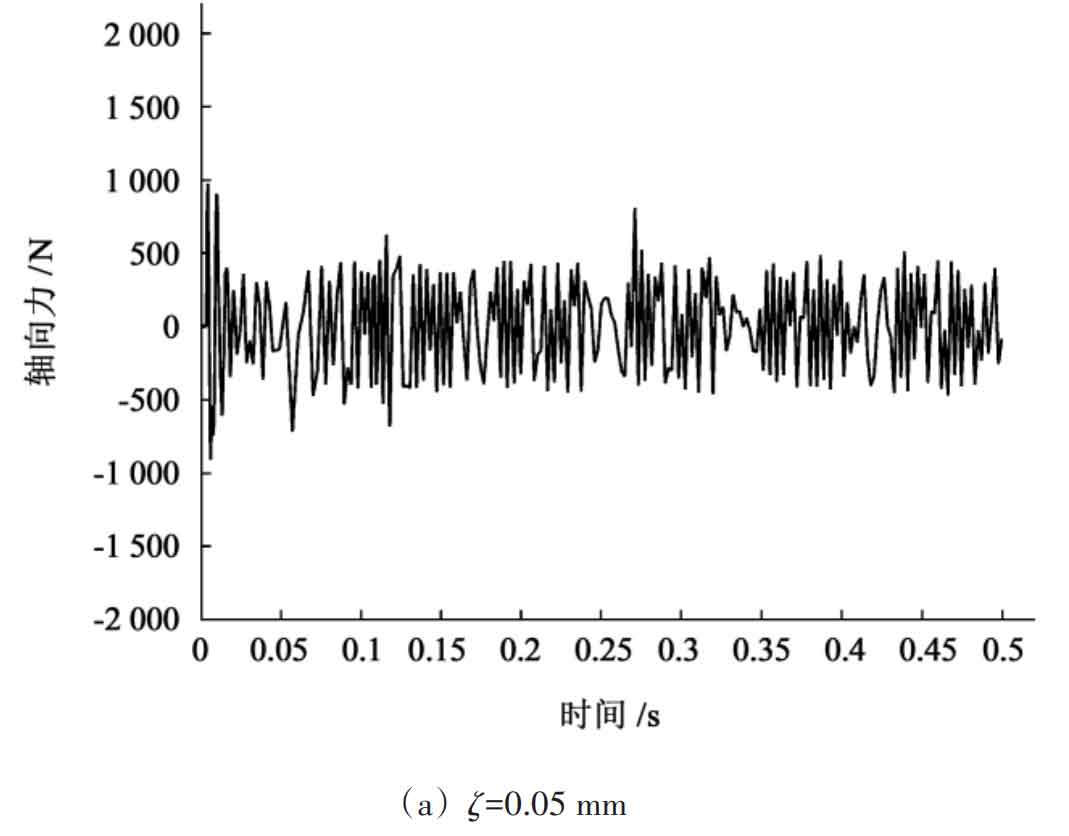

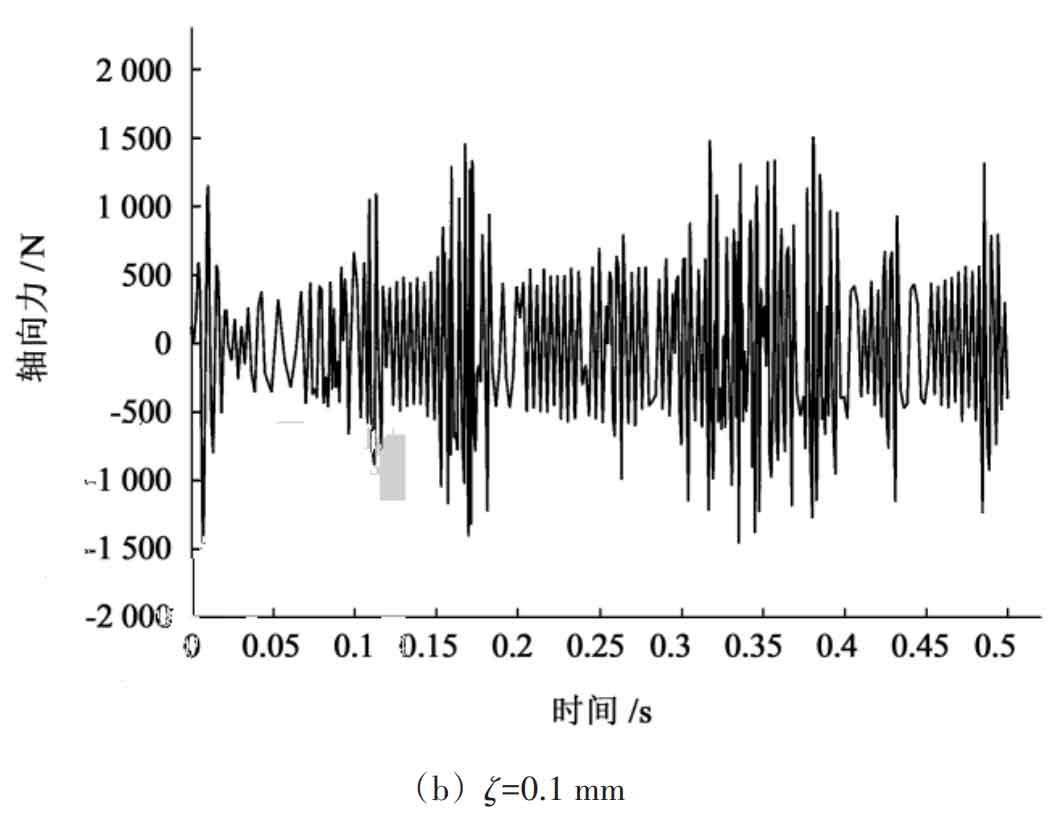

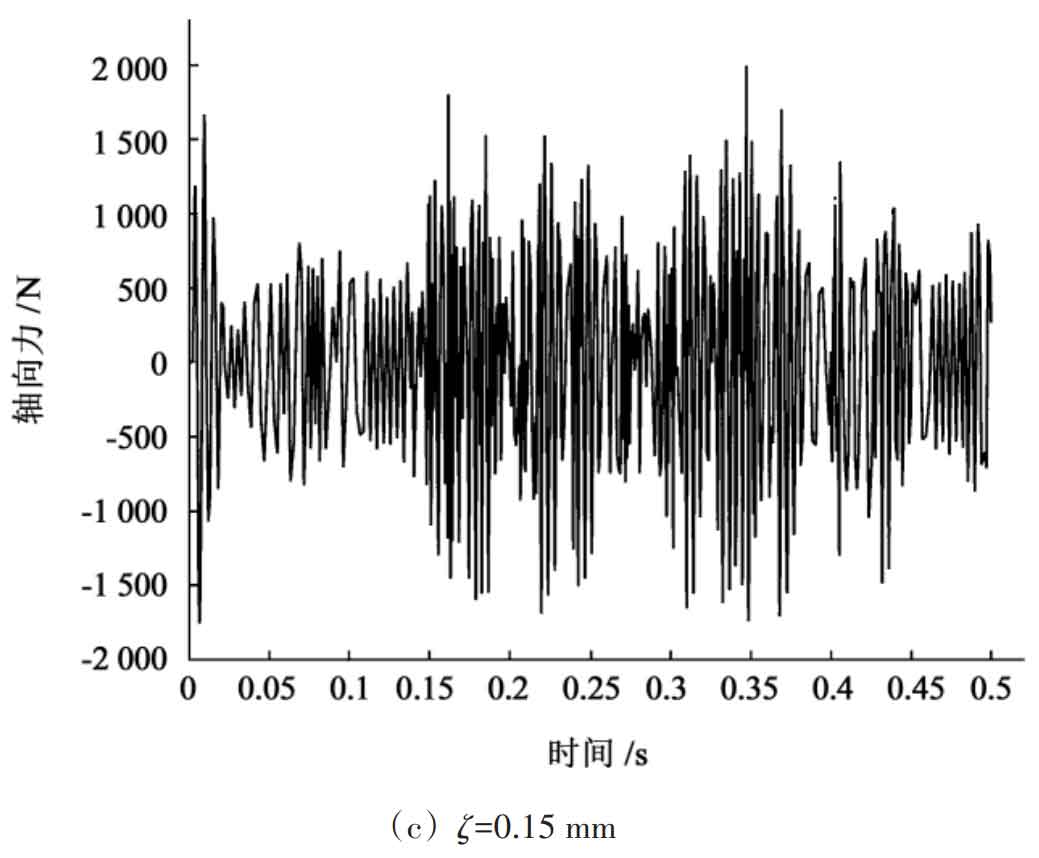

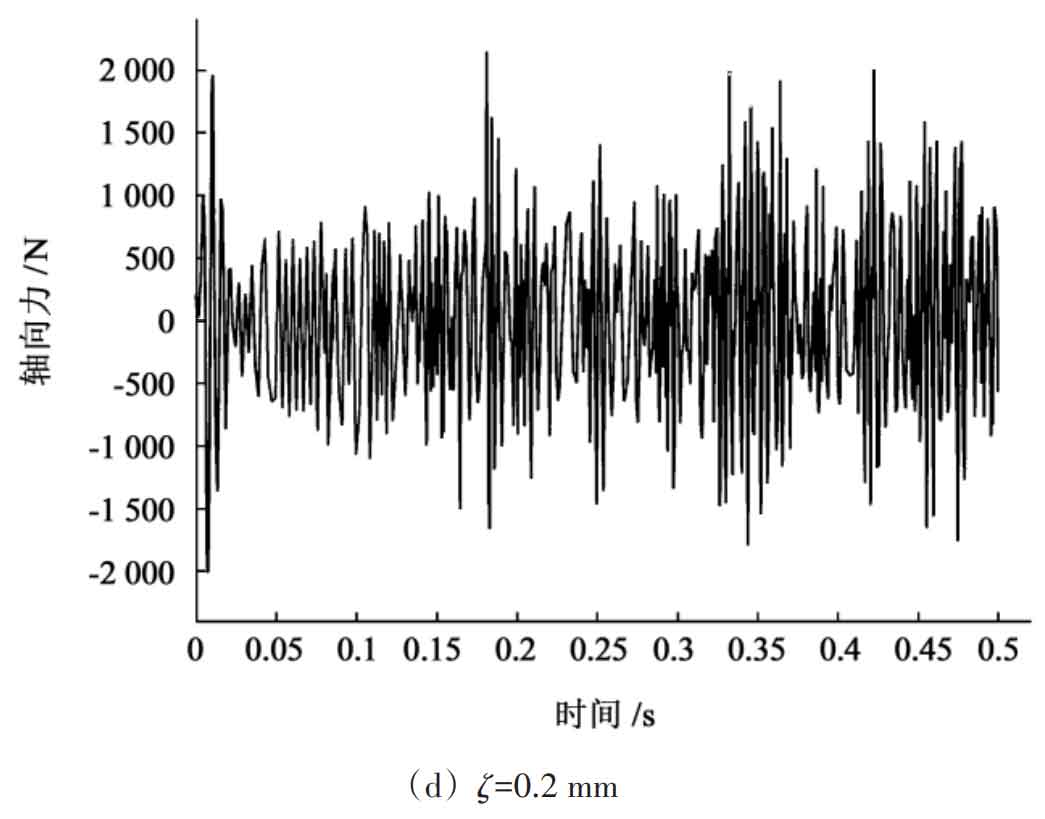

As the force along the axis of gear meshing, the axial force determines the axial vibration of gear, and indirectly reflects the stress in other directions. Similarly, the analysis of axial force is also divided into three stages. The axial force change curve of herringbone gear with different centering errors is shown in the figure.

It can be seen from the figure that the variation law of axial force and axial displacement under the same centering error is similar. In the initial stage, there is no axial force of meshing transmission due to insufficient initial clearance and contact. After entering the loading stage, the tooth contact collision, sudden change of axial force and gear stiffness make the tooth surfaces of left and right helical gears collide and rebound continuously. Because