Gear is one of the most important structural parts of the aviation transmission system, and the working environment is very complex, which needs to withstand tensile and compressive alternating stress, shear stress, impact dynamic stress, and also need to have wear resistance, corrosion resistance, and resistance

high temperature and other capabilities. The quality, bearing capacity, dry running capacity, life and other core indicators of the aviation reducer are closely related to the transmission capacity of the gear transmission system. Compared with helical cylindrical gears and herringbone cylindrical gears, the bearing capacity of spur cylindrical gears is lower, but the structure is simpler, the economy is better, and it does not bear axial force, which can simplify the design of the support. It is conducive to reducing the mass of the transmission system, and is the most widely used gear form in the aero transmission system, and the planetary gear train widely used in the helicopter final reducer is generally a spur cylindrical gear. With the progress of science and technology, the gear transmission system is developing in the direction of high speed, heavy load and high precision in the fields of aviation and aerospace, which puts forward higher requirements for the bearing capacity of gears. The bearing capacity of the gear can be improved by increasing the modulus of the spur cylindrical gear and increasing the tooth width, but at the same time, the volume and mass of the gear transmission system are increased, and the requirements of the small volume and high power-to-weight ratio of the aviation gear transmission are increased paradoxical. The high power-to-weight ratio requirements of the helicopter transmission system have put forward higher requirements for the bearing capacity of the gears, and the conventional spur cylindrical gears have gradually failed to meet the development of the gears of the helicopter transmission system

demand, and the emergence of new materials and new processes requires long-term accumulation. The new unconventional toothed gear design has become a breakthrough point to improve the carrying capacity of the gear, which is to solve the problem of high power-to-weight ratio of aviation gear transmission. It is one of the breakthroughs and important development directions of the high-demand dilemma of small size and low vibration. Gear transmission is achieved by sequential meshing between two pairs of teeth, and only by ensuring that the previous pair of teeth has not left the meshing when the latter pair of teeth has entered the meshing, can the gears be transmitted at a continuous fixed angular rate [6].The coincidence degree of the normal low contact ratio (LCR) spur cylindrical gear pair is 1~2, that is, 1 pair or 2 pairs of gears are in the meshing state at the same time; High contact ratio (HCR) The coincidence degree of the spur cylindrical gear is 2~3, that is, there are 2 pairs or 3 pairs of teeth

The wheel is in a meshing state at the same time. Compared with LCR spur cylindrical gear transmission, due to the large number of tooth pairs meshed by HCR spur cylindrical gears at the same time, the load borne by each pair of teeth is relatively reduced, so it can effectively reduce the dynamic load, improve the load distribution, increase the gear bearing capacity and improve the smoothness of the transmission, and reduce vibration and noise, which has strict requirements for comfort The helicopter is very advantageous. At the same time, the HCR spur cylindrical gear drive system has a degree of coincidence greater than 2 and can continue to operate even if one tooth is lost, which can improve and increase the safety and damage resistance of the helicopter transmission system. In this paper, it is based on the domestic and international research of HCR spur cylindrical gears.

1 HCR spur cylindrical gear transmission technology

HCR spur cylindrical gearing is not entirely a new form of gearing, but a high contact ratio is obtained by reducing the gear pressure angle, increasing the tooth top height factor, increasing the number of teeth, or changing the displacement factor. After increasing the degree of coexistence, the total length of the contact line of the tooth surface increases, the average load on the unit contact line length of the tooth surface decreases, and at the same time, the worst loading point on the outside of the gear is far away from the tooth top, which is conducive to increasing the tooth the bending strength of the wheel; However, the use of HCR spur cylindrical gears introduces new problems, as HCR spur cylindrical gears have a smaller tooth top width, a sharper tooth top, and a tooth tip when subjected to heat treatments such as carburizing or nitriding There will be too much carbon in the part, which will cause the gear teeth to break or become brittle, and the tooth top will collapse and other problems; At the same time, the high contact ratio increases the sliding velocity, which can lead to serious gluing problems.

