Another way to eliminate undercutting is the “multi space supplement” of gear design. That is, increase the tooth top of the pinion and reduce the tooth top of the mating gear by the same amount. Although the external diameter of the pinion increases and the meshing gear decreases accordingly, the indexing circle and base diameter remain unchanged. Therefore, they have the same center distance and the same transmission ratio as before.

Because the tooth top height of the pinion is increased and the contact surface of the gear is increased, the strength of the tooth is much stronger than that of the undercut teeth.

The two methods mentioned above are not exclusive. Generally, the most appropriate method is to use the two methods of increasing pressure angle and “long space supplement” together. For example, undercutting occurs when the cutting pressure angle is 20 ° and less than 17 teeth. It is also required to increase the indexing circle of large and small gears as much as possible. This must increase the center distance so that it is inconsistent with the standard center distance.

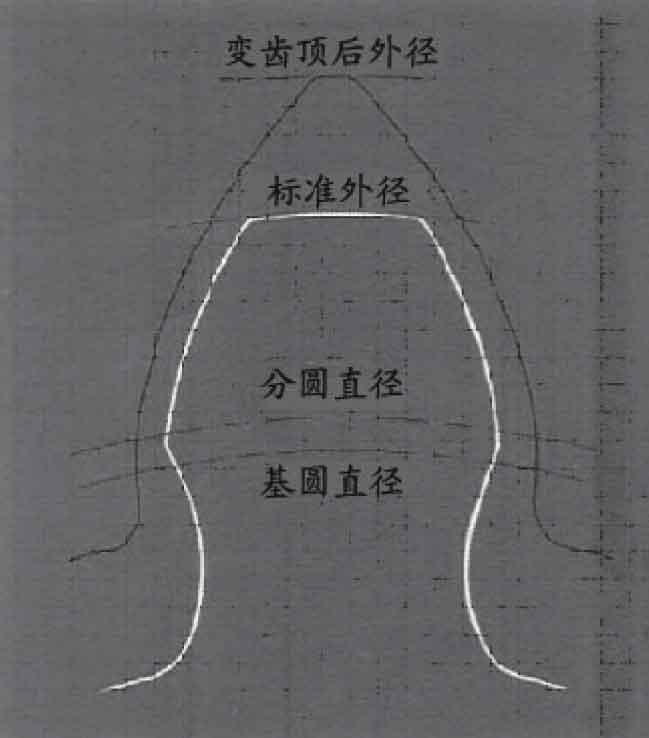

The figure shows the tooth profile of a single tooth with a 14.5 ° pressure angle and 10 teeth. From the design point of view, the root of the tooth is obviously undercut. By extending the form of base circle involute, the high top gear is designed. Generally, the pressure angle should be increased to 20 °, and the diameter of the addendum circle exceeds the original size. As shown in the figure, there is no undercutting. At the same time, the tooth thickness at the addendum is significantly greater than that before the change.