive System | Controls tool rotation, cutting depth, and horizontal positioning |

| Workpiece Drive System | Positions and rotates the workpiece |

| Base Angle Drive System | Adjusts the workpiece angle for gear cutting |

The working principle of spiral bevel gear machines involves the use of continuous indexing or individual indexing methods to cut all pitch forms of spiral bevel gears and hypoid gears. The cutting process is usually dry, using carburized hardened metal milling cutters.

2.2 Types and Characteristics of Electric Spindles Used in Spiral Bevel Gear Machines

Electric spindles used in spiral bevel gear machines come in various types, with the Siemens 1FW6230 torque motor – based electric spindle being a common choice. These electric spindles have specific characteristics, such as high – torque output, precise rotational accuracy, and the ability to operate at high speeds. For example, the A, B, and C axes of the German – made 11 – axis 6 – 联动 (6 – axis linkage) spiral bevel gear machine (C50) are equipped with Siemens 1FW6230 torque motor – based electric spindles. The A – axis has an axial and radial run – out of no more than 0.4μm, while the B – axis has an axial and radial run – out of no more than 0.8μm. These high – precision requirements ensure the quality of the machined gears.

3. Failure Analysis of Electric Spindles on Spiral Bevel Gear Machines

3.1 Common Failure Modes

3.1.1 Water Leakage and Blockage – Related Failures

Water leakage and blockage are frequent problems in electric spindles. Water leakage can occur due to damaged seals or malfunctioning cooling systems. When water enters the electric spindle, it can cause short – circuits and damage to the electrical components. Blockage, on the other hand, can lead to insufficient cooling, resulting in overheating and subsequent burnout of the electric spindle. Table 2 shows the possible causes and consequences of water leakage and blockage failures.

| Failure | Possible Causes | Consequences |

|---|---|---|

| Water Leakage | Damaged seals, cracked coolant pipes | Short – circuits, damage to electrical components |

| Blockage | Deposits in coolant channels, debris | Insufficient cooling, overheating, electric spindle burnout |

3.1.2 Electrical and Servo – Related Failures

Electrical and servo – related failures are also common. These can include issues such as drive system errors, servo malfunctions, and problems with the control system. For example, the 611D or S120 series drive systems may encounter errors, and the servo motors may fail to operate properly. These failures can lead to inaccurate positioning, poor machining quality, and even machine stoppage.

3.2 Impact of Failures on Production

The failures of electric spindles have a significant impact on production. When an electric spindle fails, the production line may come to a halt, resulting in lost production time and increased costs. In addition, the quality of the machined products may be affected, leading to potential product recalls or customer complaints. For example, if the electric spindle experiences abnormal vibrations during gear machining, the surface finish of the gears may be poor, and their performance may be compromised.

4. Domestic and Foreign Application and Maintenance Status of Electric Spindles

4.1 Foreign Maintenance Solutions

In response to electric spindle failures, foreign manufacturers often propose solutions such as modular replacement of large components. For example, for the C50 machine, the German side suggests replacing the A and B axis modules as a whole. This solution, however, is costly and time – consuming. It may cost nearly 5.58 million yuan for 3 sets, and the repair cycle can be as long as 365 days. Moreover, it usually requires the return of the replaced defective parts to the manufacturer at no cost.

4.2 Domestic Maintenance Difficulties and Gaps

Domestic maintenance of electric spindles on spiral bevel gear machines faces several difficulties. In the past, when attempting to repair the A – axis of the C50 machine, issues such as vibration marks on the spiral bevel gear surface and loss of the automatic function of the integrated loading and unloading double manipulator occurred. For the B – axis, there has been no in – machine repair experience, and the lack of detailed technical information, such as limited diagrams in the machine’s manual, makes maintenance even more challenging.

5. Innovative Solutions for Electric Spindle Application Projects

5.1 Development and Application of Special – Purpose Tools

5.1.1 (Self – Made A and B Axis Pullers for Removing Electric Spindles in – Machine)

Inspired by common three – jaw and four – jaw pullers, self – made A and B axis pullers were developed. For the B – axis, a gantry – type puller made of 40mm thick steel plate was designed to pull out the electric spindle as a whole from the machine body. For the A – axis, due to the space limitations of the machine tool body, a ring – shaped special – shaped puller made of 50mm thick plate was developed. The design and application of these pullers are shown in Figure 1 (B – axis gantry – type puller) and Figure 2 (A – axis ring – shaped special – shaped puller).