1.1 Theoretical research

1.1.1 Gear strength

At present, there is little literature on HCR spur cylindrical gears, and most scholars at home and abroad use the test method or finite element method to calculate the root stress, and there is a lack of national standards or international standardization organizations(International Standard Organization, ISO) standard gear calculation formula to study HCR spur cylindrical gear root stress. Xianbo Zhengzhuang [9] summarized the research on HCR spur cylindrical gears before the 80s of the 20th century, and pointed out that compared with ordinary coincidence spur cylindrical gears, HCR spur cylindrical gears have greater advantages in strength and noise, compared with LCR spur cylindrical gears, the tooth surface strength of HCR spur cylindrical gears increases significantly, and the bending strength of the gear increases when the coincidence degree of the spur cylindrical gear exceeds 2.0. Wang et al., Li

, Yin Gang, Li Jie, etc., Luo Lifeng, etc The stiffness, inter-tooth load distribution, contact stress and root bending stress of HCR spur cylindrical gears were calculated by using the finite element method, and the distribution of root bending stress and contact stress of HCR spur cylindrical gears and LCR spur cylindrical gears was analyzed, which was in good agreement with the existing test results, indicating that HCR spur cylindrical gears can effectively improve the bearing capacity of gears. Fang Zongde et al. measured the stiffness of HCR spur cylindrical gears by laser speckle method, calculated the load distribution of HCR spur cylindrical gears and LCR spur cylindrical gears according to the measured stiffness, and tested the dynamic performance of HCR spur cylindrical gears, and proposed an optimal design method for HCR spur cylindrical gears. Li Qingyuan et al. calculated the stiffness and inter-tooth load distribution of HCR spur cylindrical gears by simplifying the tooth shape into a variable cross-section trapezoidal shape, and compared the load distribution of HCR spur cylindrical gears and LCR spur cylindrical gears. Ajmi et al., Yaldirim et al., Qu Zhenzhen et al., Niu Hui et al., Yu Songlin et al., Huang KangThe implementation method of HCR spur cylindrical gears was studied, and the selection method of the design parameters of the gears was given. Li Fajia et al., Fan Shichao et al. studied the strength calculation and parameter optimization of HCR spur cylindrical gears, gave the calculation methods of gear bending and contact strength, and carried out verification tests, and carried out engineering application verification, the results show that HCR spur cylindrical gears have inherent advantages in strength.

1.1.2 Gear Vibration and Noise

Many scholars have studied the dynamic performance of HCR spur cylindrical gears. Xianbo Zhengzhuang [9] pointed out that the HCR spur cylindrical gear is better than the LCR spur cylindrical gear in terms of noise, and the test results of the vibration characteristics of the spur cylindrical gear with the coincidence degree of 1.53, 1.75 and 2.09 show that when the coincidence degree of the gear is greater than 2, the vibration amplitude of the gear is significantly reduced, and the high-frequency vibration frequency is significantly reduced. Lin et al., Cornell et al The mass spring model is used to establish the gear vibration equation, and the influence of parameters on the dynamic characteristics of HCR spur-toothed cylindrical gears is analyzed, and the influence of different coincidence degrees on the dynamic load coefficient of the system is emphatically analyzed. Qu Zhenzhen et al., Li Tongjie et al., Li Fajia et al., Zhang Zufang et al., Fang Zongde et al. conducted theoretical research on the dynamic performance of HCR spur cylindrical gears, analyzed the dynamics of HCR spur cylindrical gear transmission system, and carried out test verification The theoretical calculation results are well verified, which fills the lack of research on the dynamic characteristics of the gear in China.

