The failed bevel gear is that two teeth of the driven wheel of the bevel gear pair of the middle axle of an ordinary traction vehicle are broken, and the driving wheel is intact. The vehicle has been used for 8 months with a mileage of 100573km. The warranty period for parts is 18 months. In case of failure, the warranty period for parts is still within the warranty period. The axle housing of its related parts is in good condition, without interference with the bevel gear pair. The threads of the driving wheel and driven wheel and the assembly nuts are in good condition, without potential related effects of loosening. The material used for bevel gear is 22CrMoH steel (Japanese brand SCM822), which has high economy and suitable mechanical properties, and is mostly used for driving gear and driven gear of rear axle of medium-sized automobiles. The general technical requirements for heat treatment of heavy-duty carburized bevel gears are as follows: effective hardened layer depth at 1/2 gear height is 1.7 ~ 2.1mm, surface hardness is 58 ~ 63HRC, core hardness is 33 ~ 45HRC, martensite level is 1 ~ 4, retained austenite level is 1 ~ 4, carbide level is 1 ~ 2, core structure level is 1 ~ 4, surface non martensite thickness is ≤ 0.02mm, and grain size is higher than level 6.

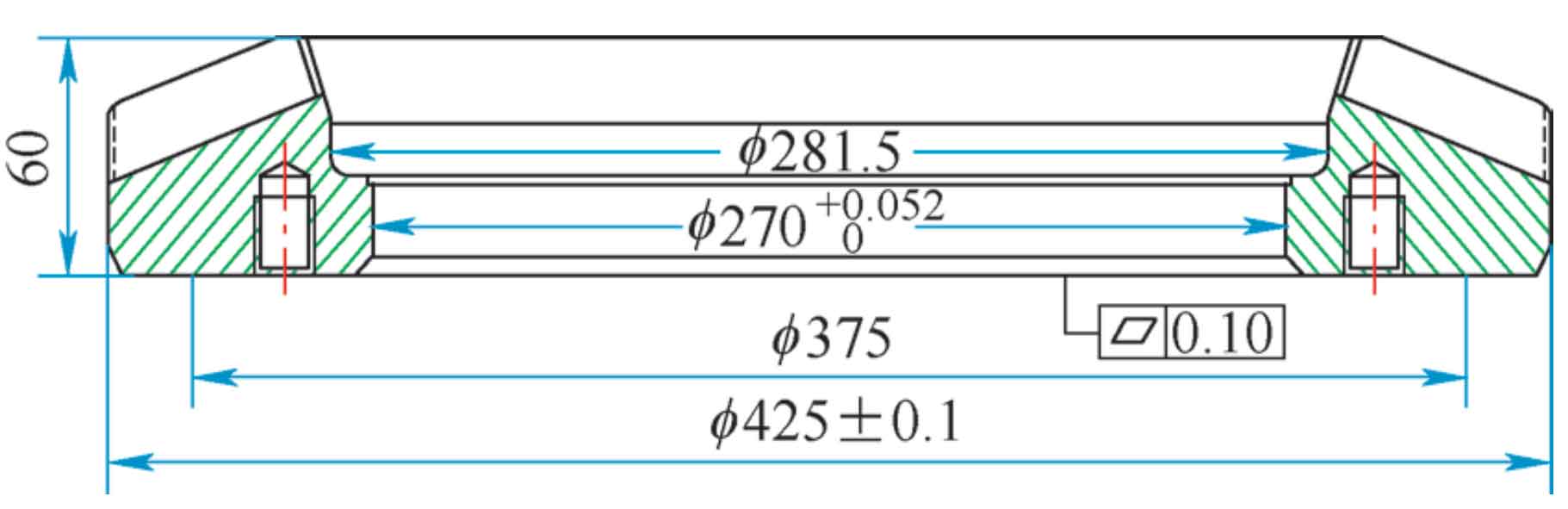

The production process of carburized and quenched driven gear is as follows: round steel blanking → forging → isothermal normalizing → rough turning → fine turning → drilling and tapping → gear milling → chamfering → cleaning → heat treatment (carburizing, press quenching, low temperature tempering) → shot blasting cleaning → turning inner holes → grinding gear pairing → packaging and warehousing. The structure of the failed bevel gear is shown in the figure.