[Insert Figure 1: B – axis gantry – type puller here] [Insert Figure 2: A – axis ring – shaped special – shaped puller here]

5.1.2 (Self – Made A and B Axis Rigid Protective Frames for Enhanced Safety)

To ensure the safety of maintenance personnel, self – made A and B axis rigid protective frames were created. The B – axis rigid protective frame was made by modifying a bridge shell transport frame, while the A – axis rigid protective frame was designed as a spliced structure due to the influence of the adjacent B – axis. These protective frames prevent the electric spindle from accidentally falling during maintenance, as shown in Figure 3 (B – axis rigid protective frame) and Figure 4 (A – axis rigid protective frame).

[Insert Figure 3: B – axis rigid protective frame here] [Insert Figure 4: A – axis rigid protective frame here]

5.1.3 (Self – Made Motor Stator Reinforcement Rings to Prevent Deformation)

Since the stator coil frame of the 1FW6230 torque motor is made of aluminum and is prone to deformation during disassembly and lifting, a stator reinforcement ring was designed. This ring is pre – connected to the stator coil and then lifted using a lifting eye bolt, protecting the stator from deformation, as illustrated in Figure 5 (torque motor stator reinforcement ring).

[Insert Figure 5: Torque motor stator reinforcement ring here]

5.1.4 (Self – Made U – Shaped Flat Plate Straps for Lifting the B – Axis)

Due to the limited swing angle of the C – axis, the B – axis cannot be horizontally removed and installed. A self – made U – shaped flat plate strap made of 40mm wide and 5mm thick flat iron was used to replace soft ropes and single – point lifting, ensuring safe and stable lifting of the B – axis, as shown in Figure 6 (U – shaped flat plate strap).

[Insert Figure 6: U – shaped flat plate strap here]

5.1.5 (Self – Made Cross – Shaped Lifting Beams for A – Axis Stator Coils)

The A – axis, being solid and having a different structure from the B – axis, requires a special method for removing and installing the stator coil. A self – made cross – shaped lifting beam was used to accurately position and lift the A – axis stator coil, as depicted in Figure 7 (A – axis cross – shaped lifting beam).

[Insert Figure 7: A – axis cross – shaped lifting beam here]

5.1.6 (Self – Made Screw – Type Traction Tools for Installing Electric Spindles)

For the installation of the B – axis electric spindle, a self – made screw – type traction tool was developed. This tool uses a M24×1000mm screw and an 80mm square tube to gradually pull the electric spindle into the end cover. When the outer ring is about 10mm from the B – axis housing, the tool is replaced with a copper rod for final installation, as shown in Figure 8 (screw – type traction tool).

[Insert Figure 8: Screw – type traction tool here]

5.1.7 (Self – Made Support Wheels for Transporting Wet Chip Conveyors)

In some C50 machines with wet chip conveyors, the lack of space for the conveyors to enter and exit led to the modification of support wheels. By adding support plates and changing the direction wheels to universal wheels, the wet chip conveyor can be easily moved, as demonstrated in Figure 9 (wet chip conveyor support wheel modification).

[Insert Figure 9: Wet chip conveyor support wheel modification here]

5.1.8 (Self – Made “Ear Spoons” for Removing Workpiece Disc Springs)

During the disassembly of the B – axis, a small “ear spoon” – like tool was used to remove 12 DIN2093 disc springs arranged in a positive – negative manner. These disc springs provide a pulling force of \(4.0×10^{4}N\) to hold the workpiece, and are compressed by 1.6MPa air pressure to release the workpiece. Figure 10 shows the “ear spoon” and the disc springs.