1.2 Applied Research and Progress

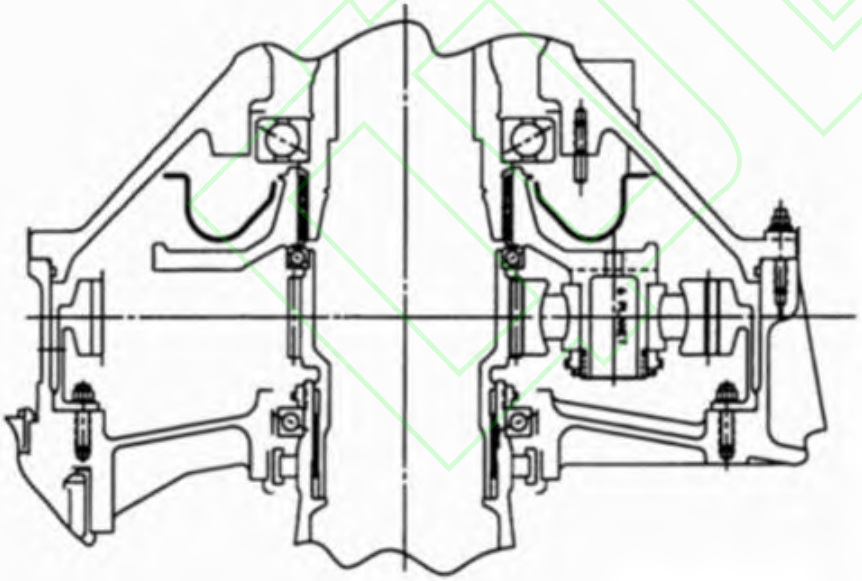

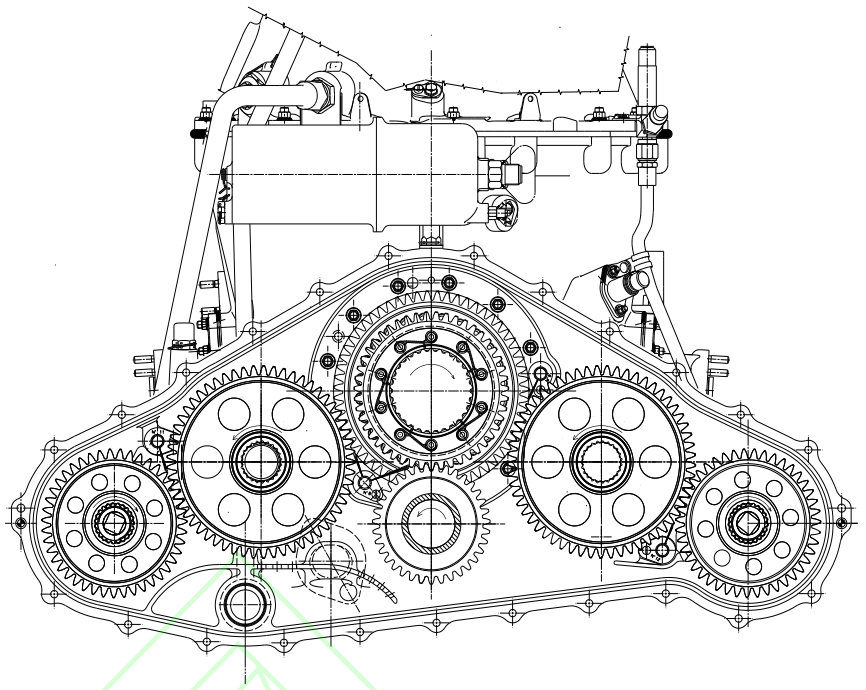

HCR spur cylindrical gears have the advantages of large load capacity, stable transmission, low vibration and noise, so many world-class airlines have carried out application research on HCR spur cylindrical gears in helicopter reducers, and adopted this technology in a number of new helicopter transmission systems, and HCR spur cylindrical gears are also used to replace the original LCR spur cylindrical gears in the technical improvement and modification of some models of helicopters in service. In the 70s of the 20th century, the American Bell Helicopter Company first adopted HCR spur cylindrical gears in the transmission system of the Bell-222 helicopter, and in 1992, Bell Helicopter Company made the first attempt to manufacture a 2-stage HCR spur cylindrical planetary gear system with a smaller mass and a degree of overlap greater than 2.1 in the ART (the Advanced Rotorcraft Transmission) program jointly carried out by the U.S. military and NASA, the structure of the planetary gear system is transmitted in conjunction with the original 2-stage LCR spur-toothed cylindrical planetary wheel The dynamic system has the same reduction ratio and number of teeth; However, during the design process, it was found that the temperature of the high-speed HCR spur cylindrical gear planetary drive system was too high, while the low speed class HCR spur cylindrical gear row Therefore, the number of teeth of the 2-stage planetary gear was adjusted, the number of teeth of each gear was increased, the bearing size was increased, the reduction ratio was reduced from the original 3.875 to 3.818, and the structure of the 2-stage planetary gear was shown in Figure 1, the mass was reduced by about 3.6 kg and the bending strength was increased by 20% compared with the LCR spur-toothed cylindrical planetary gear transmission system. Compared to LCR spur cylindrical planetary gearing, HCR spur cylindrical planetary gearing has smaller mass, lower noise and longer life. Bell Helicopter also compared five different planetary transmission configurations of LCR spur cylindrical gear planetary transmission, closed differential transmission, free planetary transmission, composite planetary transmission and HCR spur cylindrical gear planetary transmission through testing, and the results showed that compared with the other four planetary transmission configurations, the HCR spur cylindrical gear planetary transmission configuration was lightweight, low noise, low cost, low risk, small space size, and high It has the best combination of performance parameters in terms of longevity, strong viability and high efficiency.