the speed and load are not fully loaded, the peak value of axial force in the first tooth collision is not the maximum value. After the maximum peak value in the second or third collision, the oscillation amplitude of axial force first decreases and then increases with time, and gradually tends to be stable. The oscillation period during this period is also longer than the steady speed stage. The axial force in the steady speed movement stage still fluctuates up and down, but it changes periodically as a whole. There are obvious fluctuations in the amplitude of axial force in each cycle, which is consistent with the periodic change of coincidence degree. The abrupt fluctuation of axial force and other meshing forces will further affect the stability of gear pair transmission and aggravate the vibration and noise of the system.

The data of the influence of different alignment errors on the axial force of herringbone gear are further counted and sorted, and the relevant statistical results are obtained. With the increase of centering error, the average value and maximum value of axial force increase, and the fluctuation of standard deviation becomes larger and larger. The centering error directly affects the peak value and oscillation amplitude of axial force. According to the finite element simulation results, the fluctuation period of axial force under different centering errors is basically the same, and the meshing frequency of gear pair is 999 Hz, which is consistent. Based on the periodic change of coincidence degree, the larger the centering error, the more frequent the fluctuation and mutation of axial force, and the more chaotic the axial force change curve, which shows that the centering error seriously reduces the stability of gear pair, easily causes problems such as de meshing, knocking and reducing meshing stiffness, and affects the meshing transmission of herringbone gear pair.