[Insert Figure 10: “Ear spoon” and disc springs here]

5.2 Optimization of Installation and Adjustment Techniques

5.2.1 (Using Spacer Pads for Installing the Stator and Rotor of the Torque Motor)

The installation of the stator and rotor of the 1FW6230 torque motor is challenging due to the strong magnetic attraction between them. Initially, 3 nylon pad strips with a width of 190mm and a thickness of 0.5mm were used to separate the stator and rotor during installation. Later, A3 rubber sleeves were found to be more effective and were adopted instead. Table 3 compares the characteristics of nylon pad strips and A3 rubber sleeves.

| Spacer Material | Advantages | Disadvantages |

|---|---|---|

| Nylon Pad Strips | Easy to obtain, relatively inexpensive | Prone to wear, less effective in long – term use |

| A3 Rubber Sleeves | Better wear resistance, more stable separation effect | Slightly more expensive |

5.2.2 (Using Hammer – Type Copper Rods for Installing Electric Spindles)

Due to the large interference fit between the B – axis end cover outer ring and the machine housing and the installation of the NNU double – row cylindrical roller bearing, the screw – type traction tool could not complete the final 10mm installation. A φ120mm×1000mm hammer – type copper rod was used to gently tap the electric spindle into the housing, similar to “a monk striking a bell” in a temple. However, care must be taken not to apply excessive force to avoid damaging the Z – axis linear guide rail slider and the grating ruler reading head.

5.2.3 (Using the PWT18 Quick – Adjustment Instrument to Test and Adjust the Grating Ruler)

The rotation position of the A, B, and C axes is monitored by the coupling of the grating drum on the rotor and the reading head on the stationary side of the stator. The installation gap between the grating drum and the reading head needs to be precisely adjusted. The PWT18 grating ruler quick – adjustment instrument is used to measure and adjust this gap, ensuring that the grid amplitude is around 1Vss (within the allowable range of 0.6 – 1.2Vss) and the origin signal black bar is within the specified range. Incorrect gap settings can lead to servo failures and multiple alarms on the C50 display.

5.3 Troubleshooting and System Optimization

5.3.1 (One – Click Ghost Restoration of Industrial Computer Hard Disk Data)

When the C50 electric spindle experiences problems such as screen – displayed rotor position synchronization errors and servo failures, the maintenance personnel can use the one – click Ghost method. By creating an EBOOT USB startup disk and performing a one – click Ghost operation on the SINUMERIK 840D system, the system data can be restored, and the safety – integrated function can be pasted into the servo driver. This method quickly resolves system – related issues and reduces downtime.

5.3.2 (Eliminating Vibration Marks on Spiral Bevel Gear Surfaces)

To address the problem of vibration marks on spiral bevel gear surfaces, a comprehensive approach was taken. This included using graphical monitoring, parameter optimization, and instrument measurement. The fixtures of the C50 were replaced, the B – axis speed loop was optimized by adjusting parameters such as \(MD1200 = 3 \to 4\), \(MD1219 = 510 \to 1080\), \(MD1220 = 150 \to 500\), and \(MD1407 = 12000 \to 15000\). The fixture tightening method was also changed, and the cutting process parameters were optimized to improve the surface quality of the gears.

5.3.3 (Handling the Safety – Integrated SPL Function of the Whole Machine)

When the safety – integrated chain of the C50 is triggered, the loading door may not open or close properly. To solve this problem, an 8 – wire 1 – program method was adopted. This involves short – circuiting specific terminals in the electrical control cabinet, such as N900 – N901, N902 – N903, N567 – N267, and N667 – N376, to ensure the normal operation of the loading door.

5.3.4 MDA (Using the MDA Cycle Program to Investigate Sudden Tooth – Cutting Stops)

For multi – axis linkage CNC machine tools like the C50, the MDA cycle program can be used to find the root cause of screen – displayed alarms. By programming the vertical axis (such as the X – axis) and the swing axis (such as the C – axis) to run in a cycle in the MDA mode, maintenance personnel can analyze noises, monitor the load of the ball screw pair, and determine the actual angle of the C – axis alarm. This helps in modifying the C – axis parameters and eliminating (shutdown failures).

6. Formation of Autonomous Operation and Maintenance Technology

6.1 The Process of Establishing Autonomous Operation and Maintenance Technology

The company’s intelligent manufacturing operation and maintenance team, in the face of limited technical drawings and lack of experience, used methods such as electrical signal deduction, mechanical action coupling, and working medium flow analysis to complete the in – machine disassembly and reinstallation of the water – cooled electric spindle. Through continuous experimentation and improvement, they developed a complete set of autonomous operation and maintenance technology for water – cooled electric spindles. This technology includes the use of special – purpose tools, installation and adjustment techniques, and troubleshooting methods.