Figure 1 A 2-stage high-coincidence spur cylindrical planetary gear structure developed by Bell Helicopter in the United States

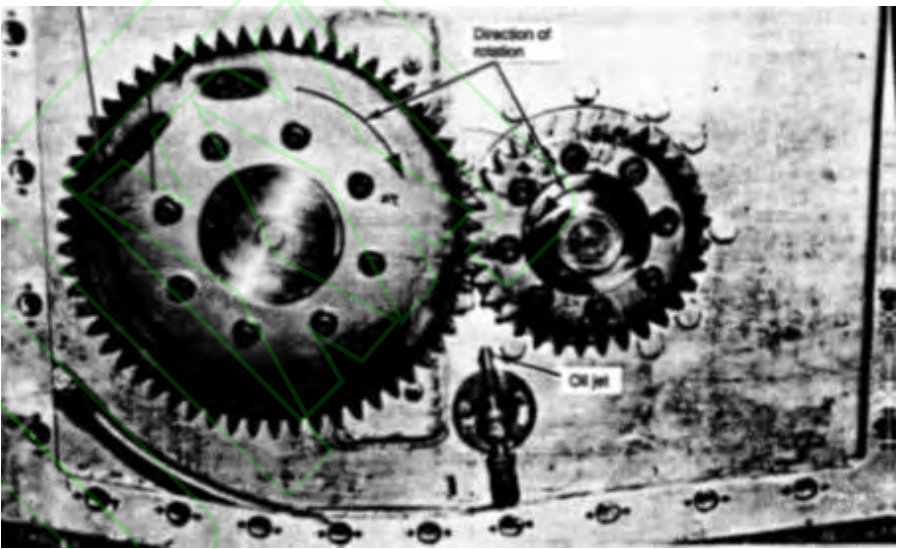

The XV-15 tiltrotor developed by Bell Helicopter in the United States, namely the Bell-301, continues the previous research basis, and sets the HCR spur cylindrical gear train as a high-speed stage of the 2-stage planetary gear train, and increases the end tooth width in order to meet the gluing limit, although it increases the mass of the gear, and does not have obvious advantages in terms of strength, but reduces the noise of the entire transmission system and has stronger survivability, so compared with the planetary transmission system designed in the ART program, the XV-15 The operation of the planetary drive system has the advantage of quieter operation and lower vibration levels.Boeing of the United States has also carried out the research of HCR spur cylindrical gears and non-involute toothed spur cylindrical gears, and obtained a large degree of coincidence by increasing the tooth top height coefficient, changing the pressure angle and displacement coefficient HCR spur cylindrical gears at 2.1, the HCR non-involute gear test setup is shown in Figure 2. The radius of curvature along the tooth profile of the new toothed gear is relatively unchanged, and the relative sliding speed of the gear at both ends of the meshing line (near the start and end positions of meshing) is small, which reduces the bearing capacity of the tooth surface glue and improves the contact durability of the tooth surface. In order to balance the bearing capacity and contact durability of the glue, the problem of gluing and contact strength was finally solved by improving the load distribution and increasing the relative radius of curvature near the start and end of the meshing by using non-involute tooth profiles, which provided a good way to solve the glue damage problem that plagued HCR straight tooth cylinders.

Figure 2 A high-coincident non-involute gear test setup developed by Boeing in the United States

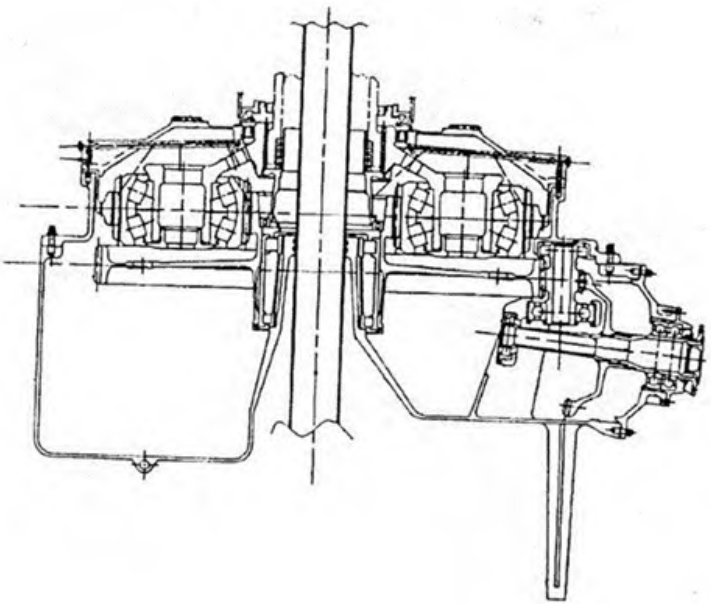

In the design of the main and minus planetary gears of the McDonnell-Douglas Company (McDonnell Douglas) participating in the ART program in the United States, two schemes, HCR spur cylindrical gear planetary gears and node internal meshing gear planetary gears, were adopted, and the degree of coincidence of HCR spur cylindrical gear planetary gears was about 2.22. According to the design requirements of ART, the HCR spur cylindrical gear planetary gear train final reducer is shown in Figure 3, and the transmission efficiency is reduced compared with the LCR spur cylindrical gear planetary drive at the same torque and tooth bending stress level, and the tooth surface The increase in contact temperature is large, as shown in Table 1, but the mass is reduced by about 5% (31 kg), the noise is reduced by about 9.5 dB, and the service life is extended by about 1 time.

Figure 3 McDonnell-Douglas developed a high-coincident spur cylindrical gear planetary gear train final reducer

Table 1 Comparison of the high-coincident planetary gear train developed by McDonnell-Douglas in the United States and the basic ordinary coincident planetary transmission