6.2 Significance and Application Prospects of Autonomous Operation and Maintenance Technology

The formation of autonomous operation and maintenance technology has far – reaching significance. It not only reduces the dependence on foreign manufacturers for maintenance services but also greatly shortens the maintenance cycle and reduces maintenance costs. This, in turn, improves the overall production efficiency and competitiveness of the enterprise. For example, before the establishment of this technology, the repair of electric spindles often took months, but now it can be completed within a much shorter time frame.

Moreover, this autonomous operation and maintenance technology can be extended and applied to other types of electric spindles, such as those used in lathes, machining centers, grinders, and (knife – grinding machines). By sharing the experience and techniques gained from the maintenance of electric spindles on spiral bevel gear machines, it provides a valuable reference for the operation and maintenance of electric spindles in different industrial fields. Table 4 shows a comparison of the performance before and after the application of autonomous operation and maintenance technology.

| Performance Indicator | Before Autonomous Operation and Maintenance Technology | After Autonomous Operation and Maintenance Technology |

|---|---|---|

| Maintenance Cycle | Long (e.g., 365 days for some major repairs) | Shortened significantly (e.g., within a few weeks) |

| Maintenance Cost | High (e.g., nearly 5.58 million yuan for 3 sets of A and B axis replacements) | Reduced substantially |

| Production Downtime | Long, affecting production schedules | Minimized, ensuring continuous production |

7. Future Developments and Challenges in Electric Spindle Technology

7.1 Technological Advancements and Trends

The future of electric spindle technology for spiral bevel gear machines is expected to witness several advancements. Firstly, there will be a continuous pursuit of higher precision and speed. New materials and manufacturing processes will be developed to improve the rigidity and dynamic performance of electric spindles, enabling them to achieve even smaller tolerances in gear machining. For example, the use of advanced ceramic bearings or magnetic bearings may become more widespread, reducing friction and improving rotational accuracy.

Secondly, the integration of intelligent monitoring and self – diagnosis systems will be a major trend. These systems will be able to continuously monitor the operating status of electric spindles, such as temperature, vibration, and load, and predict potential failures in advance. This will allow for preventive maintenance, further reducing downtime and maintenance costs. Figure 11 shows a conceptual diagram of an intelligent monitoring system for electric spindles.

[Insert Figure 11: Conceptual diagram of an intelligent monitoring system for electric spindles here]

In addition, the development of more energy – efficient electric spindles is also on the horizon. With the increasing emphasis on sustainable manufacturing, reducing energy consumption in machining processes is crucial. New motor designs and control algorithms will be explored to improve the energy efficiency of electric spindles.

7.2 Challenges in the Development and Application of Electric Spindle Technology

However, the development and application of electric spindle technology also face some challenges. One of the main challenges is the need for high – end talent. The design, operation, and maintenance of advanced electric spindles require professionals with in – depth knowledge of mechanical engineering, electrical engineering, and control systems. Currently, there is a shortage of such comprehensive talent in the industry.

Another challenge is the compatibility issue. As new technologies and components are constantly emerging, ensuring the compatibility of electric spindles with different spiral bevel gear machines and other peripheral equipment becomes a complex task. For example, when upgrading the control system of a spiral bevel gear machine, it may be difficult to ensure seamless integration with the existing electric spindle.

Furthermore, the high cost of research and development for advanced electric spindle technology is also a deterrent. Developing new materials, intelligent monitoring systems, and energy – efficient designs requires significant investment, which may be a burden for some enterprises, especially small and medium – sized ones.

8. Conclusion

In conclusion, the application of electric spindles on spiral bevel gear machines is a critical aspect of modern gear manufacturing. The failures of electric spindles can cause significant disruptions to production, but through innovative solutions and the development of autonomous operation and maintenance technology, these challenges can be effectively addressed. The 15 innovative points proposed in this article, including the development of special – purpose tools, optimization of installation and adjustment techniques, and troubleshooting methods, have provided a comprehensive approach to improving the performance and reliability of electric spindles.

Looking ahead, the future of electric spindle technology holds great promise, with the potential for higher precision, intelligence, and energy efficiency. However, to fully realize these advancements, the industry needs to overcome challenges such as talent shortages, compatibility issues, and high R & D costs. By working together and continuously innovating, the manufacturing industry can ensure the continued development and improvement of electric spindle technology for spiral bevel gear machines, leading to more efficient and high – quality gear production.