| 主减速器行星轮系类型 | 重合度 | 齿面宽度/mm | 传动效率/% | 齿面接触温度/℃ |

| 普通重合度直齿圆柱齿轮行星传动 | 1.59 | 100 | 99.93 | 131 |

| 高重合度直齿圆柱齿轮行星传动 | 2.22 | 83 | 99.85 | 170 |

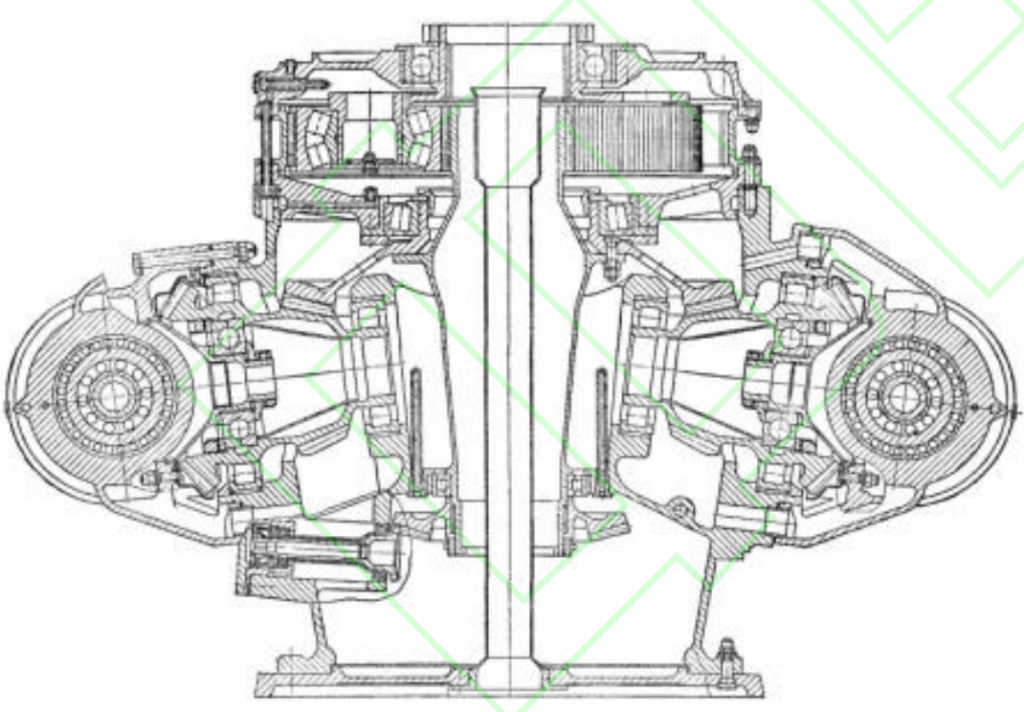

According to the results of the dynamic analysis, the tooth surface of the HCR spur cylindrical gear was dynamically modified, and the results showed that the HCR spur cylindrical gear could be modified by the quadratic curve, and the optimal modification area was from 90% of the tooth top height to the tooth top position. At the same time, the company carried out a performance comparison test of the modified HCR spur cylindrical gears and LCR spur cylindrical gears, and the results showed that the fatigue life of the modified HCR spur cylindrical gears at a failure rate of 10% was twice that of the LCR spur cylindrical gears, and the glued load capacity was slightly higher than that of the LCR spur cylindrical gears. It can be seen that the reasonable modification of HCR spur cylindrical gears can effectively reduce the tooth surface contact temperature of the gear and improve the anti-gluing ability of the gear, but the current research on the modification method of HCR spur cylindrical gear is in the stage of learning from LCR spur cylindrical gear, and further research is needed In order to solve the problem of high temperature rise and insufficient gluing capacity of HCR spur cylindrical gears. The SA-365N “Dolphin” helicopter final drive planetary drive system developed by the French national aerospace industry company is shown in Figure 4. The system also adopts the transmission form of HCR spur cylindrical gears, in which the meshing overlap degree of the sun gear and the planetary gear and the planetary gear and the fixed ring gear are 2.17 and 2.18 respectively, and the test flight junction HCR spur cylindrical gears have been shown to significantly increase the load-bearing capacity of the planetary gear train while reducing the noise and vibration of the drivetrain.

Figure 4 SA-365N developed by the French national aerospace industry

“Dolphin” helicopter final drive planetary transmission system

The Italian company Agusta has adopted HCR spur cylindrical gears in the improvement and upgrade of the input stage gear of the A109 helicopter final drive, and the improved helicopter models are AW109, AW109 The input stage of the helicopter final drive is shown in Figure 5 show. The drivetrain delivers a 10 percent increase in drive power, a 20 percent reduction in gear tooth width, an 8 percent reduction in mass, and an average reduction in meshing frequency noise measured on the test bench9 dB, the noise tone (frequency) is stable under different flight conditions, and the maximum noise is reduced by 13 dB(A).

Figure 5 AW109 helicopter final drive developed by Agusta, Italy Input level

2 Technical challenges of HCR spur cylindrical gears in the aviation field of China

Domestic research on HCR spur cylindrical gear transmission technology started in the 80s of the 20th century, China introduced the French SA365N1 “Dolphin” II helicopter production patent for production and localization, the domestic model is the straight 8 heavy helicopter, the helicopter final reducer uses HCR spur cylindrical gear, until the beginning of the 21st century, the country really began to apply research on HCR spur cylindrical gears. Given the unique advantages of HCR spur cylindrical gears in aero drivetrains With broad application prospects, China has significantly increased the research on HCR spur cylindrical gear transmission technology in order to make a breakthrough, so as to achieve a technological leap in China’s aviation transmission system. Researchers from Nanjing University of Aeronautics and Astronautics, Northwestern Polytechnical University, Jinan University and other universities have carried out continuous research on the strength analysis, tooth contact analysis and vibration characteristics analysis of HCR spur cylindrical gears, which has promoted the theory of HCR spur cylindrical gear transmission in China On development. Some domestic research institutions have carried out application research on HCR spur cylindrical gear transmission, and preliminarily obtained the characteristics of HCR spur cylindrical gear transmission. In recent years, although some research progress has been made in the field of HCR spur cylindrical gear transmission technology in China, the application of HCR spur cylindrical gears in China’s aviation transmission system technology is still relatively small, and the main technical difficulties are as follows:

1) There is a lack of fatigue strength calculation standard for HCR spur cylindrical gears. There is currently no publicly available HCR spur cylindrical gear transmission strength Calculation standards and software. The American Gear Manufacturers Association (AGMA) Gear Calculation Standard clearly states that this standard does not apply to the precise design of spur cylindrical gears with an end face coincidence greater than 2; ISO gear gauge Although the calculation standard takes into account the coincidence greater than 2, it does not calculate the distribution of the load between multiple pairs of meshing teeth, but makes a simple correction and does not accurately calculate the HCR spur teeth The strength of cylindrical gears. At present, the research on HCR spur cylindrical gears is mainly limited to the calculation and analysis of bending stress at the root of the tooth, and the bending stress measurement and verification test is also carried out under non-operating conditions In the future, it is necessary to further discuss the contact strength and gluing strength of HCR spur cylindrical gears, and carry out the verification of full-scale aviation transmission test pieces under real working conditions, which is HCR straight Toothed cylindrical gears provide guidance for the engineering application of lightweight, high-power aerodynamic drivetrains. 2) The modification method of HCR spur cylindrical gears is insufficient. Since the design of HCR spur cylindrical gears requires a small pressure angle and a large crest height coefficient, there is a tendency to a large slip rate at the crest, which increases the risk of gluing. HCR Spur Cylindrical Gear Design Section It is very likely that the mass of the province will exceed the increased mass caused by increasing the tooth width in order to guarantee the load-bearing capacity of the glue. In order to reduce the risk of gluing, it is necessary to avoid gluing damage to the gear through measures such as modification and increase operational reliability. According to the results of McDonnell Douglas and Sikorsky Aircraft, the gears must be reshaped to reduce the contact temperature of the tooth flanks of HCR spur cylindrical gears and to reduce the risk of gluing. The research on the modification method of HCR spur cylindrical gears is still in the stage of learning from LCR spur cylindrical gears, although certain results have been obtained, but the results are poor. There are scholars from the point of view of vibration Considering the modification, the modification is carried out with the vibration as the goal, which has a poor relationship with the actual demand. 3) The carburizing process of the tooth surface of HCR spur cylindrical gear is not perfect. Under normal circumstances, HCR spur cylindrical gears have a larger tooth top height coefficient, a smaller tooth tip thickness, and a sharper tooth top, but in order to make the gear obtain a longer service life, carburizing, nitriding and other processes will be used, and carburizing and nitriding on the thin tooth surface are easy to cause the tooth top to become brittle and cause tooth chipping. In order to avoid chipping or fracture at the tip of the tooth, the top of the HCR straight cylindrical gear is generally not carburized and is protected by copper plating prior to carburizing. The hardness of the tooth top will be reduced after copper plating protection, and the wear resistance of the gear will become a prominent problem, so the heat treatment process of the gear has become a difficult point in the production of HCR straight cylindrical gears, which needs to be further studied

Investigate. 4) HCR spur cylindrical gear lubrication design is not perfect. The unavoidable disadvantage of using HCR spur cylindrical gears is that the increase in the height of the teeth causes meshing between the teeth。

3 Conclusion

Foreign HCR spur cylindrical gear transmission technology has been gradually applied in aviation transmission system, but there is a certain gap in this technology in China, and mature design theory and method have not yet been formed, and several technical problems in engineering application still need to be solved urgently, mainly in the following aspects:

1) There is no general standard for the calculation of the strength of HCR spur cylindrical gears, and the selection of key design parameters and the correction of calculation coefficients need to be further determined, rather than simply applied. Because the HCR spur cylindrical gear adopts a large tooth top height coefficient and a large displacement coefficient non-standard pressure angle, if the strength of the standard gear is used instead in the strength calculation, a large error will be generated, which will affect the accuracy of the results.

2) The modification of HCR spur cylindrical gears has not yet formed a mature theory. Due to the particularity of the contact characteristics of HCR spur cylindrical gears, the existing modification theory cannot meet the requirements, and it is necessary to strengthen the research on modification, and give the modification methods and modification formulas suitable for engineering needs.

3) The tooth profile characteristics of HCR spur cylindrical gear determine that the tooth top thickness of the gear is small, which poses a new challenge to the processing and heat treatment.

4) HCR spur cylindrical gears have a large sliding rate at the top and root of the teeth, resulting in problems such as decreased efficiency and increased heat generation, which need to be fully considered in the design to prevent damage in the form of gluing.